This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You grab a fabric bolt at the store, and the tag reads “180 GSM.” You grab another—”220 GSM.” Without context, these numbers mean nothing. But GSM (grams per square meter) is one of the most reliable indicators of whether a fabric will drape like silk or stand firm like canvas, whether it’ll breathe on a hot day or trap warmth when you need it.

This single measurement reveals how tightly fibers pack together, how the material will behave when you cut and sew it, and whether it’s suited for a summer dress or winter upholstery. Once you understand what those numbers represent, choosing the right fabric transforms from guesswork into strategy.

Table Of Contents

- Key Takeaways

- What Does GSM Mean in Fabric?

- How GSM is Measured

- Fabric Weight Vs. Fabric Density

- How GSM Affects Fabric Properties

- GSM Ranges for Common Fabric Types

- Choosing The Right GSM for Projects

- Low GSM Vs. High GSM Fabrics

- Factors Influencing GSM Selection

- Tips for Selecting Fabric by GSM

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- GSM (grams per square meter) measures fabric density and weight, directly determining how material drapes, breathes, and holds up under use—lighter fabrics under 150 GSM work for summer garments while heavyweight options above 300 GSM suit upholstery and outerwear.

- You can estimate GSM at home by cutting a 10×10 cm fabric square, weighing it on a kitchen scale, and multiplying the gram weight by 100, giving you practical data for comparing materials without lab equipment.

- Higher GSM doesn’t automatically mean better quality—the right choice depends on matching fabric weight to your project’s specific needs, whether that’s breathability for athletic wear (120-180 GSM) or durability for work aprons (300+ GSM).

- Fabric density and thread count work together beyond simple weight measurements, meaning two fabrics with identical GSM can perform completely differently based on fiber type, weave structure, and finishing treatments.

What Does GSM Mean in Fabric?

GSM is one of those terms you’ll see everywhere once you start working with fabric, but it’s not as complicated as it sounds. Think of it as the fabric world‘s way of putting a number on weight—how heavy or light a material actually is.

If you’re working with lighter materials, checking out a guide to lightweight sewing fabrics can help you match the right GSM to your project.

Let’s break down what GSM means, the key terms you’ll encounter, and why it matters when you’re choosing fabric for your projects.

Definition of GSM

GSM stands for grams per square meter—a weight measurement that tells you how dense and heavy your fabric is. Think of it as a material thickness indicator that lets you compare textile quality across different fabrics.

When you’re choosing fabric, GSM standards give you a concrete number: higher GSM means heavier, denser fabric, while lower GSM means lighter, more breathable material.

Key Fabric GSM Terminology

You’ll encounter a few terms that help you nail down the right fabric choice. Grams per square meter is the full phrase behind GSM—a weight measurement that quantifies fabric density. When suppliers mention fabric thickness or material selection, they’re often referencing this same standard.

Understanding GSM calculation and how it connects to fabric weight gives you control over your project outcomes. For a deeper dive, you can learn more about the GSM measurement process and why it matters in fabric quality.

- Fabric density determines how tightly fibers pack together

- Weight measurement reveals the heft you’ll feel in hand

- GSM calculation standardizes comparisons across different textiles

- Fabric thickness affects drape and structure of your finished piece

- Material selection becomes easier when you decode these terms

Why GSM Matters in Sewing

Once you grasp these fabric properties, sewing techniques shift into focus.

GSM guides your needle choice—lightweight fabrics under 100 grams per square meter need finer needles, while heavy materials demand sturdy ones. Thread tension adjustments follow fabric weight directly.

Proper fabric selection prevents skipped stitches and improves seam durability. That’s why understanding GSM transforms your fabric choice from guesswork into confident decision-making.

Knowing about fabric weight and quality also ensures you choose the best materials for durability and function.

How GSM is Measured

You don’t need fancy lab equipment to figure out a fabric’s GSM. Manufacturers use precision tools to get exact numbers, but you can get a pretty close estimate at home with basic supplies.

Let’s look at both the professional method and a simple calculation you can do yourself.

