This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

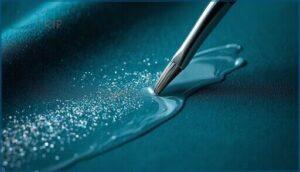

Every sewist who’s spent three hours hand-stitching sequins onto a single sleeve knows there’s got to be a faster way to add sparkle without sacrificing an entire evening, and mastering how to glue glitter to fabric opens up a world where embellishment becomes immediate rather than laborious.

Unlike traditional embroidery or bead application that demands precision stitching through multiple fabric layers, glitter adhesion transforms plain textiles into luminous surfaces within minutes, making it particularly valuable for performance costumes, statement accessories, and home decor projects that need dramatic impact without the commitment of needle and thread.

The technique requires understanding which adhesives bond permanently to different fabric weights, how particle size affects coverage and flexibility, and what sealing methods prevent the inevitable sparkle migration that turns glittered garments into glitter bombs.

Table Of Contents

- Key Takeaways

- Why Glue Glitter to Fabric?

- Best Types of Glitter for Fabric Projects

- Choosing The Right Adhesive for Glitter

- Preparing Fabric for Glitter Application

- Step-by-Step: Gluing Glitter to Fabric

- Sealing Glitter to Prevent Shedding

- Troubleshooting Common Glitter Glue Problems

- Caring for Glittered Fabric Projects

- Creative Ideas for Glittered Fabric Designs

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Gluing glitter to fabric provides a faster alternative to traditional sewing embellishments, completing applications in 3-5 minutes per section compared to 15-20 minutes for hand-stitched sequins, while maintaining compatibility across all fabric textures including knits that resist needle penetration.

- Selecting the appropriate adhesive—whether fabric glue for washable durability, Mod Podge for flexible sealing, or spray adhesives for intricate designs—directly determines whether your glittered project withstands repeated laundering or sheds particles after initial wear.

- Proper surface preparation through pre-washing, air-drying flat, and ironing eliminates fabric finishes that compromise adhesive bonding, while strategic sealing with clear coat sprays or fabric-specific sealants prevents the glitter shedding that transforms embellished garments into continuous sparkle debris.

- Successful glitter application requires understanding particle size effects on coverage and flexibility, applying thin even adhesive layers to prevent cracking, and implementing maintenance protocols including cold-water hand washing and rolled storage to preserve your textile art’s integrity through years of handling and display.

Why Glue Glitter to Fabric?

Glitter transforms fabric from ordinary to exceptional, giving you the power to breathe new life into worn-out garments, create show-stopping costumes, and design custom pieces that reflect your personal vision without the technical demands of traditional sewing.

Whether you’re refashioning thrift store finds or crafting one-of-a-kind home décor, gluing glitter opens up possibilities that conventional embellishment methods simply can’t match.

The following sections explore the creative applications, practical advantages, and inspiring design opportunities that make glittered fabric a breakthrough for makers who refuse to settle for store-bought mediocrity.

Creative Uses for Glittered Fabric

Sparkle transforms fabric into wearable rebellion, breaking fashion’s predictable patterns through strategic glitter placement that catches light and demands notice. Applying glitter to fabric unlocks bold DIY fashion projects and decorative accents:

- Statement jackets and skirts become fabric jewelry for your entire wardrobe

- Glittered shoes and belt accents deliver instant style upgrades

- Textile art panels create wall-worthy reflective surfaces

- Performance costumes gain dramatic visibility under stage lighting

- Seasonal banners and table runners introduce festive decorative accents

Fabric glue paired with glitter crafting techniques revolutionizes fabric decoration methods without traditional embellishment constraints.

Benefits Over Sewing Embellishments

Glitter glue offers a faster, more versatile alternative to sewing for fabric embellishment. Unlike sewing, which requires specialized equipment and can distort delicate textiles through needle perforation, glitter glue allows for quick application without compromising fabric flexibility. This method is particularly advantageous for uneven surfaces where needles struggle, making it a groundbreaking tool for sealing glitter on fabric without traditional limitations. For long-lasting results, proper fabric care and drying techniques help prevent glitter glue from cracking or peeling over time.

