This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You know that sinking feeling when your sewing machine coughs up a bird’s nest of thread, or your “trusty” spool snaps for the third time in an hour? That’s your thread waving a white flag. Old sewing thread isn’t just annoying—it’s a saboteur, quietly undermining your stitches and eating away at your patience.

Even the prettiest spool can hide years of sun damage, humidity, and fiber breakdown, ready to ruin your next project. Spotting the signs you need to replace old sewing thread means you’ll spend less time cursing at tangles and more time making seams that last. Here’s how to tell when your thread’s past its prime.

Table Of Contents

- Key Takeaways

- Key Signs Your Sewing Thread Needs Replacing

- How Thread Deteriorates Over Time

- Thread Types and Their Typical Lifespan

- Simple Tests to Check Thread Quality

- How Improper Storage Damages Thread

- Common Problems Caused by Old Thread

- Best Products for Managing Old Sewing Thread

- Creative Ways to Repurpose Expired Thread

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Old thread doesn’t just sit there harmlessly—snapping mid-seam, fuzzy texture, color fading, and excessive lint in your machine are all signs that fiber breakdown has already sabotaged your spool.

- Polyester thread outlasts cotton and silk by decades (20–50 years vs. 5–10), so the material you choose determines how long you can trust your stash without a second thought.

- A quick tug test or forearm knot check takes under five minutes and tells you immediately whether a spool is still worth threading—no guesswork, no wasted projects.

- Expired thread doesn’t just ruin seams; it grinds against tension discs, clogs bobbin areas with lint, and causes long-term machine wear that costs far more than a fresh spool ever would.

Key Signs Your Sewing Thread Needs Replacing

Your thread might be sabotaging your projects without you even realizing it. Most sewers keep using the same spools for years, assuming thread doesn’t expire—but fiber breakdown is real, and it happens faster than you’d think.

Your thread is quietly sabotaging your projects — fiber breakdown is real, and it happens faster than you think

Here are six clear warning signs that it’s time to toss that spool and start fresh.

If your thread keeps snapping or bunching up, these common thread tension and breaking issues are usually the first red flags to watch for.

Frequent Thread Snapping During Sewing

Frequent thread snapping during sewing almost always signals thread degradation—those fibers have turned brittle from years of light, air, and temperature swings. If you’re seeing repeated breaks mid-seam, your thread strength is sabotaged.

Old cotton that snaps with a firm tug, especially at high sewing speed, can’t handle the needle damage and fabric friction modern machines dish out. Check thread tension and machine calibration, but if breaks keep coming, that spool’s done.

Factors such as proper thread storage conditions also play a vital role in preserving thread quality over time.

Fuzzy or Fraying Thread Texture

Beyond snapping, watch for that telltale fuzzy halo—it screams fiber breakdown and surface wear. When you spot visible thread fray along the strand, those outer fibers are shedding fast, sabotaging thread quality before you even start sewing.

Run a quick fuzz inspection by rolling the thread between your fingers; rough texture or fraying tests that reveal tiny loose hairs mean fiber degradation has won. That spool’s ready for retirement.

Remember, maintaining stable relative humidity and temperature is vital to preserve your thread’s quality and lifespan.

Noticeable Color Fading or Yellowing

Color shift is a dead giveaway your thread has hit its expiration date. When sunlight hits a spool, you’ll see fading effects on the exposed side—chalky, washed-out tones instead of the original shade.

Yellowing causes from heat, humidity, or plain old aging show up as creamy or beige casts, signaling thread degradation and reduced dye stability. UV resistance fails fast on cotton and rayon, leaving you with discoloration that screams “replace me.

Excessive Lint Buildup in Sewing Machine

If your sewing machine’s bobbin area looks like a lint factory, your thread is shedding fibers faster than you can sew. Old thread breaks down, depositing fuzz between feed dogs and under the hook mechanism—classic thread shedding that clogs tension discs and causes skipped stitches.

That dust accumulation kills sewing efficiency and signals thread quality failure. Clean the bobbin case after every 8–10 hours, but if lint returns immediately? Replace the spool.