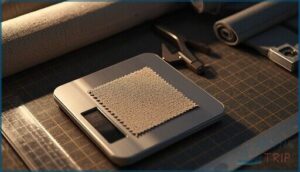

DIY GSM Measurement at Home

You don’t need a lab to measure fabric weight—just a kitchen scale and a ruler. Cut a 10 by 10 centimeter square sample for fabric sampling, weigh it on a digital scale, then multiply that weight by 100 to estimate grams per square meter. This DIY home measurement gives you real fabric density data for fabric comparison.

- Precision matters: Use a scale accurate to 0.1 grams

- Flat samples work best: Smooth wrinkles before weighing

- Multiple tests confirm accuracy: Check several fabric sections

- Compare weights side-by-side: Build your material density reference library

GSM Calculation Formula

The core formula for GSM measurement is straightforward: divide your fabric weight in grams by the area in square meters. For that 10×10 cm sample, you’re working with 0.01 square meters—so a 2-gram piece equals 200 grams per square meter.

This weight calculation gives you the fabric density number you need for smart material selection across any weaving or construction project.

Fabric Weight Vs. Fabric Density

You might think fabric weight and density mean the same thing, but they’re actually two different measurements that work together.

Weight tells you how heavy the fabric is, while density reveals how tightly the fibers are packed.

If you’re not sure which specs matter most for your project, these fabric selection tips for bags can help you compare options more confidently.

Understanding both gives you a clearer picture of how a fabric will perform in your projects.

Understanding Fabric Weight

Fabric weight tells you exactly how heavy your material is, measured in grams per square meter. When you pick up a swatch, you’re feeling the mass concentrated in that area—the weight calculation reveals whether you’re holding a featherlight voile or a sturdy canvas. This single number unlocks precise fabric analysis across your entire project.

| Weight Category | GSM Range | Typical Applications |

|---|---|---|

| Sheer/Lightweight | 30–150 GSM | Summer tees, linings, scarves |

| Medium Weight | 150–350 GSM | Button-downs, denim, quilting cotton |

| Heavyweight | 350+ GSM | Outerwear, upholstery, canvas bags |

| Jersey Knits | 120–220 GSM | T-shirts, casual wear, activewear |

| Technical Fabrics | Varies widely | Performance gear, protective clothing |

How Density Affects Fabric Properties

Density packs more yarns into each square inch, which changes how your fabric performs beyond simple weight. When fibers sit closer together, you’ll notice reduced stretch and improved thermal insulation as those tiny air pockets trap warmth. Tighter weave patterns limit yarn mobility, so your material resists snagging and holds its shape longer, even if two fabrics share the same grams per square meter.

| Density Level | Fabric Thickness | Key Performance Traits |

|---|---|---|

| Low density | Thinner, airier | Fast drying, high breathability, more drape |

| Medium density | Moderate body | Balanced warmth and airflow, everyday wear |

| High density | Thicker, stiffer | Exceptional durability, windproof, better insulation |

| Tight weave | Compact structure | Reduced pilling, enhanced abrasion resistance |

| Loose weave | Open structure | Cooling effect, flexible movement, lighter feel |

GSM Compared to Other Units

You’ll spot GSM alongside other measurement standards depending on where you shop. In the US, ounces per square yard (OZ) shows up frequently on fabric labels, while Europe sticks to grams per square meter. A quick conversion uses the factor 0.0295—multiply your GSM by this number to estimate OZ, helping you compare fabrics across regional preferences and measurement standards.

| Unit | Conversion to GSM | Common Region |

|---|---|---|

| Ounces per square yard (OZ) | Divide OZ by 0.0295 | United States, UK |

| Grams per square meter (GSM) | Direct measurement | Europe, Asia, Global standard |

How GSM Affects Fabric Properties

GSM isn’t just a number on a fabric label—it shapes how your material looks, feels, and performs in real-world use.

The weight per square meter influences everything from the way fabric falls and drapes to how well it stands up to wear over time. Let’s break down the three main properties that GSM controls in any textile.

