This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

By 2025, cotton polyester blends account for nearly 43% of all blended fibers produced globally—and that number keeps climbing. That didn’t happen by accident. Since the “wash and wear” revolution of the early 1950s, this fabric combination has quietly taken over closets, gyms, and living rooms worldwide because it solves a real problem: pure cotton wrinkles and stretches out, pure polyester traps heat and feels plasticky against skin.

The blend splits the difference in a way neither fiber can manage alone. Whether you’re choosing fabric for a uniform, a t-shirt, or a set of bed sheets, understanding how these fibers work together puts better decisions in your hands.

Table Of Contents

- Key Takeaways

- What is Cotton Polyester Blend Fabric?

- Key Properties of Cotton Polyester Blends

- Advantages and Disadvantages

- Popular Uses and Applications

- Choosing The Right Blend Ratio

- Sewing Tips for Cotton Polyester Blends

- Care and Maintenance Guidelines

- Environmental Impact and Sustainability

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Cotton-polyester blends dominate modern textiles because they fix what each fiber gets wrong on its own — cotton’s wrinkling and polyester’s heat-trapping.

- The ratio you pick changes everything: go 80/20 for softness, 50/50 for balance, or 65/35 polyester-heavy when durability and easy care matter most.

- A 65/35 blend dries 45% faster than pure cotton and withstands 22,500 abrasion cycles — real numbers that justify why this fabric shows up in uniforms, sportswear, and bedding.

- The biggest catch is environmental: blended fibers are nearly impossible to recycle, and high-polyester content sheds microplastics — so certifications like OEKO-TEX and recycled-polyester options are worth seeking out.

What is Cotton Polyester Blend Fabric?

Cotton polyester blend fabric is exactly what it sounds like — a mix of two fibers working together to cover each other’s weaknesses. It’s one of the most common fabrics you’ll find in everyday clothing, and for good reason.

Choosing the right needle matters too — a universal or stretch needle works great for sewing cotton polyester blends and other common fabrics.

Here’s what you need to know about what it’s made of, where it came from, and the ratios that make all the difference.

Definition and Composition

Cotton polyester blend fabric is exactly what it sounds like — cotton and polyester fibers spun together into one unified material. The cotton brings softness and breathability from its natural cellulose structure, while polyester adds strength and wrinkle resistance through its synthetic polymer chemistry.

Fiber mixing happens at the yarn stage, so the resulting fabric structure delivers both materials’ properties simultaneously. Understanding these chemical properties helps you make smarter fabric selection decisions. For additional details on the differences and properties of each material, see this detailed guide on.

History and Development

The fabric evolution behind cotton polyester blends traces back to the early 1950s, when textile manufacturing and production shifted toward the “wash and wear” revolution. This historical context matters because it shaped how we dress today.

- By 1952, blend innovations hit the mainstream market

- Cotton’s market share dropped from 78% as textile science and technology progressed

- Market trends pushed cotton polyester blends to 42.9% of global blended fibers by 2025

Rising demand for performance fabrics continues to drive worldwide.

Common Blend Ratios

That wash-and-wear revolution didn’t just change manufacturing — it gave us options. Today, cotton polyester blends come in ratios built for specific jobs.

An 80/20 blend keeps cotton content high for softness and breathability. A 50/50 hits the middle ground on fabric durability and comfort. Go 65/35 polyester-dominant, and polyester benefits like wrinkle resistance and toughness take over — perfect for uniforms and heavy daily use.

Key Properties of Cotton Polyester Blends

What makes cotton polyester blend fabric actually work comes down to a few core properties. These aren’t just marketing claims — they’re the real reasons this fabric shows up everywhere from gym bags to bedsheets.

Here’s what you need to know.

Durability and Strength

Think of polyester as cotton’s bodyguard. In tensile testing, a 65/35 cotton polyester blend hits around 99 kg warp strength — that’s roughly 40% tougher than pure cotton. Here’s what that durability means for you:

- Wear Durability: Martindale abrasion tests show 22,500 cycles before noticeable wear

- Fabric Abrasion: 60/40 blends show 75% less surface wear than 100% cotton

- Seam Integrity: Poly-blend threads deliver ~30% stronger seams

Pilling resistance also improves markedly with proper finishing — keeping your fabric looking sharp longer.

Breathability and Comfort

Breathability in cotton polyester blends isn’t a coin flip — it’s about ratio. A 70/30 cotton-heavy blend gives you real air permeability and skin feel that stays comfortable all day.