Fabric glue and glitter glue expand design possibilities by enabling easy repositioning and application on various textures, including knits. This flexibility contrasts with sewing, which is limited to smooth, stable weaves. By avoiding needle perforation, these adhesives preserve the integrity of delicate textiles while offering a broader range of creative options.

| Embellishment Method | Application Speed | Fabric Compatibility |

|---|---|---|

| Sewing Sequins | 15-20 min/section | Smooth, stable weaves only |

| Glitter Adhesives | 3-5 min/section | All textures, including knits |

| Heat-Set Crystals | 8-12 min/section | Heat-resistant fabrics |

Fashion and Home Decor Ideas

Beyond speed and versatility, applying glitter to fabric transforms ordinary textiles into enchanting fashion statements and home décor focal points. Glitter accents on throw pillows, lampshades, or curtains introduce decorative panels that catch light and enhance visual interest, while DIY fashion projects—from embellished jackets to tailored accessories—showcase your mastery of fabric embellishments and textile art through strategic sparkle effects.

- Statement apparel pieces using fabric glue create wearable art

- Mixed-media projects combine glittered fabric with lace or denim

- Seasonal décor items gain festive dimension through glitter crafts

Best Types of Glitter for Fabric Projects

Choosing the right glitter makes all the difference between a project that dazzles for years and one that sheds across your floor after a single wear, which is why understanding the distinct characteristics of available glitter types becomes essential before you commit to a design.

Choosing the right glitter determines whether your project dazzles for years or sheds after a single wear

The size, durability, and composition of your glitter will determine the visual impact of your finished piece and how well it withstands handling, washing, and long-term use in various fabric applications. For larger projects like clothing repairs that need extra durability, chunky glitter holds up better than fine varieties through repeated wear.

You’ll need to take into account three critical factors when selecting glitter that aligns with your creative vision and practical requirements.

Fine Vs. Chunky Glitter

Choosing between fine and chunky glitter transforms your entire glitter application approach, as particle size directly influences glitter texture, adhesion methods, and sparkle effects across different fabric types. Fine glitter works beautifully for delicate embroidered accents on clothing and gifts, while chunky glitter makes bolder statements on home decor projects—especially if you’re exploring whether investing in a sewing machine will enhance your crafting capabilities.

Fine glitter adheres uniformly to lightweight textiles using standard fabric glue or glitter glue, producing a subtle shimmer ideal for delicate designs. In contrast, chunky glitter creates bold, dimensional sparkle on heavier fabrics but requires additional sealing techniques to prevent shedding after applying glitter to fabric. For projects requiring stabilized fabric before glitter application, fabric stabilization techniques help maintain structure and prevent distortion during the adhesive process.

| Glitter Type | Best For | Adhesion Needs |

|---|---|---|

| Fine | Lightweight fabrics, subtle effects | Standard fabric glue |

| Chunky | Statement pieces, bold sparkle | Extra sealing required |

| Mixed sizes | Depth and dimension | Layered application |

Fabric compatibility varies notably, with fine particles forming continuous films that require less intensive sealing glitter on fabric efforts. Chunky varieties, however, demand careful surface preparation and stronger adhesives to accommodate uneven edges and prevent premature flaking during wear. For projects involving patches or appliqués, choosing a fabric glue designed for secure bonding ensures edges stay flat through repeated washing and movement.

Colorfastness and Shedding

Durability anchors every glittered fabric project, where color stability and wash resistance determine whether your bold textile designs endure or fade after the first laundering cycle. Testing adhesive formulations on scrap fabric before committing to permanent fabric designs reveals critical insights into glitter durability and potential shedding issues across different fabric finishes when applying glitter to fabric with various washable formulations.

