This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Glass transforms the moment you layer fabric across its surface. The texture catches light differently, colors deepen behind the smooth transparency, and suddenly a plain window or jar becomes something worth a second look.

But getting fabric to grip glass takes more than wishful thinking—the two materials resist each other naturally, and most standard adhesives fail within days. The trick lies in choosing products that bridge the gap between porous textile fibers and non-porous glass, then preparing both surfaces so they’re primed to bond.

Master the right gluing fabric to glass tips, and you’ll discover techniques that hold strong through humidity, handling, and time.

Table Of Contents

- Key Takeaways

- Can You Glue Fabric to Glass?

- Choosing The Right Glue for Fabric and Glass

- Top 9 Products for Gluing Fabric to Glass

- How to Prepare Glass and Fabric for Gluing

- Step-by-Step Guide: Gluing Fabric to Glass

- Common Problems and Mistakes to Avoid

- Safety and Longevity Tips for Glass Crafting

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- You can glue fabric to glass successfully if you choose adhesives that bond with both porous fabric fibers and smooth, non-porous glass surfaces—options like epoxy, silicone, PVA (Mod Podge), and spray adhesives each offer distinct strengths for different project needs.

- Surface preparation is the make-or-break step: clean glass with soap and water, degrease with isopropyl alcohol or acetone, let it dry completely, and handle only the edges with clean gloves to prevent oils from ruining the bond.

- Apply adhesive in thin, even layers rather than thick globs to avoid cloudy finishes, air bubbles, and weak spots—most bonding failures happen because you’re using more glue than the surface actually needs.

- Full curing time (typically 24 to 72 hours for strong adhesives like epoxy) is non-negotiable for durability, and skipping proper cure conditions or exposing projects to moisture, temperature swings, or UV light too early will cause peeling and bond failure.

Can You Glue Fabric to Glass?

Yes, you can glue fabric to glass, and it’s easier than you might think. The key is choosing an adhesive that bonds with both porous fabric and smooth, non-porous glass surfaces.

Let’s look at where this technique shines, what makes it tricky, and when you’ll actually want to use it.

Common Fabric-to-Glass Applications

You can glue fabric to glass for all kinds of creative projects. Fabric facades and window coverings add texture to plain glass.

Stained glass projects come alive with textile inserts, while glass mosaics get extra dimension from fabric backing.

Upholstery panels incorporating glass bring modern flair to interiors. Textile decals let you customize any glass surface. If you’re layering fabrics or adding stitched details, advanced fabric manipulation techniques can help secure glass accents without sacrificing structure.

Fabric decoration through decoupage transforms ordinary glassware into standout pieces.

Challenges of Gluing Fabric to Glass

While fabric-to-glass projects look impressive, surface tension makes glass naturally resistant to many adhesives. Material compatibility matters because not every adhesive manages both surfaces well. Before bonding anything, check these sewing safety tips to avoid fume exposure and workspace hazards when using specialty adhesives.

Bond strength drops fast when you skip proper glass preparation, and fabric delamination happens if you choose the wrong fabric glue. Adhesive failure often strikes when oils or dust interfere, so surface preparation techniques determine whether your creation lasts or peels away. Coated or heavy-weight fabrics can weaken adhesive bonds, and if you’re working with curtain hems, no-sew hemming methods may leave residue when repositioned.

When Fabric Bonding is Most Useful

Once you’ve tackled those challenges, you’ll discover when fabric bonding truly shines. These situations make gluing fabric to glass your best move:

- Creating smooth fabric decoration on glass without visible fasteners

- Achieving durable bonds where mechanical fastening won’t work

- Preserving light transmission through clear glass surfaces

- Combining textile flexibility with rigid glass in glass repair projects

- Using decoupage and bonding techniques for upcycling crafts

Surface preparation determines your success with textile adhesion and material bonding.

