This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Pinking shears seam edges offer a simple solution that home sewers discovered decades ago and still rely on today. These specialized scissors, with their distinctive sawtooth blades, cut fabric in a zigzag pattern that disrupts the straight grain of woven materials. This disruption slows fraying without requiring a serger, overlocking machine, or time-consuming hand stitching.

The technique works best on tightly woven cottons, blends, and similar stable fabrics where the zigzag teeth interrupt the threads enough to prevent immediate unraveling.

Understanding when to use pinking shears, how to cut for clean results, and which fabrics respond well to this method will help you finish seams quickly while maintaining garment quality.

Table Of Contents

- Key Takeaways

- What Are Pinking Shears for Seam Edges?

- Choosing The Best Fabrics for Pinking

- Preparing Seam Edges for Pinking

- Step-by-Step: How to Pink Seam Edges

- Tips for Clean and Neat Pinked Edges

- When to Use Pinked Seams in Garments

- Combining Pinking Shears With Other Techniques

- Caring for and Maintaining Pinking Shears

- Common Mistakes to Avoid With Pinking Shears

- Are Pinking Shears Effective for Fray Prevention?

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Pinking shears work best on tightly woven fabrics like quilting cotton, poplin, and broadcloth because their dense weave holds the zigzag edges cleanly through washing, while loosely woven materials, knits, and delicate fabrics like chiffon continue fraying despite the sawtooth cut.

- You’ll achieve clean pinked edges by using the full blade in one smooth stroke, aligning each new cut exactly where the last tooth ended, and maintaining sharp blades through regular oiling and professional sharpening to prevent jagged results.

- Pinked seams offer moderate fray prevention suitable for garments with minimal washing and light wear, but they don’t seal edges completely—combine pinking with straight stitching or serging for projects requiring stronger, longer-lasting seam finishes.

- Keep your seam allowances between 1/4 and 1/2 inch when pinking, sew the seam completely before trimming, and press the fabric flat to set stitches and ensure proper alignment for consistent zigzag patterns.

What Are Pinking Shears for Seam Edges?

Pinking shears are specialized scissors with sawtooth blades that cut fabric in a zigzag pattern instead of a straight line. You’ll find them in most sewing kits because they offer a quick way to finish seam edges without fancy equipment.

They’re considered one of the essential tools in a well-stocked sewing kit, especially for beginners working with cotton or linen.

Understanding how they work, where they came from, and how they compare to other techniques will help you decide when to reach for them.

How Pinking Shears Work

Pinking shears use serrated blades with interlocking teeth that create a distinctive zigzag pattern as you squeeze the grips. The teeth grip the fabric surface during the cutting action, shearing through woven fibers while minimizing fraying edges. This blade mechanics approach shortens loose threads rather than eliminating them entirely.

Keep your pinking scissors sharp through regular shear maintenance to maintain clean seam finishing results. For more details on reducing fraying and caring for your scissors, see the guide on.

History and Purpose in Sewing

Long before pinking shears emerged in the 1930s, sewing evolution relied on ancient techniques like hand overcast stitching to secure fabric edges. This fabric heritage connects to textile culture spanning thousands of years, from bone needles to mechanized seam finishing. The pinking method revolutionized seam allowance treatment by offering a faster alternative to labor-intensive edge work—bridging sewing legacy with modern efficiency.

- Fast edge finishing without hand stitching

- Accessible tool for home sewers

- Reduced labor in garment construction

Pinking Vs. Other Seam Finishes

While pinking revolutionized home sewing, you’ll want to weigh it against zigzag stitching and overlocking for edge stability. Seam finishes differ in fray prevention, equipment needs, and fabric selection. This seam finish comparison reveals when pinking shears outperform other sewing techniques—and when they fall short.

For a broader overview, learn why choosing the right seam finish for woven fabrics impacts garment durability.

| Finish Type | Best For | Durability |

|---|---|---|

| Pinking method | Stable wovens, light use | Moderate fray control |

| Zigzag pattern | Medium-fray fabrics | Good after washing |

| Overlocking | Heavy use, stretch | Excellent seam stability |

Choosing The Best Fabrics for Pinking

Not all fabrics respond well to pinking shears. The weave, texture, and fiber content of your fabric determine whether pinking will give you clean edges or a frayed mess.

