This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

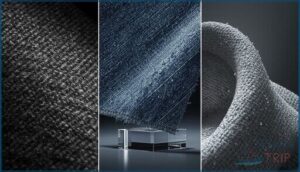

The difference between a project that delights and one that disappoints often comes down to a single decision you make before your scissors even touch the fabric. When you run your fingers across velvet versus canvas, you’re not just feeling texture—you’re evaluating pilling resistance, dimensional stability, and performance characteristics that will determine whether your finished piece survives its first wash or fades after three months in sunlight.

Each fabric surface tells a specific technical story through its weave structure, fiber composition, and applied finishes, and learning to read that story transforms guesswork into precision. Your fabric surface characteristics guide starts with understanding that what you see and feel on the surface directly correlates to how that material will behave under tension, abrasion, and environmental stress.

Table Of Contents

Key Takeaways

- Fabric surface characteristics—encompassing texture and hand feel, durability markers, and applied finishes—directly determine how materials perform under tension, abrasion, and environmental stress, making surface analysis the foundation of reliable fabric selection before any cutting begins.

- Visual texture frequently deceives where tactile assessment reveals truth: smooth surfaces like satin create low friction and even light reflection ideal for linings, while rough textures such as linen provide high friction and matte finishes that mask wear but may irritate skin.

- Durability performance hinges on quantifiable surface features including pilling resistance (influenced by yarn twist and fiber length), colorfastness ratings (measured on ISO 105 and Blue Wool scales), and stretch recovery properties that determine whether garments maintain shape across repeated wear cycles.

- Surface treatments—such as waterproof membranes, stain-resistant fluorocarbon finishes, wrinkle-resistant crosslinking resins, and softening agents—fundamentally alter fabric behavior to meet specific performance requirements, but each coating system carries distinct maintenance implications and durability trade-offs you must evaluate against project demands.

What Are Fabric Surface Characteristics?

Fabric surface characteristics define the physical and visual properties that determine how a textile looks, feels, and performs in your sewing projects. These characteristics encompass everything from the smoothness of silk to the coarse texture of burlap, directly influencing both aesthetic appeal and functional durability.

Choosing the best fabric for your sewing machine means considering how surface texture affects thread tension, needle performance, and overall stitch quality.

Understanding these properties lets you match the right fabric to your intended use, whether you’re crafting garments, upholstery, or decorative items.

Definition and Importance in Sewing

Fabric surface characteristics describe the outer layer of a textile—how it looks, feels, and behaves under your hands and machine. These traits stem from fiber type, weave structure, and finishing treatments, shaping everything from sewing techniques to garment construction.

In material science and surface analysis, understanding these fabric properties isn’t optional—it’s the foundation of smart fabric selection and long-lasting fabric durability. For a deeper look at key concepts like fabric density and surface contour, consult established industry resources.

Visual Vs. Tactile Properties

You’ll notice that Visual Texture—what your eye sees in patterns, ridges, or shine—doesn’t always match the Surface Sensation your fingers detect. Some fabrics look rough but feel smooth, creating Sensory Deception that catches you off guard.

Visual texture doesn’t always match how fabric feels—your eyes can deceive you where your fingers reveal the truth

That’s why experienced sewists test both Tactile Characteristics and Visual Characteristics before cutting, since Fabric Perception shapes comfort and Fabric durability in ways photos can’t reveal.

For a deeper understanding, it’s important to examine technical characteristics of fabrics alongside surface sensation.

How Surface Characteristics Affect Project Selection

Once you understand sensory deception, you can match surface analysis to fabric selection with precision. Texture impact determines project success through three durability characteristics:

- Abrasion zones—smooth satins show scuffs on high-friction garments; rough upholstery hides wear

- Cleaning access—tight weaves simplify care considerations; deep piles trap debris

- Structural needs—crisp surfaces hold shape; drape requires flow

Material properties guide every choice you make.

Texture and Hand Feel Properties

When you run your hand across fabric, you’re experiencing its texture and hand feel—two characteristics that directly influence both your sewing process and the final outcome of your project.

These properties encompass surface smoothness, dimensional structure, movement behavior, and physical weight, each contributing to how the fabric performs in different applications. Understanding these tactile and structural elements helps you match fabric characteristics to project requirements with technical precision.