Choosing The Right Glue for Fabric and Glass

Picking the right adhesive is the make-or-break moment for your fabric-to-glass project. You need a glue that can grab onto both materials and hold strong, which isn’t as simple as reaching for whatever’s in your craft drawer.

Let’s look at the key types that actually work and how spray, epoxy, and PVA options stack up against each other.

Key Glue Types for Fabric-to-Glass Projects

Your project’s success starts with picking the right bonding agent. Epoxy resins create high-strength, permanent bonds that withstand mechanical stress, while silicone adhesives offer flexibility and moisture resistance. PVA-based options like Mod Podge work well for decorative glass crafts, though they’re less durable. Spray adhesive provides quick tack for positioning fabric, and hot glue delivers rapid results for lightweight applications.

| Adhesive Type | Best For |

|---|---|

| Epoxy Resins | Permanent, high-strength bonds |

| Silicone Adhesives | Flexible, weather-resistant projects |

| PVA/Mod Podge | Decorative, indoor glass crafts |

Comparing Spray, Epoxy, and PVA Options

Each adhesive selection brings distinct tradeoffs in adhesive strength, bond durability, and curing times for gluing fabric to glass. After proper glass preparation, here’s how they stack up: For projects requiring maximum hold and flexibility, choosing durable fabric glue designed for patches ensures your glass-to-fabric bonds withstand repeated washing and temperature changes.

- Spray Adhesive – Covers 6 to 12 square feet per can, tacks in 15 to 60 minutes, ideal for lightweight fabric selection and quick positioning.

- Epoxy Resin – Delivers exceptional bonding with pot life from 5 to 60 minutes, excellent for high-stress applications.

- PVA Glue – Dries clear in 20 minutes to 2 hours, best for decorative indoor projects with flexible finishes.

Top 9 Products for Gluing Fabric to Glass

Finding the right product makes all the difference when you’re gluing fabric to glass. You’ll need something that bonds securely without yellowing or peeling over time. For projects that also involve stitched fabric edges, you’ll want to explore buttonhole stitch options and their strength comparisons to reinforce seams that might contact the glass surface.

Here are nine reliable products that crafters and DIY enthusiasts trust for fabric-to-glass projects.

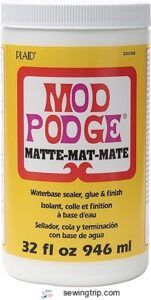

1. Mod Podge Matte Sealer Glue

When you need a reliable all-in-one solution for gluing fabric to glass, Mod Podge Matte Sealer Glue stands out as a go-to choice in glass crafting. This water-based fabric glue excels in craft applications, drying clear with a smooth matte finish that won’t distract from your design.

Its adhesive strength works best with lighter fabrics like cotton or linen, though proper glass preparation—cleaning and degreasing—is essential for best fabric bonding.

The adhesive techniques are straightforward: apply thin, even layers and allow 24 hours for full curing to achieve greatest durability.

| Best For | Crafters working on decorative projects who need to bond lightweight fabrics like cotton or linen to glass surfaces with a clear, non-glossy finish. |

|---|---|

| Material | Water-based acrylic |

| Brand | Mod Podge |

| Primary Use | Crafting/sealing |

| Weight/Size | 32 oz |

| Form | Liquid |

| Country Origin | Made in USA |

| Additional Features |

|

- Dries clear with a smooth matte finish that doesn’t interfere with your design

- Water-based and non-toxic formula makes cleanup easy with just soap and water

- Works as an all-in-one glue, sealer, and finish for multiple craft applications

- Requires proper glass prep (cleaning and degreasing) for reliable adhesion

- Works best with lighter fabrics—heavier textiles may not bond as well

- Needs a full 24-hour cure time and isn’t designed for outdoor or heavy-duty use

2. Quikrete Concrete Mix Bag

You might be surprised to see a Quikrete Concrete Mix Bag in a fabric-to-glass guide, but understanding its cement strength and mix ratios offers a valuable contrast to traditional glass adhesives.