Loss of Twist, Sheen, or Elasticity

Twist relaxation is sabotaging your stitches before you notice. When plies separate and gaps appear between strands, you’re watching fiber breakdown in real-time—that’s thread deterioration stealing your thread quality.

Old sewing thread loses its glossy finish, turning dull or chalky. Elasticity loss makes elastic thread sag instead of snap back. Surface roughness drags through guides, guaranteeing thread breakage. This fiber degradation has no expiration date—just visible warnings.

Visible Damage or Worn Appearance

Neglect is written all over Frayed Threads and Worn Spools—think fuzzy texture, obvious discoloration, or brittle breaks that snap with a sharp tug.

If you spot visible nicks, powdery ends, or cracks on the spool, you’re staring at classic signs of aging and fiber degradation. Don’t gamble with thread breakage; swap out anything showing these red flags before it sabotages your project.

How Thread Deteriorates Over Time

You might assume thread lasts forever if you keep it on the shelf, but that’s not how fiber science works. Everything from UV rays to moisture is quietly breaking down your thread’s structure—even when it looks fine sitting there.

Here’s what’s actually happening to your spools over time and why some materials fail faster than others.

Effects of Sunlight and Heat Exposure

UV damage is sabotaging your thread faster than you think. Ultraviolet light breaks down polymer chains, slashing strength by up to 50% within the first year of sun exposure.

Heat resistance varies by material—cotton dries brittle, while polyester tolerates more warmth before weakening. Combined UV exposure and heat accelerate fiber degradation dramatically, causing thread breakage, color fading, and thread deterioration that ruins seams before you notice.

Impact of Humidity and Moisture

Moisture damage is sneakier than sun exposure—humidity quietly destroys thread from the inside out. Cotton absorbs roughly 7% of its weight in moisture at 65% relative humidity, which permanently weakens fibers and causes thread breakage over time.

Watch for these humidity effects:

- Mold growth above 80% humidity leaves stains and fiber degradation

- Yellowing and dullness from prolonged damp storage

- Weakened tensile strength from repeated swelling cycles

Storage solutions with humidity control prevent textile deterioration.

Damage From Dust, Air, and Contaminants

Airborne contaminants sabotage thread faster than you’d think. Dust accumulation leaves a gray film that increases needle friction and chemical exposure from cleaners or aerosols dulls dye and dries protective finishes.

Oily kitchen vapors attract lint, creating sticky spots that upset tension. Heavy dust makes thread shed more fibers—causing fiber damage and thread breakage—so visibly contaminated spools should be tossed to protect thread quality.

Influence of Thread Material Type

Ever notice how cotton thread snaps like dry spaghetti, while polyester thread keeps humming along? Thread durability hinges on material science—fiber comparison is key.

Here’s what sabotages yarn quality:

- Cotton thread gets brittle and fades fast.

- Polyester thread resists UV and moisture, lasting decades.

- Silk thread needs gentle storage or loses strength.

Choose thread material wisely—your seams depend on yarn properties!

Thread Types and Their Typical Lifespan

Not all thread ages the same way—some spools will outlast your entire sewing collection, while others turn brittle and unreliable in just a few months.

The material you’re working with makes a huge difference in how long you can trust it. Here’s what you need to know about each thread type and how long it’ll actually hold up.

Cotton Thread Shelf Life and Weaknesses

Cotton thread has a shelf life of 5 to 10 years under ideal storage solutions, but it weakens faster than you’d think. Natural fiber breakdown from UV light, heat, and humidity accelerates thread degradation and reduces cotton strength.

Here’s what sabotages your spools:

| Shelf Life Factors | Impact on Cotton Thread |

|---|---|

| Sunlight exposure | UV rays dry fibers, causing thread breakage within 2–3 years |

| High humidity | Encourages mold and accelerates fiber breakdown |

| Temperature swings | Weakens thread quality and creates brittle spots prone to snapping |

Cotton thread produces heavy lint as it ages—your machine will tell you when it’s expired.

Polyester Thread Durability and Longevity

Polyester fiber flips cotton’s weakness on its head—your spools stay strong for 20 to 50 years when you store them properly. Synthetic materials resist UV damage, moisture, and chemical exposure that ruins natural thread.