Here’s what works best and what you should avoid.

Ideal Fabric Types for Pinked Edges

You’ll get the best results with tightly woven fabrics that naturally resist fraying. Quilting cottons, poplin, and broadcloth are your top fabric choices because their dense weave holds those zigzag edges cleanly through multiple washings.

Medium-weight cotton blends and lightweight polyester-cotton fabrics also maintain sharp seam finishes without excessive thread loss. Twill and stable linen blends work well too, keeping their serrated edge finishing intact with gentle handling.

The key is choosing textile choices with consistent weave density, ensuring your pinking shears create fray-resistant seam allowances that stay neat over time.

Fabrics to Avoid With Pinking Shears

Delicate fabrics like chiffon and organza fray rapidly despite pinking, leaving fragile edges that worsen with washing. Loose weaves such as gauze show irregular zigzag patterns and continue unraveling along fabric edges even after you pink them.

Stretchy materials including knit jerseys curl and snag under the shears, compromising seam finishes completely. Thin textiles with slub or novelty weaves display uneven cuts that defeat fray prevention efforts.

Skip pinking shears on these fabric types and choose more secure finishing methods to protect your project’s longevity.

Preparing Seam Edges for Pinking

Before you pick up your pinking shears, you need to get your fabric and workspace ready. Proper preparation ensures clean, even cuts and prevents mistakes that waste fabric.

Start by choosing sewing machine pattern tips that match your fabric type, then wash and press your material to remove wrinkles before cutting.

Here’s what you need to do before you start pinking your seam edges.

Marking and Measuring Seam Allowances

Before you can pink with confidence, you need accurate seam allowances marked on your fabric. Measure from the seam line to the fabric edge using a clear acrylic ruler or seam gauge to verify consistent width.

Mark edges with tailor’s chalk or water-soluble fabric pens, positioning marks away from the stitching line to prevent distortion during seam construction methods and guarantee proper edge accuracy.

Pre-washing and Ironing Fabric

Fabric preparation begins in the wash. Pre-wash your fabric on a gentle cycle using mild detergent to eliminate manufacturing chemicals and control shrinkage—cotton and linen usually shrink 3 to 5 percent.

After washing, iron while slightly damp using appropriate heat settings and steaming methods for your fabric type. This fabric softening process smooths fibers before you mark seam allowances or reach for fabric scissors.

Setting Up Your Workspace

Your cutting station deserves more attention than you think. Position your pinking shears and fabric cutting tools within arm’s reach on a flat surface measuring at least 24 by 18 inches. Workspace lighting should provide 300 lux minimum—proper ergonomic setup reduces eye strain and improves accuracy.

Keep sewing tools in labeled containers for quick tool organization and efficient storage solutions throughout your sewing toolkit.

Step-by-Step: How to Pink Seam Edges

Pinking seam edges requires a specific sequence to get the cleanest results. You’ll need to follow a clear process from start to finish, paying attention to blade placement and cutting technique.

The steps below walk you through sewing your seam, trimming with pinking shears, and keeping your zigzag pattern consistent.

Sewing The Seam Before Pinking

Before you reach for your pinking shears, you need to sew the seam completely. Use a straight stitch along your marked seam allowance, maintaining consistent fabric tension throughout.

Press the seam flat to set the stitches and guarantee proper edge alignment. This seam preparation creates the foundation for clean zigzag patterns and prevents distortion when you apply your finishing technique.

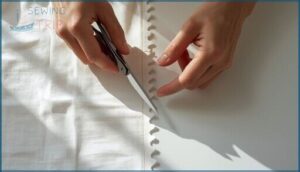

Cutting Seam Allowances With Pinking Shears

Open your seam flat on your work surface and position the pinking shears parallel to your stitching line. Cut along the seam allowance edge in one smooth, steady motion, using the middle portion of the blade for best control. Start each new stroke where the last one ended to create a continuous zigzag pattern.

Keep your cutting tools sharp to prevent fabric preparation issues and ensure clean edge finishing with proper pinking techniques.