While Mod Podge and fabric glue excel at bonding lightweight materials, concrete mix demonstrates why adhesive techniques matter—this 60-lb bag yields about 0.45 cubic feet with 4000 psi compressive strength, far exceeding what’s needed for gluing fabric to glass.

The lesson? Match your adhesive’s bag properties and bonding power to your project’s actual demands.

| Best For | DIYers and homeowners tackling small concrete repairs like patching cracks, filling holes, or fixing garage floors without needing to buy a full-size bag. |

|---|---|

| Material | Portland cement/concrete |

| Brand | Quikrete |

| Primary Use | Small repairs |

| Weight/Size | 10 lbs |

| Form | Dry mix |

| Country Origin | USA brand |

| Additional Features |

|

- Just add water and mix—no complicated measurements or extra ingredients needed

- Perfect size for quick fixes without waste or leftover concrete sitting around

- Contains everything you need in one bag: Portland cement, sand, and gravel

- The 10 lb size limits you to very small projects compared to standard 60 lb bags

- Price per pound is higher than buying larger bags at home improvement stores

- You’ll need multiple bags for anything beyond minor repairs, which adds up fast

3. Sika Concrete Patch Repair Mix

When you’re expanding your adhesive selection guide, Sika Concrete Patch Repair Mix seems out of place—but it teaches critical lessons about surface preparation and curing techniques. This acrylic latex patch bonds to concrete at over 500 psi, proving that proper substrate prep and controlled curing matter more than brute strength.

While it’s not for gluing fabric to glass, understanding its mixing tips and adhesive compatibility helps you appreciate why glass adhesives require clean, oil-free surfaces and patience during drying.

| Best For | DIYers and homeowners tackling small to medium concrete repairs on driveways, patios, steps, and foundations where a quick, easy-to-apply fix is needed without mixing from scratch. |

|---|---|

| Material | Acrylic latex |

| Brand | SIKA |

| Primary Use | Crack repair |

| Weight/Size | 3.2 lbs |

| Form | Paste |

| Country Origin | USA brand |

| Additional Features |

|

- Premixed and ready to use right out of the container, so you skip the hassle of measuring and mixing—just grab a putty knife and go.

- Acrylic latex formula cleans up with water and has low VOC emissions, making it safer and more convenient than solvent-based products.

- Works on vertical and horizontal surfaces with a textured finish that blends naturally into existing concrete.

- Not strong enough for vehicle traffic despite being marketed for driveways, so you’ll need a different product for high-use areas.

- Deep cracks often need multiple layers, which stretches out your repair time and uses more product than expected.

- Quality control issues with lid seals and packaging mean you might receive a dried-out or leaking container.

4. Quick Setting Concrete Cement

Quick setting concrete cement hardens in 10 to 15 minutes, making it useful as a structural filler behind fabric-to-glass assemblies. You won’t use it like E6000 or other glass adhesives, but it can reinforce decorative panels by distributing stress across the glass surface.

When working with rapid setting cement properties, mix small batches with water and apply quickly before it cures. This concrete mixture’s low-odor formula suits indoor projects, and its fast cure helps secure fabric backing layers during assembly—complementing traditional fabric glue methods.

| Best For | DIYers and contractors who need to patch concrete steps, curbs, or holes quickly, or anyone looking to add structural backing behind decorative glass panels where fast curing matters. |

|---|---|

| Material | Acrylic paste |

| Brand | Quikrete |

| Primary Use | Rapid repairs |

| Weight/Size | 10.25 lbs |

| Form | Paste |

| Country Origin | USA brand |

| Additional Features |

|

- Sets in 10-15 minutes so you can finish small repairs without waiting around all day

- Easy to shape and mold while it’s still workable, giving you control over the final look

- Works well as a structural filler behind fabric-to-glass projects to distribute stress and add rigidity

- Hardens so fast you need to work in small batches and move quickly once you’ve mixed it

- Costs more than regular cement, which adds up if you’re doing multiple repairs

- Not meant for big concrete jobs since it’s cement-based—stick to patches and small fixes

5. Hartline Rockite Expansion Cement

Hartline Rockite Expansion Cement reaches 4,500 psi compression strength and sets in just 15 minutes, offering serious bonding strength for glass crafting projects where you need structural support behind fabric layers.

