This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Every sewist hits that moment when they realize a seam went wrong three steps ago. The fabric puckers, the zipper sits crooked, or you accidentally sewed the sleeve inside out.

Your first instinct might be to work around it or convince yourself it’s “good enough.” But here’s the truth: knowing when to use a seam ripper in sewing separates rushed projects from polished ones.

This small, forked tool gives you permission to fix mistakes instead of living with them. The real skill isn’t avoiding errors—it’s recognizing which ones deserve correction and how to remove stitches without damaging your fabric.

Table Of Contents

Key Takeaways

- A seam ripper isn’t just for fixing mistakes—it’s essential for removing basting stitches, opening buttonholes, adjusting fit during alterations, and stripping out decorative topstitching you want to change.

- You should rip and redo seams when they drift 3-5 millimeters off your stitching line, show on visible areas like collars or hems, affect garment fit by restricting movement, or create puckering you can’t ignore.

- Different fabrics demand specific ripping techniques—delicate materials like silk need every third or fourth stitch cut from the bobbin side with cardboard inserted between layers, while heavy fabrics like denim require reinforced blades and breaking every second stitch.

- The real skill in sewing isn’t avoiding errors but recognizing which mistakes deserve correction early, using your seam ripper strategically to protect fabric integrity, and fixing problems before they compromise your entire project.

What is a Seam Ripper Used For?

A seam ripper isn’t just for fixing mistakes—it’s your go-to tool for a surprising range of sewing tasks. Whether you’re correcting an error or making intentional changes to a project, this little tool gives you the freedom to undo and redo with confidence.

If you’ve never explored all the ways you can use one, check out what a seam ripper is used for beyond just ripping out seams.

Let’s look at the most common ways you’ll use it in your sewing routine.

If you’re planning to add decorative details like beads or sequins, check out these practical tips for working with embellishments to make the process smoother.

Correcting Sewing Mistakes

Mastery in sewing means owning your mistakes early. Your seam ripper becomes your repair tool the moment you spot crooked lines, misplaced fabric, or wonky tension.

If you’re just getting started, this beginner’s guide to sewing walks you through essential techniques that prevent those frustrating mistakes in the first place.

Sewing mastery starts with catching your mistakes early—a seam ripper turns crooked lines and wonky tension into opportunities for repair

Here’s when fabric protection and error analysis matter most:

Understanding common sewing project mistakes helps you avoid fabric waste and achieve professional-looking results every time.

- Misaligned seams pulling your garment off-grain

- Wrong stitch type creating puckers you can’t ignore

- Pattern pieces sewn backward despite your careful planning

- Dense overlapping stitches begging for precise removal

- Basting that’s overstayed its welcome

Learning how to approach fixing sewing mistakes can help you turn errors into valuable opportunities for growth. Sewing corrections save your project every time.

Removing Unwanted Stitches

Beyond fixing mistakes, you’ll reach for your seam ripper to remove decorative topstitching, release basting threads, or strip out old alterations.

It’s one of those must-have hand sewing accessories that earns its place in your toolkit after the first rescue mission.

Slip the sharp blade under unwanted stitches, slice through thread carefully, then pull sections free. Thread management keeps your fabric clean during removal—work in small increments to maintain damage control.

This stitch removal method protects fibers while giving you complete seam correction freedom.

Adjusting or Altering Seams

When garment alterations demand precision, your seam ripper becomes essential for fabric shaping and pattern adjustments. You’ll use it to release side seams for letting out or taking in width, open dart modifications to shift fit, and undo hem adjustments that need repositioning.

Seam rebalancing requires careful stitch removal—this sewing technique protects fabric integrity while giving you complete control over garment repair and structural changes. To minimize distortion during pattern changes, many sewists rely on techniques like the seam method for precise alterations.

Opening Buttonholes and Basting

You’ll reach for your seam ripper when opening buttonholes—mark the center slit, then carefully cut from the wrong side for better control.

It’s also perfect for removing basting stitches, those temporary guides holding fabric in place. Use contrasting thread for basting techniques so thread removal stays simple.

Always test buttonhole placement on scrap fabric first to confirm your button fits perfectly.

