This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A zipper slider that’s jumped the tracks can turn your favorite jacket into a wardrobe liability. This frustrating malfunction happens more often than you’d think—sliders slip off when teeth bend, stops break, or the slider itself gets damaged from repeated use.

The good news is that you don’t need a tailor’s expertise to fix it. Most zipper failures can be repaired at home with basic tools and about fifteen minutes of focused work. Understanding how to put a zipper back on saves you the cost of professional repairs and extends the life of clothing, bags, and gear you’d otherwise retire.

The process involves diagnosing the damage, gathering the right tools, and carefully guiding the slider back onto the teeth so it catches properly on both sides.

Table Of Contents

Key Takeaways

- Most zipper failures happen when the slider jumps off the tracks due to bent teeth, broken stops, or a worn slider, but you can fix these issues yourself in about fifteen minutes with basic tools like needle-nose pliers.

- You’ll save money by repairing instead of replacing since professional zipper work costs $16 to $49, and most problems involve simple fixes like tightening a loose slider or realigning the teeth rather than replacing the entire zipper.

- The repair process requires removing the top stop with pliers, carefully feeding both sides of the zipper tape through the slider channels simultaneously, and then securing everything with new stops to prevent future separation.

- Regular maintenance with lubricants like beeswax or graphite keeps zippers running smoothly and prevents future problems, but missing teeth or severely damaged tape means it’s time for a full replacement instead of repair.

How to Put a Zipper Back On

Putting a zipper back on isn’t as hard as it looks once you know the basic approach. You’ll need to assess the damage, gather a few simple tools, and follow a clear sequence of steps to get your zipper working again.

Before you start, it helps to know when a repair is worth your time and when replacement makes more sense.

Step-by-Step Overview

Fixing broken zippers starts with an initial assessment of the damage. Next comes tool preparation—gather needle-nose pliers and any replacement parts you need.

Then you’ll tackle slider removal by clearing the stops. Track alignment follows, ensuring both sides feed evenly into the zipper slider. Knowing the zipper slider size is key for a successful repair.

Final testing confirms smooth operation. This process keeps your gear functional without replacing the entire zipper, saving money and reducing waste.

When to Repair Vs. Replace

Not every zipper problem demands a full replacement. Repair cost generally runs $16 to $49 professionally, but minor wear and tear—like a loose slider—takes minutes to fix yourself. When garment value is high or damage severity is low, DIY feasibility wins. Missing teeth or torn tape mean replacement.

For simple alignment issues, zipper repair techniques beat buying new gear every time. Many consumers use Yelp to find local alterations services.

Assess Zipper Damage

Before you can fix a zipper, you need to figure out what’s wrong with it. Not every zipper problem can be solved with a quick repair, so it’s worth taking a close look first.

Let’s walk through how to spot the issue and decide if your zipper is worth saving.

Identifying Common Zipper Issues

A derailed zipper usually signals one of several culprits. Here’s what to look for during your zipper troubleshooting:

- Slider malfunction — The pull widens over time, losing its grip on the teeth and causing separation.

- Bent zipper teeth or zipper misalignment — Damaged coils prevent proper closure, creating a stuck zipper situation.

- Environmental factors and material defects — Dirt, debris, or poor construction quality accelerate teeth separation and overall zipper malfunction.

Inspecting Zipper Teeth and Stops

Once you’ve spotted the issue, look closely at the teeth. Run your fingers down each side—you’ll feel any gaps where teeth are missing or rough spots where they’re bent. These flaws prevent smooth operation and signal whether simple slider work will suffice or if you’re facing bigger trouble.

| What to Check | What It Means |

|---|---|

| Tooth Alignment | One extra tooth on one edge is normal; gaps or uneven spacing indicate wear that causes 30–40% of warranty claims. |

| Stop Function | Metal or plastic crimps at the top keep the slider on track; missing stops mean instant slider detachment. |

| Contamination Effects | Lint, sand, or grit creates that sticky feeling and wears teeth faster—cleaning solves many stuck zippers. |

Straightening bent teeth with gentle plier pressure works if damage spans under an inch. Longer sections with missing teeth usually mean it’s time for a full replacement, not a quick fix.

Determining Repair Feasibility

How do you know if reattaching your slider will actually work? Damage assessment starts with matching repair complexity against your skill level and the garment’s value. Inspecting the zipper reveals whether you’re facing a quick win or a lost cause.