Here’s why polyester thread wins the longevity race:

- 30% stronger than cotton at the same thickness

- Manages high-speed sewing without constant thread breakage

- Keeps bright colors through bleach and sun exposure

- Resists rot in damp conditions

- No expiration date panic for your stash

Thread quality stays reliable for decades, not years.

Rayon and Silk Thread Degradation

Rayon thread and silk thread fail faster than polyester—rayon gives you only 6 to 12 months before fiber oxidation and moisture effects wreck its cellulose base. Protein breakdown sabotages silk’s strength over time, leaving brittle strands that snap mid-seam.

UV damage steals their signature sheen, while thread embrittlement makes both feel dry and papery instead of smooth.

Comparing Natural Vs. Synthetic Thread Aging

Here’s the aging difference that changes everything: natural fiber deterioration happens two to five times faster than synthetic durability.

Cotton loses tensile strength within 5–10 years, even with careful storage, while polyester maintains 85–90 percent of its original thread quality for 20–50 years.

Fiber comparison shows synthetics resist UV damage, moisture swings, and thread breakage—no expiration date guessing games required.

Simple Tests to Check Thread Quality

You don’t need a lab to figure out if your thread is still safe to use. A few quick tests will tell you whether those spools are ready to sew or ready for the trash.

Here’s how to check thread quality in under five minutes.

Pull and Tension Strength Test

Want to know if your thread is sabotaging your seams? A Pull and Tension Strength Test exposes weakness fast. Here’s your sewing thread quality assessment checklist:

- Hand Pull Check—does it snap too easily?

- Machine Tension—feel resistance with presser foot down.

- Bobbin Drop Test—watch for loose or tight thread movement.

- Visual Pull—look for fuzz, color loss.

- Pull test—compare old vs. new.

Forearm Knot Durability Test

Your fingers become the instrument in this classic durability testing method. Cut a forearm-length strand—about 10 to 12 inches—and tie a single overhand knot at center. Pull slowly, hands apart. Healthy thread resists firmly before breaking; weak spools snap with barely any pressure.

A knot cuts strength roughly 50 percent, so if breakage happens easily during knot tying, that thread’s headed for fiber breakdown and seam failure.

Friction and Surface Inspection

Simple tactile inspection catches thread wear before it sabotages your seams. Run a strand slowly between your fingertips—healthy thread glides smoothly, while degraded fiber feels scratchy, grabby, or rough. This friction test reveals surface roughness you can’t always see.

Watch for these Fiber Analysis red flags:

- Jerky motion instead of steady glide signals micro-snags ready to catch in tension disks

- Squeaking or rasping against your fingernail means hardened fibers and thread breakage risk

- Heat buildup from light rubbing shows excessive friction that causes skipped stitches

- Powdery or chalky feel indicates worn finish and signs of aging in thread quality

Thread maintenance starts with your hands.

Sewing a Test Seam on Scrap Fabric

Real stitching reveals what static tests miss. Run old thread through a full seam on scrap fabric that matches your project weight—two layers mimicking real garment construction. Thread both needle and bobbin with the suspect spool, set standard straight stitch at 2.5mm, then watch for thread breakage, skipped stitches, or tension wobbles during sewing.

| What to Check | Good Thread | Bad Thread |

|---|---|---|

| Seam integrity during stitching | Smooth, consistent feed | Snapping, jerky motion |

| Stitch appearance on both sides | Balanced, neat locks | Loops, uneven tension |

| Strength when tugged | Holds firmly | Pops or distorts |

| Thread quality surface | Clean lines | Fuzz, broken fibers |

| Observing thread behavior | Glides through guides | Catches, resists |

Inspect stitches on both sides after sewing—bobbin thread pulled topside or uneven lengths signal deteriorated thread strength ready to fail under real stress.

How Improper Storage Damages Thread

You can do everything right when you sew, but if you’re storing your thread wrong, you’re basically sabotaging yourself before you even start. Heat, light, humidity, and dust all gang up on thread fibers in ways most sewers don’t realize until they’re dealing with constant breakage.