Common Situations to Use a Seam Ripper

You’ll reach for your seam ripper more often than you think. Some mistakes announce themselves the moment you flip your fabric over, while others sneak up after you’ve sewn three more seams.

Here are the most common situations when ripping becomes your best move forward.

Crooked or Misaligned Seams

You’ll know your seam’s crooked when the fabric edges tilt or refuse to line up evenly. Misaligned patterns and uneven seam allowances scream for seam correction—this is where your seam ripper becomes essential.

Breaking those wayward stitches carefully prevents fabric distortion while you master stitch realignment. Don’t let a wonky seam sabotage your project when the right sewing tools can set things straight.

Incorrect Stitch Type or Tension

Tension control and stitch balance matter more than you think. When your thread breakage increases or fabric distortion appears along the seam, your machine’s telling you something’s off.

Wrong stitch types create puckering, wavy lines, or skipped stitches that wreck sewing accuracy. Grab your seam ripper and undo those problem stitches before they compromise your entire project—proper sewing techniques demand it.

Pattern or Fabric Placement Errors

Precision in fabric alignment and grain line placement separates amateur work from polished garment construction.

When directional prints end up upside down or stripes refuse to meet at the seam, your seam ripper becomes your best ally.

Print matching errors and fabric distortion from off-grain cutting demand immediate seam correction—don’t let these sewing techniques slip by unnoticed.

Removing Temporary Basting Stitches

Basting thread holds your project together just long enough—then it’s time to set it free.

These temporary stitches come out fast when you know the right stitch removal methods:

- Clip every few stitches with your seam ripper for smoother fabric protection

- Pull gently along the seam line to avoid stretching delicate weaves

- Use contrasting thread so you can spot what needs removal instantly

- Press afterward to erase any lingering needle marks

Smart thread management turns seam repair into a simple finish-line task.

How to Decide When to Rip Seams

You’ve probably been there—staring at a seam issue that’s just not right, wondering if you should fix it now or push through and hope for the best. Choosing when to rip and repair isn’t always obvious, especially when you’re deep into a project.

Let’s walk through a few key considerations that’ll help you make the call with confidence.

Assessing The Severity of Mistakes

Not every wonky seam deserves the seam ripper—severity thresholds matter. Before you start seam ripping and removal, evaluate the error using clear criteria that separate fixable flaws from deal-breakers.

| Mistake Assessment Factor | When It’s Severe Enough to Rip |

|---|---|

| Deviation From Line | Drifts 3–5 millimeters or more from your marked stitching path |

| Visibility | Shows on high-traffic areas like collars, hems, or center front |

| Fit Impact | Changes circumference, pulls across fabric, or restricts movement |

| Fabric Risk | Stable textiles tolerate correction; delicate weaves may tear during textile repair |

Error evaluation protects both your garment and your sanity—knowing when stitches truly need removal prevents unnecessary fabric risk and wasted correction timing.

Identifying Early Vs. Late Correction

Correction timing separates efficient sewers from those who rip seams twice. Early error detection happens during construction—you catch crooked stitches before layering facings or adding hems.

Late corrections surface after fitting, when fabric assessment reveals seam allowances pulling or puckering. Early fixes use minimal seam ripping and removal; late repair strategies risk fraying if you’ve already overlocked edges.

Spotting misaligned stitches before you commit saves fabric and sanity.

Protecting Fabric From Damage

Fabric protection starts before the first cut. When you use a seam ripper, avoid forceful pulling—it distorts weave and weakens fibers. Instead, break stitches in small sections and lift threads gently.

This fabric care approach prevents puckering and snags, especially on delicate materials. Sharp blades reduce dragging, so keep your seam ripper fresh. Gentle handling during fabric manipulation preserves the textile and keeps your project looking professional, not mangled.

Considering Project Progress

Progress monitoring means weighing what you’ve completed against what’s left. If you’re five hours into a garment and spot a wonky seam allowance early on, rip it now—your checkpoint reviews and quality control depend on solid foundations.

Time management wins when you catch errors before they snowball. Use your seam ripper strategically, not impulsively, to keep project tracking on course and your sewing techniques sharp.