- Slider widening – Simple squeeze with pliers; takes 5 minutes and needs zero sewing skills.

- Missing teeth – Sections over one inch long usually require full replacement; shorter gaps can be worked around.

- Cost analysis – Professional zipper work runs $40–50, so reserve paid repairs for jackets worth at least double that amount.

- Worn alignment – Uneven wear and tear on both tracks prevents proper clamping; replacing the slider won’t fix stripped rails.

- Broken stopper – Metal or plastic top tabs are easy to replace; bottom box stops on jackets demand more patience but remain feasible for most DIYers.

If teeth alignment looks salvageable and you have pliers on hand, you’re good to go. Otherwise, weigh repair time against simply replacing the broken zipper entirely.

Gather Tools and Materials

Before you start repairing your zipper, you’ll need to round up a few basic tools. Most of these items are probably already in your home, so don’t worry about making a special trip to the store.

Let’s look at what you’ll need to get the job done right.

Essential Tools for Zipper Repair

You don’t need much for a DIY zipper fix—just the right tools. Needle-nose pliers are your primary tool for tightening loose zipper pulls and crimping stops.

Many repair kits include assorted sliders, metal stops, sewing needles, and thread for repairing clothing items. For alignment during reattachment, zipper jigs hold everything steady while you work.

| Tool Category | Primary Use |

|---|---|

| Needle-nose pliers | Tightening sliders and crimping stops |

| Zipper repair kits | Replacement sliders and hardware |

| Alignment jigs | Holding slider during reattachment |

| Lubricant aids | Restoring smooth zipper movement |

Optional Items for Easier Repair

A few extras make the job smoother. Small pliers with fine tips let you manipulate tiny stops without frustration. Magnification devices reduce eyestrain when threading tracks back on. Fabric clips or masking tape hold zipper halves aligned during reattachment. For lubricant types, you can use ChapStick, a bar of soap, or coconut oil—each eases slider movement after repair without fancy products.

- Small pliers – Grip delicate stops and hardware securely

- Magnification devices – Improve visibility on intricate alignments

- Fabric clips or masking tape – Keep zipper edges steady

- ChapStick, bar of soap, or coconut oil – Reduce friction for smooth sliding

Choosing The Right Replacement Parts

Matching replacement parts to your original hardware is critical. The zipper gauge—usually stamped on the slider back—determines which stops, pulls, and slider bodies fit your teeth. A size 5 slider won’t clamp size 8 teeth properly.

Check whether your chain type is coil, molded plastic, or metal, then select the matching slider material and stop types. Many repair kits bundle compatible components by gauge, simplifying your search.

Remove and Reattach The Zipper Slider

The heart of zipper repair is getting the slider back where it belongs. You’ll need to remove the stopper at the top, guide the zipper teeth back through the slider, and make sure everything lines up correctly.

Here’s how to handle each step with confidence.

Removing Top Stops or Iron Stoppers

The first task in repairing a stuck zipper is removing the top stop—the small metal or plastic piece that keeps the slider from running off.

Grip metal stops with needle-nose pliers and gently twist them free. For plastic stops, use wire cutters and cut carefully to protect the tape underneath. This pliers technique creates clearance for slider prep.

Always wear safety glasses—small metal pieces can fly loose when pried.

Preparing Zipper Teeth for Reattachment

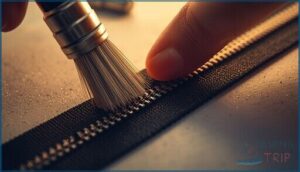

Once the stop is off, cleaning zipper teeth is essential—debris causes 63% of malfunctions in outdoor jackets. Brush dirt from each track, then run your fingertip along both rows to check for bent or missing elements.

Measuring tooth width helps confirm the slider matches; a size-5 slider won’t clamp properly on size-8 tracks. Aligning zipper teeth and releasing zipper tension by straightening the tape ensures smooth reattachment positioning.

Using The Fork Method to Reattach

Now you’ll use the fork method setup to thread your slider back on. Place the slider upside down between the two middle tines so its opening faces up—this keeps it steady during tape insertion.

- Align both tape ends evenly at the bottom before you start

- Feed each tape into its matching channel with light tension

- Pull both tapes upward smoothly to engage the teeth

- Test by zipping a few centimeters to check for gaps

If resistance appears, back out and reinsert.

Alternative Slider Reattachment Techniques

When the fork method isn’t practical, pliers retensioning offers an on-track fix. Gently crimp both sides of your zipper slider with needle-nose pliers—small adjustments restore grip without removing anything.

