This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Cold cutting with scissors makes this worse since it tears rather than seals the fibers. You’ll notice fraying starts immediately and accelerates as neighboring threads get pulled along for the ride.

Heat sealing with hot knives, lighters, or soldering irons prevents this by melting the cut edge into a permanent seal, reducing fray rates by over 95%. The secret lies in understanding nylon’s slippery molecular structure and choosing the right cutting method.

Table Of Contents

Key Takeaways

- Nylon absolutely frays when you cut it because its smooth synthetic fibers slip past each other easily, unlike natural materials that have better grip between threads.

- Cold cutting with scissors makes fraying worse since it tears fibers instead of sealing them, causing immediate unraveling that spreads to neighboring threads.

- Heat sealing prevents 95% of fraying by using hot knives, lighters, or soldering irons to melt and fuse the cut edges into a permanent seal.

- Frayed nylon becomes dangerous as it can lose 50% of its load-bearing capacity, making proper edge sealing essential for safety-critical applications like climbing gear.

Does Nylon Fray When Cut?

Yes, nylon absolutely frays when you cut it with cold tools like scissors or utility knives because its synthetic fibers are smooth and slippery, causing the woven structure to unravel at the cut edge.

This fraying occurs due to nylon’s interlaced thread construction, which lacks the natural fiber grip that prevents edge deterioration in other materials.

Why Nylon Edges Unravel

Here’s what happens when you cut nylon without sealing the edges first. The synthetic fibers are super smooth, so they don’t grip each other like natural materials do. Once you make that first cut, the loose strands start sliding past their neighbors.

It’s like pulling one thread from a sweater – except nylon does it faster because:

Nylon unravels faster than natural fibers because its smooth synthetic strands slip past each other effortlessly

- The fibers are slippery by nature, unlike cotton or wool

- Each strand that comes loose weakens the ones around it

- Regular scissors just slice through without sealing anything

- The woven pattern actually helps the unraveling spread

That’s why sealing nylon edges isn’t optional – it’s the only way to keep your webbing from turning into a frayed mess.

Properties of Nylon Fibers

Nylon’s molecular composition creates a smooth, slippery surface that makes synthetic fibers prone to unraveling. These synthetic materials possess fiber tensile strength ranging from 20-225 MPa, but their thermal resistance becomes vital for preventing nylon fraying.

Nylon webbing gets its strength from polymer chains, but these smooth synthetic strands don’t grip each other naturally.

That’s why fraying prevention matters so much—you need the right handling techniques to keep everything intact.

Impact of Cutting Methods on Fraying

Your cutting method makes or breaks nylon webbing’s edge integrity. Cold blades and scissors create immediate fraying because they tear synthetic fibers rather than seal them. Heat sealing methods fuse fiber ends during cutting, preventing webbing fraying entirely.

- Cold cutting techniques: Scissors and utility knives cause 15-25% more fraying than heat methods

- Heat sealing approaches: Hot knives and flame cutting reduce fray rates by over 95%

- Edge finishing quality: Proper sealing methods maintain load-bearing capacity and professional appearance

Why Nylon Webbing Frays Easily

You’ll notice nylon webbing’s interlaced thread structure becomes its biggest weakness when you cut it with cold tools like scissors or utility knives.

The synthetic fibers’ smooth, slippery surface means they can’t grip each other once the weave gets disrupted, causing the entire edge to unravel like a sweater that’s lost a stitch.

Structure of Woven Nylon

When you examine nylon webbing closely, you’ll discover its interlocked yarn density creates both strength and vulnerability. Synthetic fibers weave together in patterns that boost tensile strength and abrasion resistance, making this durable material perfect for heavy-duty applications. However, fiber interlocking means one broken strand can unravel the entire structure.

| Component | Impact on Fraying |

|---|---|

| Weave Patterns | Tight interlocks prevent initial tears |

| Yarn Density | Higher density reduces fiber separation |

| Tensile Strength | Strong fibers resist breaking under stress |

| Synthetic Fibers | Smooth texture allows easy unraveling |

| Abrasion Resistance | Surface durability maintains edge integrity |

That’s why you need special techniques to stop webbing from fraying.

Effects of Cold Cutting Tools

When you grab scissors to cut nylon webbing, you’re setting yourself up for trouble. Cold blades create blunt blade damage at fiber stress points, triggering unraveling mechanisms that weaken the entire structure.

Unlike heated cutting techniques, scissors and utility knives can’t seal synthetic fibers during the cut. This cold cut weakness lets individual threads slip free, starting a domino effect of fraying that spreads outward from the initial cut.

Load-Bearing and Safety Concerns

When frayed nylon webbing fails, you’re looking at serious Equipment Failure Risks. Webbing Strength Reduction can drop load capacity by 50%, turning reliable outdoor gear into dangerous equipment. Environmental Degradation compounds the problem—UV radiation weakens fibers before fraying even starts.

