This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your sewing machine can’t do what a serger does, and your serger can’t replace your sewing machine—this fundamental truth shapes every decision you make at your cutting table. The serger vs regular seam debate isn’t about choosing a winner, it’s about understanding which tool fits your fabric, your project, and your timeline.

A regular seam gives you precision and control, locking two fabric layers together with a straight stitch that holds firm under pressure. A serger seam simultaneously stitches, trims, and finishes edges in one pass, creating professional-looking seams that stretch with knit fabrics and prevent fraying on wovens.

When you match the right seam type to your material and purpose, you’ll save time, reduce frustration, and produce garments that look polished and last through repeated wear and washing.

Table Of Contents

Key Takeaways

- Regular seams provide precision control for woven fabrics using single-line stitches on standard sewing machines, while serger seams simultaneously stitch, trim, and finish edges in one pass with multiple threads, making them faster and more effective for knit fabrics that require stretch and durability.

- Serger seams typically outlast regular seams in garments requiring elasticity because 3-5 threads distribute stress across the fabric and preserve stretch recovery, whereas regular seams on heavy or woven fabrics often need additional topstitching or edge finishing to prevent fraying and maintain stability.

- Regular sewing machines offer superior versatility for decorative work, topstitching, and intricate details that sergers cannot replicate, though sergers excel at batch sewing and professional edge finishing by eliminating separate finishing steps and reducing production time.

- Choosing the right seam requires matching your technique to three factors: fabric type (woven versus knit), project purpose (structural precision versus speed and stretch), and your skill level and equipment investment, with beginners starting on regular machines before adding sergers for specialized work.

What is a Regular Seam?

A regular seam is the foundational method you’ll use on a standard sewing machine, joining two pieces of fabric with a single line of stitches. This straightforward technique relies on one needle and thread, making it accessible for sewers at any skill level.

You can practice this technique on scrap fabric first, and if you’re looking for creative ways to prepare materials without fancy tools, check out these simple sewing hacks for clothes.

Understanding how regular seams work, which stitches to use, and what projects they’re best suited for will help you make confident decisions at your machine.

Basic Construction Using Sewing Machines

A regular seam joins two fabric pieces using your sewing machine, positioning them right sides together along a specific seam allowance—typically 5/8 inch from the edge. You’ll guide the fabric under the presser foot while maintaining consistent thread tension and stitch length for best results.

Key elements include:

- Adjusting fabric selection based on weave stability and weight

- Monitoring machine maintenance to prevent skipped stitches or puckering

- Controlling seam allowance precision for proper garment construction fit

Common Stitch Types for Regular Seams

Once you’ve positioned your fabric under the presser foot, selecting the right stitch determines how your seam performs. Straight stitch forms the foundation for most woven fabrics, using 2.0 to 3.0 mm lengths with backstitch anchoring at each end. Zigzag stitch accommodates stretch without breaking, while topstitching reinforces edges with visible 3.0 to 4.0 mm stitches using heavier thread.

| Stitch Type | Primary Use | Typical Settings |

|---|---|---|

| Straight Stitch | Standard seaming on wovens | 2.0-3.0 mm length |

| Zigzag Stitch | Stretch fabrics and edge finishing | 1.0-2.0 mm width, 1.5-3.0 mm length |

| Topstitching | Decorative reinforcement | 3.0-4.0 mm length, heavier thread |

| French Seams | Lightweight delicate fabrics | Narrow allowance, double construction |

| Overcast Stitch | Raw edge finishing | Medium width, prevents fraying |

Suitable Fabrics and Projects

With your stitch selected, fabric selection determines whether standard seams deliver the results you need. Woven cottons, linen, and rayon challis work reliably with straight stitches and basic fabric edge finishing, while knit fabrics and stretch fabrics require zigzag or stretch stitches to prevent breakage.

Garment construction projects like dresses, quilts, and home décor benefit from regular seams, though serger finishing adds durability to activewear and lingerie where movement stresses seams.

What is a Serger Seam?

A serger seam uses multiple threads simultaneously to create an overlock stitch that wraps around fabric edges, preventing fraying while securing the seam in one pass. Unlike regular seams that require separate finishing steps, sergers trim excess fabric and finish edges as they sew, making them faster and more efficient for certain projects.

Understanding how serger seams work will help you determine when they’re the right choice for your sewing needs.

