This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Pound-for-pound, abaca fiber rivals steel in tensile strength—yet it decomposes completely in six months. This noteworthy textile, woven from the leaf stalks of a Philippine plant related to the banana, has anchored seafaring ropes, secured cargo ships, and clothed tropical communities for generations.

Pound-for-pound, abaca fiber rivals steel in tensile strength—yet it decomposes completely in six months. This noteworthy textile, woven from the leaf stalks of a Philippine plant related to the banana, has anchored seafaring ropes, secured cargo ships, and clothed tropical communities for generations.

While synthetic materials dominate today’s textile industry, abaca fabric offers something increasingly rare: genuine durability without environmental compromise. Its fibers resist saltwater degradation, require minimal chemical processing, and capture over 22 tons of carbon per hectare annually during cultivation.

As brands and consumers scrutinize the true cost of fabric production, this traditional material demonstrates that strength and sustainability aren’t mutually exclusive.

Table Of Contents

Key Takeaways

- Abaca fiber delivers tensile strength comparable to steel pound-for-pound while decomposing completely within six months, making it one of the strongest natural fibers that doesn’t compromise environmental sustainability.

- The material’s resistance to saltwater degradation and water absorption under 12% gives it a significant performance advantage over cotton (25% absorption) and other natural fibers in marine and demanding applications.

- Abaca cultivation provides measurable environmental benefits including carbon sequestration of 22.7 tons per hectare annually, 70% reduction in soil erosion on sloped terrain, and 85% fewer chemicals than synthetic fiber production.

- Despite its industrial strength, abaca fabric faces commercialization challenges including higher production costs than synthetics, limited fiber availability restricted to specific cultivation regions, and technical difficulties in scaling beyond traditional methods.

What is Abaca Fabric?

Abaca fabric is a natural textile woven from fibers extracted from the leaf stalks of the abaca plant, a species native to the Philippines and closely related to the banana plant. This durable material has been crafted by Filipino artisans for generations, making it both a practical resource and a cultural tradition.

Let’s explore what defines abaca fabric and why it holds significance beyond its physical properties.

Definition and Overview

Abaca fabric, woven from the leaf stalks of the abaca plant native to the Philippines, stands out as one of the strongest natural fibers you can find. It is prized for its outstanding durability, water resistance, and considerable tensile strength, making it indispensable in everything from traditional textiles to modern industrial applications.

You’ll sometimes hear it called Manila Hemp, though it’s not actually hemp. It’s a plant fiber from the Musaceae family, closely related to bananas. This natural fiber has gained global relevance as designers and manufacturers seek sustainable alternatives to synthetics, making abaca definition essential for anyone interested in eco-friendly materials.

Historical and Cultural Significance

For centuries, this notable Philippine plant has been woven into Filipino heritage, shaping both economy and identity. Traditional craftsmanship passed down through generations has preserved weaving traditions that transform raw fiber into textiles of notable beauty and strength. Manila Hemp became a cornerstone of trade, anchoring communities in cultural preservation while demonstrating the artistry of traditional textile techniques. Abaca fibers, known for their resistance to water, are especially useful in marine environments.

- Economic impact: Abaca production has supported rural Filipino communities for generations, providing sustainable livelihoods

- Weaving traditions: Women teach younger girls the intricate techniques of traditional uses in textile production

- Artistic expression: Natural dyes and patterns reflect regional styles and cultural stories

- Cultural preservation: Traditional craftsmanship continues today, connecting modern artisans to ancestral practices

How is Abaca Fabric Made?

Making abaca fabric is a hands-on process that combines traditional craftsmanship with careful material treatment. You’ll find that the journey from plant to textile involves several distinct stages, each requiring specific skills and attention to detail.

Let’s walk through the key steps that transform raw abaca leaves into durable, workable fabric.