Polyester quietly manages thermal regulation, trapping just enough warmth without smothering you. The result? Fabric softness that holds up, a comfortable fit, and breathability that works for most everyday conditions.

Moisture Management

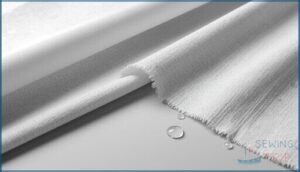

Moisture management is where cotton polyester blends really earn their keep. Cotton pulls sweat in — it can hold nearly 8% of its weight in moisture — while polyester’s hydrophobic fibers use capillary action for sweat transport, pushing that moisture outward.

That balance of absorption and wicking is exactly what beginners need — and choosing the right fabric for your first sewing projects gets a lot easier once you understand how fibers work together.

Cotton absorbs sweat while polyester pushes it out, making their blend a moisture-management powerhouse

The result is faster drying speed, smarter evaporative cooling, and steadier thermal regulation. A 65/35 blend dries roughly 45% faster than pure cotton.

Advantages and Disadvantages

Every fabric has trade-offs, and cotton polyester blends are no different. Knowing what you’re getting — and what you’re giving up — helps you make smarter choices.

Here’s a clear look at the benefits, drawbacks, and cost factors worth considering.

Benefits Over Pure Cotton or Polyester

Cotton polyester blends hit a sweet spot that neither fiber reaches alone. You get the softness and breathability of cotton paired with polyester’s durability and wrinkle resistance — without sacrificing either.

A 65/35 polyester-cotton mix holds its shape wash after wash, dries faster, and costs less to produce. For performance balance, moisture management, and fabric durability, this blend simply outperforms both pure options in everyday use.

Potential Drawbacks

No fabric is perfect — and blends are no exception. The same polyester that boosts durability creates real tradeoffs you should know about:

- Breathability Issues and Skin Irritation increase in high-polyester blends, especially in heat.

- Pilling Problems appear at friction points after repeated washing.

- Microplastic Pollution and Heat Risks make blends unsuitable near open flames or waterways.

Cost Considerations

Price is where cotton polyester blends genuinely win. Basic broadcloth runs $5–$11 per yard — cheaper than pure cotton, easier on your fabric budgeting than premium natural fibers.

Wholesale discounts drop costs further for bulk orders. Factor in lifecycle savings from durability and easy care, and the math is hard to argue with.

| Cost Factor | Cotton Polyester Blends |

|---|---|

| Material Pricing | $5–$11/yard retail |

| Wholesale Discounts | Tiered bulk pricing available |

| Lifecycle Savings | Lasts longer, less replacement |

| Fabric Production | Lower than pure cotton |

Popular Uses and Applications

Cotton polyester blend fabric shows up in more places than most people realize. Its combination of comfort, durability, and easy care makes it a go-to choice across a surprising range of products.

Here’s where you’ll actually find it being put to work.

Everyday Clothing and Apparel

Your wardrobe works harder when you choose the right fabric. Cotton polyester blends show up everywhere in everyday clothing — from 50/50 casual wear tees to work attire button-downs and athletic gear — because they hold their shape, resist fading, and dry fast.

- Street fashion graphic tees stay vivid wash after wash

- Work attire shirts need less ironing, saving real time

- Athletic gear wicks moisture without sacrificing comfort

Smart fabric selection drives modern fashion trends.

Home Textiles and Furnishings

Beyond your wardrobe, cotton polyester blend does serious work throughout your home. Smart fabric selection here means less maintenance and longer-lasting results.

| Home Application | Key Benefit |

|---|---|

| Bedding Options | Breathable yet wrinkle-resistant |

| Curtain Designs | UV-resistant, easy machine wash |

| Upholstery Materials | Abrasion-resistant, spill-friendly |

From table settings to upholstery fabric, this blend keeps your home decor looking sharp with minimal fabric care effort.

Sportswear and Uniforms

Sports teams and corporate staff both demand a lot from their kit. That’s why cotton polyester blends dominate sportswear and uniforms — they nail moisture management while holding up through brutal wash cycles.

A 50/50 or 60/40 poly-to-cotton ratio gives you the sportswear comfort and uniform durability you need. Tensile strength stays consistent, fabric selection gets easier, and athletic performance doesn’t suffer when the fabric does its job.

Choosing The Right Blend Ratio

Not all cotton-polyester blends are created equal, and the ratio you choose changes everything about how a fabric feels and performs. The right mix depends on what you actually need — durability, softness, breathability, or some balance of all three.

