This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your rotary cutter glides across the fabric, slicing through three layers at once. But instead of a clean cut, you get a jagged edge and a damaged dining room table underneath. Without a proper cutting mat, even the sharpest blade won’t give you the precision quilting demands.

Fabric cutting mats for quilting do more than protect your furniture—they keep your cuts straight, your measurements accurate, and your blades sharper for longer. The right mat transforms your cutting station from frustrating to efficient, whether you’re trimming half-square triangles or squaring up an entire quilt top.

Table Of Contents

- Key Takeaways

- Best Fabric Cutting Mats for Quilting

- Key Features of Quilting Cutting Mats

- Benefits of Using Cutting Mats in Quilting

- Types of Cutting Mat Materials

- Choosing The Right Cutting Mat Size

- Understanding Measurement Grids and Markings

- Rotary Cutter Compatibility and Safety

- Proper Maintenance and Care for Cutting Mats

- Comparing Price Ranges and Brands

- Essential Quilting Tools to Use With Cutting Mats

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- A quality self-healing cutting mat protects your work surface, keeps rotary blades sharper longer, and delivers the precision quilting demands through built-in measurement grids and non-slip backing.

- Size matters—most quilters find the 24″ x 36″ mat hits the sweet spot for cutting full-width fabric without hogging your entire workspace, though larger projects may need bigger surfaces.

- The best mats use layered PVC construction that actually closes up after cuts, maintaining a smooth surface through thousands of slices while keeping grid lines visible for accurate measurements.

- Store your mat flat away from heat and sunlight to prevent warping, and replace it when deep gouges won’t heal or grid lines fade—typically after 2-5 years of regular use.

Best Fabric Cutting Mats for Quilting

You need a cutting mat that can keep up with your quilting projects without showing every mark and slice. The right mat protects your table, keeps your cuts accurate, and lasts through countless fabric layers.

Here are four proven options that quilters trust for their workspaces.

1. Olfa Self Healing Rotary Cutting Mat

The Olfa Self-Healing Cutting Mat provides a generous 24″ x 36″ workspace, featuring measurement grids that enhance cutting accuracy. Its self-healing surface reseals after each rotary cutter pass, protecting blade sharpness and extending mat durability.

The green mat with yellow grid lines ensures clear visibility, while its 1.5mm thickness offers a lightweight yet stable design. One side is tailored for quilting tools, and the other side handles general cutting tasks.

Mat maintenance remains straightforward, and user safety is enhanced by the non-slip backing, which keeps the mat steady during tricky diagonal cuts.

| Best For | Quilters, sewers, and crafters who need a large workspace for cutting multiple fabric layers with rotary tools and want precise measurements built right in. |

|---|---|

| Size | 24″ x 36″ |

| Self-Healing | Yes |

| Double-Sided | Yes |

| Grid Lines | Yes |

| Material | Not specified |

| Weight | 2.3 lbs |

| Additional Features |

|

- Self-healing surface keeps the mat smooth and extends the life of your rotary blades by resealing after cuts

- Double-sided design with grid lines on one side for accurate measuring and a plain side for general cutting

- Large 24″ x 36″ size gives plenty of room for big fabric pieces and quilting projects

- Some users report an unpleasant chemical smell when first unpacked

- The mat can warp if not stored flat and away from direct sunlight or heat

- Cut marks may start to show over time with heavy use, and the 1.5mm thickness feels thin to some customers

2. Fiskars Self Healing Cutting Mat

When you need an extra-large workspace, the Fiskars 24″ x 36″ Self Healing Cutting Mat gives you room to handle full-width fabric and long strips without repositioning.

This eco-friendly mat features double-sided durability with clear measurement grids and 30, 45, and 60-degree bias lines for cutting accuracy. Made from flexible polypropylene, it works seamlessly with your rotary cutter while protecting both your blade and table.