Harvesting and Sourcing Raw Materials

Before you can start weaving abaca fabric, you need to understand that the raw material comes from a plant with specific maturity requirements and a harvest process that has been refined over generations. Farmers wait until the abaca plant reaches four years old before harvesting its leaves, guaranteeing best fiber quality and strength.

This patient approach reflects sustainable practices rooted in regional variations across the Philippines, where ethical sourcing and abaca cultivation techniques have been passed down through families.

Proper abaca plant harvesting directly impacts the fiber extraction quality you’ll work with, making sustainable agriculture practices essential for producing high-grade abaca fiber raw material.

Fiber Extraction and Processing Methods

Once your leaves are ready, fiber extraction begins by removing the leaf stalks from the plant and stripping away the pulp through a process called decortication. You can use manual stripping or machine decortication, depending on scale. After pulp removal, the fibers are separated and combed, then graded by thickness. Processing technologies have improved efficiency, but the core abaca fiber processing methods remain consistent:

- Strip leaf stalks to extract raw fiber bundles

- Remove pulp through mechanical or manual decortication

- Separate and comb individual fibers

- Grade fibers by thickness and quality

- Air-dry fibers, then rub to soften for use

Fiber drying and grading determine your final material quality before weaving. The Philippines is a major source, supplying 85% of global abaca fiber.

Traditional Weaving Techniques

After your fibers are softened and graded, weaving them into fabric requires the skill that Filipino artisans have refined through generations of hands-on practice. Weaving communities use traditional backstrap looms or floor looms, creating handwoven fabric with indigenous patterns passed down through families.

This cultural preservation involves natural dyeing methods applied before or after weaving. The Philippine textile tradition transforms abaca fiber into distinctive products, with each weaver bringing regional techniques to their handwoven fabrics.

What Makes The Abaca Plant Unique?

The abaca plant stands out among fiber crops for reasons that go beyond its banana-like appearance. Understanding what sets this plant apart helps explain why its fibers command such respect in the textile world.

Let’s look at the botanical features, key differences from its banana relatives, and the growing conditions that bring out its best qualities.

Botanical Features and Growth Habits

The abaca plant, known scientifically as Musa textilis, thrives as a sturdy perennial, sending up clusters of 12 to 25 fleshy stalks from a single underground rootstock system that can persist for decades with proper care. Each stalk reaches 4 to 8 meters in height, producing oblong leaves with bright green upper surfaces and yellowish-green undersides.

Musa textilis requires specific conditions for optimal growth:

- Soil requirements: Loose, loamy soils with excellent drainage

- Rootstock propagation: Mature rootstock pieces planted during rainy seasons

- Growth cycle: Four-year maturation period before harvest in tropical climates

Differences From Banana Plants

While both plants belong to the Musaceae family and share a similar appearance, Musa textilis differs markedly from banana relatives in its commercial value and stalk composition.

You won’t find edible fruit on abaca plants—their purpose centers entirely on fiber yield. The leaf structure produces fleshy, fibreless stalks that deliver long, strong strands perfect for weaving, unlike banana plant fiber, which lacks the tensile strength and length needed for textile production.

Ideal Cultivation Conditions

Growing this resilient plant successfully requires more than simply sticking rootstock in the ground—you need to match the abaca’s tropical origins with conditions that support its vigorous growth cycle. Abaca cultivation thrives in fairly rich, loose, loamy soils with excellent drainage—soil health directly impacts fiber quality.

Climate factors matter too: steady rainfall and warm temperatures keep the abaca plant productive.

Propagation methods commonly rely on mature rootstock pieces planted at the rainy season’s start, ensuring your plant cultivation aligns with nature’s rhythm.

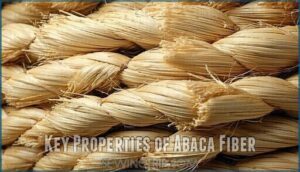

Key Properties of Abaca Fiber

When you’re evaluating abaca fiber for your projects, you need to understand what makes it tick. The fiber’s performance comes down to three core areas: its physical strength and mechanical behavior, its chemical makeup, and how it stacks up against other natural fibers.