Smooth Vs. Rough Surface Textures

When you run your palm across fabric, friction effects tell the story—smooth surfaces like satin slide effortlessly, while rough linen catches and resists. This surface aesthetics difference shapes texture comfort, fabric slippage during sewing, and visual contrast in your finished work. Understanding these material science principles guides both fabric durability and maintenance decisions and smart fabric properties selection.

When planning your fabric combinations, consider how different friction levels between materials affect both construction ease and long-term wear patterns.

| Surface Type | Friction Characteristics | Light Reflection |

|---|---|---|

| Smooth (satin, silk, polished cotton) | Low friction reduces skin irritation; creates garment slippage during handling | Even light reflection produces shiny, saturated color appearance |

| Rough (linen, canvas, coarse wool) | High friction increases drag and potential chafing in movement areas | Scattered light creates matte, muted, diffuse finish |

| Mixed Weave (twill, gabardine) | Moderate friction balances comfort with structural stability | Directional sheen offers subtle visual interest |

Smooth fabrics feel cooler and more slippery against your skin, making them ideal for linings and sleepwear where fabric care prioritizes comfort. Rough-textured materials provide substantial, grounded sensation but may irritate sensitive skin—think scratchy wool versus fine cotton. During sewing, smooth surfaces shift under the presser foot, requiring careful pinning, while rough fabrics grip feed dogs firmly for straighter seams.

For durability, tightly woven smooth fabrics like gabardine resist abrasion better than loose rough weaves, though rough surfaces cleverly mask minor wear marks and stains within their uneven topography.

Nap and Pile Characteristics

You’ll encounter two distinct surface structures when selecting pile or napped materials. Nap forms when fiber brushing lifts loose ends from flat cloth—think flannel’s cozy warmth. Pile uses extra yarns woven upright, creating velvet’s plush luxury.

Pile height and density determine fabric crushing resistance and pilling potential. Nap direction affects color appearance, so align pattern pieces carefully. Higher pile density improves fabric durability and maintenance while proper fabric care preserves texture and fabric properties.

Drape and Stiffness

Fabric drape describes how cloth bends and falls under its own weight, ranging from silk’s fluid cascade to denim’s rigid hold.

Stiffness levels resist folding, so tighter plain weaves lock yarns in place and reduce drape behavior compared to satin’s smooth floats.

Fabric structure and fiber content together control fold resistance—rayon flows easily while crisp linen stands away from your body, shaping garment silhouettes differently.

Weight and Thickness Impact

Bulk in a garment comes from both weight and thickness measurement—heavier fabrics above 475 GSM add warmth through thermal insulation but also create stiffness, while lightweight materials under 150 GSM drape softly yet sacrifice durability characteristics.

Fabric density controls how yarns pack together, affecting weight distribution across seams and influencing texture, so you’ll handle construction differently when bulk reduction matters for custom silhouettes or layered textile properties.

Durability and Performance Surface Features

When you’re selecting fabric for a project that needs to last, you can’t just rely on how it looks or feels—you need to understand how it performs under stress. The surface characteristics that determine durability aren’t always visible at first glance, but they’ll make or break your finished piece over time.

Let’s examine the three critical performance features that separate fabrics built to endure from those that won’t hold up.

Pilling Formation and Prevention

Pilling develops when loose fiber ends migrate to the fabric surface, tangle under abrasion, and form stubborn balls that cling to the cloth. You’ll find pills most often where friction is highest—underarms, seat areas, cuffs.

Yarn twist, surface finishing techniques like biopolishing, and fiber length all influence pilling resistance. Tightly woven fabrics with high thread counts trap fibers effectively, reducing pill formation during textile testing and everyday wear.

Colorfastness and Light Resistance

When you wash a new garment and watch its color bleed into the water, you’re witnessing poor colorfastness—a fabric’s inability to retain dye under stress. Dye Stability depends on fiber type, dye class, and finishing processes that lock pigment molecules into the structure.

