This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Regular sewing thread lacks the sheen, smoothness, and flexibility that embroidery thread offers, which means you’ll face more breakage, duller designs, and potential tension headaches. Understanding the differences between these thread types helps you decide when to take the risk and when to reach for the real deal.

Table Of Contents

Key Takeaways

- Regular thread can technically work in embroidery machines, but it causes frequent breakage, tension problems, and duller designs because it lacks the sheen, smoothness, and flexibility of purpose-built embroidery thread.

- The key differences matter: embroidery thread uses continuous filament rayon or polyester with high sheen and 40-weight construction, while sewing thread offers 20-40% higher tensile strength but a matte finish that’s better suited for seams than decorative stitching.

- When using regular thread, you’ll need to adjust machine settings—loosen tension slightly, reduce stitch length, slow down speed, and match needle size to thread weight—to prevent jamming and improve stitch quality.

- For projects where appearance and durability matter, stick with 40-weight polyester embroidery thread, which delivers consistent results without constant troubleshooting and holds up better through repeated washing and wear.

Can You Use Regular Thread in Embroidery Machines?

You can technically use regular sewing thread in your embroidery machine, but it’s not always the best choice. The differences between thread types matter more than you might think, and understanding when regular thread works—and when it doesn’t—can save you frustration.

Let’s look at what sets these threads apart, situations where regular thread gets the job done, and problems you might run into.

Differences Between Sewing and Embroidery Thread

Sewing thread and embroidery thread differ mainly in composition, tensile strength, and appearance. Embroidery thread uses continuous filament rayon or polyester with a trilobal structure for high sheen and vivid colors, while sewing thread incorporates cotton, polyester, or core-spun blends with a matte finish.

Sewing thread offers 20–40% higher tensile strength and better durability. Thread weight also varies—embroidery thread generally comes in 40-weight, while sewing thread is often 50-weight for stronger seams.

Understanding the thread material composition is important for project success.

When Regular Thread is Acceptable

You might be surprised to learn that regular sewing thread can work in your embroidery machine—but only in specific situations. Simple projects like practice runs or hand embroidery transferred to machine work fine with sewing threads.

Cost savings matter for large-scale projects using cotton thread types. Blending threads creates unique texture effects on specific fabrics. Regular thread weight also works when embroidery thread density isn’t critical.

Potential Issues With Regular Thread

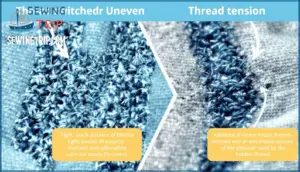

While regular thread can work sometimes, it often causes real headaches. Thread breakage happens frequently at high machine speeds because sewing thread isn’t built to withstand the friction. Tension problems and thread jamming occur when bobbin thread doesn’t match properly. You’ll notice stitch imperfections and thread fluff accumulating in your machine. Incorrect threading can also contribute to these issues.

Over time, this can lead to machine damage from excess lint buildup. Color fading also becomes an issue since sewing thread lacks the colorfast properties of embroidery thread.

How Thread Type Affects Embroidery Results

Your thread choice matters more than you might think. The type of thread you use directly affects how your embroidery looks, holds up, and performs on the machine.

Let’s break down the three key ways thread impacts your finished work.

Stitch Quality and Appearance

The thread you choose doesn’t just fill in your design—it shapes how crisp, vibrant, and professional those stitches actually look. Regular sewing thread often lacks the sheen and smooth finish that embroidery thread delivers, which can dull your design’s impact.

Thread fiber matters too—polyester resists thread fluff better than cotton, while tension settings affect stitch definition and texture effects across color blending areas.

Design Density and Coverage

When most embroidery designs are digitized, they assume you’re using 40-weight, 2-ply thread—so swapping to regular sewing thread can throw off the entire balance of fill density and pattern coverage. Regular thread’s finer diameter means more needle penetrations to achieve proper coverage, which can stress fabric stability and distort delicate designs.