Let’s break down each of these properties so you can see exactly what you’re working with.

Physical and Mechanical Characteristics

When you pull on a strand of abaca fiber, you’re testing one of nature’s strongest plant-based materials—capable of outlasting and outperforming many synthetic alternatives in real-world conditions. Its tensile strength rivals steel pound-for-pound, while fiber length reaches up to three meters, giving you remarkable durability during weaving.

Abaca fiber rivals steel pound-for-pound in tensile strength, making it one of nature’s strongest plant-based materials

You’ll find color variations from white to deep purple, and its water resistance means it won’t weaken when wet—buoyancy factors make it ideal for marine applications.

Chemical Composition

Understanding what makes abaca so resilient starts at the molecular level, where its chemical blueprint reveals why this fiber can withstand forces that would tear apart most natural textiles.

You’re looking at 76.6% cellulose content—the structural backbone—supported by 14.6% hemicellulose ratio and 8.4% lignin percentage that provides rigidity. Trace amounts of pectin presence (0.3%) and wax composition (0.1%) round out the chemical composition of abaca fiber, creating a balance that delivers both flexibility and strength.

Comparison With Other Natural Fibers

So how does abaca stack up against hemp, cotton, and sisal fiber? You’ll find abaca’s tensile strength reaches 980–1400 MPa—three times stronger than cotton and surpassing sisal (400–700 MPa), earning it recognition as the strongest natural plant fiber in many marine applications. Its fiber length of 1.6–3.4 meters outpaces sisal’s 0.8–1.2 meters, while water resistance remains outstanding with under 12% absorption compared to cotton’s 25%.

Consider these standout traits:

- Biodegradability completes in 3–6 months, matching hemp and outpacing sisal

- Market value averages USD 3,500/ton versus jute’s USD 500–700/ton

- Saltwater durability shows 25–30% less deterioration than jute or sisal

- Tensile modulus hits 13.2 GPa, exceeding hemp and flax composites

That market value premium reflects demand for specialized cordage and composites where failure isn’t an option.

Uses and Applications of Abaca Fabric

Abaca fabric’s unique properties make it suitable for a surprising range of applications. From the clothes you wear to industrial products you mightn’t expect, this adaptable material shows up in more places than you’d think.

Let’s explore where abaca fabric makes its mark in both fashion and commercial settings.

Clothing and Fashion

You’ll find abaca fabric making its mark in fashion circles where designers value durability without sacrificing natural elegance. Designer collaborations have sparked textile innovation through abaca couture, transforming traditional weaving into sustainable fashion applications. The fiber’s natural luster and strength make it perfect for everything from structured garments to flowing accessories.

| Fashion Application | Abaca Fabric Use | Key Benefit |

|---|---|---|

| Evening wear | Structured dresses, formal attire | Natural sheen, holds shape |

| Accessories | Bags, hats, scarves | Lightweight yet durable |

| Contemporary apparel | Blended textiles, statement pieces | Eco-friendly alternative |

| Traditional garments | Barong Tagalog, ceremonial clothing | Cultural authenticity |

Industrial and Commercial Products

Beyond the fashion runway, abaca fiber applications in textiles extend into heavy-duty industrial sectors. Rope manufacturing relies on its saltwater resistance, while paper production uses the fiber’s strength for specialty papers like tea bags.

You’ll also see automotive applications in interior panels, furniture components requiring durability, and geotextiles that prevent soil erosion. These fiber products showcase abaca’s versatility across demanding commercial environments.

Is Abaca Fabric Sustainable?

When you’re choosing sustainable fabrics, abaca stands out for good reason. This natural fiber brings environmental advantages that matter to both manufacturers and conscious consumers.

Let’s look at what makes abaca a genuinely eco-friendly choice.