Here’s a breakdown of the most common ratios to help you pick the one that fits your needs.

Common Ratios and Their Effects

The ratio is everything. An 80/20 cotton polyester blend keeps that soft, natural feel while adding just enough polyester for light wrinkle resistance — ideal for loungewear.

A 50/50 blend hits the sweet spot for fabric durability and everyday tees.

Push to 65/35 polyester-dominant, and you’re optimizing for workwear performance metrics — faster drying, stronger abrasion resistance, and less ironing needed.

Selecting Ratios for Specific Needs

Knowing the numbers is one thing — knowing your numbers is what matters.

Match your blend to what your life actually demands:

- Hot climates: Choose 60%+ cotton for breathability and skin comfort

- Cold or wet workplaces: Go 60–70% polyester for fabric durability and faster drying

- Sensitive skin: Stay above 60% cotton to minimize irritation

- Heavy sweating: A 40/60 cotton-polyester blend improves sweat management without sacrificing softness

- Low care effort: 65%+ polyester resists wrinkles straight from the dryer

Climate considerations and daily activity together tell you exactly where to land.

Pros and Cons of Different Ratios

Every blend ratio is a trade-off — comfort vs. durability, softness vs. stability. Here’s how the most common cotton polyester mix options stack up in real fabric performance:

| Ratio | Strengths | Weaknesses |

|---|---|---|

| 80/20 Cotton-heavy | Soft, breathable, skin-friendly | Wrinkles, shrinks more |

| 50/50 Balanced | Durable, shape-retention | Less breathable |

| 65/35 Polyester-heavy | Fast-drying, wrinkle-resistant | Traps heat |

Ratio comparison makes your choice obvious.

Sewing Tips for Cotton Polyester Blends

Sewing with cotton polyester blend isn’t complicated, but a few small details make a big difference in your results. Get these basics right and you’ll avoid the most common frustrations — uneven seams, fraying edges, skipped stitches.

Here’s what to focus on before you cut your first piece.

Recommended Needle and Thread Types

Your needle and thread selection can make or break a seam. For most cotton polyester blends, a size 80/12 universal sewing machine needle paired with all-purpose polyester thread is your go-to combination.

Heavier fabrics need a 90/14 needle. Knit blends require a ballpoint needle to prevent snags.

Strong polyester thread manages stress points — waistbands, armholes — without breaking down over time.

Cutting and Stabilizing The Fabric

Fabric preparation is your first line of defense against crooked seams. Prewash, then press the wrong side flat before you touch your cutting tools.

A sharp rotary cutter manages long straight cuts cleanly — smaller blades follow curves without stretching.

For fraying prevention and edge stabilization, stay stitch curved edges immediately after cutting. Sharp scissors and careful fabric handling keep every piece true.

Machine Settings for Optimal Results

Your sewing machine settings are the difference between a crisp seam and a puckered mess. For medium-weight cotton polyester, start with a stitch length of 2.0–3.0 mm and thread tension around 4–5.

Needle selection matters too — a size 80/12 universal works for most weights. Adjust presser foot pressure for smooth feed control, and always test on scrap first.

Care and Maintenance Guidelines

Taking care of your cotton polyester blend doesn’t have to be complicated — but a few wrong moves can shorten its life fast.

The good news is that this fabric is forgiving when you know the rules. Here’s what you need to keep it looking sharp wash after wash.

Washing and Drying Best Practices

Treat your cotton polyester blend the way it deserves — with a little discipline. Wash in cool to warm water, 30 to 40°C, to avoid fabric shrinkage and fiber stress. Check care labels before anything else.

For stain prevention, keep the first few minutes below 40°C so sweat and blood don’t set. Tumble dry on low, and you’re done.

Ironing and Wrinkle Prevention

Cotton polyester blend fabric practically irons itself — almost. Set your iron temperature between 110–150°C, and use a pressing cloth to protect the surface from shine or scorching.

Slightly damp fabric responds better than bone-dry. Move in smooth, straight strokes; don’t hover.

Thanks to polyester’s wrinkle resistance, one or two passes removes most creases. Hang immediately after to lock in the finish.

Stain Removal Tips

Stains don’t wait, so neither should you. Act fast — ideally within a few hours.

Pretreatment Steps and Stain-Specific Solutions:

- Grease Stain Removal: Massage liquid dish soap into the spot, wait five minutes, rinse with warm water.

