This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Both start as synthetic polymers, yet their microscopic structures create performance characteristics that couldn’t be more different. Polyester fibers measure 10-15 micrometers in diameter, while microfibers clock in under 1 micrometer, making them finer than silk.

This size gap translates to real-world consequences: polyester withstands abrasion and maintains shape through hundreds of wash cycles, while microfiber cradles moisture and delivers softness that rivals natural fibers.

Your choice between them determines whether your garment dries in minutes or holds sweat close, whether your upholstery withstands years of use or provides luxurious comfort.

Table Of Contents

Key Takeaways

- Polyester and microfiber are both synthetic materials, but fiber diameter makes the difference—polyester measures 10-15 micrometers while microfiber is under 1 micrometer, creating distinct performance characteristics where polyester excels in durability and moisture-wicking for activewear, and microfiber dominates in absorbency and softness for cleaning and bedding.

- Microfiber absorbs up to seven times its weight in water and traps 99% of bacteria, making it ideal for towels and cleaning cloths, while polyester repels moisture with only 0.4% absorption and dries 40% faster, which suits athletic wear and outdoor applications.

- Polyester outlasts microfiber significantly—withstanding over 1,000 wash cycles versus microfiber’s 300 cycles—and costs 10-20% less upfront, though microfiber’s superior softness and breathability justify its higher price for comfort-focused applications like bedding.

- Both fabrics create serious environmental problems, with polyester accounting for 40% of textile carbon emissions and microfiber shedding up to 700,000 fibers per wash load that become ocean microplastics, making recycled alternatives and careful laundering essential considerations.

What is Polyester Fabric?

Polyester is a synthetic fabric made from polyethylene terephthalate (PET), the same material found in plastic bottles. This petroleum-based polymer accounts for about 55% of global fiber production, making it the world’s most widely used textile material.

The manufacturing process involves combining terephthalic acid with ethylene glycol through polymerization, then extruding the molten polymer through tiny holes to form continuous fibers. These polyester fibers are then woven or knitted into fabric.

You’ll recognize polyester by its smooth texture, resistance to wrinkles, and quick-drying properties. With tensile strength reaching up to 900 MPa and moisture absorption of only 0.4%, polyester materials deliver outstanding durability and low maintenance—key characteristics that explain why polyester fabric dominates sportswear, upholstery, and everyday apparel markets worldwide.

Its versatility is also due to its excellent chemical resistance, making it suitable for various applications.

What is Microfiber Fabric?

Microfiber fabric represents a category of synthetic textiles defined by their ultrafine size—specifically, fibers measuring less than 1 denier in diameter, often as fine as 0.2 deniers. That’s thinner than a strand of silk or human hair.

You’ll find microfiber fabric usually composed of polyester and polyamide (nylon) blended at ratios like 80:20 or 70:30, where polyester provides structural integrity while polyamide enhances absorbency.

Production methods involve extruding molten polymer through precision spinnerets, creating fibers with engineered cross-sections—star or wedge shapes—that heighten surface area. This, combined with weave types and finishing treatments, results in high absorbency, with microfiber capable of holding up to seven times its weight in water. The microfiber yarn production is a vertically integrated process.

The fiber composition and denier measurement work together to deliver outstanding softness, moisture management, and particle-trapping capabilities that distinguish microfiber from standard polyester fabrics.

Key Differences

While polyester and microfiber share synthetic origins, they differ in ways that affect how they feel, perform, and serve you. The distinctions matter most when you’re choosing fabrics for specific needs.

Let’s break down the three main differences that set them apart.

Texture

Texture differences reveal important performance characteristics between these materials. When comparing microfiber and polyester, distinct surface qualities become immediately apparent. Microfiber, with its ultra-fine fibers measuring less than one denier, offers a silk-like softness and greater tactile comfort. In contrast, polyester’s thicker filament size results in a stiffer, smoother feel.

Key texture distinctions include:

- Fabric drape: Microfiber’s lower fiber denier creates softer draping and reduced skin friction

- Weave density: Microfiber’s finer fiber size permits tighter weaving without sacrificing surface feel

Absorbency

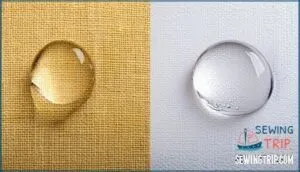

Beyond surface feel, absorbency reveals a stark performance gap between these materials. Microfiber can absorb up to seven times its weight in water, achieving liquid uptake rates 3–4× faster than polyester under identical conditions. That’s because its ultra-fine fibers create capillary action that draws moisture inward, while polyester’s hydrophobic nature repels liquids with less than 0.4% moisture absorption by weight.