Here’s what’s actually happening to your thread when storage conditions go sideways.

Risks of Direct Sunlight and Heat

UV damage and heat exposure are sabotaging your thread without you realizing it. Sunlight breaks down molecular bonds, reducing strength by up to 40% in just six months. Here’s what happens:

- Direct sunlight causes fiber degradation and visible chalkiness on synthetic threads

- Extreme temperatures above 95°F dry out cotton, creating permanent thread brittleness

- Outer layers turn fragile while inner wraps stay intact—uneven thread deterioration

Storage solutions matter: keep spools away from windows and heat sources to prevent thread breakage.

Effects of High Humidity and Temperature Swings

Your sewing room’s humidity swings are quietly wrecking your thread. When relative humidity bounces between 44 and 70 percent, cotton fibers swell and contract repeatedly—fiber degradation accelerates fast.

Temperature fluctuations make it worse: cycling from hot to cold weakens tensile strength, causing thread breakage long before any expiration date. Moisture damage isn’t obvious until your seam snaps mid-project.

Problems With Open Racks and Dust Accumulation

Humidity isn’t the only culprit sabotaging thread quality—dust from open racks causes serious machine tension issues and dusty thread friction. When airflow spreads particles onto exposed spools, you get:

- Gritty buildup in tension discs that ruins stitch consistency

- Visible fabric marks from dirt-covered thread on light materials

- Clogged bobbin areas demanding constant cleaning

- Weakened outer layers from years of dust exposure

Proper storage beats constant thread maintenance headaches.

Benefits of Airtight and Dark Storage Solutions

Sealed containers solve both dust and decay in one move. Airtight storage with opaque walls shields fibers from UV breakdown and moisture swings, extending thread preservation by years.

Climate control inside closed boxes keeps humidity stable around 40–60%, preventing cotton from going brittle or limp. Dark, sealed bins maintain thread quality long past any expiration date—no constant maintenance required.

Common Problems Caused by Old Thread

Old thread doesn’t just sit there looking sad—it actively sabotages your sewing projects in ways you mightn’t immediately connect to the spool. You’ll see these problems show up in your stitches, your machine’s performance, and even the finished garment itself.

Here’s what happens when deteriorated thread meets your next project.

Increased Needle Friction and Skipped Stitches

Friction issues start sabotaging your sewing efficiency the moment old thread drags through the needle eye. Degraded thread quality increases needle friction, which can push needle temperatures above 150°C at high speeds—hot enough to weaken synthetic fibers and cause skipped stitches.

You’ll notice rough, fuzzy surfaces scraping against fabric, uneven tension, and missing loops where your hook should catch. Proper thread maintenance prevents these frustrating stitch quality problems before they ruin your seams.

Weak Seams and Garment Failure

Old thread quality undermines sewing durability with popped stitches, seam grinning, and sudden bursting—especially in high-stress areas like crotch seams and underarms. Weak seams that pull apart under normal wear mean your thread replacement timeline just expired.

When you spot gaps along side seams or fabric distortion around pockets, thread fatigue has sabotaged garment longevity. Seam reinforcement won’t fix deteriorated fiber—you need fresh thread.

Thread Breakage During Machine Sewing

Constant snapping mid-seam signals degraded fiber quality that can’t handle your machine’s thread tension or sewing speed. Watch for breakage patterns: if your thread pops every few inches, especially in the needle or bobbin area, you’re fighting brittle fibers—not a machine calibration issue.

Fresh sewing thread with solid thread quality eliminates this frustration instantly, preventing weak seams and saving your project.

Reduced Stitch Quality and Fabric Damage

Stitch irregularity screams fiber breakdown before your eyes. When aging thread feeds through your machine, expect wonky stitch lengths, skipped loops, and wavy seam lines that pucker lightweight fabrics.

Fuzzy thread fraying increases friction in the needle eye, so stitches sit too tight in one spot and too loose in another—sabotaging fabric durability and leaving seam weakness that splits after a single wash.

Best Products for Managing Old Sewing Thread

You’ve tested your thread and some of it’s past its prime—now what? Whether you’re discarding weak spools or repurposing them for crafts, having the right tools makes the job faster and less messy.