The lifetime warranty from Fiskars backs their quality commitment, though some quilters note the grid markings can wear with heavy use.

| Best For | Quilters and sewers who need a generous workspace for cutting full-width fabric, long strips, or large pattern pieces with precision. |

|---|---|

| Size | 24″ x 36″ |

| Self-Healing | Yes |

| Double-Sided | Yes |

| Grid Lines | Yes |

| Material | Polypropylene |

| Weight | 2.06 lbs |

| Additional Features |

|

- Extra-large 24″ x 36″ surface handles big projects without constant repositioning

- Double-sided design with clear grids and angle lines extends usability and lifespan

- Backed by a full lifetime warranty from Fiskars

- Grid markings and numbers can fade or rub off with regular use

- Some users experience fabric slippage during cutting

- May feel too hard or brittle compared to other cutting mats

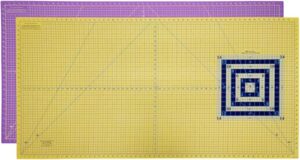

3. Martelli Self Healing Cutting Mat

For serious quilters who work with full-width fabrics, the Martelli 30″ x 60″ Self-Healing Cutting Mat delivers outstanding workspace. This double-sided mat features color-contrasting grids that boost cutting accuracy and work for both left and right-handed quilters.

The self-healing PVC surface maintains blade longevity through thousands of cuts, while the measurement indicators and block guide simplify your quilting efficiency. At 12 pounds, it stays put during rotary cutter use. The stain-resistant material simplifies mat maintenance—just wipe with a damp cloth.

Some quilters find it pricey, but frequent users appreciate the durability.

| Best For | Quilters and fabric designers who regularly work with full-width fabrics and need a large, durable workspace for precise cutting projects. |

|---|---|

| Size | 30″ x 60″ |

| Self-Healing | Yes |

| Double-Sided | Yes |

| Grid Lines | Yes |

| Material | Plastic |

| Weight | 12 lbs |

| Additional Features |

|

- Extra-large 30″ x 60″ surface accommodates standard fabric widths and provides generous workspace for big projects

- Self-healing PVC surface resists cut marks and extends rotary blade life through thousands of cuts

- Double-sided design with color-contrasting grids and measurement guides works for both left and right-handed users

- Higher price point compared to standard cutting mats on the market

- May arrive rolled and require time to flatten, with potential for waves or warping over time

- Heavy at 12 pounds, making it less portable for classes or workshops

4. Dahle Self Healing Cutting Mat

The Dahle 36″ x 48″ Self-Healing Cutting Mat brings professional-grade performance to your quilting space. Its 5-layer PVC construction withstands rotary cutter abuse while protecting your work surface and maintaining blade sharpness through thousands of cuts.

You’ll find inch, metric, and angled guides screened right on the surface for cutting efficiency. At 11 pounds, this mat stays anchored during use—critical for user safety. The self-healing surface repairs minor cuts, though deeper grooves may remain visible over time. Hand wash only for proper mat maintenance.

| Best For | Quilters and crafters who need a large, durable work surface that can handle heavy rotary cutter use while keeping blades sharp and workspace protected. |

|---|---|

| Size | 18″ x 24″ |

| Self-Healing | Yes |

| Double-Sided | Yes |

| Grid Lines | Yes |

| Material | Polypropylene |

| Weight | 1.1 lbs |

| Additional Features |

|

- Five-layer self-healing construction stands up to repeated cuts without developing permanent grooves that throw off measurements

- Built-in grid with multiple measurement systems (inch, metric, and angles) eliminates the need for separate rulers during layout

- Heavy 11-pound weight keeps the mat firmly in place during cutting, reducing slips and improving safety

- May arrive with creases or folds that take time to flatten out completely

- Deeper cuts can leave visible marks even with the self-healing surface

- Requires hand washing only and can show stains over time, especially compared to darker mats

Key Features of Quilting Cutting Mats

You want a cutting mat that works as hard as you do. The right features make all the difference between frustration and freedom at your cutting table.

Let’s look at what separates a great quilting mat from one that’ll just gather dust in your craft room.

Self-healing Surface Technology

Think of self-healing cutting mats as your workhorse with built-in recovery powers. The surface uses tiny micro-cells that snap shut after your rotary cutting passes through.

This healing process keeps fabric cutting smooth across hundreds of cuts without deep gouges. Quality cutting mat materials bounce back fast, preserving surface durability and mat longevity.

Your blade interaction stays consistent, meaning cleaner cuts every time.

Durable Material Composition

Your cutting mat’s material durability determines whether it lasts five projects or five years. Self-healing cutting mats rely on layered PVC or PVC alternatives that give your blade somewhere soft to land while maintaining cutting mat thickness for stability.