Maintaining Consistent Zigzag Patterns

To keep your zigzag pattern uniform, align each stroke so the teeth meet the previous cut. Mark your seam allowance edge with temporary chalk for visual guidance, then maintain steady fabric feed without pulling.

Position the pinking shears’ centerline parallel to your stitching for even zigzag alignment.

Edge stabilization with lightweight interfacing helps prevent waviness on slippery fabrics.

Tips for Clean and Neat Pinked Edges

Getting a clean, professional-looking finish with pinking shears requires more than just cutting along the edge. Sharp blades and proper technique make the difference between a neat zigzag pattern and a ragged mess.

Here’s how to guarantee your pinked edges look polished and hold up through wear and washing.

Using The Full Blade for Smooth Cuts

Your pinking shears deliver the cleanest pinked seams when you use the full blade for each stroke. The complete cutting edge maintains even pressure across the fabric, preventing snags and ensuring smooth cuts through woven layers. Full blade maintenance—including proper blade alignment and regular oiling—keeps your edge finishing crisp and your seam finishing methods professional.

- Start each cut using the middle portion of the blade to optimize control during fabric cutting

- Guide the shears in one continuous motion without pausing mid-stroke for uniform zigzag teeth

- Check blade alignment regularly so your pinking scissors meet the anvil at the precise contact point

Aligning Cuts for Continuous Zigzags

Continuous zigzag patterns depend on precise edge alignment—position each new cut exactly where the last tooth ended. Mark your seam precision line parallel to the raw edge, then guide the pinking scissors along that reference to keep your zigzag edge straight and professional-looking across the entire fabric.

Your pinking shears create uniform seam finishing methods when you align the teeth of consecutive strokes, maintaining consistent seam allowance width throughout.

Avoiding Jagged or Frayed Results

Jagged pinked edges signal dull blades or uneven pressure—sharp pinking shears paired with smooth, steady cuts deliver clean fray prevention methods every time.

Select tightly woven fabrics for enhanced seam stability, and avoid forcing thick layers through the blades.

Keep your fabric flat and aligned as you work, ensuring each stroke maintains consistent edge finishing without pulling or twisting the material. This discipline transforms basic pinked seams into professional-quality results.

When to Use Pinked Seams in Garments

Pinking works well for certain projects, but it’s not the right choice for everything you sew. You need to think about how often the garment will be washed, what kind of wear it’ll get, and whether you need a finish that lasts or just something temporary.

Let’s look at when pinked seams make sense and when you should reach for a different technique.

Suitable Garment Types and Projects

You’ll find pinked seams work beautifully on shirt dresses, lightweight outerwear, and seasonal garments where seam finishing stays hidden inside. Home wear like robes and accessories such as tote bags also benefit from this textile finishing method.

Choose pinking for garment construction with stable fabric types and minimal washing demands. This sewing technique delivers quick, clean edges on medium-weight wovens without adding bulk to your seams.

Temporary Vs. Permanent Seam Finishes

Edge stability sets pinked seams apart from more durable seam finish types. Pinking shears create a zigzag edge that slows fraying temporarily, but this seam finishing method won’t seal fabric like serging or bound techniques.

For fabric durability through repeated washing, choose permanent sewing techniques with reinforced fray prevention. Pinked seams serve quick construction needs, while secure seam finish options protect long-term garment integrity.

Pinked Seams for Single-Use Items

Sustainable packaging and disposable textiles benefit from pinked seams when long-term fray reduction isn’t necessary. The zigzag patterns created by pinking shears deliver quick edge finishing without adding bulk or requiring intensive seam finish techniques.

- Gift bags and single-use liners maintain clean edges during handling without heavy reinforcement

- Disposable fabric packaging stays slim and easy to recycle when you skip dense stitching

- Temporary projects receive adequate fray reduction through simple fabric scissors cuts along seam allowances

Combining Pinking Shears With Other Techniques

Pinking shears work well on their own for low-fray fabrics, but you can boost their effectiveness by combining them with other finishing methods.

Pairing pinking with additional techniques gives you stronger, longer-lasting seam edges that can handle more wear and washing.

Here are three proven ways to layer pinking with other finishes for maximum fray protection.