Stitch Density Impact factors include:

- Thread weight effects directly alter how fills appear—thinner thread creates gaps where 40-weight would provide solid coverage

- Design digitizing factors don’t account for sewing thread’s reduced surface area per stitch

- Coverage adjustment tips involve reducing stitch density to prevent fabric puckering from excessive penetrations

- Design intricacy suffers when thread doesn’t match the programmed spacing

- Fabric distortion increases as compensating stitches multiply beyond original design intent

Durability and Longevity

Your choice between Thread Fiber types dramatically shapes how long your embroidered project survives everyday wear and tear. Polyester sewing thread outperforms rayon in Wash Resistance—holding vibrant colors past 50 launderings while rayon fades within 10-20 cycles.

Polyester thread outlasts rayon by holding vibrant colors past 50 washes while rayon fades within 10-20 cycles

Regular sewing thread struggles with durability under embroidery’s high-speed demands, increasing breakage rates by 40% and reducing lifespan below one year on heavily washed items.

Thread weight matters too: 40wt balances detail with Material Wear protection, while improper Stitch Density accelerates Color Fading and thread separation.

Adjusting Machine Settings for Regular Thread

When you switch to regular thread, your embroidery machine won’t automatically adjust itself to compensate. You’ll need to fine-tune a few key settings to prevent problems like thread breakage, tension issues, or poor stitch quality.

Here’s what you need to change to get the best results with non-embroidery thread.

Thread Tension and Stitch Length

Getting your tension and stitch length just right isn’t rocket science, but it can make or break your embroidery project. Regular thread often needs tension troubleshooting since it’s thicker than embroidery thread.

Here’s what you need to adjust:

- Loosen thread tension slightly to prevent thread breakage and puckering

- Reduce stitch length for better fabric stability with heavier thread size

- Test stitch regulation on scrap fabric to confirm thread compatibility

- Check bobbin threads match your top thread for balanced tension

Needle Selection for Different Threads

Your needle is just as important as your thread—pick the wrong one, and you’ll spend more time troubleshooting than stitching. Match your needle size to thread size and fabric thickness. Regular thread needs a larger eye size to pass through smoothly.

For woven fabrics, sharp point embroidery needles work best, while ballpoint needles suit knits. Your needle choice directly impacts thread compatibility and stitch quality.

Machine Speed and Thread Breakage

Cranking up the speed on your embroidery machine might seem like a time-saver, but it’s often the fastest route to snapped thread and ruined projects. Regular thread can’t withstand high speeds like embroidery thread can. Slow down to reduce tension problems and thread breakage.

Dense designs need even slower speeds—speed impact on thread quality is real, especially with heavier thread weight and improper needle choice.

Best Practices for Using Regular Thread

Using regular thread successfully isn’t just about making adjustments—it’s about building habits that protect your machine and keep your stitching smooth from start to finish. Start every project with test stitching on scrap fabric. This lets you check tension adjustment, needle and thread interaction, and overall stitch quality before committing to your final piece. Here are three habits that’ll save you headaches:

- Clean your machine regularly to prevent lint buildup that causes thread breakage with sewing threads

- Slow down your speed control when working with denser designs to reduce friction and heat

- Match your needle choice to both thread weight and type—a sharp needle works better for polyester sewing thread than a ballpoint

If you notice persistent breakage, try thread lubrication or switch to a larger needle size. Machine embroidery demands attention to these details, especially when you’re not using purpose-built embroidery thread.

Choosing The Right Thread for Your Project

Picking the right thread isn’t just about grabbing what’s on sale—it’s about matching thread characteristics to your specific project needs. Your fabric type, design complexity, and desired finish all play a role in thread selection.

Let’s break down the key factors that’ll help you make smart choices every time.

Comparing Thread Fibers and Weights

When choosing between fiber types, you’ll need to weigh sheen comparison against thread durability. Polyester thread offers better strength and longevity—lasting over a decade with proper care—while rayon delivers vibrant colors but weakens when wet. Cotton thread alternatives excel in heat resistance, perfect for items you’ll iron frequently.

Thread weight and type directly shape coverage: 40wt is standard, but 60wt needs denser stitching to avoid gaps.