- Self healing technology in quilting cutting mats uses bonded construction—soft surface with rigid backing prevents warping

- High-density polyethylene (HDPE) offers material handling advantages with better edge wear resistance over time

- Eco friendly options now include recycled-content formulations, though durability metrics can vary by brand

- Cutting mat thickness of 1/4 to 1/2 inch provides the sweet spot between portability and longevity

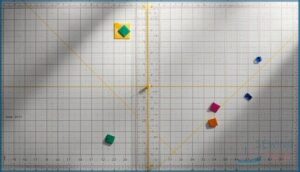

Grid Lines and Measurement Markings

Precision starts with readable grid lines—you’ll find 1-inch intervals on standard cutting mats, often broken into 1/8-inch and 1/4-inch subdivisions for quilting essentials like binding strips. High-contrast markings guarantee measurement accuracy under any lighting.

Look for diagonal cutting guides at 45 and 60 degrees for bias cuts, plus centerlines that help with ruler alignment during rotary cutting. Grid accuracy matters when your seam allowances demand flawlessness.

Non-slip Backing and Stability

Your mat won’t budge during cuts if it has proper non-slip backing. Textured rubber or silicone grip testing confirms slip resistance on glass and wood surfaces—critical for mat stabilization when your rotary cutter applies pressure.

Check that backing materials on self-healing cutting mats provide edge security without damaging your workspace. Quilting cutting mats with quality non-slip backing stay planted through every fabric pass.

Benefits of Using Cutting Mats in Quilting

A good cutting mat does more than sit on your table. It actually transforms how you work with fabric and tools, making every step smoother and more precise.

Let’s look at the specific ways a quality mat improves your quilting projects.

Protecting Work Surfaces

Your table deserves better than blade scars and gouges. A self-healing cutting mat acts as armor for your work surface, absorbing every rotary cutter pass without transferring damage below.

The non-slip backing keeps your quilting board stable while the mat’s cushioning prevents blade depth penetration.

Proper workspace optimization means damage prevention that preserves your furniture’s finish through thousands of cuts.

Extending Rotary Blade Lifespan

Your rotary blades will thank you for investing in a quality self-healing cutting mat. These surfaces distribute cuts across tiny flexible materials, preserving blade sharpness far longer than hard tabletops.

Proper mat maintenance and clean rotary cutting techniques prevent abrasive buildup that dulls edges. This tool optimization means fewer blade replacements and better precision cutting throughout your quilting projects.

By ensuring the accuracy of our scientific study methods, we can better understand the importance of proper tool maintenance.

Preventing Fabric Slipping

Keeping your fabric in place makes all the difference when you’re chasing precision cutting. Quality self-healing cutting mats deliver slip resistance through textured surfaces and nonslip backing that boost fabric stability by 15–40%.

Here’s how to optimize fabric grip:

- Use gridded mat texture to anchor your material

- Keep your surface clean for consistent fabric visibility

- Pair sharp rotary cutting blades with proper backing

- Add clips on slippery fabrics like satin

Improving Cutting Accuracy

Precision cutting transforms your quilting when you trust accurate mat grid lines. Studies show that high-contrast markings improve alignment and reduce miscuts by 20 percent. Sharp rotary cutting blades paired with proper fabric tension deliver measurement accuracy you can count on.

| Cutting Techniques | Accuracy Tips |

|---|---|

| Mat calibration checks | Verify grid alignment monthly |

| Blade sharpness testing | Replace after 8-10 projects |

| Fabric tension control | Press flat before cutting |

| Precision cutting setup | Use non-slip backing always |

| Rotary cutting practice | Cut away from body steadily |

Your fabric cutting techniques improve as your cutting mat maintains its uniform surface texture.

Types of Cutting Mat Materials

Not all cutting mats are created equal in terms of material. The surface you choose affects everything from how well your blade glides to how many years your mat will last.

Let’s break down the three main materials you’ll encounter so you can pick the right one for your quilting style.

Self-healing PVC Mats

Most self-healing cutting mats you’ll find are made from PVC material, and there’s good reason for that. The healing process works because the PVC formulation creates a surface that closes up after your rotary cutting passes through.

You’ll notice better cutting accuracy on this smooth base, and the surface durability holds up through years of quilting projects without deep gouges affecting your work.

Polyurethane and Polyester Options

Beyond standard PVC, you can upgrade to polyurethane or polyester cutting mats for serious quilting work. Polyurethane surfaces resist razor cuts better and handle temperature changes without warping, giving you reliable edge stability.