You’ll mix this expansion control compound with water, then pour it to anchor decorative glass panels or reinforce fabric-backed assemblies.

Safety precautions matter—wear gloves and eye protection during cement mixing, as the material generates heat.

While it’s not a traditional fabric glue or adhesive application method, Rockite acts as a powerful bonding agent when structural reinforcement complements your decorative work.

| Best For | DIYers and professionals who need to anchor hardware, secure posts, or patch concrete and masonry with a fast-setting, high-strength cement that bonds permanently to metal and concrete. |

|---|---|

| Material | Powder |

| Brand | Hartline |

| Primary Use | Anchoring/bonding |

| Weight/Size | 1 lb |

| Form | Powder |

| Country Origin | Made in USA |

| Additional Features |

|

- Sets in just 15 minutes and develops impressive 4,500 psi compression strength for reliable, long-lasting repairs

- Works great for anchoring bolts, posts, screws, and hardware in both vertical and horizontal applications

- Easy to mix with water and pour, making it accessible for small jobs and intricate repairs

- No mixing directions included, so getting the right powder-to-water ratio takes some trial and error

- Can become too watery or break easily if not mixed carefully or poured too thin

- Generates heat during mixing and requires protective gear like gloves and eye protection for safe handling

6. Goldblatt Masonry Hand Tool Set

For larger glass crafting projects that require structural mortar work around your fabric-adorned pieces, the Goldblatt Masonry Hand Tool Set delivers eight essential tools, including a 16-inch finishing trowel and 6-inch edger. You’ll get ergonomic grips and a carrying bag for organized tool maintenance.

While these masonry tools won’t apply adhesive directly to fabric, they’re valuable for construction safety when building frames or bracing for your glass projects. The set works well for beginners tackling medium-scale work, though some users note the tools run smaller than expected.

| Best For | Beginners and DIY enthusiasts working on small to medium masonry projects who need a complete starter set with organized storage. |

|---|---|

| Material | Stainless steel/alloy |

| Brand | Generic masonry |

| Primary Use | Masonry finishing |

| Weight/Size | 8-piece set |

| Form | Hand tools |

| Country Origin | Not specified |

| Additional Features |

|

- Comes with eight essential tools and a convenient carrying bag for easy organization and transport

- Ergonomic handles designed to reduce hand fatigue during extended use

- Affordable value for a complete set that covers most basic masonry tasks

- Tools are smaller than some users expected, which may limit effectiveness on larger projects

- Not built for heavy-duty or professional daily use—durability may not match premium brands

- Quality can be inconsistent, with some users preferring to stick with their older tools

7. Concrete Finishing Tool Set

If you’re setting up permanent installations that anchor fabric-covered glass panels, the Concrete Finishing Tool Set gives you three stainless steel tools—an 11″ x 4″ flat trowel, 6″ edger, and 6″ groover—for concrete edging and surface smoothing around your displays.

You’ll appreciate the rust-resistant blades and ergonomic grips during extended finishing techniques. Though weighing under two pounds, these concrete tools handle light to medium projects like sidewalk borders for outdoor glass art.