Here’s a quick cost analysis:

| Fiber Properties | Weight Impact | Thread Durability |

|---|---|---|

| Rayon (high sheen) | 40wt standard | Weakens when wet |

| Polyester (moderate sheen) | 30wt/60wt options | 10+ years lifespan |

| Cotton (matte finish) | 50–80wt typical | Heat-resistant |

| Silk (lustrous) | Varies | 6 months–2 years |

| Cotton-poly blend | Thread size flexible | 2,000–6,000 cN strength |

Matching Thread to Fabric and Design

Pick the wrong thread for your fabric, and you’ll watch tight weaves pucker under heavy thread or delicate designs disappear into thick material.

Pair lightweight fabrics with 60wt thread and fine needles—dense weaves withstand 30wt without puckering.

Design thread needs shift with complexity: intricate details demand thinner thread weight, while bold patterns benefit from heavier options.

Always test fabric thread pairing and thread finish options before starting your full project.

Recommendations for Optimal Results

Once you know what works for your fabric and design, stick with 40wt polyester embroidery thread for most projects—it delivers consistent results without constant adjustments.

Run thread testing before big jobs, keep tension balance dialed in, and pair proper stabilizer usage with design adaptation. Regular machine maintenance prevents breakage, and choosing embroidery thread wisely—understanding thread weight and machine embroidery thread differences from sewing thread—makes all the difference.

The importance of thread selection can’t be overstated.

Frequently Asked Questions (FAQs)

Can I mix embroidery and sewing threads?

Mixing sewing thread with embroidery thread in a single project affects stitch density, aesthetic consistency, and durability. Blending thread types works for practical repairs, but machine embroidery demands uniform thread weight and tension for smooth results.

What happens if I use thick thread?

Thick thread causes design distortion and reduced detail because the extra bulk fills spaces too quickly. You’ll face tension problems and fabric stress from forced penetration, along with potential needle damage.

The needle and thread interaction becomes strained, and mismatched needle sizes for heavy thread weight create machine embroidery problems.

Does thread color affect embroidery machine performance?

Thread color doesn’t directly affect machine performance, but dye consistency and color vibrancy matter. Darker threads may have heavier dyes affecting thread lubrication and tension slightly.

Colorfastness impacts durability. Blending colors requires attention to thread tension and embroidery thread quality for best weaving results.

How do I test thread before starting?

Run test stitchouts on fabric scraps to check thread compatibility and tension adjustments. Monitor the needle and thread interaction, bobbin case performance, and thread weight performance.

Adjust machine maintenance settings if you notice issues with thread size or thread tension during testing.

Can I use metallic thread in place?

Yes, but metallic thread requires special attention. Machine compatibility issues arise because metallic thread properties—like stiffness and texture—cause friction. You’ll need a larger needle size, reduced machine speed, and adjusted stitch density.

Thread weight impacts design coverage, so alternatives like polyester with metallic finish work better for dense patterns.

Conclusion

What’s the point of having an embroidery machine if you can’t trust your thread to deliver? You can use regular thread in your embroidery machine when you’re in a bind, but it’s a compromise that shows in every stitch.

For projects that matter—where appearance, durability, and smooth operation count—dedicated embroidery thread makes all the difference. Think of it as choosing the right tool for the job: technically interchangeable, but one path leads to frustration while the other provides results you’ll actually want to keep.

- https://www.maggieframes.com/blogs/embroidery-blogs/how-many-threads-for-machine-embroidery-expert-guide-to-optimal-stitch-quality

- https://www.reddit.com/r/Machine_Embroidery/comments/1ln3g54/i_have_plenty_of_sewing_thread_would_it_work_for/

- https://maggieframestore.com/es/blogs/maggieframe-noticias/ultimate-guide-to-embroidery-thread-packs-for-machine-embroidery

- https://www.magnetichoop.com/blogs/news/embroidery-thread-vs-sewing-thread-unveiling-the-critical-differences

- https://absolutedigitizing.com/top-10-machine-embroidery-thread-brands-for-amazing-designs/