- Protein Stain Solutions: Use an enzyme detergent with protease for blood, sweat, or milk.

- Bleach Safety: Dilute chlorine bleach to 5% — chlorine weakens polyester fibers in your Cotton Polyester Blend.

- Garment Care and Maintenance: Never machine-dry until the stain is fully gone — heat sets stains permanently.

Environmental Impact and Sustainability

Cotton polyester blends are convenient, but they come with a real environmental cost worth knowing about. The mix of natural and synthetic fibers makes recycling tricky and disposal messier than most people realize.

Here’s what you need to know about where this fabric stands — and where it’s headed.

Eco-Friendly Production Practices

Behind every responsible blend is a chain of decisions — from organic farming that skips synthetic pesticides to green manufacturing that cuts energy at the mill level.

Eco friendly dyes and safer chemical management keep toxins out of waterways. Certifications like OEKO-TEX verify sustainable textile practices are actually followed.

Choosing sustainable fashion means supporting sustainable materials, sustainable textiles, and the entire system built around them.

Recycling and Disposal Options

Production choices matter, but so does what happens at the end of a garment’s life. Less than 1 percent of textile waste gets recycled into new clothing — most polycotton still ends up in landfills.

Chemical recycling and fiber separation technologies are changing that, breaking blends into reusable components that feed a real circular economy.

Take-back programs make eco-friendly fashion choices easier.

Future Trends in Sustainable Blends

With recycling on the rise, brands are pushing cotton polyester blends in clothing toward biobased materials and green manufacturing.

Eco-friendly textiles now feature recycled polyester, organic cotton, and circular economy designs.

Sustainable fabrics with improved fabric properties and characteristics are set to dominate future trends in textiles, making sustainable fashion and ecofriendly fashion more accessible and practical for everyday wear.

Frequently Asked Questions (FAQs)

What is a good cotton polyester blend?

A 60/40 cotton polyester blend hits the sweet spot for most people. You get fabric softness and breathability from the cotton, plus the durability factors polyester brings — without sacrificing comfort.

What’s better, 100 cotton or 60 cotton 40 polyester?

Neither wins outright — it depends on what you need. For softness and breathability, 100 cotton wins. For durability, wrinkle resistance, and drying speed, the 60 cotton 40 polyester blend holds its ground.

Is 55 cotton 45 polyester good?

Yes — a 55 cotton 45 polyester blend strikes a smart balance. You get cotton’s softness and breathability with polyester’s durability, shape retention, and easy care, making it reliable for everyday wearability.

Is 85 cotton 15 polyester good?

An 85/15 blend is genuinely good. The dominant cotton fibers deliver fabric softness and breathability, while 15% polyester fibers quietly boost durability and moisture control — all without sacrificing that natural, comfortable feel.

How do cotton polyester blends affect skin sensitivity?

Your skin reacts to what touches it all day. Cotton polyester blends can cause skin irritation if polyester content is high, reducing breathability and trapping sweat — especially for those with a fiber allergy.

Can cotton polyester blends be altered or tailored easily?

Cotton polyester blends are genuinely tailor-friendly. Solid Fabric Handling, low shrinkage, and stable seams make Alteration Techniques straightforward — whether you’re hemming, taking in side seams, or applying clean Seam Finishing with minimal fuss.

What certifications should consumers look for when buying?

Look for OEKO TEX Labels, GRS Certification, and Bluesign Standards. These confirm chemical safety, recycled materials, and cleaner production. GOTS matters when organic cotton content is high.

How does fabric weight impact warmth and wearability?

Fabric weight controls everything. Higher GSM means better warmth retention but less breathability.

For cotton polyester blends, hitting that 150–250 GSM sweet spot balances moisture management, durability, and all-day wearability without sacrificing comfort.

Are cotton polyester blends safe for baby clothing?

Yes — mostly. Cotton polyester blends are generally safe for babies, but high polyester content can trap heat and irritate sensitive skin.

Choose blends with 60% or more cotton for better breathability and baby skin safety.

Conclusion

Picking the perfect fabric rarely feels simple—but this cotton polyester blend fabric guide cuts through the confusion. Blending both fibers isn’t a compromise; it’s a calculated upgrade.

You now know the ratios, the care routines, the sewing settings, and the sustainability tradeoffs. That knowledge doesn’t sit on a shelf—it shapes every purchase you make from here forward.

Choose deliberately, care consistently, and the fabric you pick will work exactly as hard as you do.