For closed zippers, a screwdriver opening lets you widen the slider gap slightly, rethread the teeth, then compress it shut.

Donor sliders from old jackets work perfectly when your broken zipper pull matches the size and tooth type.

Secure and Test The Zipper Repair

Once you’ve got the slider back on the track, you need to lock everything in place so it doesn’t slip off again. This final stage keeps your repair working smoothly for the long haul.

You’ll also want to check that everything zips without catching or sticking.

Reinstalling Stops or Tabs

After reattaching your slider, you need to install new stops to keep it from sliding off. Position top stops just above the teeth—not over them—and crimp them with pliers.

Stop alignment matters: place the stopper on the zipper tape edge and squeeze firmly. For bottom tabs, align both sides evenly.

Testing reliability is simple: run the zipper pull up and down several times to confirm the stops hold.

Lubricating and Maintaining The Zipper

Once your zipper’s reassembled, proper maintenance keeps it working smoothly. Apply beeswax-based lubricant to the teeth—it’s safe for plastic zippers and won’t attract dirt. Rub it along both sides, then cycle the pull several times.

For metal zippers, graphite or Teflon-based products work well. Clean the teeth first to prevent grit buildup.

Lubricate every few months for daily-use items, less often for occasional gear. This simple step prevents future stuck zipper problems.

Frequently Asked Questions (FAQs)

How do you reattach a zipper?

Getting back on track with a stuck zipper starts with slider rethreading tips: use pliers to remove the top stop, align both zipper teeth sides, and guide them through the slider carefully—no extensive weaving needed.

How to get a zipper back on the track?

Start by widening the slider with pliers to expose both track ends.

Use the fork method or your fingers to guide zipper teeth through each channel, ensuring proper alignment before testing smooth operation.

How do you put a zipper back on a zipper with a fork?

Place the slider onto the fork’s middle prongs for slider stabilization.

Insert both zipper tapes evenly through the slider channels, ensuring tape alignment.

Pull downward with continuous motion until smooth engagement of the teeth confirms proper reattachment.

How to fix a separated zipper?

When repairing a jacket zipper with separated teeth, pinch the slider gently with pliers to restore tooth alignment.

Check for bent zipper teeth, straighten them carefully, and apply light lubrication to prevent future separation.

How do you put a zipper back on?

You remove the top stop with pliers, align both zipper teeth into the slider simultaneously, then crimp a new stop above it.

Compatibility between slider size and track type ensures smooth operation and prevents future separation.

How do you replace a zipper pull?

When zipper pulls break, about 80% can be fixed rather than replaced entirely. Use pliers to open the slider’s ring, slide on the new pull tab, then close the ring securely—done in under five minutes.

How do you reattach a zipper slider?

You’ll need to match the slider size, then use needle-nose pliers or the fork technique to guide both zipper tapes into the slider channels.

After alignment issues are resolved, secure with stop replacement and confirm testing repair works smoothly.

How do you pull a zipper back on a track?

First, remove the top stop with pliers to access the track. Align both sides of the zipper tape evenly, then feed them into the slider channels. Track insertion requires careful slider alignment to prevent immediate separation.

Can I repair a zipper with missing teeth?

A missing tooth spells the end for most zippers. Professional opinions confirm that zipper replacement is the only reliable fix, since repair durability fails when teeth are gone—worn out zipper tracks can’t hold properly.

How do I fix a zipper that keeps splitting open?

When your zipper keeps splitting open, the slider channel has likely widened, causing teeth interlocking failure. You’ll need to gently squeeze the slider with pliers to restore tension, but contamination effects and garment fit impact repair technique durability.

Conclusion

Why pay for professional repairs when you’ve already got the skills to handle it yourself? Learning how to put a zipper back on transforms a common frustration into a manageable fix. You’ve saved money, extended the life of your gear, and gained confidence in your repair abilities.

Keep your tools handy and maintain your zippers regularly. That favorite jacket isn’t headed for the donation pile anymore—it’s back in rotation where it belongs.

- https://www.globalgrowthinsights.com/market-reports/zipper-market-103364

- https://www.stellarmr.com/report/Zipper-Market/1903

- https://market.us/report/zipper-market/

- https://www.techsciresearch.com/report/zipper-market/21200.html

- https://www.keezippers.com/article/zipper-industry-2025-market-status-trends-and-future-prospects-15.html