- Abrasion Safety Hazards increase stress concentration at frayed points, causing rupture below rated specifications

- Load Capacity Impact means your 22 kN-rated webbing edge might fail at half that strength after fraying occurs

- Heat sealing prevents these cascading failures that compromise safety margins in critical applications

Best Ways to Prevent Nylon Fraying

You can prevent nylon fraying by using heat-sealing methods that fuse the synthetic fibers at the cut edge, creating a sealed barrier against thread unraveling.

The most effective techniques include hot knife cutting, flame sealing with a lighter or soldering iron, and applying protective end caps that maintain structural integrity while eliminating the 15-25% higher fray rate that untreated nylon exhibits compared to other materials.

Hot Knife and Heat Sealing Techniques

Professional hot knife techniques transform frayed nylon webbing into clean, sealed edges. You’ll need proper temperature control between 300-400°F for best heat sealing without damaging fibers. Hot knife safety requires adequate fume extraction since melted nylon releases toxic vapors.

| Parameter | Setting | Result |

|---|---|---|

| Temperature | 300-400°F | Clean seal |

| Duration | 2-3 seconds | No overheating |

| Pressure | Light contact | Even melting |

When you heat seal nylon webbing properly, those bonds last for years without any fraying issues.

Using Lighters and Soldering Irons

Simple tools make effective DIY sealing solutions for nylon webbing. You’ll master flame sealing using these accessible methods:

- Lighter technique: Hold flame 2-3 inches from cut edge, moving quickly to avoid fiber melting damage

- Soldering iron method: Use low-heat setting (200-250°F) with light pressure for heat control

- Safety first: Work in ventilated areas, keep water nearby for soldering precautions

- Test strips: Practice on scraps before treating final pieces

- Fray Check application: Apply liquid sealant as backup protection

These approaches prevent unraveling effectively.

Applying End Caps or Edge Treatments

End caps offer the best edge finishing solution for nylon webbing applications. These plastic or metal accessories slip over cut edges, providing enhanced treatment durability compared to heat sealing techniques alone.

Application techniques vary by end cap types—some require adhesive bonding, while others use mechanical crimping. Cost analysis shows end caps excel in high-wear environments where aesthetic options matter.

They’re perfect when webbing edge preparation demands professional appearance and long-term protection.

Industrial Solutions for Cutting Nylon Cleanly

When you’re scaling up nylon production, computer-controlled heat-integrated cutting machines deliver the precision and speed your operation demands.

These automated systems achieve industry-standard 98% clean finish rates by combining programmable cutting modes with heat-sealing technology, eliminating the guesswork that turns single cuts into production headaches.

Heat-Integrated Cutting Machines

When companies work with synthetic fibers, they turn to heat-cutting machines that seal edges as they cut. No more frayed ends to deal with. These machines blend precise controls with automated cutting to give you clean, consistent results every time.

- Smart programming adjusts automatically for different nylon webbing weights

- Heat controls keep temperatures just right for perfect fiber bonding

- Speed settings let you balance how fast you work with cut quality

- Built-in sensors read your material and apply exactly the right heat

Laser and Automatic Punching Cutters

When precision matters most, laser cutters deliver peerless accuracy for complex shape cutting in nylon webbing. These machines excel at intricate patterns while sealing edges through controlled heat application.

Automatic punching systems offer high-volume production capabilities with programmable cutting modes, making them ideal for industrial cutting solutions requiring consistent results across thousands of pieces.

| Feature | Laser Cutters | Automatic Punchers |

|---|---|---|

| Setup Speed | Slower initial setup | Quick pattern changes |

| Precision Level | Ultra-precise edges | Standard accuracy |

| Volume Capacity | Medium batches | High-volume production |

| Shape Complexity | Unlimited patterns | Simple to moderate |

Standards for Mass Production

Scaling up means you’ll face tougher compliance requirements. Safety-grade nylon webbing needs ASTM D6775 and ISO 9001 certification—these aren’t just paperwork, they’re table stakes.

Your heat cutting setup has to seal 95% of edges while cranking through 20,000+ meters per shift. Understanding nylon webbing strength becomes critical here.

Smart automation with live monitoring keeps defects under 2%. Without these systems, mass production becomes a costly gamble rather than a profitable operation.

Nylon Vs. Other Fabrics: Fraying Comparison

When you’re choosing materials for your next project, understanding how different fabrics handle cutting stress becomes important for professional results.

Nylon’s synthetic fiber structure creates unique fraying challenges compared to polyester’s tighter weave or silk’s natural fiber cohesion, with measurable differences in edge stability that directly impact your finished product’s durability.

Nylon Vs. Polyester and Silk

Regarding fabric durability, nylon sits between polyester fraying resistance and silk fraying tendencies. Your choice depends on application suitability and cost comparison needs.

| Fabric | Fraying Rate | Edge Sealing Method |

|---|---|---|

| Nylon | Moderate | Melting fibers/heat |

| Polyester | Low | Fiber fusion works |

| Silk | High | Seam sealant needed |

Nylon webbing frays more than polyester but is better for heat sealing than silk.