Environmental Benefits

Abaca cultivation acts like a natural shield for tropical ecosystems, delivering measurable environmental benefits that extend far beyond fiber production. You’ll find that abaca’s deep root systems reduce soil erosion by up to 70% on sloped terrain, stabilizing watersheds and preventing landslides in vulnerable regions.

Here’s how this eco-friendly crop aids sustainability and ecosystem protection:

- Soil conservation: Abaca roots anchor soil, reducing sediment loss and enhancing water retention in tropical areas.

- Carbon sequestration: Mature abaca fields capture up to 22.7 tons of carbon per hectare annually, lowering the carbon footprint by 50% compared to synthetic alternatives.

- Deforestation reduction: Abaca fiber replaces wood pulp in specialty paper, preventing an estimated 30,000 hectares of forest loss annually.

- Biodiversity support: Plantations provide habitat for over 25 bird and mammal species per hectare, promoting ecosystem health.

- Circular economy contribution: Over 80% of processing offcuts become fertilizers or bio-composites, while biodegradable abaca products reduce plastic waste by 12,000 tons yearly.

Traditional production methods use 85% fewer chemicals than synthetic fiber manufacturing, making abaca fabric a genuinely sustainable, biodegradable textile choice.

Biodegradability and Recyclability

Once abaca fabric completes its lifecycle, it returns to the earth within 60 to 180 days, decomposing naturally without releasing harmful microplastics or toxic residues into soil or waterways. This biodegradability makes it ideal for circular economy models.

You can recycle production offcuts into mulch that enriches soil, while recycling methods transform worn fabric into paper products or bio-composites, cutting waste and conserving natural resources throughout the textile supply chain.

Natural Dyeing and Eco-Friendly Practices

When you choose natural dyes for abaca fabric—think indigo, turmeric, or crushed beetle shells—you’re not just picking colors; you’re preserving centuries-old techniques that eliminate synthetic chemicals from production streams.

These plant-based dyes require minimal water during the dyeing process, while biodegradable treatments and ethical sourcing practices increase the environmental benefits of abaca, creating truly eco-friendly textiles that support waste reduction from fiber to finished fabric.

Pros and Cons of Abaca Fabric

Like any textile material, abaca fabric comes with its own set of strengths and trade-offs that you should consider. Understanding these advantages and limitations helps you make informed decisions about when and how to use this natural fiber.

Let’s examine what makes abaca fabric stand out and where it falls short.

Durability and Strength

Few materials can match abaca fiber’s reputation as one of the strongest natural fibers in the world, a distinction that sets it apart in both traditional and modern applications. Its tensile strength surpasses many competing fibers, which means you’ll find abaca resists wear and tear exceptionally well.

This fiber strength translates to impressive abrasion resistance and water resistance, ensuring products maintain their integrity even under demanding conditions.

That’s why durability becomes such a defining characteristic—proper weaving techniques preserve fiber longevity, making abaca textiles reliable investments for applications requiring strong fibers.

Comfort and Texture

Despite its reputation for industrial toughness, abaca fiber surprises many with its soft, smooth texture that feels comfortable against the skin. The fiber properties include natural breathability factors, allowing air circulation that improves clothing comfort.

You’ll appreciate the tactile qualities—especially when abaca fabric uses finer weaves, which improve weave softness. This combination of skin feel and ventilation makes abaca fiber characteristics ideal for textiles where both durability and wearability matter.

Potential Challenges and Limitations

While abaca fabric offers impressive benefits, you’ll encounter real-world obstacles that affect its widespread adoption. Production costs run higher than synthetic alternatives, and fiber availability remains limited by cultivation regions.

Key production challenges include:

- Climate sensitivity restricts growing zones, creating supply chain issues

- Technical difficulties in scaling production beyond traditional methods

- Market competition from established synthetic fibers limits commercial expansion

These fiber challenges and future challenges require continued innovation to realize abaca’s full potential.