Tool maintenance stays simple since the no-rivets construction cleans easily after pour work, keeping your bonding prep areas tidy.

| Best For | DIYers and homeowners who need to finish small to medium concrete projects like sidewalks, patios, or base installations for outdoor displays. |

|---|---|

| Material | Stainless steel |

| Brand | Generic concrete |

| Primary Use | Concrete finishing |

| Weight/Size | 3-piece set |

| Form | Hand tools |

| Country Origin | Not specified |

| Additional Features |

|

- Stainless steel blades resist rust and clean up easily after each use

- Lightweight 3-piece set includes the essential tools (trowel, edger, groover) for most finishing jobs

- Ergonomic handles and no-rivets design make extended work more comfortable

- Tools are smaller than expected and may feel undersized for larger projects

- No pole attachment option, making it harder to reach or cover bigger areas

- Not built for professional or heavy-duty commercial use

8. Workpro Rotary Hammer Drill Bits Set

When you’re mounting large glass-and-fabric pieces into masonry walls, the Workpro Rotary Hammer Drill Bits Set delivers seventeen carbide-tipped pieces—twelve drill bits plus five chisels—for secure adhesive bonding installations. You’ll break through concrete and brick with the U-shaped flute design that clears debris fast, and hammer drill safety stays simple with the SDS-Plus shank that won’t slip during heavy work.

Masonry drilling tips recommend carbide for lasting edge sharpness, though bit sharpening techniques rarely apply since replacement beats re-grinding.

Rotary hammer maintenance means checking wear indicators before your next glass installation project.

| Best For | DIYers and homeowners tackling masonry drilling projects who need a complete set of carbide-tipped bits and chisels for concrete, brick, and stone work without breaking the bank. |

|---|---|

| Material | Cemented carbide |

| Brand | Generic SDS |

| Primary Use | Drilling/chiseling |

| Weight/Size | 17-piece set |

| Form | Drill bits/chisels |

| Country Origin | Not specified |

| Additional Features |

|

- Comes with 17 pieces including multiple drill bits and chisels, giving you plenty of options for different drilling and chiseling tasks right out of the box.

- Carbide tips hold their edge well in masonry materials and the U-shaped flute design clears dust and debris efficiently during drilling.

- SDS-Plus shank design prevents slippage during heavy hammering and works with most common rotary hammer drills on the market.

- Not built for heavy-duty or industrial use, so frequent professional work might wear them down faster than premium alternatives.

- Some bits in the set may feel redundant depending on your specific projects, and the storage case organization isn’t perfect for everyone.

- Quality can vary with how hard you push them, and once they’re worn down, you’ll need to replace them since resharpening isn’t really practical.

9. Concrete Block For Masonry Walls

After drilling anchor holes, you’ll need a solid base for glass-and-fabric installations—that’s where concrete blocks for masonry walls come in. These 8-inch thick units meet ASTM C90 masonry codes and provide stable wall reinforcement when you’re bonding large decorative glass panels.

Block installation creates permanent surfaces for adhesive anchoring, and proper grout in the cores boosts structural strength. You won’t glue fabric directly to the block, but the durable concrete backing lets your glass-adhesive projects hold securely for years.

| Best For | Contractors and builders working on load-bearing walls, foundations, or structural projects that need durable, code-compliant masonry units with solid anchoring capability. |

|---|---|

| Material | Concrete |

| Brand | Generic |

| Primary Use | Load-bearing walls |

| Weight/Size | 8 inches thick |

| Form | Solid block |

| Country Origin | Not specified |

| Additional Features |

|

- Meets ASTM C90 standards for load-bearing applications, ensuring reliable structural performance and code compliance

- Weather-resistant and energy-efficient concrete construction provides long-term durability and potential cost savings

- Uniform 8-inch thickness with hollow cores allows for reinforcement and grout placement to boost wall strength

- Heavy weight requires special handling equipment or extra labor for transportation and installation

- Low thermal performance without additional insulation means you’ll need to add foam or other materials for energy efficiency

- Requires proper curing, moisture maintenance, and skilled installation to prevent voids, cracking, or moisture intrusion

How to Prepare Glass and Fabric for Gluing

You can’t skip the prep work if you want fabric to actually stay on glass. A clean, oil-free surface makes all the difference between a project that lasts and one that peels off in a week.