Microfiber absorbs up to seven times its weight in water and draws moisture 3–4× faster than polyester, which repels liquids with its hydrophobic structure

For cleaning efficiency, microfiber removes up to 99% of bacteria with water alone—surpassing polyester by 30–50%. However, polyester’s water retention disadvantage becomes an advantage in drying times, requiring roughly 40% less time to dry completely. This quick drying characteristic makes polyester ideal when you need rapid moisture evaporation rather than high absorbency.

Breathability

When air permeability matters for your comfort levels, microfiber edges ahead with 10–15% better airflow than polyester due to its thinner fibers and less densely packed weave. Both materials rank lower in thermal regulation compared to natural fabrics, but microfiber sheets achieve up to 8% improved moisture vapor transmission. Polyester balances its limited fabric ventilation with effective moisture wicking during athletic activity, promoting evaporation rather than absorption.

Key breathability differences include:

- Microfiber provides enhanced air permeability through its ultra-fine fiber structure

- Polyester offers better moisture wicking properties for active wear applications

- Both fabrics show limited natural ventilation, though microfiber retains 20–25% more body heat in cooler conditions

Understanding fabric breathability comparison helps you match fabric properties to your specific moisture absorption and breathability needs.

Durability Comparison

When evaluating fabric durability, polyester consistently outperforms microfiber in mechanical resilience. Polyester’s thicker fiber diameter provides greater tensile strength and abrasion resistance, allowing it to withstand higher cyclical loads before rupture. In contrast, microfiber’s finer construction offers softness but compromises structural integrity under stress.

In wash durability tests, high-quality microfiber endures up to 300 cycles, while recycled polyester shows 50% higher fiber degradation. However, polyester maintains dimensional stability and resists fiber degradation better than microfiber under repeated laundering and mechanical agitation, demonstrating its environmental exposure advantage.

| Property | Winner |

|---|---|

| Tensile Strength | Polyester |

| Wash Durability | Polyester |

| Abrasion Resistance | Polyester |

Best Uses

Choosing between polyester and microfiber depends on what you’re using them for. Each fabric shines in different applications based on its unique properties.

Let’s look at where each material performs best in apparel and home goods.

Apparel

When you’re shopping for athletic wear or everyday clothing, polyester clothing delivers exceptional durability—holding up through 1,000+ washes—while microfiber apparel offers that silk-like softness you’ll feel instantly. For sportswear applications, polyester’s moisture-wicking moves sweat three times faster than cotton, but microfiber’s 25% better breathability keeps you cooler during intense workouts.

- Activewear: Microfiber absorbs 40% more moisture, perfect for yoga pants and performance tees

- Cost analysis: Polyester runs 10–20% cheaper, stretching your clothing budget further

- Fashion trends: Microfiber’s matte finish suits luxury casual wear beautifully

- Sustainable alternatives: Recycled polyester now represents 14–16% of apparel manufacturing

Your comfort factors depend on what you prioritize—polyester for longevity in sportswear, microfiber when softness matters most in clothing materials.

Home Goods

Your home textiles deserve thoughtful selection. Microfiber bedding delivers seven times more moisture absorption for enhanced comfort, while polyester sheets withstand 3–5 years of use compared to microfiber’s 1–3 year lifespan. For cleaning efficiency, microfiber cloths trap 99% of bacteria without chemicals, whereas polyester upholstery maintains loft 30% better in cushions.

| Application | Microfiber Advantage | Polyester Advantage |

|---|---|---|

| Bedding | Softer, breathable microfiber sheets | Wrinkle-resistant, color retention |

| Cleaning Products | Removes dust at fiber level | Lower cost comparison (10–20% cheaper) |

| Home Furnishings | Lightweight drape, plush feel | Durability in upholstery options |

Choose microfiber sheets when comfort matters most, and polyester for long-lasting home textiles.

Environmental Impact

Both polyester and microfiber carry significant fabric sustainability concerns that you should understand. Polyester emissions account for roughly 40% of total textile carbon output, and the fashion industry released 944 million metric tons of CO₂ in 2023 alone.

Microplastic pollution is equally troubling—one laundry load releases up to 700,000 fibers into waterways, with microfiber pollution representing over 60% of global microplastic contamination. Ocean contamination studies found polyester-based fibers in 92% of coastal sediments.

Recycling challenges persist, as less than 15% of polyester textiles get recycled worldwide. Sustainable alternatives include recycled PET microfiber, which cuts emissions by 32%, and enzyme-based biodegradation technologies showing promise in laboratory settings.