Step-by-Step Seam Ripper Techniques

Now that you’ve decided it’s time to rip, let’s walk through the actual process. Using a seam ripper correctly isn’t hard, but there’s a right way to do it that protects your fabric and saves you frustration.

Here’s how to remove those stitches cleanly and get ready to sew it right.

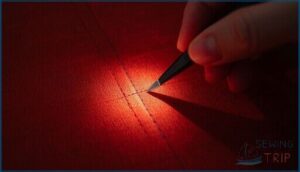

Identifying The Stitch Line

Before you can rip, you need to spot the stitch line—the sewing line where fabric pieces join. Look for the visible thread path running parallel to the fabric edge, usually at your seam allowance distance.

Check pattern alignment and fabric grain to confirm you’re targeting the right stitches. Good lighting helps you see exactly where your seam ripper needs to work.

Breaking Stitches Safely

Once you’ve found your seam ripper, it’s time to break stitches safely. Slide the seam ripper’s sharp point under a single stitch, then push gently upward until the blade cuts through the thread.

Work one stitch at a time with steady, controlled pressure—hold the fabric taut and keep the blade flat against the seam to avoid nicking fibers. Rip in short increments rather than yanking aggressively.

Removing Loose Threads Cleanly

After you’ve snipped the seam, pull out long continuous sections of thread first—this clears the biggest mess fast. Then grab tweezers or your fingers to coax out visible loose strands along the seam line.

For stubborn bits clinging to the weave, roll a lint roller or low-tack tape over both sides. Clean thread removal keeps your fabric prep sharp and ready.

Pressing and Preparing for Reseaming

Accuracy transforms your next attempt from hope to certainty. Once the seam’s clear, press the fabric lightly with a preheated iron set to the correct fabric setting—this realigns fibers and flattens any puckering.

Follow these pressing techniques before reseaming:

- Align and press fabric edges to create a true seam line

- Use a pressing cloth on delicate fabrics to prevent scorching

- Apply seam stabilizers along curved areas to prevent stretch

- Pin or baste pieces after pressing to prevent shifting

- Allow fabric to cool completely before restitching

This fabric preparation ensures your seam ripper work pays off.

Tips for Seam Ripping on Different Fabrics

Not all fabrics behave the same way when you’re ripping out stitches. What works on cotton fabric might spell disaster for silk fabric, and denim fabric requires a completely different approach than chiffon fabric.

Here’s how to handle your seam ripper across different fabric types without causing damage or leaving those telltale marks behind.

Delicate and Lightweight Fabrics

Silk, chiffon, and organza demand a feather-light touch. You’ll want to cut every third or fourth stitch from the bobbin side to minimize fiber damage and weave protection issues. Thread tension marks can become permanent on these fabrics, so work slowly. A cardboard insert between layers prevents accidental cuts and fabric distortion, keeping seam stability intact while you remove those problem stitches.

| Fabric Type | Key Precaution |

|---|---|

| Silk & Satin | Cut from bobbin side to reduce surface snags |

| Chiffon & Organza | Insert cardboard barrier between layers |

| Voile & Batiste | Break every 3-4 stitches to limit perforation |

| Lace & Mesh | Slide tip between stitches, not under fabric |

| Sheer Linings | Use minimal pressure to avoid melting fibers |

Thick or Heavy Materials

Heavy Fabric Handling calls for muscle and strategy. You’ll need a heavy duty seam ripper with a reinforced blade to cut through denim, canvas, and upholstery without bending.

Thick Seam Management means breaking every second stitch on the bobbin side, where Dense Material Cutting won’t cause visible holes. Bulk Reduction happens when you pull threads in short sections, preventing fabric distortion and maintaining weave integrity throughout the ripping process.

Curved or Hard-to-Reach Seams

Curved Seam Repair demands precision and patience when your curved blade can’t reach inside armholes or necklines. You’ll master Tight Space Techniques by working from the seam allowance side, keeping the red ball against fabric while you guide the point between layers.

- Stretch the seam gently with both hands to expose stitches and maintain Fabric Tension Control without distorting the curve

- Use a lighted seam ripper with magnifier for Precision Seam Ripping on dark linings or tight collars

- Switch to fine precision tools as Ergonomic Tool Choices that reduce hand fatigue during long unpicking sessions

Removing Serged or Overlocked Stitches

Serged Stitch Removal demands a different game plan than standard seams because overlocked threads interlock around your fabric edge.

