This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ll find knits in t-shirts and activewear because they’re flexible and comfortable, stretching with your body movements.

Wovens appear in dress shirts and jeans, offering durability and shape retention but limited stretch—only 20-30%.

Knits resist unraveling when cut, while wovens fray without hemming, and this construction difference affects everything from how garments fit to which sewing techniques work best for each fabric type.

Table Of Contents

Key Takeaways

- You’ll get up to 250% stretch from knit fabrics thanks to their interconnected loop construction, while woven fabrics only stretch 20-30% and maintain a rigid structure through perpendicular yarn interlacing.

- Knits won’t fray when you cut them because of their loop-based design, but woven fabrics will unravel at the edges and need hemming to prevent fraying.

- You should choose knits for comfort and movement – they’re perfect for t-shirts, activewear, and casual clothing that needs to move with your body.

- Woven fabrics give you durability and shape retention – they’re ideal for structured garments like dress shirts, jeans, and formal wear that need to hold their form.

Key Differences Between Knit and Woven Fabric

Two fundamental approaches define fabric construction in the textile world. When you’re choosing between knit vs woven materials, you’re basically picking between flexibility and structure.

Knit fabric uses interconnected loops of continuous yarn, creating natural stretch properties that allow garments to move with your body. This loop-based construction means knits don’t require traditional garment closures like zippers since they stretch enough for easy wear.

Woven fabric takes a different path through yarn interlacing, where threads cross at right angles to form a stable grid. This perpendicular structure eliminates stretch but provides excellent shape retention. You’ll notice woven fabrics have a fraying tendency when cut, unlike knits that resist unraveling due to their looped construction. Understanding the basics of plain weave characteristics helps to appreciate the stability of woven fabrics.

The difference becomes clear when you consider applications: knits excel in activewear and casual clothing, while wovens dominate structured garments like dress shirts and custom-made pieces.

How Knit Fabrics Are Made

When you look at knit fabrics under a microscope, you’ll see continuous loops of yarn interconnected like tiny chains that create the fabric’s signature stretch.

This loop-based construction differs completely from woven fabrics, making knits the go-to choice for comfortable, flexible garments that move with your body.

Loop-Based Construction Explained

Knit fabric construction revolves around continuous yarn forming interconnected loops through interlooping methods.

This loop formation creates the signature stretch and flexibility that distinguishes knit vs woven fabric construction.

Key elements of knit structures include:

- Loop formation – Single yarn creates interlocking loops horizontally and vertically

- Yarn properties – Continuous thread runs throughout entire fabric width

- Interlooping methods – Loops pull through previous row’s loops for stability

- Fabric density – Loop size determines fabric weight and stretch capacity

- Knit structures – Loops allow fabric to stretch while maintaining shape recovery

Types of Knit Fabrics (Jersey, Rib, Ponte)

Among knit fabric families, three standouts dominate the textile landscape.

Jersey knit offers lightweight breathability with natural stretch, making it perfect for t-shirts and dresses.

Rib knit features raised vertical lines and superior crosswise stretch, ideal for cuffs and waistbands.

Ponte knit provides structured stability with moderate stretch, excellent for jackets and fitted bottoms requiring professional appearance.

Other options like French terry are absorbent and suitable for activewear.

Manufacturing Processes and Equipment

Modern textile manufacturing transforms yarn into fabric through specialized equipment, with knit machinery operating at speeds exceeding 1,500 rpm while consuming 40% less energy than traditional woven looms.

Knit machinery revolutionizes textile production with lightning speed and remarkable energy efficiency.

Knit fabric production requires fewer manufacturing steps, making it 30% more time-efficient. Factory specialization determines whether facilities focus on knit structure or woven structure production.

To enhance production, consider investing in specialized knitting machines.

- Lightning-fast production speeds make your favorite t-shirts available faster than ever

- Energy-efficient processes reduce environmental impact while maintaining quality standards

- Streamlined manufacturing cuts production time, getting comfortable clothing to market quickly

- Specialized facilities guarantee expert handling of delicate knit fabrics throughout production

How Woven Fabrics Are Made

Unlike knit fabrics that use looped construction, woven fabrics are created by interlacing two separate sets of yarns at perfect right angles to form a stable grid structure.

This perpendicular weaving process produces fabrics with minimal stretch and exceptional durability, making them ideal for structured garments that need to maintain their shape.

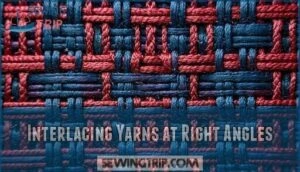

Interlacing Yarns at Right Angles

Understanding woven structure starts with visualizing perpendicular yarn interlacing.