Here’s how to get both your glass and fabric ready for a bond that holds.

Cleaning and Degreasing Glass Surfaces

Your glass surface is only as good as its prep work. Start by washing the glass with mild dish soap and water to strip away dust, fingerprints, and grime—essential surface preparation for any glass decoration or glass art project.

Next, degrease using 70% isopropyl alcohol or acetone on a lint-free cloth. This cleaning step ensures adhesive compatibility and strong contamination control, so your fabric actually sticks.

Drying and Dust-Removal Techniques

Patience is your ally here. After cleaning, let the glass air dry for 1–2 hours—longer if humidity’s high—since proper moisture management prevents adhesive compatibility issues. Speed things up with a warm-air blower held at a safe distance.

Then, wipe down with a lint-free microfiber cloth for dust control, removing every speck. This surface preparation method guarantees a perfect bond when you move to adhesive application methods.

Handling Glass Without Contamination

With clean, lint-free gloves on, you’ll transform your glass handling into a contamination control practice borrowed from cleanroom protocols. Touch only the edges—never the bonding surface—since skin oils sabotage adhesive selection. Surface preparation methods demand this discipline. Hold pieces by their perimeter or use tools for glass restoration best practices.

These surface preparation tips guarantee your bonding glass project succeeds every time. By wearing cleanroom grade gloves, you can minimize contamination risks.

Step-by-Step Guide: Gluing Fabric to Glass

You’ve cleaned your glass and prepped your fabric—now it’s time to actually glue them together. The method you use depends on which adhesive you picked, but the core steps stay pretty much the same.

Here’s how to apply your glue, keep everything lined up, and make sure it cures properly for a bond that lasts.

Applying Different Types of Adhesives

Your adhesive choice determines how you’ll work. Spray adhesives need a smooth, sweeping motion about six inches from the glass—coat the fabric, not the glass itself, for better control. Liquid options like E6000 Craft Adhesive require thin, even beads along edges to prevent bleed-through. PVA glue works best brushed directly onto glass in small sections.

Each bonding agent has unique curing times and surface prep demands.

Ensuring Proper Alignment and Pressure

One wrong move and your fabric slides out of place, ruining hours of prep work. Use alignment tools like a straightedge or level to position fabric parallel to glass edges.

Apply steady, even pressure with a brayer or flat tool to spread adhesive distribution uniformly. This pressure control prevents air pockets and maximizes bonding strength.

Hold fabric firmly for at least one minute to lock alignment before the glue application sets.

Curing and Drying Best Practices

Think of the curing process as your project’s final exam—rush it and you’ll fail. Check the manufacturer’s recommended curing time (usually 24 to 72 hours for epoxies) and maintain stable temperature and humidity in your drying environment.

Keep moisture control tight: no water exposure until cure time optimization is complete. Thermal stress from heat or cold can wreck bond strength before it fully develops.

Common Problems and Mistakes to Avoid

Even when you follow every step correctly, fabric-to-glass projects can still go sideways. Most failures come down to a handful of preventable mistakes that catch beginners off guard.

Here’s what commonly goes wrong and how you can avoid the same pitfalls.

Why Fabric Sometimes Won’t Stick

Poor surface preparation is the main culprit when fabric won’t bond to glass. Oils from your fingertips, dust, or residue create barriers that prevent proper adhesion. Here are the top reasons your project might fail:

- Contaminated glass surfaces – Fingerprints and cleaning product residue block adhesive contact

- Adhesive incompatibility – Some glues need porous surfaces, which glass lacks

- Inadequate cure conditions – Humidity and temperature affect bonding techniques and proper curing

Overusing or Misapplying Adhesive

Too much glue is just as bad as too little. Excess adhesive creates cloudy finishes, traps air bubbles under your fabric, and extends curing time. You’ll also get weak spots where thick layers don’t cure completely.