Here are five products that help you cut, secure, and transform old thread without the frustration.

1. Metrosene Sewing Thread Gift Set

When you’re stocking up on fresh thread, Metrosene gift sets deliver reliable performance that won’t sabotage your projects down the line.

These 100% polyester spools resist shrinking and hold up through repeated washes without bleeding dye onto lighter fabrics. The 50-weight construction glides smoothly through domestic machines at standard tension settings, and each spool packs about 164 yards—enough for multiple garment seams.

With sets ranging from 8 to 28 coordinated colors, you’ll cover everyday mending and quilting without guesswork.

| Best For | Sewers who need a versatile color range for everyday projects like garment repairs, quilting, and basic sewing on synthetic or natural fabrics. |

|---|---|

| Brand | Mettle |

| Material | 100% Polyester |

| Form Factor | Spool Set |

| Weight | 11 ounces |

| Use Case | Sewing/Fabric |

| Made In | China |

| Additional Features |

|

- 28-spool set gives you plenty of color options without buying thread individually

- Polyester construction handles machine washing and heat without shrinking or bleeding

- Works smoothly on most home sewing machines across different fabric types

- Thread can break or fray more easily than premium brands during use

- Colors might not match your existing fabric stash perfectly

- Quality control issues reported by some users, with occasional weak spools

2. X-Acto Precision Cutting Knife

Trimming frayed ends on stubborn old thread becomes simple with an X-Acto No. 1 precision knife. The classic #11 fine-point blade slips under tangled nests and snipped fibers without snagging your fabric—something bulky scissors can’t manage.

You’ll navigate tight corners around buttonholes and seams with pencil-like control, and the safety cap keeps the blade covered in your sewing kit.

When you’re switching out expired spools, that razor edge cleanly cuts through lint buildup and removes stubborn tail ends your seam ripper can’t reach.

| Best For | Crafters and hobbyists who need precise control for detailed cuts on medium to heavy materials like paper, plastic, and thin wood. |

|---|---|

| Brand | X-Acto |

| Material | Aluminum/Brass/Steel |

| Form Factor | Handheld Tool |

| Weight | 0.8 ounces |

| Use Case | Cutting/Crafts |

| Made In | USA |

| Additional Features |

|

- Easy blade replacement system lets you swap out dull blades quickly without tools

- Pencil-like aluminum handle gives you excellent control for intricate cuts and tight corners

- Versatile enough to cut through multiple materials from fabric and paper to plastic and thin metal

- Blade can fall out when cutting through thicker or harder materials

- Safety cap may arrive loose and not secure the blade properly during storage

- Not designed for very thick materials—you’ll need a heavier-duty tool for those jobs

3. Beacon Permanent Fabric Adhesive

When old thread snaps mid-seam and you need a fast repair, Beacon Fabri-Tac permanent adhesive rescues your project without rethreading that finicky machine.

The waterproof formula grabs in about an hour and fully cures in 24, bonding fabric, lace, leather, and trims with flexible hold that won’t crack when garments move.

You’ll find it ideal for securing hems or reattaching embellishments on items where old thread already failed. Just work in small sections—its acetone base dries fast and won’t soak through most materials.

| Best For | Sewers and crafters who need quick fabric repairs without a needle and thread, especially for hems, embellishments, and projects where washing durability matters. |

|---|---|

| Brand | Beacon |

| Material | Plastic |

| Form Factor | Bottle |

| Weight | 4.8 ounces |

| Use Case | Bonding/Repair |

| Made In | USA |

| Additional Features |

|

- Sets in about an hour and becomes fully waterproof after 24 hours, holding strong even through washing

- Works on multiple materials like fabric, leather, lace, and trims with a flexible bond that moves with the garment

- Won’t soak through most fabrics thanks to its fast-drying acetone formula

- Gets goopy and sticky during application, so you need to work carefully in small sections

- May irritate skin and requires gloves for some users, plus you’ll want good ventilation

- Dries quickly, which means mistakes are hard to fix once it sets

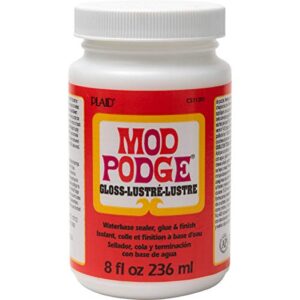

4. Mod Podge Gloss Sealer Glue

When repurposing old thread into decorative crafts, Mod Podge Gloss lets you seal those fragile fibers into permanent art pieces instead of tossing them.