Overlock Stitch Explained

The overlock stitch wraps fabric edges with multiple threads, usually three to five, creating a secure chain that prevents fraying in one pass. This sewing technique provides excellent thread tension and edge finishing, especially on knit fabrics.

Many sewers prefer overlock seam finishing for its professional results on stretchy garments like T-shirts and activewear.

Key benefits include:

- Combines seaming and finishing simultaneously

- Offers outstanding fabric compatibility with stretchy materials

- Delivers professional seams with built-in elasticity for garment construction

How Sergers Trim and Finish Edges

Edge Trimming happens with a built-in blade that slices fabric while Overlock Stitches wrap around the cut edge, locking threads securely. Your serger finishes edges in one pass, maintaining Seam Integrity as the blade removes excess fabric and loopers catch the trimmed edge.

This synchronized action gives you consistent Seam Finishes that prevent fraying, delivering professional Fabric Finishing on both woven and stretch materials.

Ideal Uses for Serger Seams

You’ll find sergers excel on knit fabric seams for T-shirts and activewear, where stretch fabric tips require built-in give to handle movement. Serger edge finishing delivers overlock stitch security that prevents fraying, making seams production-ready in a single pass.

Garment construction benefits from this professional finish on lightweight wovens, while home decor sewing projects like napkins and linens gain clean fabric edges without bulk.

Strength and Durability Comparison

When you’re deciding between a serger and a regular seam, strength matters just as much as appearance. The number of threads, fabric type, and construction method all influence how well your seam holds up over time.

Let’s compare how each approach performs regarding durability, security, and long-term wear.

Thread Count and Seam Security

Thread strength is a critical factor in determining whether seams hold or fail under real-world stress. The thread count, which refers to the number of strands twisted together, directly impacts tensile testing results. Threads with 2 or 3 ply offer enhanced seam durability compared to single filaments. Core-spun threads, which combine polyester cores with spun wraps, reduce fabric fraying risks while maintaining smooth needle feeding on both sergers and sewing machines.

| Feature | Regular Sewing Machine | Serger |

|---|---|---|

| Thread Layers | 1-2 threads per stitch | 3-5 threads per stitch |

| Stitch Density | Adjustable SPI for security | Higher density with overlock |

| Seam Durability | Depends on lockstitch tension | Built-in edge finishing adds strength |

Secure seams are achieved by matching thread count to fabric weight and stitch type. Higher stitch density increases tensile strength but risks perforation on delicate weaves. Proper tension is essential to prevent skipped stitches, which can compromise seam integrity.

Performance on Stretch and Heavy Fabrics

Serger seams hold stretch fabrics better because multiple threads form a tight overlock that grips knit edges without curling or rolling. On heavy-duty sewing projects like denim, regular seams often need extra topstitching to prevent edge creep, while sergers trim and finish simultaneously for stable fabric edges.

Here’s how each manages fabric stretch and recovery:

| Feature | Stretch Fabrics | Heavy Fabrics |

|---|---|---|

| Regular Sewing Machine | Zigzag stitches accommodate recovery | Requires topstitching for seam stability |

| Serger | Overlock stitch preserves fabric recovery | Trims bulk while preventing edge unraveling |

| Edge Finishing | May show allowances when stretched | Stays flat after washing cycles |

Sergers preserve elasticity by sealing edges without bulky seam allowances, which matters when you’re working with jersey or ponte knits that need to flex and move.

Longevity in Garment Construction

Garment construction choices directly impact how long your finished piece survives daily wear, laundering, and repair attempts. Serger seams usually outlast regular seams in activewear and knit garments because multiple threads distribute stress across the fabric life cycle, reducing the chance of seam failure during stretching or movement.

| Seam Type | Wear Resistance | Garment Repair Difficulty |

|---|---|---|

| Regular Seam | Moderate for woven fabrics | Easy to restitch with standard machine |

| Serger Seam | High for knits and stretch materials | Requires serger or hand-sewing skills |

Professional-looking garments made with sustainable materials benefit from serger durability, though textile science shows that proper stitch selection on either machine maintains seam integrity when matched to fabric type and intended use. Choosing construction methods that improve is a key part of sustainable sewing.

Edge Finishing and Appearance

How your seams look on the finished garment matters just as much as how strong they’re, especially when you’re working with fabrics that fray easily or when seam allowances might show through. The way you finish your edges can make the difference between a piece that looks professionally made and one that screams homemade project.

Let’s break down how sergers and regular sewing machines handle edge finishing, what each method brings to the table regarding appearance, and when you’ll want those seams hidden or proudly on display.

