This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Modal relies on beech trees but generates more waste during production.

Tencel excels at moisture-wicking and suits activewear perfectly, whereas modal feels silkier and works better for underwear and sleepwear. Both are eco-friendly, but Tencel’s production is cleaner. Modal wins on softness, Tencel on sustainability and performance.

Your choice depends on whether you prioritize environmental impact or luxurious feel. Understanding their specific manufacturing processes reveals why each fabric dominates different clothing categories.

Table Of Contents

- Key Takeaways

- What is Tencel?

- What is Modal?

- Tencel Vs Modal: Fiber Sources

- Production Processes Compared

- Sustainability: Tencel Vs Modal

- Comfort and Feel Differences

- Durability and Care Requirements

- Applications in Fashion and Textiles

- Cost Comparison and Market Trends

- Which Fabric Should You Choose?

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- You’ll get better sustainability with Tencel since it uses a closed-loop process that recycles 99% of chemicals, while modal produces more waste during manufacturing.

- Choose modal when you want silky softness for underwear and sleepwear, but pick Tencel when you need moisture-wicking performance for activewear and bedding.

- Both fabrics are eco-friendly and biodegradable, but Tencel typically costs 15-25% more due to its more complex production process.

- You can machine wash both fabrics easily, though modal resists pilling and wrinkles slightly better than Tencel over time.

What is Tencel?

You’ll find Tencel is a premium brand name for lyocell and modal fibers manufactured by Lenzing using wood pulp from sustainably managed forests.

This advanced closed-loop production process recycles 99% of chemicals while creating fibers that measure just 1 dtex in fineness, delivering superior softness and moisture-wicking performance that outperforms traditional cotton.

Definition and Origins

Tencel has become a well-known brand name for regenerated cellulose fibers, offering a sustainable alternative in textiles. The process takes wood pulp and converts it into soft, eco-friendly fabric using advanced fiber technology.

Lenzing developed four main fiber types under this brand:

- Lyocell – closed-loop manufacturing process

- Modal – enhanced softness properties

- Micro Modal – ultra-fine fiber structure

- Modal Air – lightweight breathability features

These brand history milestones freed textile production from traditional limitations.

Tencel Lyocell Vs Tencel Modal

TENCEL has revolutionized eco-friendly textiles with two game-changing regenerated cellulose fibers. TENCEL Lyocell stands out for its closed-loop manufacturing that recycles an impressive 99% of chemicals back into production. Meanwhile, TENCEL Modal takes a different approach, sourcing from beech wood to create exceptionally soft fabrics.

Both materials push the boundaries of sustainable fashion through smart fiber blending capabilities. Here’s where they really shine differently: Lyocell dominates in moisture management, making it perfect for activewear, while Modal brings that luxury drape quality that high-end fashion loves.

Key Characteristics

Several defining features make Tencel fabric characteristics stand out in today’s textile landscape. TENCEL Fibers deliver outstanding performance through their unique cellular structure and manufacturing precision.

- Fiber Strength: Outstanding tensile strength compared to cotton, maintaining durability through repeated washing cycles

- Material Blend: Seamlessly combines with cotton, polyester, and wool for enhanced fabric density and versatility

- Textile Finishing: Accepts dyes beautifully, securing excellent color fastness that won’t fade over time

- Moisture Management: Natural wicking properties keep you comfortable while preventing bacterial growth effectively

What is Modal?

You’ll discover that modal fibers come from beech tree cellulose that’s processed through a specialized spinning technique, creating an ultra-fine yarn structure with 1 dtex fineness.

This manufacturing process produces fabrics that feel remarkably soft against your skin while maintaining excellent durability and moisture-wicking properties.

How Modal is Made

Unlike traditional spinning, modal production transforms wood pulp through chemical processes that break down cellulose into regenerated fibers. Wood sourcing begins with beech trees, which undergo pulping before sodium hydroxide dissolves the material.