You’ll master Overlock Techniques by identifying the needle threads first—those straight parallel lines on the right side—then clipping every third stitch before pulling. Thread Identification protects your seam allowance from accidental cuts while the looper threads unravel cleanly, leaving fabric ready for Seam Repair.

Top Seam Rippers for Sewing Projects

Not all seam rippers are created equal, and having the right tool makes a real difference in your sewing experience.

Some are built for heavy-duty projects, while others excel at delicate work or tight spaces.

Here are seven seam rippers that can handle whatever your sewing projects throw at you.

1. Missouri Star Heavy Duty Seam Ripper

When you’re tackling dense seams or working through heavy duty materials like denim or multiple quilt layers, the Missouri Star Heavy Duty Seam Ripper becomes one of your essential quilting essentials.

This sewing tool features an ergonomic handle that won’t tire your hand during extended seam ripper usage, plus a chrome-plated blade sharp enough to slice through stubborn stitches cleanly. The mini-ball provides fabric protection while you work, and proper seam ripper safety comes built-in with a protective cap.

It’s reliable thread management for serious sewing techniques.

| Best For | Quilters and sewers who frequently work with heavy fabrics like denim or multiple quilt layers and need a comfortable, reliable tool for removing stitches. |

|---|---|

| Blade Material | Chrome plated steel |

| Handle Type | Soft grip ergonomic |

| Protective Cover | Yes |

| Length | 5.5 inches |

| Weight | 1.13 ounces |

| Primary Use | Seam ripping and thread cutting |

| Additional Features |

|

- Ergonomic soft grip handle makes extended use comfortable, especially helpful for people with arthritis

- Sharp chrome-plated blade cuts through dense seams and stubborn stitches cleanly

- Includes safety features like a mini-ball for fabric protection and a blade cover for storage

- Quality control issues reported by some users, including dull blades or dirt on arrival

- May not hold up to heavy-duty use as well as expected, with some users reporting breakage

- Inconsistent quality compared to older models or previous purchases

2. Clover Ergonomic Seam Ripper

If your hands ache after hours of sewing, the Clover Ergonomic Seam Ripper changes everything. Its contoured handle fits your palm naturally, reducing strain on wrists and fingers—perfect for marathon seam ripping sessions.

The hardened steel blade sharpness stays reliable through countless stitches, while the protective ball tip guards against fabric snags. This durability and ergonomic design make it a standout among sewing tools.

You’ll find the nonslip handle materials give you better control, and the included safety cap keeps the blade secure between projects.

| Best For | Sewers with hand fatigue, carpal tunnel, or anyone who does frequent seam ripping and needs a comfortable, strain-reducing tool. |

|---|---|

| Blade Material | Steel |

| Handle Type | Ergonomic |

| Protective Cover | Yes (vinyl cap) |

| Length | 5 inches |

| Weight | 0.32 ounces |

| Primary Use | Seam ripping and removal |

| Additional Features |

|

- Ergonomic handle reduces wrist and hand strain during extended use

- Sharp, durable steel blade cuts through stitches cleanly without snagging fabric

- Includes a safety cap to protect the blade and prevent accidents

- Higher price point compared to standard seam rippers

- Shipping can take up to 45 days in some cases

- Some users report the cap design could be better

3. Dritz Small Blade Seam Ripper

When precision matters more than power, the Dritz Small Blade Seam Ripper earns its place in your sewing tools. Its slender steel blade slices through stitches with surgical accuracy, especially in tight seams and buttonholes where bulkier rippers fumble.