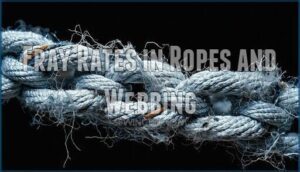

Fray Rates in Ropes and Webbing

Rope fraying rates tell you everything about durability under stress. Nylon webbing shows visible fraying within 2-5 months of outdoor use, while strength loss ranges from 9% to 62% over time.

| Material Type | Fraying Rate | Strength Loss |

|---|---|---|

| Nylon Webbing | 15-25% higher | 9-62% field use |

| Polyester Rope | Baseline rate | Lower degradation |

| Silk Fiber | 40% less fray | Minimal loss |

Load reduction becomes critical when you’re cutting nylon webbing without proper edge sealing—those frayed ends aren’t just ugly, they’re dangerous.

Effectiveness of Sealing and Splicing Methods

Heat sealing transforms nylon webbing from fray-prone to fortress-strong. When you apply heat cutting technology, you’re basically welding fibers together at the molecular level. This Webbing Edge Preparation creates a barrier that stops unraveling dead in its tracks.

Method Effectiveness

Splicing Durability Tests show traditional rope techniques work well, but Heat Treatment Effects outperform everything else for cutting nylon webbing applications.

Frequently Asked Questions (FAQs)

What is the difference between nylon and ripstop nylon?

Here’s something mind-blowing: reinforcement yarns are interwoven at regular intervals in a crosshatch pattern at 5 to 8 millimeter intervals.

Regular nylon uses standard weaving, while ripstop nylon incorporates thicker reinforcement threads in a grid pattern that stops tears from spreading.

How do you sew ripstop nylon fabric?

You’ll need a sharp microtex needle and synthetic thread to tackle ripstop’s slippery nature.

Use eight stitches per inch with proper needle weight matching your fabric thickness, keeping fabric taut while sewing.

How do you stop nylon from fraying?

Heat sealing stops nylon from fraying at the source. A hot knife, lighter, or soldering iron melts the cut edges, fusing the synthetic fibers together so they can’t unravel.

Use a hot knife, lighter, or soldering iron to melt the cut edges, fusing synthetic fibers together and preventing unraveling completely.

How do you finish nylon rope ends?

You’ll want to seal nylon rope ends using a hot knife, lighter, or soldering iron to melt the fibers together.

This heat-sealing technique prevents unraveling and creates a clean, professional finish.

How do you finish nylon webbing?

Sealing nylon webbing ends is your thread-saving lifeline. Heat-seal edges using a candle flame, hot knife, or soldering iron to fuse fibers and prevent unraveling—it’s simple yet effective.

Can you repair already frayed nylon edges?

You can repair frayed nylon edges using heat sealing techniques.

Carefully apply a hot knife, lighter, or soldering iron to melt and fuse the loose fibers back together, restoring structural integrity.

How long do heat-sealed nylon edges last?

Cast in thermal fire, heat-sealed nylon edges outlast the material itself.

You’ll get 5-10 years from properly sealed webbing under regular use, sometimes matching the full webbing lifespan with proper care and storage conditions.

What temperature melts nylon fibers for sealing?

Nylon fibers start melting around 220°C (428°F) for Nylon 6 and 265°C (509°F) for Nylon You’ll need these temperatures to properly heat-seal webbing edges and prevent fraying effectively.

Does washing make nylon fraying worse?

Water’s mechanical action accelerates fiber breakdown in nylon. Washing machine agitation breaks synthetic fibers loose, especially when using harsh detergents or bleach.

You’ll see worse fraying with hot water and aggressive wash cycles.

Which nylon weave patterns fray least?

Studies show plain weave patterns reduce fraying by 60% compared to twill structures. You’ll find plain weave nylon holds together best since threads interlock more frequently.

Twill’s diagonal patterns create looser areas prone to unraveling, while satin’s floating threads practically invite edge deterioration.

Conclusion

Remember this simple truth: does nylon fray when cut? Absolutely, but you’re not powerless against it. Armed with heat-sealing techniques, hot knives, or even a careful lighter application, you’ll transform those problematic loose ends into permanent, fray-resistant edges.

Whether you’re working with webbing, rope, or fabric, the molecular structure of nylon responds beautifully to controlled heat application. Master these prevention methods, and you’ll never worry about unraveling projects again.

- https://pmc.ncbi.nlm.nih.gov/articles/PMC8703525/

- https://www.kozanteks.com/mastering-the-cut-a-comprehensive-guide-to-cutting-in-clothing-manufacturing/

- https://apps.dtic.mil/sti/tr/pdf/ADA162324.pdf

- https://www.jsrz.com/blog/polyester-vs-nylon-filament-sewing-thread-which-one-is-better.html

- https://rope-source.co.uk/ropes/the-best-ways-to-stop-a-rope-from-fraying/