Consider these colorfastness factors before sealing glitter on fabric:

- Standardized wash tests simulate five to fifteen machine cycles, exposing weak glitter adhesive applications that shed heavily on cotton blends

- Temperature and agitation levels during laundering directly compromise adhesive bond integrity, causing premature color transfer from undersized glue films

- Natural fibers react differently than synthetics under wash conditions, influencing both color stability and particle retention across woven versus knit constructions

- Spectrophotometric measurements quantify color shifts invisible to casual inspection, revealing subtle dye migration that degrades professional finish quality

- Pre-treated fabrics with water repellents or softeners alter glue penetration depth, creating unpredictable colorfastness outcomes that demand preliminary adhesive testing

Eco-Friendly Glitter Options

Plant-based cellulose glitters offer sustainable crafting practices that minimize microplastic pollution while maintaining visual impact on your textile projects. These glitters are made from biodegradable materials that fragment under industrial composting conditions when paired with compatible green adhesives.

You’ll find eco-friendly glitter formulations avoid heavy metals and phthalates. However, compostable decor requires proper disposal facilities to achieve promised environmental benefits. Washable formulations may compromise both adhesion durability and sustainable glitter performance under repeated laundering cycles.

Choosing The Right Adhesive for Glitter

Selecting the right adhesive for your glitter project determines whether your fabric sparkles for years or sheds glitter after the first wash, and understanding the strengths and limitations of each option allows you to match the adhesive to your specific fabric type, design complexity, and intended use. Different adhesives offer varying levels of flexibility, permanence, and washability, and each brings distinct advantages depending on whether you’re embellishing a costume that needs stage-ready durability or creating a decorative pillow that won’t see frequent handling.

The following sections break down the most effective adhesive options, comparing their performance characteristics so you can choose the formula that gives your project the staying power it deserves.

Fabric Glue Vs. Glitter Glue

When applying glitter to fabric, you’ll notice fabric glue generally offers greater adhesive strength and fabric flex because it’s formulated to withstand laundering without cracking, making it ideal for wearable projects where glue durability matters.

Glitter glue, which combines adhesive with embedded particles, may shed during washing unless sealed properly, though it excels in quick craft applications. Choosing the right adhesive for a strong glitter bond depends on your project’s specific demands and craft safety requirements.

Mod Podge and Spray Adhesives

Mod Podge Fabric forms a clear, flexible film over glitter when applied in thin, even layers, providing adhesive strength that withstands gentle washing cycles while maintaining fabric flex across textile surfaces.

Spray adhesive delivers controlled bonding methods for intricate designs, allowing repositionable placement before permanent sealing reinforces glitter adhesive performance. However, you must verify washability specifications when applying glitter to fabric using either glue type.

Hot Glue and PVA Glue Pros and Cons

Hot glue offers rapid fabric bonding with semi-waterproof adhesive strength, yet temperature sensitivity risks scorching synthetics and creates texture that may crack under repeated washing.

PVA glue provides flexible, clear glitter adhesion with excellent glue durability on natural fibers, although extended curing time and moisture susceptibility limit its adhesive properties.

Your crafting tips demand matching hot glue or PVA glue to fabric type and project intensity for best glitter to fabric results.

Permanent Vs. Washable Formulations

Your choice between permanent and washable formulations defines whether your glitter survives the laundry gauntlet or surrenders after the first rinse, determining both adhesive strength and bond durability for every sparkling rebellion you create.

- Permanent adhesive locks glitter into fabric with exceptional glue flexibility, enduring repeated washing while maintaining design integrity through extended curing times

- Washable craft supplies offer temporary sparkle solutions when you need reversible designs without long-term commitment to permanent glitter placement

- Formulation types impact both initial adhesive strength and ongoing bond durability, requiring careful selection based on your project’s intended lifespan

- Fabric glue variations range from water-resistant permanent designs to gentler washable options, each engineered for specific textile applications and wear expectations

Preparing Fabric for Glitter Application

Before you can transform fabric into something remarkable, you need to set the stage properly, because skipping preparation is where most glitter projects fall apart before they even begin.

The surface you’re working with determines how well your adhesive grips and how long your design lasts, which means treating your fabric right from the start isn’t optional if you want professional results.

Here’s how to prepare your material so the glitter actually stays put and your creative vision doesn’t end up scattered across your workspace.