Apply thin, even coats instead of heavy dollops. Most bonding failures happen because you’re working with more adhesive than the glass surface actually needs.

Most bonding failures happen because you’re working with more adhesive than the glass surface actually needs

Dealing With Peeling or Weak Bonds

If your fabric lifts from the glass, surface contamination is the usual culprit—contaminants cut bond strength by up to 60 percent. Adhesive layer thickness matters too; going thinner than recommended reduces bonding strength by 20 to 40 percent.

Thermal cycling effects from repeated heating and cooling create micro-cracks, while polymer compatibility issues between hydrophobic fibers and water-based adhesives weaken glass adhesion.

Safety and Longevity Tips for Glass Crafting

Working with adhesives and glass requires attention to safety and smart techniques that protect both you and your project. The right precautions during application can prevent accidents, while specific strategies after gluing will guarantee your fabric-to-glass creations last for years.

Here’s what you need to know about staying safe and making your work durable.

Working With Adhesives Safely

Your workspace becomes a chemical laboratory when you open adhesives, so treat bonding agents with respect. Wear nitrile gloves to avoid skin contact with adhesive materials, and work in well-ventilated areas to control fumes from chemical handling. Keep an eyewash station nearby for emergency response.

Understanding adhesive hazards and following safety protocols protects you from temperature and humidity effects that compromise adhesive bonding strength.

Improving Bond Durability

Longevity starts with surface preparation—clean glass creates the foundation for adhesive bonding strength that lasts years. Your adhesive selection determines how well bonding agents resist temperature and humidity effects, while proper curing conditions let material bonding methods reach full strength.

Mechanical interlocking between fabric weave and adhesive creates layers of security. Bond testing after cure time confirms your work can handle real-world stress.

Handling and Using Finished Projects

Patience pays dividends when decorating glass objects—your finished glass art projects need full curing time before you handle them. Temperature and humidity shape adhesive longevity and bond strength, so follow manufacturer timelines exactly.

Protect surface protection and fabric durability with these glass crafting techniques:

- Wait for complete cure before moving pieces

- Inspect regularly for delamination or cracking

- Apply protective sealants for water resistance

- Support bonded areas during glass maintenance to reduce stress

Frequently Asked Questions (FAQs)

Can you wash fabric glued to glass?

Yes, but only if you use moisture-resistant adhesives like silicone. Hand wash gently with cool water and mild detergent. Most craft glues fail under repeated washing, so test first.

How long does fabric-to-glass adhesive last?

Most fabric-to-glass bonds last two to fifteen years, depending on adhesive type and conditions. Epoxy offers excellent adhesion and temperature resistance.

UV exposure and moisture can reduce bond strength and fabric durability over time.

Does temperature affect fabric-to-glass bonding strength?

Temperature control dramatically impacts adhesive performance and bond durability. Heat causes glass expansion and weakens thermal effects on most glues, while cold reduces flexibility.

Maintaining room temperature ensures ideal temperature resistance for lasting crafting with glass projects. This consideration is vital for achieving methodological rigor in crafting and scientific applications.

Can you remove fabric from glass later?

Fabric detachment depends on your adhesive choice. Water-based options like PVA allow bond reversal with moisture, while epoxy creates permanent bonds.

Expect glass residue requiring surface cleaning with solvents, especially after removing silicone or spray adhesives.

Will sunlight damage fabric glued to glass?

Direct sunlight speeds up fabric fading and adhesive degradation through UV exposure. Glass coatings with UV protection improve color stability, while temperature swings weaken bonds.

Choose UV-resistant adhesives for better resistance to elements when crafting with glass.

Conclusion

Think of fabric meeting glass like two strangers learning to shake hands—it takes the right introduction. You’ve now got the gluing fabric to glass tips that make that introduction stick: clean surfaces, matched adhesives, patient curing.

Your next jar won’t just sit on a shelf. It’ll wear texture like a second skin, catching eyes and holding fast through every season you give it.