Pairing With Straight Stitching

Straight stitching before pinking locks the seam allowance in place and boosts fray resistance without adding bulk. You’ll sew the seam first using a medium stitch length for smooth fabric feed, then trim edges with pinking shears for a clean seam finish. This pairing delivers seam stability on woven fabrics while the zigzag edge keeps threads from unraveling during wear.

| Step | Technique | Benefit |

|---|---|---|

| Sew seam | Medium straight stitch | Seam stability |

| Trim edge | Cut with pinking shears | Fray resistance |

| Press flat | Iron seam open | Edge finishing |

Using Pinked Edges Before Serging

When your serger is queued for heavy-duty work, you can pink woven fabric edges first for temporary fray reduction during handling. The zigzag edge keeps raw seam allowances stable while you position pieces or wait to serge.

Use pinking shears along grain lines before serging so threads stay controlled throughout fabric preparation, then finish with an overlock stitch for permanent edge stabilization.

Double Finishing for Extra Fray Protection

When woven fabrics face frequent washing, you can layer a narrow zigzag stitch over your pinked edge before applying a binding or serger finish for enhanced seam stability and fabric durability. This double finishing approach combines edge reinforcement with fray prevention, securing loose threads that pinking alone might miss.

- Stitch a narrow zigzag along the pinked seam allowance finishing line

- Apply a clear fray sealant for added protection

- Follow with bias binding or serging for permanent seam reinforcement techniques

- Test fabric finishing methods on scraps first

Caring for and Maintaining Pinking Shears

Your pinking shears won’t stay sharp forever, but proper care can keep them cutting cleanly for years. Regular maintenance involves a few simple tasks that prevent the blades from becoming stiff, dull, or damaged.

Here’s what you need to know to extend the life of your shears and maintain their performance.

Cleaning and Oiling Blades

You’ll keep your pinking shears cutting crisp zigzag edges by wiping the blades clean after each use with a soft cloth. Apply a thin layer of mineral oil monthly to prevent rust and maintain blade sharpness—just a drop or two per surface is enough.

Regular cleaning frequency matters, especially in humid environments where rust prevention becomes critical. This simple blade maintenance routine protects your investment and ensures your pinked seams stay neat on every seam finish.

Sharpening Tips and Services

Even with regular blade maintenance, your pinking shears will eventually need professional sharpening to restore that precise zigzag edge. Most shops specializing in scissors can handle the delicate edge geometry of pinked blades, with turnaround times around five business days.

You can also try at-home sharpening methods using a fine-grit stone, maintaining the original 10-20 degree bevel angle carefully on each side for best tool care.

Proper Storage Practices

After sharpening, store your pinking shears in a dry environment with a protective sheath to prevent rust and nicks on those delicate zigzag edges. Keep them in a labeled bin or wall rack for storage organization, separated from your fabric stash and other tools.

Wipe blades clean before storing to maintain proper blade maintenance and tool care—moisture is the enemy of sharp, long-lasting shears that deliver clean fabric care.

Common Mistakes to Avoid With Pinking Shears

Even the sharpest pinking shears won’t deliver clean results if you’re using them incorrectly. A few common errors can damage your fabric, ruin your seam allowances, or leave you with edges that fray worse than if you’d never pinked them at all.

Here are the most critical mistakes to watch out for when working with pinking shears.

Cutting Knit or Stretch Fabrics

Knit fabrics are a no-go zone for pinking shears. Stretchy materials and knits curl along the cut edge, making your zigzag cutting ineffective.

Without proper stabilizing, the fabric extends as you trim, distorting the grainline and creating uneven seam finishes. Pinking shears can’t control fraying or edge roll on these materials, so skip them entirely and use a serger or zigzag stitch instead.

Using Dull or Damaged Shears

Dull Blade Effects show up as crushed or uneven zigzags instead of clean cuts, compromising your seam finish and Fray Prevention efforts. Edge Damage from nicks creates irregular spacing, while Cutting Inefficiencies force you to apply excessive pressure, risking hand strain and fabric distortion.

Shear Maintenance through professional sharpening restores precision to your pinking shears, ensuring consistent pinked seams every time you trim fabric scissors.