The protective safety ball ensures fabric protection during seam removal, while the ergonomic handle gives you steady control. You’ll appreciate the blade maintenance—heat-treated hardened steel stays sharp through repeated use, and the clear cap prevents accidental nicks. This compact design delivers serious stitch precision without the hand fatigue of larger tools.

| Best For | Sewers and crafters who need precise control for removing tight stitches, buttonholes, and delicate embroidery work without damaging fabric. |

|---|---|

| Blade Material | Steel |

| Handle Type | Ergonomic |

| Protective Cover | Yes |

| Length | Not specified |

| Weight | 1.6 ounces |

| Primary Use | Stitch removal |

| Additional Features |

|

- Sharp, heat-treated steel blade cuts through small stitches cleanly and maintains its edge through regular use

- Protective safety ball prevents accidental fabric tears while working on delicate seams

- Ergonomic, lightweight design reduces hand fatigue during detailed stitch removal tasks

- Small size may be awkward for people with larger hands or those who prefer a fuller grip

- Not built for heavy-duty materials like thick upholstery or multiple layers of denim

- Blade will eventually dull with frequent use and the product doesn’t mention replacement options

4. Clover Seam Ripper Tool

You won’t find a more comfortable sewing tool than the Clover Seam Ripper with its brown, ergonomic design. The non-slip handle keeps your grip steady during long stitch removal sessions, while the sharp point handles seams, threads, and buttonholes with confidence.

At just 0.176 ounces, it won’t strain your hand. The blade sharpness cuts through regular stitches and even leather without damaging fabric—fabric protection meets powerful performance. One heads-up: the cap doesn’t lock securely, so practice proper tool maintenance by storing it safely between uses.

| Best For | Sewers who need a reliable, comfortable tool for removing stitches, cutting threads, and opening buttonholes in everyday sewing projects. |

|---|---|

| Blade Material | Steel |

| Handle Type | Brown standard |

| Protective Cover | Yes (small cap) |

| Length | Not specified |

| Weight | 0.176 ounces |

| Primary Use | Seam ripping and buttonholes |

| Additional Features |

|

- Ergonomic brown handle with non-slip grip makes it comfortable to hold during extended use

- Sharp point easily cuts through regular stitches, threads, and even tougher materials like leather without damaging fabric

- Lightweight at 0.176 ounces, so it won’t tire out your hand during long projects

- Cap doesn’t lock securely onto the handle, making it easy to lose

- Not precise enough for very small stitch lengths like those used in paper piecing projects

- Sharp point requires careful handling and safe storage to prevent accidents

5. Dritz Curved Seam Ripper Tool

The Dritz Curved Blade Seam Ripper breaks away from standard straight blade designs with its pioneering curved blade design that glides beneath stubborn stitches. You’ll appreciate the grips featuring a soft blue grip and thumb hold—these safety features prevent slips while protecting delicate fabric during thread removal.

The extra-sharp curved blade confronts serged seams and buttonholes without hesitation, though blade maintenance matters since frequent use dulls any sewing tools. At $9.99, this weaving essential includes a protective cover, but store it safely between seam corrections to maintain peak performance.

| Best For | Sewers and crafters who frequently need to remove stitches, seams, or buttonholes and want a comfortable tool that’s easier to control than traditional straight rippers. |

|---|---|

| Blade Material | Steel |

| Handle Type | Soft grip with thumb hold |

| Protective Cover | Yes |

| Length | Not specified |

| Weight | Not specified |

| Primary Use | Seam and stitch removal |

| Additional Features |

|

- Curved blade design slides under stitches more easily than straight rippers, making seam removal faster and less likely to damage fabric

- Soft blue grip with thumb hold gives you solid control and reduces hand fatigue during detailed work

- Sharp blade cuts through serged seams and tight stitches without much effort, and the protective cover keeps it safe when stored

- The blade will eventually dull with heavy use and may need replacing or sharpening

- Might struggle with very thick or heavy-duty fabrics where more leverage is needed

- The handle size might feel awkward if you have particularly small hands

6. Singer Seam Ripper and Tape Measure

Singer’s dual-purpose combo delivers sewing kit essentials at a fraction of specialist tool costs—you’ll score a four-inch seam ripper alongside a 60-inch vinyl tape measure displaying both inches and centimeters.