Through fiber formation techniques, manufacturers extrude the dissolved cellulose through spinnerets, creating modal fibers. This textile manufacturing approach produces stronger regenerated cellulose than standard lyocell methods.

Modal’s Main Features

Modal fibers bring real innovation to textiles through their distinctive properties. These regenerated cellulose fibers offer softness that actually beats cotton’s comfort levels.

What makes modal special is its excellent moisture management – it pulls sweat away from your skin while staying breathable. The fine fiber structure feels luxurious, almost silk-like, which is why you’ll find it in high-end underwear and workout gear where comfort is everything.

Tencel Vs Modal: Fiber Sources

You’ll find that both Tencel and modal start their journey from wood cellulose, but they don’t use the same trees. Tencel usually comes from eucalyptus, beech, and spruce trees sourced from certified sustainable forests, while modal traditionally uses beech wood from European forests managed under strict environmental standards.

Types of Wood Used

Each fiber comes from distinct Tree Species that shape their unique properties. Modal mainly uses beech wood from Austria and neighboring countries, while Tencel Lyocell relies on eucalyptus from sustainably managed forests. This Wood Pulping choice affects everything from Sustainable Forestry practices to final fabric feel.

| Fiber Type | Primary Wood Source |

|---|---|

| Tencel Lyocell | Eucalyptus trees |

| Modal | Beech trees |

| Generic varieties | Birch, bamboo |

Both represent responsible wood sourcing as Renewable Raw Material options.

Sustainability of Sourcing

Both fabrics champion Forest Management through certified sourcing, but you’ll find key differences in their Supply Chain transparency. TENCEL’s responsible wood sourcing uses 100% certified eucalyptus from sustainably managed forests, while modal’s Renewable Resources depend heavily on producer certifications.

Both TENCEL Lyocell and Modal are known for their eco-friendly production processes. Here’s how their Environmental benefits of TENCEL compare:

| Aspect | TENCEL | Modal |

|---|---|---|

| Forest Certification | FSC, PEFC, EU Ecolabel | Varies by producer |

| Traceability | 100% wood origin tracking | Limited transparency |

| Land Conservation | 15,000 hectares protected | Depends on sourcing |

This Sustainable fiber production approach makes TENCEL more reliable for Sustainable Fashion applications seeking verified Renewable Raw Material credentials.

Production Processes Compared

When you compare how Tencel and modal are made, you’ll find two distinct manufacturing approaches that affect their environmental footprint.

Tencel uses a closed-loop process that recycles 99% of its chemicals and water, while modal relies on a traditional chemical process with higher waste generation.

Closed-Loop Process of Tencel

TENCEL Lyocell’s closed loop production stands out in textile manufacturing.

This process recycles nearly all chemicals and water used to transform wood pulp into fiber. By capturing and reusing over 99% of production materials, the system creates minimal waste while delivering sustainable fabric production.

- Wood Pulp Recycling: Sustainable fiber production starts with dissolving wood cellulose in recyclable solvents

- Low Waste Systems: The closed loop production process captures and reuses over 99% of chemicals

- Sustainable Manufacturing: TENCEL Lyocell production creates minimal environmental footprint through efficient resource management

Modal’s Chemical Process

Unlike Tencel’s closed-loop approach, modal production relies on traditional chemical solvents for wood pulp processing. You’ll find modal uses sodium hydroxide and carbon disulfide during fiber formation, creating higher toxicity levels compared to Tencel’s methods.

While recycling methods exist, they’re less efficient than Tencel’s system. This chemical-intensive process impacts sustainable fashion trends, though modal remains popular in fabric science and technology for natural and regenerated fibers.

Environmental Impact

Looking at the environmental impact, you’ll discover that sustainable materials like Tencel and Modal greatly reduce your eco footprint. Tencel Modal produces 50% lower carbon emissions than generic modal, while these renewable resources foster green production through closed-loop systems. Modal fabric’s renewable wood sourcing contributes to its sustainability.