- Colorfastness to washing (ISO 105-C06) rates Color Fading from 1 to 5 after controlled cycles

- Light Exposure resistance uses the Blue Wool scale (1–8) to measure UV Resistance

- Wet and dry crocking tests reveal Fabric Bleeding through rubbing transfer

- Perspiration resistance evaluates dye behavior under acidic or alkaline body moisture

- Textile testing and evaluation through AATCC 16.3 and grey scales ensures Fabric properties meet end-use standards

Stretch and Recovery Properties

When you pull fabric and it snaps back, you’re measuring its elastic memory—the interplay of Fabric Elasticity and Recovery Rates that determines whether your garment will hold its shape or sag after wear. Stretch Testing quantifies how far fibers extend under load, while Yarn Resilience governs the return to original dimensions, defining textile properties essential for durability.

| Fabric Type | Stretch % / Recovery Rate |

|---|---|

| Cotton knit | 40% / 70% immediate |

| Elastane blend | 100% / 95% immediate |

| Polyester woven | 15% / 85% delayed |

| Single jersey | 60% / 75% immediate |

| Interlock knit | 50% / 100% lengthwise |

Fiber Stretchability ranges from rigid cotton to spandex that extends eight times its length, while fabric characteristics like weave density and stitch structure control both maximum extension and shape retention across repeated wear cycles.

Surface Finishes and Treatments

Surface finishes and treatments fundamentally alter fabric behavior, enhancing performance characteristics through chemical or mechanical modifications applied during or after manufacturing.

These engineered interventions address specific functional requirements, including moisture management, soil repellency, wrinkle reduction, and tactile quality improvement.

Understanding the mechanisms, durability, and maintenance implications of these treatments allows you to select fabrics that meet project-specific performance criteria while anticipating long-term wear behavior.

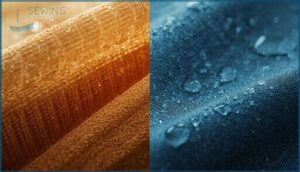

Waterproofing and Water-Resistant Coatings

Waterproof membranes and breathable coatings transform textile properties by blocking liquid water while managing moisture vapor transmission. Polyurethane coatings engineered with micropores provide hydrophobic treatments reaching over 9.2 kilograms per square meter per day in vapor movement, balancing waterproofing with wearer comfort.

PVC layers offer complete water repellency but eliminate breathability, while durable water repellent finishes create surface beading without full waterproofing. Your fabric care routine and durability characteristics depend heavily on which coating technology you select for your sewing project.

Stain-Resistant Treatments

Stain repellent systems use fluorocarbon finishes that lower surface energy so liquids bead up instead of soaking in, protecting your textile properties against oil and water based spills.

Soil release treatments make polyester more water loving, helping detergent lift dirt during washing, while silicone treatments boost softness without compromising repellency. These fabric coatings improve durability characteristics and simplify fabric care across upholstery and garment applications.

Wrinkle-Resistant Finishes

Beyond repelling spills, you’ll want fabrics that resist wrinkles. Durable press systems rely on crosslinking technology using chemical resins like DMDHEU that bond cellulose chains, helping cotton hold its shape through wear and washing. This fabric finishing delivers crease resistance with wrinkle recovery angles often exceeding 260 degrees in textile testing, transforming fabric properties so collars and seams stay smooth without heavy ironing.

- Pad-dry-cure application at 70–80% wet pick-up followed by high-temperature curing

- Modified formaldehyde-free resins that balance wrinkle recovery with fabric softness

- Wash-and-wear performance surviving dozens of laundry cycles with minimal touch-up

- Care-label recommendations for medium heat tumble drying and prompt removal

Softeners and Hand Enhancers

Where wrinkle finishes keep your fabric crisp, softeners and hand enhancers shift fabric properties toward comfort. Fabric softening systems—cationic types, silicone coatings, amino finishes, and bio softeners—deposit textile lubricants that reduce fiber friction, transforming fabric feel from boardy to pliant. Amino functional silicones bond permanently, keeping fabric appearance smooth through repeated washes, while bio softeners from plant oils offer renewable alternatives that balance fabric characteristics and selection with environmental responsibility.

| Softener Type | Key Benefit |

|---|---|

| Cationic | Reduces static, adds plush softness to cotton |

| Silicone | Creates silky, slippery hand with excellent wash durability |

| Amino Functional | Bonds to fibers, improving resilience and abrasion resistance |

| Hydrophilic | Maintains absorbency while enhancing comfort for activewear |

Choosing Fabrics Based on Surface Characteristics

You can’t pick the right fabric without understanding how its surface characteristics align with your project’s demands. Different applications—from high-traffic upholstery to delicate evening wear—require specific surface properties to perform well and last.