Thickness and Drape

GSM directly controls how your fabric hangs and moves. Higher grams per square meter means greater fabric thickness and material density, which creates deeper fold formation and slower drape behavior.

A 300 GSM cotton will stand away from your body with structure, while 150 GSM drapes softly around curves. Weight distribution changes everything—thicker textiles hold their shape, lighter ones flow and cling.

Comfort and Breathability

Lighter fabric weight directly impacts your comfort by enhancing breathability and moisture management. Air permeability determines how easily sweat evaporates, keeping you cooler in warm conditions.

When comparing breathable fabrics, look for:

- Open knits like jersey—greater airflow than tight weaves

- Moisture wicking blends that draw sweat away four times faster than plain cotton

- Softness levels that reduce cling when damp

Lower GSM usually means better thermal regulation and all-day wearability.

Durability and Strength

Beyond comfort and breathability, fabric density plays a major role in how long your project lasts. Higher GSM often means better material resistance to abrasion and tearing because denser weaving packs more fibers into each square meter. However, fabric tensile strength depends on fiber reinforcement and structural integrity—not just weight alone.

| Durability Factor | Impact on Fabric Properties |

|---|---|

| Weave tightness | Reduces snagging, improves wear testing results |

| Fiber type | Nylon blends outlast cotton in material science tests |

| Surface finish | Anti-pilling treatments extend fabric lifespan |

| GSM range | 200+ GSM generally resists daily stress better |

| Construction method | Knits stretch but wovens resist punctures |

GSM Ranges for Common Fabric Types

Different fabrics have their own typical GSM ranges, and knowing these numbers helps you understand what you’re working with before you even touch the material.

A T-shirt fabric won’t weigh the same as denim, and that difference shows up clearly in GSM values. Let’s look at the common ranges for everyday fabrics you’ll encounter in most projects.

Cotton and Jersey Fabrics

When you’re working with cotton fabrics, you’ll find cotton t-shirts commonly range from 120 to 180 GSM for everyday wear.

Jersey knits, thanks to their interlock weave patterns, usually sit around 180 to 220 GSM, giving you that soft drape and stretch. These fabric blends balance breathability with structure, making them adaptable for most apparel projects.

Denim and Canvas

If you’re sewing jeans or bags, denim fabric usually starts around 400 GSM and can push beyond 500 GSM for heavy-duty applications.

Canvas weight usually ranges from 260 to 540 GSM, offering fabric thickness ideal for upholstery and sturdy cotton blends. These higher fabric density levels translate to durability you can feel—perfect when your project needs to handle real wear.

Fleece, Sweatshirt, and Toweling

When you’re working with cozy fabrics, fleece and sweatshirt materials usually sit between 200 and 350 GSM—enough fabric thickness for warmth without feeling stiff.

Winter textiles like heavier hoodies can reach 300 to 400 GSM for plush feel and breathability.

Towel weights vary more: lightweight options start around 300 GSM, while plush towels climb to 900 GSM for that spa-like softness you’re after.

Choosing The Right GSM for Projects

Choosing the right GSM isn’t about memorizing charts—it’s about matching fabric weight to what you’re actually making. A summer dress needs something completely different from a canvas tote bag, and that’s where understanding your project’s demands comes in.

Let’s break down how GSM applies to three major categories: apparel, crafts, and home goods.

Apparel and Garment Construction

When you’re building garments, fabric selection hinges on matching GSM to the pattern’s structure and season. Summer tees work best between 120 and 180 GSM—they breathe and drape without clinging.

Year-round shirts sit around 180 to 240 GSM, balancing comfort with durability in apparel manufacturing. For jackets and structured pieces, aim for 300 GSM or higher. That extra weight gives you the body custom garment construction demands.

Quilting and Craft Projects

Quilts need medium-weight fabrics—usually 100 to 180 GSM—for easy piecing and balanced drape.

Lighter fabrics simplify your patchwork at precise ¼ inch seams, while heavier weights add unwanted bulk during assembly.

Craft ideas like tote bags or pillow covers thrive around 150 to 200 GSM, offering enough body without fighting your machine.