The material comparison shows polyester blends offer lighter profiles with solid cutting resistance. These premium options improve surface durability for rotary cutting, though they’ll cost more than basic self-healing cutting mat choices in quilting tools and supplies.

High-density Polyethylene Mats

HDPE material brings lightweight durability to your quilting workspace. High-density polyethylene mats resist warping and provide uniform cutting surfaces for rotary cutters without excessive blade dulling.

You’ll appreciate the polyethylene benefits: good impact resistance, flat stability, and compatibility with standard quilting tools and supplies. While not technically a self-healing cutting mat, HDPE surfaces withstand repeated cuts.

Regular HDPE maintenance with mild soap preserves grid visibility and extends mat durability for precise fabric work.

Choosing The Right Cutting Mat Size

Picking the right mat size can make or break your quilting workflow. You need enough space to cut comfortably without cramping your style, but you also don’t want a giant mat hogging your workspace.

Let’s look at the most popular sizes and how to match one to your setup.

Common Mat Sizes for Quilters

Your cutting mat size directly impacts your cutting efficiency and fabric management. Most quilters gravitate toward the 24 by 36 inch mat—it’s the sweet spot for quilting cutting mats, offering ample room for long strips without hogging your entire table.

Need something more portable? The 18 by 24 inch self-healing cutting mat manages most blocks while traveling to guild meetings.

Larger projects? Go bigger. Your quilter preferences and fabric cutting workflow will guide you.

Workspace Considerations

Your table height matters more than you might think for an ergonomic setup. A dedicated cutting area at least 24 by 36 inches accommodates your self-healing cutting mat and quilters workspace and organization essentials.

Consider these workspace lighting and fabric cutting and handling factors:

- Position your mat under bright 4000K lighting for clear grid visibility

- Keep ventilation systems running to minimize dust during quilting

- Store rulers within arm’s reach using storage solutions

- Follow safety protocols by maintaining clear paths around your cutting zone

Portability and Storage Options

Traveling to a quilting retreat or workshop? Smaller mats between 12×18 inches slip easily into your tote bag. Some brands offer folding mats or multi-panel designs that reduce bulk during transport. Travel cases protect your self-healing cutting mat from warping in the car.

Always store mats flat at home to prevent edge curling. Portable sizes sacrifice workspace but gain convenience for quilters on the move.

Understanding Measurement Grids and Markings

The grid lines and markings on your cutting mat aren’t just decoration—they’re your roadmap to precision cuts every single time. Understanding what those numbers, angles, and lines actually mean will transform how you work with fabric.

Let’s break down the key markings you’ll encounter so you can use your mat like a pro.

Inch Vs. Centimeter Grids

You’ll find most cutting mats come with either inch or centimeter grids, and your choice matters more than you’d think. Inch grids mark down to 1/16-inch intervals, perfect for U.S. fabric yardage and standard quilting measurements. Metric conversion becomes unnecessary when your patterns and rulers already match.

- Inch grids align naturally with American quilting standards and rotary cutting techniques

- Centimeter grids work best for international patterns and metric-based designs

- Grid visibility depends on mat color contrast and line thickness for measurement accuracy

Diagonal and Angle Guidelines

Your mat’s diagonal lines are your secret weapon for bias binding and triangle cuts. Most self-healing cutting mats print 30, 45, and 60-degree angle measurements right into their measuring grids, giving you instant grid precision without extra tools.

That 45-degree line manages standard squares perfectly, while the 30 and 60-degree marks tackle diamonds and angled cutting with real accuracy. Mat calibration stays consistent because these diagonal cutting guides won’t wear off.

Visibility and Clarity of Markings

High Contrast Mats make a real difference when you’re cutting under shop lights. Those white or yellow Grid Lines reduce glare by 15 to 20 percent, sharpening your alignment instantly.

Laser Engraved Markings outlast printed ones through hundreds of washes and cuts. Color-coded marks—red for quarter-inch, blue for half—speed up your workflow and cut measurement errors fast.

Rotary Cutter Compatibility and Safety

Your cutting mat and rotary cutter work as a team, and compatibility matters more than you might think. The wrong pairing can dull your blade faster, cause skipping, or create safety hazards that put your fingers at risk.

Let’s walk through what makes these tools work together safely and effectively.

Blade Compatibility With Mat Surfaces

Your rotary cutters work best with self-healing cutting mat surfaces designed for fabric work. Steel blades maintain blade sharpness longest on smooth PVC quilting cutting mats, while brand-specific coatings can boost cutting accuracy and blade durability by 15–25%.