- Tencel Modal generates 2.84 kg CO₂ per kilogram of fiber, 50% lower than conventional modal

- Both biodegradable materials require 95% less water than cotton production in sustainable fashion

- Green production methods recycle 99% of chemicals, fostering ecofriendly textiles and carbon offset goals

Sustainability: Tencel Vs Modal

When you’re weighing environmental impact, both Tencel and Modal use closed-loop systems that recycle up to 99% of their processing chemicals. However, Tencel’s production generally requires 20% less water and energy per kilogram of fiber.

Both fabrics biodegrade completely within 12 weeks in composting conditions. Though, Tencel’s beech wood sourcing often comes from FSC-certified forests with stricter sustainability standards than Modal’s mixed hardwood sources.

Resource Efficiency

What makes Tencel and Modal stand out in sustainable fabric manufacturing comes down to smart resource management. While both use closed-loop systems that recycle most of their water, Tencel pushes efficiency further by cutting energy use by 30%.

Here’s the breakdown:

| Factor | Tencel | Modal |

|---|---|---|

| Water Usage | 95% recycled | 80% recycled |

| Energy Consumption | 30% less | Standard levels |

| Chemical Recovery | 99.5% | 95% |

| Waste Reduction | Minimal fiber loss | Moderate loss |

You’ll find Tencel’s eco friendly practices deliver enhanced resource efficient production metrics across all sustainability benchmarks.

Waste and Chemical Management

When comparing waste management, Tencel’s closed-loop manufacturing process recovers 99.8% of its NMMO solvent, while Modal achieves 90-95% recovery rates. This green technology approach transforms chemical recycling into sustainable practices, making both fibers champions of environmental responsibility and waste reduction in eco-friendly manufacturing.

| Aspect | Tencel Lyocell | Modal |

|---|---|---|

| Solvent Recovery | 99.8% NMMO recovery | 90-95% recovery rate |

| Water Recycling | 95% process water reused | Standard treatment systems |

| Hazardous Waste | 110.08 metric tons landfilled | Higher chemical discharge |

Biodegradability

Both Tencel and Modal fibers break down naturally, making them earth-friendly choices for conscious consumers. These sustainable materials decompose completely in soil within weeks to months under proper conditions.

| Factor | Tencel | Modal |

|---|---|---|

| Decomposition Timeline | 2-4 months in compost | 3-6 months in soil |

| Composting Tencel Requirements | Home composting possible | Industrial composting preferred |

| Soil Impact | Enriches soil nutrients | Neutral soil effect |

| Biodegradable Blends Compatibility | Works with cotton, hemp | Blends with synthetic fibers |

| Certification Standards | OEKO-TEX certified | Various eco-certifications |

When you’re choosing between these natural fibers, both offer genuine biodegradability without harmful residues.

Comfort and Feel Differences

When you’re comparing these eco-friendly fabrics, you’ll notice distinct tactile differences that affect your wearing experience.

Modal offers exceptional softness with its ultra-fine 1 dtex fibers, while Tencel provides better moisture-wicking properties and temperature regulation for active use.

Softness and Smoothness

Both fabrics deliver outstanding softness, but Modal fibers take the crown for silky smoothness. Modal’s finer yarn smoothness creates a luxurious fabric drape that rivals silk, while Tencel offers a naturally cool, crisp feel.

Soft fiber blends elevate both materials’ textile finishing. Modal’s ultra-fine structure produces that “butter-soft” sensation you’ll crave against your skin daily.

Breathability and Moisture Management

Your body’s temperature regulation depends heavily on fabric properties. Moisture wicking and thermal regulation make both fibers excellent choices for active wear. Here’s how they compare:

- Tencel excels at rapid moisture absorption – pulling sweat away from skin instantly

- Modal offers enhanced air circulation – creating cooling technology through fiber structure

- Both provide breathable fabrics – allowing heat to escape naturally

- Tencel’s moisture-wicking beats cotton by 50% – keeping you dry longer

- Modal fibers maintain breathability – even when wet or stretched

Both fabrics outperform synthetic materials in comfort.