Making The Choice

Your decision ultimately hinges on five critical factors: comfort, application, budget, longevity, and eco-friendliness. Consumer textile choices should balance these competing priorities.

- Prioritize comfort: Microfiber scores 25–30% higher in softness testing, ideal for bedding and athletic wear

- Intended application: Polyester dominates in high-durability needs like uniforms and upholstery, representing 60% of global textile production

- Budget considerations: Polyester costs 20–30% less upfront, though microfiber’s 40% longer replacement intervals offset initial expenses

The fabric comparison reveals clear advantages and disadvantages. Microfiber excels in moisture management and tactile appeal, while polyester delivers greater tensile strength and wrinkle resistance. This key properties comparison shows no universal winner—your specific requirements determine which pros and cons matter most.

Frequently Asked Questions (FAQs)

Can Polyester and Microfiber Fabrics Be Easily Washed and Cared For?

Both fabrics are machine washable and dryer-friendly, making laundry care straightforward. You can use standard washing cycles with mild detergent choices.

However, microfiber needs gentler handling—stick to cold or warm washing temperatures and low-heat drying methods to preserve its absorbency and stain resistance while minimizing environmental concerns from fiber shedding.

Which Fabric, Polyester or Microfiber, is More Resistant to Stains?

Regarding stain resistance, think of microfiber as having a built-in shield. You’ll find microfiber more resistant to stains thanks to its dense weave and surface treatments, which trap liquids on top rather than letting them soak through, making cleaning easier and durability stronger.

Which is better, microfiber or polyester?

Neither fabric wins outright—your choice depends on priorities. Microfiber offers greater softness and absorbency, absorbing up to seven times its weight in water, making it ideal for cleaning and bedding.

Polyester excels in durability and cost-effectiveness, withstanding over 3,500 abrasion cycles while remaining 10–20% cheaper than microfiber.

What are the cons of microfiber fabric?

Each wash load sheds approximately 140 grams of microfibers, fueling microplastic pollution concerns. Microfiber shedding during washing creates a significant environmental impact, making proper care essential to minimize these drawbacks.

You’ll face heat retention issues, static buildup, and cleaning difficulty. Fiber degradation occurs above 140°F, reducing durability.

Is polyester fill breathable?

Polyester fill has limited breathability compared to natural fibers. Air permeability values often stay below 50 cm³/cm²/s, and MVTR ratings usually fall under 5,000 g/m²/24h—restricting vapor transfer and trapping moisture.

This makes polyester fibers less suitable for warm sleepers.

Can microfiber be 100% polyester?

Yes, microfiber can absolutely be 100% polyester—in fact, most microfiber fabrics you’ll encounter are pure polyester. The term "microfiber" doesn’t refer to material composition but to fiber diameter (under one denier).

These ultra-fine polyester fibers create that signature silky texture and enhanced moisture-wicking performance compared to standard polyester weaves.

Can polyester and microfiber fabrics be easily washed and cared for?

Both fabrics are remarkably easy to maintain. You can machine wash them on gentle cycles with mild detergent, avoiding fabric softeners and bleach. Low-heat tumble drying or air drying preserves fiber integrity while preventing shrinkage.

Prompt stain removal with appropriate techniques ensures long-lasting durability and performance.

Which fabric, polyester or microfiber, is more resistant to stains?

In terms of stain resistance, microfiber actually outperforms polyester. Its ultra-fine, densely woven fibers create a tight barrier that traps dirt and liquids on the surface, achieving up to 90% removal of oil-based stains compared to polyester’s 70-80%.

Can polyester be used for outdoor furniture?

When choosing fabric for outdoor furniture, you’ll find polyester stands up well to the elements. Solution-dyed polyester resists UV damage for 5 to 10 years, repels water effectively with proper treatment, and fights mold growth naturally—making it ideal for patio cushions and upholstery.

Is microfiber safe for sensitive skin types?

Microfiber offers softness and breathability that many find gentle, but you’ll want to watch for chemical sensitivities.

Manufacturing residues, dyes, and plasticizers can trigger skin irritation or allergic reactions in sensitive individuals, with studies showing up to 70% experiencing rashes from synthetic fabrics.

Conclusion

The right tool for the right job—that principle explains the polyester vs microfiber difference perfectly. Polyester delivers durability and moisture-wicking for activewear and outdoor furniture, while microfiber excels at absorption and softness in towels and cleaning cloths.

Your fabric choice isn’t about which material wins overall, but which properties your application demands. Match fiber diameter to function: choose sturdy polyester when longevity matters, select ultrafine microfiber when texture and liquid retention take priority.

Understanding these distinctions transforms shopping decisions from guesswork into informed selections.