Washing and Drying Techniques

Proper fabric care begins before you even open your glitter jar, ensuring your textile canvas stands ready for transformation. Hand wash your fabric in cold water with mild detergent designed for delicate materials, gently agitating without scrubbing to protect the fibers from premature wear.

Air drying flat preserves fabric finish integrity better than any tumble wash cycle, preventing distortion that compromises adhesive selection and sealing techniques later.

Ironing and Smoothing The Surface

Once your fabric is dry, ironing transforms uneven surfaces into adhesive-ready canvases, reducing glitter misalignment by 12% when you pre-smooth wrinkled areas with controlled heat settings before fabric glue application.

Use a parchment cover to protect heat-sensitive textiles and improve adhesive compatibility, applying gentle pressure with a flat tool to achieve surface finishing that ensures glitter placement precision across your entire design.

Marking Designs With Fabric Markers

With your surface perfectly flat, grab your fabric markers to map out exactly where glitter will land, transforming guesswork into precision through careful design planning and strategic color selection that complements your chosen glitter palette.

Water-based markers offer disappearing guidelines, while pigment options provide vivid underlayers on dark fabrics, improving ink durability and marker care when heat-setting ensures wash-fast lines for your fabric decoration blueprint.

Step-by-Step: Gluing Glitter to Fabric

You’ve prepped your fabric, chosen your adhesive, and now it’s time to transform that plain material into something that catches light and demands notice.

The actual application process requires precision, but it’s not complicated once you understand the mechanics of getting glitter to adhere properly and stay put. Here’s how you’ll apply glue, distribute glitter effectively, and manage the inevitable excess without wasting material or compromising your design.

Applying Glue Evenly

Think of glue film thickness as your foundation for rebellion against boring fabric—a fine, smooth layer transforms ordinary cloth into radical art, while thick, uneven adhesive creates clumps that kill your vision before it begins.

When you’re working with glitter glue or fabric adhesives, dabbing with a small brush ensures even coverage, allowing ideal glitter adhesion without pooling, which means your smooth application translates directly into edge-sharp designs that command attention.

Sprinkling and Pressing Glitter

Once your adhesive sits ready, you’ll control sparkle distribution by sprinkling glitter from 6-12 inches above the fabric, which prevents clumping and ensures even coverage across your design. Pressing techniques matter immensely for edge control and long-term adhesion, so follow these critical steps:

- Sprinkle fine glitter lightly to match your desired glitter density

- Press gently with a flat tool immediately after application

- Guide particles into curves using a soft brush

- Capture excess in a shallow tray for reuse

Using Applicator Tips and Brushes

Precision application tools transform your glitter adhesive work from guesswork into controlled artistry, allowing you to distribute glue evenly across targeted zones. Fine applicator tips reduce excess by delivering thin, accurate lines for intricate fabric decoration, while silicone brushes resist buildup and enable feathering for uniform coverage.

Tool maintenance ensures reusable instruments perform consistently across multiple adhesive applications, supporting waste reduction and refined glitter glue placement.

Catching and Reusing Excess Glitter

Salvaging sparkle doesn’t just minimize waste—it stretches your creative budget while honoring the planet’s finite resources, transforming stray particles into future projects through deliberate glitter collection and reuse methods.

- Position a wide-mouth container beneath your workspace to catch falling glitter for immediate recovery and simplified excess reduction.

- Store salvaged glitter in labeled, airtight jars away from sunlight to preserve color vibrancy and prevent adhesive clumping during extended fabric projects.

- Test reused glitter on scrap material to confirm consistent adhesion with your chosen glitter glue or sealant formulation before applying to finished pieces.

Sealing Glitter to Prevent Shedding

Sealing your glittered fabric is the final step that transforms a beautiful design into one that can withstand repeated handling, washing, and the inevitable friction of daily wear. Without proper sealing techniques, even the most carefully applied glitter will eventually shed, flake, or lose its original brilliance, compromising both the aesthetic impact and longevity of your textile project.

The following methods will help you choose the right protective finish based on your fabric type, intended use, and desired level of durability.