Unlike knit structure’s interloping loops, woven fabric creates stability through two yarn sets crossing at right angles.

This yarn interlacing forms a grid-like foundation where horizontal weft threads weave over and under vertical warp threads.

These weaving patterns determine fabric stability and characteristics for countless woven applications. Many options exist, including natural and synthetic blends for optimized comfort.

Types of Woven Fabrics (Denim, Poplin, Broadcloth)

Several popular woven fabric types showcase the versatility of interlaced yarn construction.

Denim durability comes from its distinctive twill weave pattern, creating diagonal ridges that resist wear.

Poplin weave features tight plain construction with crosswise ribs, delivering crisp texture and breathability.

Broadcloth uses dense plain weaving for smooth surfaces ideal for formal shirts.

Each fabric type demonstrates how different weaving techniques affect fabric weight, texture, and fabric properties for specific applications.

Denim jeans were first invented by Levi Strauss and Jacob Davis in the 1870s, showcasing denim durability and the importance of fabric properties.

Weaving Methods and Machinery

Woven fabric production relies on sophisticated loom types that interlace yarns at precise right angles.

Modern weaving machines control yarn tension automatically while forming clean selvedge edges. Shuttleless looms achieve speeds exceeding 1,200 picks per minute, revolutionizing weaving techniques.

These automation advancements create complex weave structures without traditional needles, producing everything from lightweight poplin to heavy-duty canvas with remarkable precision and efficiency.

Many designs are available on modern fabric looms, showcasing the variety of designs.

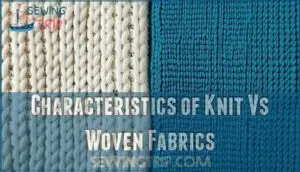

Characteristics of Knit Vs Woven Fabrics

You’ll notice significant differences when you compare knit and woven fabrics side by side. These characteristics affect everything from how your clothes fit to how they feel against your skin.

Stretch, Flexibility, and Recovery

Knit fabric stretch reaches up to 250% along the width thanks to interconnected loops, while woven fabric drape relies on rigid perpendicular yarns with only 20-30% stretch.

Your knits bounce back like a rubber band with 96-99% stretch recovery rates, but wovens lose up to 35% of their original shape after stretching.

Fabric weight, measured in GSM, affects drape and durability, so choose wisely.

Fabric characteristics matter when selecting materials.

| Property | Knit Fabric | Woven Fabric |

|---|---|---|

| Stretch Direction | Multi-directional (width & length) | Diagonal/bias only |

| Maximum Stretch | Up to 250% expansion | 20-30% without elastic |

| Recovery Time | Under 5 seconds | 15-20 seconds |

| Shape Retention | 1-2% permanent loss | Up to 8% after 10 cycles |

| Flexibility Score | 0.85/1.0 comfort index | 0.62/1.0 comfort index |

Structure, Shape Retention, and Durability

The fundamental architecture of these materials determines how they’ll perform in your projects.

Woven fabric delivers superior structural integrity through its tight interlaced construction, while knit fabric offers flexibility at the cost of some durability.

| Property | Woven Fabric | Knit Fabric |

|---|---|---|

| Fabric Stability | High dimensional stability | Prone to distortion |

| Weave Tightness | Dense, locked structure | Loose, flexible loops |

| Wear Resistance | Excellent abrasion resistance | Moderate durability |

| Shape Retention | Maintains crisp edges | Relaxed, flowing drape |

| Fiber Composition Impact | Less dependent on fiber choice | Relies heavily on fiber quality |

Appearance, Texture, and Finishing

Beyond structural differences, you’ll notice distinct visual and tactile qualities when examining these fabric types.

Surface texture varies dramatically between knit and woven materials, affecting both hand feel and fabric drape.

| Characteristic | Knit Fabric |

|---|---|

| Surface Texture | Smooth loops create soft, flexible surface |

| Visual Patterns | Uniform V-shaped stitches or ribbed lines |

| Fabric Drape | Flows and clings to body contours |

| Finishing Techniques | Minimal edge finishing; won’t fray |

| Characteristic | Woven Fabric |

| ——————- | —————— |

| Surface Texture | Firm, structured feel from interlaced yarns |

| Visual Patterns | Grid-like weave patterns clearly visible |

| Fabric Drape | Holds shape with crisp, defined lines |

| Finishing Techniques | Requires hemming to prevent fraying |

These fabric characteristics directly influence garment appearance and performance, helping you understand why certain knit advantages work better for casual wear while woven advantages suit structured clothing.