The all-in-one formula works as glue, sealer, and glossy finish on wood, paper, fabric, and canvas—perfect for thread flowers, collages, or storage-tin decoration.

It dries clear in 15–30 minutes and won’t yellow your vintage thread colors. Just brush on thin coats and rinse tools with soap while wet. Your expired spools become showpieces, not landfill.

| Best For | Crafters who want an easy, all-in-one solution for decoupage, scrapbooking, and DIY projects on multiple surfaces like wood, paper, fabric, and canvas. |

|---|---|

| Brand | Mod Podge |

| Material | Waterbase Sealer |

| Form Factor | Bottle |

| Weight | 8.3 ounces |

| Use Case | Decoupage/Sealing |

| Made In | USA |

| Additional Features |

|

- Works as glue, sealer, and finish in one bottle—saves you from buying three separate products

- Dries clear with a glossy shine that won’t turn yellow over time, keeping your projects looking fresh

- Water-based and non-toxic with quick cleanup using just soap and water

- Needs thick application for mounting, which can get messy with drips and spillover

- Brush strokes can show through if you’re not careful with how you apply it

- Only comes in gloss finish, so it’s not ideal if you want a matte or satin look

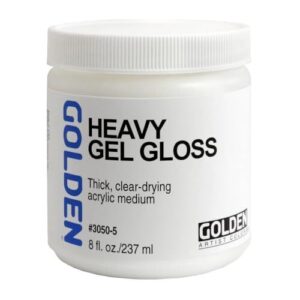

5. Golden Heavy Gel Gloss Medium

When old thread still has color but zero strength, Golden Heavy Gel Gloss locks it into mixed-media art without stress.

This 100% acrylic medium builds glossy translucent layers that embed worn fibers into rigid surfaces—canvas, wood panels, or stitched collages—where pulling tension never threatens your design.

The thick consistency holds peaks and textures, drying flexible with UV and water resistance so your thread sculpture survives handling. At $14 for 8 ounces, it’s how you turn brittle spools into gallery-worthy textile pieces instead of junk.

| Best For | Artists working with fragile vintage textiles or weak thread in mixed-media collages who need a strong adhesive medium that locks down fibers without adding mechanical stress. |

|---|---|

| Brand | GOLDEN |

| Material | Acrylic Medium |

| Form Factor | Jar |

| Weight | 7 ounces |

| Use Case | Painting/Texture |

| Made In | USA |

| Additional Features |

|

- Builds thick, textured layers with UV and water resistance that protect embedded fibers from handling damage

- Versatile medium that works as both an adhesive for collage and a glaze for extending paints and adjusting sheen

- Dries to a flexible, glossy finish that preserves the visual integrity of delicate materials in gallery-ready work

- Higher price point at $14 for 8 ounces compared to basic acrylic mediums

- Thick gel consistency may require thinning or practice to achieve desired effects for first-time users

- Only compatible with acrylic paints, limiting use for artists working primarily in oil or watercolor systems

Creative Ways to Repurpose Expired Thread

You don’t have to toss that expired thread in the trash—there’s still plenty of life left in it for projects where strength doesn’t matter.

Old spools work beautifully for decorative crafts, temporary stitching, and creative experiments you wouldn’t risk with good thread.

Here are a few smart ways to put those weakened fibers to work before you say goodbye for good.

Using Old Thread for Basting and Temporary Stitches

Thread that barely passes a tug test still works perfectly for temporary basting and fitting seams. Reserve your aging cotton or polyester for hand-basted hems, quilt sandwiches, or muslin mockups—anywhere you’ll remove the stitches later.

Use larger stitches and wax brittle fibers lightly to reduce friction. Just keep weak thread away from permanent seams where Old Thread Uses could sabotage garment integrity.