Let’s break down how to match fabric surfaces to your sewing projects, maintenance needs, and durability expectations.

Matching Surface Properties to Project Type

Your project planning hinges on aligning fabric properties with end-use demands. Material selection starts with surface analysis: smooth cotton poplin delivers crisp seams for shirts, while textured linen hides wrinkles in casual wear.

Textile testing confirms that shiny satin suits formal garments, whereas brushed surfaces create cozy loungewear. Matching texture and durability to function—activewear needs stretch, outdoor gear requires water-shedding surfaces—ensures ideal fabric performance.

Upholstery Fabric Surface Requirements

Heavy-duty upholstery fabric demands specific surface traits to withstand daily use. You’ll evaluate these key performance benchmarks:

- Abrasion testing: The Martindale abrasion test confirms wear tolerance, with contract seating requiring 30,000+ rubs for longevity in high-traffic zones.

- Flame retardancy: NFPA 260 compliance ensures safe cigarette resistance on surfaces.

- Surface cleanability: Stain-resistant coatings simplify maintenance in commercial settings.

- UV resistance: Colorfastness ratings (grade 4 minimum) prevent fading near windows.

Fabric density and pilling resistance further define upholstery fabric properties for durability.

Garment Fabric Surface Considerations

Garment drape, surface roughness, and fabric friction determine your comfort and the garment’s final silhouette.

Texture analysis reveals whether fabric properties suit structured blazers or fluid skirts, while wear resistance and pilling ratings guide fabric identifier choices for high-abrasion zones like underarms.

You’ll assess smooth versus napped surfaces for skin feel, ensuring durability matches the garment’s intended use and wear frequency.

Care and Maintenance Based on Surface Features

Fabric Brushing and Surface Cleaning protocols differ dramatically by texture: you’ll brush napped upholstery with the pile direction to prevent crushing, while pile maintenance demands soft vacuum attachments that lift compressed fibers without distortion.

For Stain Removal and Texture Preservation, blot spills immediately on water-repellent surfaces rather than rubbing, since aggressive cleaning accelerates Pilling formation and compromises the Durability of delicate Fabric properties you’ve carefully selected.

Frequently Asked Questions (FAQs)

How does humidity affect fabric surface texture?

Humidity drives fiber swelling in cotton and wool, altering surface roughness and texture.

Moisture impact on fabric properties affects drape and breathability, while very dry conditions expose micro-roughness, reducing durability and material science performance over time.

Can surface characteristics change with repeated washing?

Yes, you’ll notice texture change and pilling as repeated washing causes fabric abrasion, color fading, and finish loss.

Wash durability depends on fiber type, weave structure, and pilling resistance ratings of the original material.

What causes fabric surface abrasion over time?

Surface wear develops when fiber friction against rough surfaces, laundering, or repeated movements causes yarn breakdown and fabric fatigue—a process tracked through abrasion testing methods that predict textile durability and pilling formation patterns in material science.

Do synthetic fabrics age differently than natural ones?

Absolutely—synthetic aging keeps brightness and structure but develops stubborn pilling, while natural fiber breakdown softens gradually, fades gently, and shows thinning instead of surface hardening, affecting material durability and textile longevity differently.

How do surface finishes impact fabric breathability?

Hydrophobic finishes and thick resin coatings reduce breathability by blocking pores and limiting moisture vapor transmission, while moisture wicking treatments improve comfort by spreading sweat for faster evaporation without compromising fabric permeability.

Conclusion

Your next project won’t fail—it will simply reveal whether you invested the time to understand what you were working with. This fabric surface characteristics guide furnishes you with the technical vocabulary and evaluation criteria necessary to predict material behavior before commitment.

When you match surface properties—texture, durability markers, applied finishes—to intended application parameters, you eliminate the costliest variable in any textile project: uncertainty. Surface analysis transforms intuition into reproducible, defensible decision-making.

- https://www.textileschool.com/28796/fabric-drape-and-handle-calculations-for-textile-manufacturing/

- https://www.scribd.com/presentation/514881204/Chapter-4-Handle-Property

- https://www.cssunlandfabric.com/info/pilling-resistance-snag-resistance-abrasion-re-102827917.html

- https://www.tekstilvemuhendis.org.tr/showpublish.php?pubid=792&type=full

- https://acmemills.com/industry-news-blog/physical-properties-and-characteristics-of-fabrics/