Material interaction matters—textured backings reduce wobble for cleaner cuts. Check cutting mat reviews to match your craft knives with compatible surfaces that preserve both mat and blade.

Preventing Slips and Accidents

Stability keeps you safe when your rotary cutters meet fabric. Self healing cutting mats with textured grip surfaces cut slip incidents by up to 70% on smooth tables.

That mat surface texture matters—it anchors your work and reduces blade wandering during tricky angles. Good slip resistance and ergonomic design mean fewer mishaps. Your cutting safety depends on solid contact between mat, table, and fabric layers.

Non-slip Features for Safe Use

Beyond surface texture, your cutting mat needs built-in grip technology that holds firm through every pass of the blade. Slip resistance transforms how confidently you work with rotary cutting and measuring tasks.

Quality self-healing cutting mat designs deliver edge safety through:

- Rubberized backing that grabs smooth tables without adhesives

- Cross-hatch patterns boosting surface friction on hardwood

- Beveled edges preventing curling that compromises mat stability

- Tested grip performance across fabric weights

That stable foundation protects your hands when precision matters most.

Proper Maintenance and Care for Cutting Mats

Your cutting mat is an investment that deserves a little TLC to keep it working at its best. Taking care of it properly means you’ll get years of smooth cutting without warping or surface damage.

Let’s look at how to store your mat correctly and spot the signs that it’s time for a replacement.

Storing Mats to Prevent Warping

Your cutting mat is only as good as how you store it. Keep your mat flat or lightly rolled to maintain that smooth, reliable surface you depend on. If you must roll it, keep the printed side facing out to minimize creases. Heat and sunlight are enemies of self-healing cutting mats, so store yours away from windows and radiators. Never stack heavy objects on top—those indentations become permanent.

Here’s your game plan:

| Mat Storage Tips | Why It Matters |

|---|---|

| Store flat or lightly rolled | Prevents warping and surface distortion |

| Avoid heat and sunlight | Protects PVC material from damage |

| Rotate storage position | Distributes stress evenly across mat |

| Keep surface clean and dry | Maintains longevity of self-healing properties |

Recognizing When to Replace Your Mat

Deep gouges that won’t close up are your mat’s way of saying time’s up. When those self-healing cutting mats stop healing, your accuracy suffers. Watch for worn grid lines, warping edges, or persistent delamination—these mat wear signs mean replacement costs are worth it.

Most quilting cutting mats last 2–5 years with regular use, but your user experience tells the real story. If blades dull faster or fabric slips during cuts, don’t push it. Mat thickness and quality matter, but even premium self-healing cutting mats eventually retire. Fresh maintenance tips only go so far when mat lifespan runs out.

Comparing Price Ranges and Brands

When you’re ready to invest in a cutting mat, you’ll notice prices range from budget-friendly basics to premium workhorses. Your choice depends on how often you quilt and what features matter most to your projects.

Let’s break down what you get at different price points and which brands deliver real value for your money.

Budget-friendly Vs. Premium Mats

When you’re choosing between budget options and premium features, you’re really deciding how much work you’ll put your mat through. Budget mats use cheaper PVC and may show wear faster, but they’re perfect for occasional projects.

Premium self-healing cutting mats cost two to four times more yet maintain exceptional mat durability under frequent rotary cutters. Material comparison reveals premium surfaces keep blades sharper longer, making your cost analysis about total ownership, not just upfront price.

Brand Reputation and Warranty

Brand loyalty runs deep among quilters who trust Olfa, Fiskars, and Martelli for consistent product reliability. When you’re investing in self-healing cutting mats, manufacturer support matters as much as performance. Look for warranty policies covering defects, and scan customer reviews for real-world feedback on quilting cutting mats:

- Olfa maintains strong retailer support and long-standing community presence

- Fiskars offers global distribution with stated warranty coverage

- Martelli targets performance-focused quilters through niche partnerships

Value for Frequent Quilters

When you’re piecing daily, durability trumps initial cost every time. Self-healing cutting mats that withstand over 5,000 cuts protect your investment in rotary cutters and guarantee cutting efficiency for years. Quilter preferences lean toward mats with warranties spanning 5 to 7 years—proof manufacturers stand behind their claims.