Fabric selection directly shapes how blocks align, layers quilt together, and finished projects hold their structure.

Home Décor and Upholstery

Furniture upholstery demands fabrics at 300 GSM and above for wear resistance and shape retention on sofas or dining chairs.

Decorative panels and curtains work well between 200 and 300 GSM, balancing drape with enough body to hang cleanly. Fabric density and material properties determine how your home textiles hold up under daily use, sun exposure, and routine cleaning.

Low GSM Vs. High GSM Fabrics

Think of fabric weight like choosing between a tank top and a winter coat—they’re built for completely different jobs.

Low GSM fabrics feel light and airy, while high GSM options bring structure and warmth. Let’s break down what each category offers and when you’ll want to reach for one over the other.

Lightweight (Low GSM) Fabrics

When you’re working with fabrics under 120 GSM, you’re stepping into the domain of breathable weaves and fluid drape. Low GSM materials like cotton poplin (40–90 g/m²) or bamboo viscose blends (70–110 g/m²) offer outstanding airflow and softness. These lightweight fabrics feel cool against your skin, making them perfect for summer garments where comfort trumps structure.

| Material | Typical GSM Range |

|---|---|

| Cotton Poplin | 40–90 g/m² |

| Linen Blends | 70–110 g/m² |

| Rayon/Viscose | 40–120 g/m² |

Heavyweight (High GSM) Fabrics

Heavyweight fabrics above 300 GSM bring serious structure and durability to your projects. Dense weaving in materials like denim (360–550 g/m²) and canvas (340–480 g/m²) creates thick textiles that resist wear and hold their shape through repeated use.

High GSM uses include outerwear, upholstery, and gear that demands longevity—fabric weight translates directly into strength.

| Material | Typical GSM Range |

|---|---|

| Heavy Denim | 360–550 g/m² |

| Canvas | 340–480 g/m² |

| Terry Toweling | 500–900 g/m² |

| Heavyweight Wool | 350+ g/m² |

Pros and Cons of Each

Every fabric weight brings tradeoffs you can’t ignore. Low GSM fabrics breathe beautifully but won’t handle aggressive washing without pilling or snagging. High GSM options offer abrasion resistance and warmth yet sacrifice breathability and drive up shipping costs due to bulk. Your fabric selection hinges on balancing these durability factors against comfort and cost implications.

| Weight Category | Key Tradeoffs |

|---|---|

| Low GSM (30–120) | Breathable but tears easily |

| Medium GSM (120–240) | Balanced comfort and strength |

| High GSM (300–600) | Durable but reduces airflow |

| Extra Heavy (600+) | Maximum longevity, higher cost |

| Finishing Impact | Treatments boost durability without adding mass |

Factors Influencing GSM Selection

Picking the right GSM isn’t just about numbers on a label. You need to think about where you’ll use the fabric, what weather it needs to handle, and what trade-offs you’re willing to make between cost and performance.

Let’s look at the three main factors that should guide your decision.

Seasonal and Climate Considerations

Where you live shapes which GSM works best for your comfort and performance. Climate adaptation means matching fabric weight to your environment so you stay comfortable year-round.

Consider these seasonal guidelines:

- Hot, humid summers – Choose 100-180 GSM for maximum fabric breathability and airflow that prevents overheating.

- Cold winters – Opt for 250-400 GSM to gain thermal insulation and weather resistance against wind and chill.

- Variable spring/fall – Select 180-250 GSM for seasonal layering that adjusts to temperature swings throughout the day.

Intended Use and Durability Needs

Think about what you’re making before picking your fabric weight. A durable work apron needs 300+ GSM to handle abrasion and maintain wear resistance through 50-plus wash cycles.

Summer tees work fine at 140 GSM since fabric longevity matters less for seasonal pieces. Match your material selection to performance metrics—durability testing shows upholstery requires serious fabric properties to survive daily use.

Cost and Opacity Factors

Beyond performance metrics, your wallet and supply chain visibility shape which GSM you’ll choose. Price transparency varies wildly—higher fabric weight often means more material cost, but fabric sourcing complexity can hide fees.