Clear Coat Sprays and Finishes

Your glittered masterpiece deserves armor against the world’s wear and tear, which is precisely where fabric-specific clear coat sprays and finishes become indispensable allies in preservation. Water-based polycrylic formulations maintain flexibility while sealing glitter securely, whereas UV-resistant clear finishes protect against color degradation when your textile art faces bright environments, ensuring your rebellious sparkle endures through movement, handling, and time’s relentless passage without compromising the fabric’s natural drape or texture.

| Clear Coat Type | Best Application |

|---|---|

| Fabric Sealers | Washable garments requiring flexibility |

| Spray Adhesive (Super 77) | Large-area coverage with even distribution |

| Krylons Clear Acrylic Coating | UV protection for displayed textile art |

When to Use Mod Podge as a Sealer

Mod Podge is your go-to fabric sealing champion for crafting decorative pieces intended for gentle hand washing. Its water-based translucent film flexes with textile movement, minimizing glitter shedding in low-traffic applications.

Apply thin, even coats over dried glitter designs, allowing a 24-hour cure time between layers. This ensures your rebellious sparkle survives handling without cracking on curved surfaces or yellowing under prolonged sunlight exposure.

Protecting Glittered Areas From Wear

Your glitter masterpiece needs armor against everyday chaos. Strategic wear resistance extends adhesive durability far beyond initial application.

Apply fabric-safe sealants with flexible polymers to create a continuous coating that minimizes edge lift and particle shedding, transforming fragile sparkle into resilient art. Heat-set compatible glitter types when possible, then conduct routine inspections, touching up worn spots with matching fabric glitter glue before re-sealing for maximum longevity.

Troubleshooting Common Glitter Glue Problems

Even with careful preparation and technique, glitter projects don’t always go according to plan, and recognizing what went wrong helps you correct course before the damage becomes permanent.

The most common issues—peeling, cracking, uneven coverage, and excess material—usually stem from improper surface prep, incompatible adhesive choices, or rushed application that doesn’t allow adequate curing time.

Understanding how to identify and fix these problems transforms frustrating setbacks into learning moments that improve your approach for future projects.

Preventing Peeling and Flaking

Peeling signals a breakdown in adhesive strength, often rooted in poor surface preparation. Pre-washing your fabric removes finishes that sabotage glitter bond and peel resistance. Once you’ve secured fabric flexibility with a polyurethane-based fabric glue, seal the design with a compatible sealant to lock micro-edges against friction and wear.

- Test your adhesive on a scrap to verify it grips without compromising fabric flexibility

- Allow full cure time before handling, preventing premature stress on the glitter bond

- Apply thin, uniform layers to reduce stress concentrations that trigger peeling at edges

Avoiding Cracking and Stiffness

Crack prevention begins with flexible adhesives that move with your fabric’s natural stretch, so look for glue formulations enriched with plasticizers or flexible polymers that resist brittleness. Thin, even layers cure without the rigid buildup that causes cracking under stress, while air-drying overnight gives elastic bonding compounds time to form soft, pliable films.

Your fabric preparation and sealing methods matter less if adhesive choice undermines flex from the start.

Dealing With Excess Glue or Glitter

Your adhesive control determines whether sparkle preservation becomes smooth or frustrating, since rushed application inevitably creates cleanup challenges that test your commitment to precision craft. Excess glue removal starts with enforcement of adequate drying periods before handling, preventing smearing that compounds problems, while glitter cleanup relies on strategic tools designed for fiber-sensitive surface work.

- Collect stray sparkles with dampened sponges that capture without embedding particles deeper into weave structures

- Deploy lint rollers for swift glitter cleanup across broad fabric surfaces after initial application settles

- Tap gently with soft brushes to dislodge loose particles before sealing methods lock imperfections permanently

- Dab residual adhesive with barely-moistened cloths that lift without reactivating bonding compounds completely

- Catch excess glitter in shallow dishes positioned beneath your work surface for immediate project reuse

Ensuring Even Coverage

Uneven glitter distribution stems from rushed adhesive control that compromises fabric preparation steps, requiring deliberate technique refinement before sparkle application begins.