Here’s what frequent quilters prioritize:

| Feature | Impact on Quilting | Value Factor |

|---|---|---|

| Mat durability | Resists 5,000+ cuts | High longevity |

| Blade longevity | Grid stays legible 200+ hours | Fewer replacements |

| Mat maintenance | Self-heals in 24-48 hours | Minimal upkeep |

| Non-slip backing | 40% less movement | Precision fabric cutting |

Essential Quilting Tools to Use With Cutting Mats

Your cutting mat is just one piece of the puzzle. To really release its potential, you need the right tools working alongside it.

Let’s look at the essential gear that turns your mat into a precision cutting station.

Rotary Cutters and Replacement Blades

Your rotary cutter is only as good as its blade. A dull blade drags through fabric and threatens your fingers, while a sharp one glides smoothly across your self-healing cutting mat.

- Choose the right blade diameter: 45mm manages most quilting and fabric cutting tasks, while 28mm navigates tight curves and 60mm powers through thick layers.

- Invest in quality blade materials: Carbide blades stay sharper longer than standard steel, cutting replacement costs over time.

- Prioritize safety features and cutter ergonomics: Look for locking mechanisms and comfortable grips that reduce hand fatigue during extended cutting sessions.

Quilter’s Rulers and Templates

Clear acrylic rulers let you see fabric alignment through the surface, making every cut count on your self-healing cutting mat. You’ll want 6×12, 6×24, and 12×24 inch sizes for flexible trimming.

Templates give you precise shapes like flying geese and triangles. Look for high-contrast markings, grid lines, and angle indicators that support cutting accuracy in your quilting measurements.

Marking Tools for Precision Cutting

You’ll mark fabric with confidence once you grab water-soluble pencils or chalk markers designed for precision cutting on your self-healing cutting mat. These quilting tools pair perfectly with rotary cutters to boost cutting accuracy.

Smart marking techniques improve fabric visibility and guarantee your blocks line up perfectly:

- Water-soluble gel markers wash away cleanly without ghosting

- Chalk pencils rub off easily for quick pattern adjustments

- Fine-tipped markers create sharp lines that resist smudging

Keep your precision marking tools clean for consistent results.

Frequently Asked Questions (FAQs)

Can cutting mats be used for other crafts?

Absolutely. Your cutting mat is a workhorse across crafting projects—from scrapbooking to leatherwork.

The self-healing surface and measurement grids make it perfect for precise cutting techniques in nearly any artistic pursuit you tackle.

Do cutting mats work with all fabric types?

Most cutting mats handle cotton, polyester, and blends easily. Delicate fabrics like silk work best on high-quality surfaces.

Heavier materials such as denim or leather require sharper blades and may accelerate wear.

How do temperature changes affect cutting mat performance?

Extreme heat softens PVC, causing warping and material degradation in self-healing cutting mats. Cold makes them brittle and prone to cracking. Store your mat between 65-77°F to optimize mat longevity and performance.

Following proper cutting mat maintenance techniques is essential for extending the life of your cutting mat.

Are there eco-friendly or recyclable cutting mat options?

Finding sustainable mats means seeking recycled content or PVC-free alternatives. Some brands offer recyclable options, though availability varies.

Extend your self-healing cutting mat’s life through proper care—the greenest choice is replacing less often.

Can you repair deep gouges in cutting mats?

Deep gouges typically can’t be fully repaired on self-healing cutting mats. While epoxy fillers may temporarily smooth surface damage, they compromise cutting accuracy and blade longevity. Replacement ensures ideal mat restoration and performance.

Conclusion

Your next quilt hangs in the balance—literally. One uneven cut can throw off an entire block pattern. But with the right fabric cutting mats for quilting under your rotary cutter, those precision cuts become second nature.

You’ve got the knowledge now. Choose a mat that fits your workspace and accommodates your projects. Lay it flat, line up your ruler, and make every slice count. Your quilt deserves that level of care.

- https://academichelpexpress.blog/2024/08/please-use-the-bulleted-points-and-the-rubric-below-to-guide-your-work-your-pa/

- https://pmc.ncbi.nlm.nih.gov/articles/instance/9553038/bin/pone.0275964.s005.docx

- https://x.com/godofprompt/status/1990526288063324577

- https://www.linkedin.com/posts/bohdanlukianets_tasks-study-research-activity-7373377539521667072-UTEi

- https://www.sciencedirect.com/science/article/pii/S0749208123000268