Market dynamics push bulk pricing opacity, while fabric density impacts shipping. Smart cost analysis means checking:

- Per-yard pricing across GSM ranges

- Hidden import duties on heavier fabrics

- Minimum order quantities from suppliers

- Shipping weight surcharges

- Seasonal pricing fluctuations

Tips for Selecting Fabric by GSM

Now that you understand GSM and how it affects fabric performance, let’s talk about making smart choices when you’re actually shopping or starting a project.

The right GSM depends on what you’re making, who will use it, and how long you need it to last. Here are some practical tips to guide your fabric selection.

Ethical Data Use

When choosing fabrics, you’re actually choosing data privacy—the material properties and testing methods manufacturers collect. Ethical AI in textile production ensures fair algorithms process fabric weight and GSM measurements without bias.

User consent matters: you deserve transparency about fabric density claims. Bias mitigation in quality control means every batch meets standards. It’s accountability woven into every thread.

AI Bias Challenges

Why does algorithmic fairness matter in fabric testing? AI systems measuring GSM, fabric weight, and fabric density can carry hidden biases. Data quality gaps skew material density readings. Without bias detection, you might get unreliable fabric properties info.

Watch for these AI ethics red flags:

- Fairness metrics missing from quality reports

- Underrepresented fabric types in training data

- Performance gaps across different weaving techniques

- Outdated benchmarks missing real-world scenarios

- No transparency on measurement accuracy claims

Privacy In AI

When you upload fabric specs to AI-powered textile platforms, data protection becomes essential. Privacy laws now govern how digital security systems handle your GSM measurements and fabric weight data.

The textile industry faces cyber threats that could expose proprietary fabric properties. Before sharing fabric selection details with AI tools, check their encryption standards and AI ethics policies. Your design data deserves safeguarding.

Frequently Asked Questions (FAQs)

Does higher GSM mean thicker?

Higher GSM usually means thicker fabric, but not always.

Weight comparison alone doesn’t tell the whole story—density matters too.

Weaving style and fiber type affect thickness variance, so material selection requires considering GSM alongside fabric construction and density measurement.

Which is better, 300 GSM or 400 GSM?

It’s not a one-size-fits-all situation—fabric comparison depends on your project. For breathability tests and cooler climates, 300 GSM offers lighter material durability. For warmth and structure, 400 GSM fabric weight wins.

Does GSM affect fabric shrinkage after washing?

Yes, GSM influences fabric shrinkage. Heavier fabrics with higher GSM usually resist dimensional changes better than lightweight ones, since tighter fiber packing limits post-wash relaxation—though fiber type and finishing also matter substantially.

Can different fabrics have identical GSM values?

Two entirely different materials can share the same GSM yet feel nothing alike.

A cotton poplin and polyester satin both measuring 180 GSM deliver distinct drape because weave structure and fiber properties define texture beyond weight alone.

How does thread count relate to GSM?

Thread count measures warp and weft threads per square inch in woven fabrics, while GSM reflects fabric weight and fiber content density.

Together, both metrics help you evaluate fabric feel, breathability, and overall durability.

Does GSM change with fabric blends or mixes?

Blends shift the perceived GSM landscape. Fiber interaction and fabric construction create weight variations, even when mixed materials show identical GSM readings.

Textile blending alters material density, affecting drape and thickness without necessarily changing the measured fabric weight.

What GSM works best for athletic performance wear?

Most athletic wear performs best between 120 and 180 GSM range for tops, balancing breathability with durability.

Leggings usually need 210 to 280 GSM range for support and coverage, while sports bras range from 160 to 320 GSM range depending on impact level.

Conclusion

Understanding fabric GSM explained simply means understanding how your material will perform before you make the first cut. It tells you whether a fabric will breathe, drape, or endure.

It guides you toward the right choice for every project—whether you’re sewing a breathable blouse or upholstering a chair that needs to last. Once you decode those numbers on the bolt, you stop guessing and start building with confidence.