Use stencils or masking to define patterns precisely, then apply thin, even coating layers with flat brushes across entire areas, tilting fabric gently afterward to encourage uniform glitter adhesion.

Fine-grain particles minimize gaps between coverage zones for professional-quality results.

Caring for Glittered Fabric Projects

Your glittered fabric won’t last long if you don’t treat it right after the glue dries, which means you’ll need to rethink how you clean, store, and handle these pieces compared to regular textiles.

The sparkle you worked so hard to achieve can fade, crack, or shed completely if you approach maintenance the same way you’d with non-embellished fabrics.

Understanding the specific care requirements for glittered projects ensures your designs stay vibrant and intact through years of use, whether you’re preserving a costume piece or maintaining everyday wearable art.

Hand Washing and Spot Cleaning

Your glittered masterpiece doesn’t need to live in fear of the wash—you just need tactical fabric care that respects the adhesive bond you’ve built.

Hand washing in cold or lukewarm water with mild detergent for delicates minimizes glitter removal, particularly when you swirl gently for fifteen to thirty seconds rather than scrubbing glittered zones directly.

Spot treatment with dampened cloths lifts stains without compromising your textile care standards or triggering premature fabric glue breakdown through aggressive delicate handling techniques.

Safe Storage and Handling

Between display methods and long-term handling, fabric folding becomes your enemy. Rolling glittered textiles loosely prevents crease-induced glitter shedding while preserving adhesive integrity throughout storage solutions that prioritize breathable garment bags in cool environments.

You’ll minimize particle dispersal by placing protective layers between stacked fabrics, catching stray glitter before it migrates, and keeping glue-bonded sections away from heavy items that flatten your crafting achievements into disappointing flatness.

Ironing Without Damaging Glitter

Protect your glittered masterpiece by reversing the fabric before pressing and placing heat-sensitive adhesive bonds away from direct iron contact. Heat settings are crucial because most craft glitters can only tolerate temperatures between 150–180°C. Exceeding this threshold triggers glue reflow, causing particles to scatter across your workspace like tiny rebellious sparks escaping their canvas.

Your damage prevention toolkit includes:

- Pressing cloth barriers between iron and glitter protection zones

- Low-heat steamers that refresh fabric without direct contact

- Parchment sheets creating thermal shields during fabric preparation

- Test patches confirming adhesive resilience before committing

- Reverse-side ironing keeping glue-glitter fabric bonds intact

Long-Term Maintenance Tips

Think of glitter durability like maintaining a vintage jacket—regular check-ins preserve your investment. Inspect glittered areas every three to six months for early wear signals, then re-seal as needed to lock down shedding prevention.

Store fabric flat in low-humidity spaces where adhesive longevity thrives, and document your maintenance intervals so permanent designs outlast fleeting trends while color preservation remains intact.

Creative Ideas for Glittered Fabric Designs

Once you’ve mastered the technical process of adhering glitter to fabric, the creative possibilities extend far beyond simple embellishment, transforming ordinary textiles into statement pieces that challenge conventional craft boundaries.

Whether you’re redesigning fashion accessories, constructing immersive home decor installations, or layering multiple embellishment techniques for complex textile art, strategic glitter application can enhance your work from predictable to exceptional.

The following approaches demonstrate how combining precision technique with bold visual concepts allows you to push past traditional craft limitations and create truly original glittered fabric designs.

Patterns and Stencils

Stencil design transforms plain surfaces into canvases for rebellion, allowing you to reproduce patterns with precision cutting that rivals commercial embellishments.

Mylar fabric templates resist tearing while providing clean glitter masks that don’t bleed, and when you apply fabric glitter glue through reusable stencils using tap-dab methods, you’ll achieve professional edges without smudging.

Peel away at forty-five degrees to preserve your vision’s integrity.

DIY Fashion Accessories

Fashion embellishments reach their full potential when you craft glitter jewelry and accessories that challenge conventional sparkle textiles, using cosmetic safety-rated formulas and fabric glue designed for flexible substrates that won’t crack during wear.