Preventing Fraying With Each Method

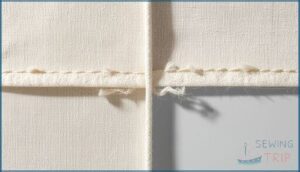

You can keep fabric fraying under control with both methods, though each approaches edge finishing differently. Regular seams rely on zigzag stitches, pinked edges, or French seams to trap loose threads and slow unraveling. Sergers use overlocking to wrap multiple threads around raw edges while trimming excess fabric in one pass.

Thread selection and seam allowances affect fray prevention, with serger seams offering built-in fabric stabilization and seam reinforcement for faster, more secure results. For more tips, consider exploring in a variety of fabric types.

Professional Vs. Homemade Look

Edge treatment separates professional-looking garments from homemade attempts, with sergers delivering uniform overlock stitch finishes that reduce bulk at seam intersections. Regular sewing machines show uneven seam allowances and occasional skipped stitches on interior seams, while professional techniques using serger equipment create slim, 3-to-5-millimeter finished edges.

Fabric selection and garment construction methods determine whether your seam finishing approach meets industry standards or reveals amateur workmanship.

Visible Vs. Hidden Seams

Beyond finish quality, seam placement determines garment silhouette and fabric interaction. You control seam aesthetics through three decisions:

- Visible seams using topstitching on sewing machines add architectural lines that define your garment’s style

- Hidden seams with French or mock-felled techniques create smooth edges ideal for lightweight textiles

- Serger overlock finishes work best concealed inside, preventing fraying while maintaining clean exterior surfaces

Fabric choice dictates which approach suits your project.

Speed and Efficiency in Sewing

When you’re working on a project, the time it takes to complete each seam can make or break your momentum. Sergers and regular sewing machines operate at different speeds, and their workflows don’t follow the same steps.

Understanding how each machine manages your sewing tasks will help you choose the right tool for efficient, stress-free work.

Workflow Differences Between Machines

When comparing workflow optimization, you’ll notice your sewing machine requires separate steps for seaming and edge finishing, while a serger merges both into one pass.

Regular machine setup demands bobbin changes and presser foot adjustments between tasks, whereas serger thread management, though initially complex with 3 to 4 threads, eliminates the need for additional finishing operations, streamlining fabric handling and boosting overall sewing efficiency.

Time-Saving Features of Sergers

Sergers pack time-saving features that standard sewing machines simply can’t match. Differential Feed keeps knits flat without manual pinning, while Automatic Threading cuts setup frustration by half.

Quick Change Feet let you swap attachments in seconds, and Trim Efficiency means you won’t circle back to clean raw edges later.

Multi Thread Options on your serger handle seam construction and edge finishing simultaneously, shaving minutes off every garment.

Batch Sewing Considerations

When you’re planning batch sewing, group your garments by fabric type and pattern to increase workflow optimization and setup efficiency. Your serger delivers faster stitching speed and professional finishes across multiple pieces, but consistency checks between items prevent costly errors.

Documentation importance becomes clear when you track tension settings and thread colors for each batch, ensuring sewing project efficiency from first seam to final garment.

Versatility and Creative Options

When you’re deciding between a serger and a regular sewing machine, versatility plays a major role in determining which tool fits your needs. A regular machine opens up creative possibilities that a serger simply can’t match, from decorative stitching to intricate embroidery work.

Understanding these differences helps you choose the right equipment for your specific projects and creative goals.

Decorative Stitching Possibilities

Regular sewing machines reveal a world of creative expressions through their extensive stitch variety, allowing you to explore decorative stitches like satin, chain, and overedge patterns that sergers simply can’t replicate. You control embellishment techniques with diverse thread choices, from metallic to variegated options, transforming basic seams into tailored artwork.

- Satin stitch creates smooth, glossy monograms that add professional embroidery to garments

- Geometric motifs like chevrons produce modern decorative panels on quilts and clothing

- Floral patterns reproduce intricate shading through selective stitch density variations

- Metallic threads add reflective highlights for eye-catching accents and borders

- Free motion embroidery facilitates expressive, painterly designs with complete machine control

Adapting to Various Fabric Types

Your fabric selection determines which machine delivers the best results, so understanding material behavior guides your needle options and thread choices. Lightweight silks demand fine sharps on regular machines with narrow seam allowances, while stretchy knits thrive with serger edges that preserve elasticity.