Choosing The Right Fabric for Your Needs

Selecting the right fabric type guarantees your garment will fit properly and function as intended throughout its lifetime.

Understanding whether you need knit or woven fabric affects everything from sewing techniques to the final garment’s performance and durability.

Best Uses for Knit Fabrics

When comfort matters most, knit fabric delivers unmatched versatility for your wardrobe.

You’ll find knit applications excel in comfort clothing like t-shirts, underwear, and pajamas where easy fit trumps structure.

The natural stretch makes knit advantages shine in active wear—leggings, athletic tops, and swimwear move with your body.

For cold weather layering garments, knitted sweaters and hoodies trap warmth while allowing flexibility underneath jackets, showcasing the natural stretch and comfort of knit fabric.

Best Uses for Woven Fabrics

Structured apparel benefits from woven fabric stability in formal wear like dress shirts and custom-made trousers.

Durable garments such as jeans rely on weaving structures for longevity. Home decor items like curtains and upholstery require woven applications for shape retention.

Industrial applications favor woven stability for strength and dimensional consistency in technical textiles. Canvas materials excel in heavy-duty applications including tote bags and outdoor gear, utilizing woven fabric for durability.

Practical Ways to Identify Fabric Types

You can identify fabric types through five reliable testing methods that don’t require special equipment or expertise.

- Stretch Test – Pull the fabric in different directions; knit fabric stretches easily while woven fabric remains rigid

- Thread Examination – Look for interconnected loops in knit fabric versus perpendicular criss-crossing yarns in woven fabric

- Wrinkle Resistance – Scrunch the material; knit fabric springs back quickly while woven fabric holds creases

- Texture Comparison – Feel the surface; knit fabric feels softer and more flexible than woven fabric’s structured feel

- Durability Assessment – Test fabric edges; woven fabric frays easily while knit fabric curls but doesn’t unravel

These fabric identification characteristics help determine proper sewing techniques.

For further assistance, consider verifying knit patterns to confirm correct fabric usage.

Impact on Garment Fit and Sewing Techniques

The fabric choice fundamentally shapes your garment’s behavior and construction approach.

Knit elasticity allows closer-fitting designs with minimal darts, while woven fabric durability demands structured shaping through seams and pleats.

Your needle selection and stitch types must match fabric properties for professional results.

| Fit Implications | Sewing Challenges |

|---|---|

| Knits hug curves naturally | Require ballpoint needles |

| Wovens need custom shaping | Use stretch stitches carefully |

| Knits accommodate size variations | Prevent seam rippling |

| Wovens maintain crisp structure | Handle fabric distortion |

Frequently Asked Questions (FAQs)

Can knit fabrics be used for formal wear?

Yes, you’ll find knit fabrics work wonderfully for formal wear when chosen thoughtfully. Ponte, fine gauge knits, and jersey blends offer sophistication while maintaining comfort and movement for professional settings.

Do woven fabrics require special washing instructions?

Ironically, woven fabrics often need gentler care than their stretchy knit counterparts.

You’ll typically need cooler water temperatures, delicate cycles, and careful drying to prevent shrinkage and maintain their structured shape.

Which fabric type is better for beginners?

Woven fabrics work better for beginners because they’re more stable during sewing, don’t stretch unexpectedly, and forgive mistakes easier than stretchy knits that require special techniques.

Are knit fabrics more expensive than woven?

Money talks, but fabric costs depend on several factors.

You’ll find knit prices vary widely based on fiber type, construction complexity, and manufacturing processes.

Generally, basic knits cost less than premium wovens, but high-end knits exceed many woven prices.

Can you mix knit and woven in garments?

Absolutely, you can combine knit and woven fabrics in a single garment.

This mixing technique creates interesting contrasts in texture, drape, and functionality.

Consider using woven fabric for structured elements like collars, cuffs, or waistbands, while incorporating knit panels for comfort and stretch in areas requiring movement.

Conclusion

Understanding the difference between knit and woven fabric empowers you to make smarter textile choices, whether you’re shopping like a medieval merchant selecting the finest cloth or simply picking workout gear.

Knits offer unmatched flexibility for active lifestyles, while wovens provide structure for professional attire.

You’ll save time and money by choosing the right construction for your needs. Remember: knits stretch, wovens don’t.

This fundamental difference between knit and woven fabric affects everything from comfort to durability in your wardrobe decisions, emphasizing that knits and wovens have distinct properties.