Making Tassels, Fringe, and Thread Flowers

Expired sewing thread is practically made for tassels, fringe, and thread flowers—strength doesn’t matter here. Wrap 20–40 loops around a card for full Tassel Making bodies, or bundle cut lengths for Fringe Techniques along a hem edge. Thread Flowers need only folded loops tied at center.

Decorative Trims and Embellishment Ideas like these thrive on textile degradation casualties—putting poor thread quality to genuinely beautiful use.

Crafting Jewelry, String Art, and Mixed Media Projects

If tassels and fringe aren’t enough to clear your expired thread stash, try Thread Wrapping for Jewelry Making or String Art—give those faded, fuzzy spools a second act. Textile degradation sabotages seam strength, but in Mixed Media and Fiber Crafting, it’s a creative asset.

- Bold ombré bracelets from layered thread

- Mini string art pendants

- Speckled thread beads for statement necklaces

Creating Felt-like Fabric or Textile Art

Felted Texture is your secret weapon for salvaging weak thread. Sandwich scraps between water-soluble stabilizer, stitch densely, and rinse—the result? A flexible, non-woven sheet perfect for Thread Painting or Needle Embellishment.

Fiber Blending in Wet Felting traps old thread inside wool, adding color and durability.

Smart thread management means textile maintenance becomes art, not sabotage.

Frequently Asked Questions (FAQs)

How to tell if old sewing thread is still good?

Pull off a few inches and give it a firm tug. Good thread holds; bad thread snaps fast. That quick strength test tells you almost everything about old thread quality.

Does old thread go bad?

Yes, old thread absolutely goes bad. Thread degradation is real — fiber breakdown from heat, light, and moisture quietly destroys material durability. Without proper storage solutions and thread maintenance, even decent thread lifespan shrinks fast.

Is it okay to sew with old thread?

Sure — if it passes a basic strength test. Old thread that snaps with almost no effort is a sewing risk, not a storage solution. Strong thread means safe fabric durability.

Can expired thread still damage my sewing machine?

Absolutely — expired thread doesn’t just ruin your project. Through lint accumulation, thread friction, and tension issues, it quietly drives machine wear that compounds over time, turning routine sewing machine maintenance into a much bigger headache.

How should I dispose of old unusable thread?

Old thread doesn’t have to end up tangled in a landfill. Cotton thread is compostable; synthetic thread goes to trash in short, cut pieces to protect wildlife and sorting equipment.

Does thread brand affect how quickly it ages?

Brand Comparison matters—a lot. Premium brands use tighter Fiber Quality control and sophisticated Manufacturing Processes, so their thread longevity trounces bargain spools.

Better thread quality means slower expiration, especially with good Storage Solutions. Testing sewing thread strength reveals these differences quickly.

Can I mix old and new thread in one project?

Yes, but with caution. Old thread that passes a basic strength test can work for low-stress areas. Keep new thread in structural seams and reserve older spools for basting or decorative details.

How often should I audit my thread collection?

Aim for an annual thread audit as your baseline. If your storage conditions are poor or you sew often, bump that to seasonal checks — your thread longevity and care routine depends on it.

Conclusion

Thread is the backbone of every stitch you’ll ever sew—and a weak backbone collapses everything built on top of it. Knowing the signs you need to replace old sewing thread isn’t just maintenance advice; it’s how you protect hours of careful work from unraveling at the seams.

Test it, trust your instincts, and don’t let a two-dollar spool sabotage a twenty-hour project. Fresh thread isn’t a luxury. It’s the foundation your craftsmanship deserves.

- https://www.foxcountryquilts.com/does-thread-expire-how-shelf-life-sunlight--storage-affect-your-quilting.htm

- https://gequiltdesigns.com/blogs/the-quilters-toolkit/does-thread-expire-tips-for-storing-it-so-it-lasts

- https://quiltadvice.com/blog/when-should-you-throw-out-thread/

- https://dergipark.org.tr/en/download/article-file/2141539

- https://www.needlenthread.com/2014/05/thread-talk-old-embroidery-threads.html