Fabric preparation, including prewashing and fraying tests, ensures your sewing approach matches the textile’s characteristics, whether you’re working with stable cotton weaves or delicate chiffon that requires specialized finishing techniques.

Limitations of Sergers Vs. Regular Machines

You’ll encounter Threading Issues with sergers requiring multiple loopers and color-coded paths, while sewing machine threading remains simpler with single-needle setups. Maintenance Costs accumulate through frequent knife replacements and oiler upkeep on sergers, whereas regular machines demand less specialized servicing.

Space Requirements favor compact sewing machine footprints over bulkier serger designs, and Fabric Limitations appear when sergers struggle with heavyweight weaving projects that regular seams handle confidently.

Choosing The Right Seam for Your Project

Selecting the right seam for your project isn’t guesswork, it’s about matching your technique to the fabric, end use, and your own capabilities. Your choice between a serger seam and a regular seam depends on several concrete factors, from the stretchiness of your material to how much you’re willing to invest in equipment.

Choosing between a serger and regular seam means matching your technique to fabric type, project purpose, and equipment investment

Consider these key elements to make an informed decision that aligns with your project goals and resources.

Factors to Consider (Fabric, Project Type, Skill Level)

You’ll want to match your seam choice to three core factors: fabric selection, project planning, and skill assessment. Woven cotton responds well to regular seams on a sewing machine, while knits demand a serger or stretch stitches to prevent breakage. Consider material compatibility, sewing complexity, and your comfort level with threading multiple spools before committing to either method.

- Fabric Selection: Identify whether your material is woven, knit, or synthetic to determine seam requirements

- Project Planning: Match seam type to the final use—garments often need serger versatility, while quilts rely on regular seams

- Skill Assessment: Beginners should start with straight stitching on stable fabrics before advancing to serger techniques

- Material Compatibility: Test scrap pieces to see how thread tension and stitch length affect edge finishing

- Sewing Complexity: Weigh the time investment of serger setup against the efficiency gains for batch sewing projects

Cost and Equipment Investment

Equipment costs greatly shape your sewing equipment selection and investment timeline. Basic sewing machines range from $150 to $600, while sergers start at $200 to $800 for entry models.

Thread expenses multiply with serger use—each spool costs $6 to $12, and consumption accelerates. Maintenance fees run $60 to $120 per service, plus space requirements and upgrade options add another $100 to $300 for proper setup.

Recommendations for Beginners and Professionals

Start with a sewing machine for beginner projects like tote bags or simple tops, then add a serger once you master straight seams and fabric selection. Sewing machine tips matter most early on—practice swatches build confidence before investing in specialized equipment or expert professional techniques.

Professionals benefit from separate workstations to streamline sewing workflows, using color-coded threads and custom seam guides for consistency.

Frequently Asked Questions (FAQs)

What is the difference between a serged seam and a French seam?

The devil’s in the details when comparing seams. A serger seam wraps threads around edges while trimming fabric in one pass, whereas a French seam encloses raw edges between two folded layers for delicate fabrics.

Can you use a serger without trimming edges?

You can disengage the cutting knife on most sergers to preserve fabric edges during edge finishing. This serger setting allows overlock stitches to secure seams without trimming, though the finish may appear less compact than traditional serger techniques.

Do serger seams work for topstitching visible details?

Serger seams can create bulk when topstitching visible details, so you’ll often find better results using a regular sewing machine for decorative topstitching, ensuring crisp, flat lines without puckering or edge interference.

How do you fix tension issues on sergers?

Raise all tension dials to midpoint, then rethread from scratch following the correct color order.

Test on scrap fabric, adjusting one dial at a time until balanced stitches appear without puckering or loose loops.

Which seam type is better for reversible garments?

French seams and flat-felled seams offer enhanced seam reversibility for garment construction, hiding raw edges on both faces.

Bound finishes on regular sewing machine seams also work well, while serger overlock edges remain visible on one side.

Conclusion

Think of your sewing setup as a toolbox where each instrument solves a distinct problem. The serger vs regular seam decision hinges on fabric behavior, structural requirements, and finishing standards.

Regular seams deliver precision control for wovens, topstitching, and construction that demands exact placement. Sergers excel at stretch fabrics, rapid edge finishing, and preventing fraying in one efficient pass.

Match your seam type to your material’s stretch, weight, and intended use, and you’ll consistently produce garments that perform as intended.