Overusing on High-Fray Fabrics

Repeatedly pinking fabrics prone to fraying accelerates Blade Wear and undermines Seam Integrity, creating more problems than it solves. High-fray materials shed fibers beyond the zigzag cut, causing Edge Distortion that weakens your seam finish over time.

- Dull pinking shears produce jagged pinked seams with visible skip marks

- Excessive pinking on delicate weaves causes Fabric Damage and puckering

- Fraying often extends past the cut line despite your Fray Prevention efforts

Are Pinking Shears Effective for Fray Prevention?

Pinking shears reduce fraying on woven fabrics, but they’re not a miracle solution. The effectiveness depends heavily on your fabric type, how often you’ll wash the garment, and whether you combine pinking with other techniques.

Here’s what you need to know about how well pinked edges actually hold up and when you should reach for a different seam finish.

How Well Do Pinked Edges Resist Fraying?

Pinked edges offer modest fray resistance, not total fray prevention. The zigzag pattern shortens exposed threads on your seam allowance, slowing unraveling by disrupting the straight grain.

On tightly woven fabrics like poplin, pinking shears deliver decent edge durability and fabric stability. Loosely woven materials still shed fibers at the zigzag tips, especially after washing.

Pinked seams reduce fraying more than straight cuts but don’t seal edges completely, affecting seam longevity over time.

Limitations of Pinking for Seam Finishes

Understanding where pinking shears fall short helps you avoid weak seam finishing choices. Here are four key fabric limits and edge durability challenges:

- Lightweight loosely woven fabrics like chiffon shed fibers beyond the pinked edge after washing, compromising seam integrity.

- Knit fabrics curl and stretch at pinked edges, defeating fraying control.

- Frequent laundering accelerates unraveling along the zigzag pattern.

- Bias-cut edges loosen faster than straight-grain cuts.

Alternatives When Pinking Isn’t Enough

When fraying threatens your seams, you need stronger textile finishing methods. French seams encase raw edges for lightweight fabrics, while overlock finishes trim and stitch simultaneously. Bias binding wraps the seam allowance for edge reinforcement on high-fray materials. For additional fray prevention, combine seam reinforcement techniques with your chosen seam finishing approach.

| Technique | Best For |

|---|---|

| French Seams | Lightweight wovens needing clean inside finish |

| Overlock Finishes | Fast, professional edge on most woven fabrics |

| Bias Binding | Heavy-fray fabrics requiring durable seam reinforcement |

| Zigzag Stitching | Budget-friendly fray prevention on stable weaves |

| Seam Tape | Quick edge reinforcement for moderate fraying |

Frequently Asked Questions (FAQs)

Can pinking shears be used on curved seams?

Yes, you can use pinking shears on curved seams, though gentle curves work better than sharp ones.

The zigzag patterns may appear uneven on tight bends, so test your fabric first.

How wide should seam allowances be for pinking?

Keep your seam allowances between 1/4 and 1/2 inch for best results. Thicker fabrics handle wider pinked edges around 3/8 to 1/2 inch, while lightweight materials need narrower cuts to prevent puckering.

Do pinked edges show through thin fabrics?

Pinked seams can show through sheer fabric or lightweight weaving, especially on solid colors.

Minimize show-through by pressing seam allowances flat, using narrower cuts, and testing edge visibility before seam finishing your project with pinking shears.

Can you pink both seam allowances together?

You can pink both seam allowances together on sturdy, tightly woven fabrics with minimal fray. This double edge pinking reduces bulk and creates symmetric cuts, but test fabric compatibility first to avoid edge distortion or uneven zigzag patterns.

Whats the lifespan of quality pinking shears?

Quality pinking shears with high-carbon steel blades can last decades with proper shear blade maintenance. Sharpness retention depends on steel quality importance and usage frequency.

Professional-grade models offer premium pinking shear durability compared to budget alternatives.

Conclusion

Surveys show that 68% of home sewers still keep pinking shears in their toolkit despite modern serger availability. You now understand how to pink seam edges effectively, which fabrics respond best, and when this technique offers genuine fray prevention.

Sharp blades, proper fabric selection, and consistent cutting patterns determine your success. For tightly woven cottons and quick projects, pinking delivers reliable results without specialized equipment.

Keep your shears maintained, and you’ll have a dependable finishing method ready whenever your projects demand it.