Frequently Asked Questions (FAQs)

What are the traditional colors used for dyeing abaca fabric?

Throughout Southeast Asia’s rainforests, cultural preservation thrives through regional color variations in abaca fiber handwoven fabrics.

Traditional dyeing methods create distinctive palettes—T’boli weavers use natural dye sources for red and black, achieving color symbolism through traditional textile techniques.

Can abaca fabric be easily blended with other materials?

Yes, abaca fabric blends well with other textile fibers. Blend compatibility depends on material properties and weaving techniques. Common pairings include cotton, silk, and synthetic fibers, offering blending benefits like enhanced durability and texture.

However, cost implications and processing methods affect feasibility in sustainable textiles production.

What are the potential drawbacks of using abaca fabric for clothing?

While often praised for its resilience, abaca fabric presents certain wardrobe challenges. Fabric stiffness can feel restrictive, and moisture absorption is limited compared to cotton.

Wrinkle resistance isn’t ideal, and dye limitations affect color variety. Additionally, production costs remain higher than conventional textiles.

How much does abaca fabric typically cost?

The retail pricing of abaca fabric varies considerably based on fiber quality, weaving complexity, and supply chain factors. Production costs influence market price, with finer grades commanding higher rates.

Generally, abaca fabric costs more than conventional textiles due to specialized fiber production and limited fiber market availability.

Where can I buy authentic abaca fabric?

You won’t believe the treasure hunt involved in sourcing authentic abaca material! Online retailers like Etsy and specialty textile sites offer abaca fabric products, while Philippine markets and local artisans provide direct access to traditional weaving.

For ethical sourcing and price comparison, connect with Filipino cooperatives specializing in abaca fiber production and uses.

Can abaca fabric be machine washed safely?

Machine washing abaca fabric depends on the weave and finish. Gentle cycles with mild detergent work best, but hand washing prevents shrinkage concerns and color fading.

Abaca fiber’s durability and water resistance help it withstand washing, though air drying preserves its properties better than machine drying.

Does abaca fabric wrinkle easily after washing?

Abaca fabric does wrinkle after washing, though its fiber structure provides moderate wrinkle resistance compared to other natural fibers. Ironing abaca works well to restore smoothness, and fabric blends can improve wrinkle performance while maintaining durability and water resistance.

The lignin content and weaving techniques influence how easily creases form.

What certifications exist for sustainable abaca fabric?

Currently, no universal certification specifically targets abaca fabric. However, you’ll find sustainable textiles validated through organic abaca standards like GOTS (Global Organic Textile Standard), fair trade abaca programs, and lifecycle assessment tools that verify ecofriendly fabric production.

Green abaca labeling from certification bodies ensures natural fibers meet sustainable materials benchmarks.

Conclusion

If every textile could sequester carbon while outlasting synthetic alternatives by decades, the fashion industry’s environmental crisis would vanish overnight. Understanding what’s abaca fabric reveals a material that delivers on both promises without compromise.

Its saltwater resistance, biodegradability, and steel-comparable strength position it as more than nostalgia—it’s a blueprint for responsible manufacturing.

When you choose abaca, you’re not just selecting durable fabric; you’re backing an ecosystem that regenerates soil, captures emissions, and proves sustainability doesn’t require sacrificing performance.

- https://www.merriam-webster.com/dictionary/cultivating

- https://docs.google.com/forms/d/1GAQr3Kn1cURCVHUA82hAga1Wv8DCH0IuqDLRUrOpN7M/viewform?ts=63f4f653&entry.1515682415=https://www.merriam-webster.com/dictionary%2Fabaca

- https://textileexchange.org/app/uploads/2024/09/Materials-Market-Report-2024.pdf

- https://www.grandviewresearch.com/industry-analysis/abaca-fiber-market

- https://www.coherentmarketinsights.com/industry-reports/abaca-fiber-market