Your accessory design toolkit should include:

- Fine cosmetic-grade glitter for comfortable headbands and hair clips

- Resin-based topcoats that maintain flexibility while preventing shedding

- Edge sealing techniques to stop glittered belts from flaking when flexed

- Water-based adhesives for skin-contact pieces that won’t irritate

- Encapsulated glitter layers within clear acrylic for washable fabric crafting techniques

Home Decor and Textile Art Projects

Your living room canvas expands beyond clothing when you introduce glitter finishes to throw pillows, lampshades, and gallery-worthy textile art that defies decor trends with rebellious sparkle effects. Fabric accents transform ordinary textiles into conversation pieces using fabric glue engineered for heavier weaves and architectural applications.

| Application | Technique Advantage |

|---|---|

| Throw pillows | Creates focal points with geometric glitter patterns |

| Lampshades | Diffuses light through sparkling reflections |

| Wall art panels | Highlights alcoves with sealed glitter layers |

| Canvas textiles | Mix-in adhesive blends improve durability |

Proper fabric decoration demands heat-set methods on synthetics, pre-adhesive priming to prevent dye migration, and topcoat protection that reduces shedding in high-traffic zones. Here, your glitter-to-fabric vision meets everyday functionality.

Combining Glitter With Other Embellishments

You can push your textile art beyond standard sparkle by layering glitter resin with bead embellishments and sequin effects that demand advanced fabric blending techniques, transforming ordinary projects into dimensional masterpieces through strategic embellishment methods.

- Glitter pairs with resin or fabric medium to create crack-resistant textile adornments

- Sequins overlay glittered zones using clear-drying fabric glue for invisible anchoring

- Bead embellishments require two-step adhesion preventing wobble during crafting with glitter

- Strategic spacing between elements maintains flexibility while reducing glue seepage

Finish with clear sealer protecting your embellishment tips investment from abrasion.

Frequently Asked Questions (FAQs)

Can glitter be applied to stretchy fabrics?

Yes, glitter adheres beautifully to stretch fabric when you pair it with flexible adhesive formulated for elastic surfaces—think glitter glue or fabric glue designed specifically for stretchy materials that move without cracking.

How long does glitter glue take to dry?

Glitter glue application usually dries to the touch within 15 to 60 minutes, depending on adhesive types, glue thickness, and environmental effects like humidity.

However, the full curing process often requires 24 hours for maximum durability.

Is glitter safe for childrens clothing projects?

Most cosmetic-grade glitter labeled non-toxic works safely for children’s fabric crafting techniques when you pair it with skin-safe adhesive, supervise application closely, conduct patch tests for skin irritation, and consider eco-friendly options reducing toxicity risks.

When evaluating the safety of materials, it’s vital to factor in the importance of methodological rigor in scientific studies.

Can you layer different glitter colors effectively?

Like stacking gemstones in a crown, you can absolutely layer glitter colors.

Success hinges on particle size, adhesive selection, and proper sealing techniques to achieve dimensional glitter effects without compromising fabric flexibility or color clarity.

Does humidity affect glitter adhesive performance?

Elevated humidity directly undermines adhesive strength by slowing cure times and promoting polymer breakdown. This compromises glue durability and moisture resistance, ultimately causing uneven adhesion and accelerated glitter shedding on your fabric projects.

Conclusion

The real transformation happens not when you first learn how to glue glitter to fabric, but when you realize permanent sparkle was never about perfecting technique—it was about refusing to let embellishment intimidate you into playing safe with plain textiles.

Your willingness to experiment with adhesives, sealing methods, and application tools determines whether glittered surfaces become wearable art or craft-fair casualties, so treat each project as evidence that you’re capable of creating luminous, lasting beauty without traditional constraints.

- https://en.wikipedia.org/wiki/Glitter

- https://academichelpexpress.blog/2024/08/please-use-the-bulleted-points-and-the-rubric-below-to-guide-your-work-your-pa/

- https://www.sciencedirect.com/science/article/pii/S0749208123000268

- https://pmc.ncbi.nlm.nih.gov/articles/instance/9553038/bin/pone.0275964.s005.docx

- https://www.scribd.com/document/356795007/Research-Methods-Knowledge-Base