The black-handled ripper features that signature protective ball for fabric protection tips during stitch removal, though you’ll need extra caution since it lacks a storage cap for seam ripper safety. The flexible tape measure wraps around curved surfaces for tape measure accuracy, making this budget-friendly pair perfect for building your starter collection of sewing tools.

| Best For | Beginner sewers and budget-conscious crafters who need basic measuring and seam-removal tools without spending on premium options. |

|---|---|

| Blade Material | Steel |

| Handle Type | Plastic |

| Protective Cover | No |

| Length | 4 inches |

| Weight | Not specified |

| Primary Use | Seam opening |

| Additional Features |

|

- Dual measurement display (inches and centimeters) on a flexible 60-inch tape that wraps around curved surfaces and flat fabrics

- Protective ball tip on the seam ripper helps prevent accidental fabric damage during stitch removal

- Affordable two-tool combo provides essential sewing kit basics at a fraction of buying specialist tools separately

- No protective cap on the seam ripper creates potential safety hazards during storage

- Metal tip on the tape measure is canted rather than straight, which may affect measurement precision

- Quality inconsistencies reported by some users, with materials feeling less durable than expected

7. Clover Straight Tailors Awl Tool

Clover’s straight tailors awl tool might catch you off guard in this lineup—it’s not technically a seam ripper, but it’s one of those crafting aids that earns permanent real estate in your sewing tools kit.

This white-handled tailor tool weighs just 0.32 ounces and excels at fabric piercing for buttonholes and delicate embroidery prep work.

You’ll reach for this awl when pulling perfect corners or guiding tricky seams through your presser foot. The steel tip makes quick work of those tiny holes your sewing techniques demand, though you’ll want to mind that sharp point.

| Best For | Sewers and quilters who need precision help with pulling corners, piercing buttonholes, and guiding fabric through tight spots during detailed work. |

|---|---|

| Blade Material | Steel |

| Handle Type | Plastic |

| Protective Cover | Yes (case) |

| Length | 7.5 inches |

| Weight | 0.32 ounces |

| Primary Use | Piercing holes and guiding fabric |

| Additional Features |

|

- Incredibly lightweight at just 0.32 ounces, so it won’t tire your hand during long projects

- Comes with a protective case to keep that sharp point safe when stored

- Versatile enough for sewing, embroidery, quilting, and even needle lace work

- Sharp point requires careful handling to avoid accidents

- Struggles with thick or heavy-duty fabrics

- Pretty basic tool without any extra accessories or features included

Frequently Asked Questions (FAQs)

Can I reuse stitches after ripping seams?

Don’t reuse thread after ripping seams—it’s kinked and weakened, and unreliable.

Those stitches have been stressed, abraded, and bent.

Fresh thread ensures your seam holds strong without risking fabric damage or sewing quality issues.

How often should I replace my seam ripper?

Replace your seam ripper when the blade dulls and struggles to cut threads cleanly.

Light hobby use lasts one to two years; frequent sewing demands replacement every three to six months for ideal tool maintenance and blade sharpness.

What causes seam ripper blades to dull quickly?

Watch your sharp blade slice through stubborn poly thread on dense denim—that friction creates edge wear fast.

Your cutting technique, fabric density, and maintenance habits determine how quickly sewing tools dull during seam finishing.

Should I rip from right or wrong side?

Start on the wrong side for most seams—stitches show clearer, and any nicks hide in the seam allowance.

Switch to the right side for topstitching or when thread pulls easier.

When is fabric too damaged to resew?

If your fabric has holes bigger than a third of the seam allowance, severe fraying, or threadbare areas, it’s beyond repair limits.

Fabric damage thresholds mean replacement beats resewing every time.

Conclusion

Imagine this scenario: you’re halfway through a dress when you notice the side seam curves the wrong direction. You could keep going and hope no one notices. Or you could grab your seam ripper, fix it in five minutes, and finish with confidence.

That choice defines your growth as a sewist. Mastering when to use a seam ripper in sewing means you’re no longer afraid of mistakes—you’re equipped to handle them like the capable maker you’ve become.

- https://fabric-fabric.com/blog/fabric-nap-sewing-textile-importance

- https://lindehobby.com/what-is-a-nap-in-sewing-unraveling-texture-tips-for-seamless-creations-2106/

- https://www.thebusinessofapparel.com/post/why-stripes-in-apparel-look-crooked-and-how-to-make-them-perfectly-straight

- https://madamsew.com/blogs/sewing-blog/use-your-seam-ripper-like-a-pro

- https://makersnook.com/what-is-a-basting-stitch/