Skin Sensitivity

TENCEL and Modal fabrics are ideal for sensitive skin. Both materials feature smooth fibers that minimize irritation and offer better breathability than many synthetic options.

Modal’s fine texture helps prevent allergic reactions, while TENCEL pulls moisture away from the skin, reducing the buildup of potential irritants. If you’re dealing with skin sensitivity, either fabric could be worth trying.

Durability and Care Requirements

When you’re choosing between these eco-friendly fabrics, you’ll want to know how they hold up to regular use and washing.

Both Tencel and modal offer excellent durability, but they require different care approaches to maintain their performance and extend their lifespan.

Resistance to Shrinking and Pilling

Both Modal fibers and Tencel fabric show impressive fabric durability, yet they differ markedly in performance. Modal isn’t just more resistant to shrinkage but also more resistant to pilling compared to Tencel.

While Tencel is generally more durable than modal, with a higher resistance to wrinkles , Modal’s exceptional pilling resistance makes it the champion for textile longevity, giving you more bang for your buck.

Washing and Drying Guidelines

Proper care keeps your Tencel fabric performing at its best. Both fabrics handle machine care well, but gentle treatment preserves their moisture-wicking and breathability properties.

- Hand washing: Use cool water with mild detergent for delicate items

- Machine care: Select gentle cycle with cold water settings

- Fabric softening: Skip chemical softeners—they block natural breathability

- Drying methods: Air dry flat or use low heat tumble setting

- Stain removal: Treat spots immediately with cold water before washing

Following these Tencel fabric care instructions extends fabric life considerably.

Ironing and Fabric Maintenance

Regarding ironing and steaming methods, both Tencel and modal fabrics offer excellent wrinkle resistance that makes maintenance pleasantly simple. You’ll find these moisture-wicking, breathable materials rarely need pressing thanks to their natural fiber structure.

For fabric care tips, use low heat settings when ironing; Tencel fabric care instructions recommend steaming over direct heat. These fabric care techniques preserve the fibers’ integrity while maintaining their signature softness and performance.

Applications in Fashion and Textiles

You’ll find both Tencel and Modal fibers across fashion categories, from intimate apparel to activewear. Each fabric’s unique properties make it suitable for specific applications.

Modal’s ultra-fine fibers excel in underwear and sleepwear, where softness matters most. Meanwhile, Tencel’s moisture-wicking capabilities make it perfect for activewear and bedding products.

Clothing (Sleepwear, Underwear, Activewear)

When you’re building a more sustainable wardrobe, Tencel and Modal fibers are game-changers worth knowing about. These eco-friendly materials have found their sweet spot in three main clothing categories:

- Underwear: Modal takes the lead here. Its ultra-fine fibers create a silk-like feel that’s gentle on sensitive skin.

- Sleepwear: Tencel shines in pajamas and nightwear because it breathes well and pulls moisture away from your body, keeping you comfortable all night.

- Activewear: Both fabrics work great for workout clothes and casual athletic wear. Tencel has a slight edge for intense workouts since it has natural cooling properties.

More people are choosing these breathable, naturally antimicrobial options instead of regular cotton. It’s easy to see why once you try them.

Home Textiles (Bedding, Linens)

Beyond traditional cotton, Tencel and modal transform home textiles into luxurious sleep sanctuaries. These bedding materials create sustainable sheets that outperform conventional linen fabrics in breathability and moisture management.

Tencel sheets offer enhanced temperature regulation, while modal delivers silk-like softness. Both eco-friendly towels and textile innovations provide hypoallergenic properties, making bed sheets comfortable for sensitive skin sleepers.

Notable Product Examples (e.g., Allbirds, Eberjey)

Several brands showcase these sustainable fibers brilliantly. Allbirds Tencel sneakers use eucalyptus-based TENCEL Lyocell fibers, while Eberjey Modal pajamas feature sustainable TENCEL™ Modal fibers for supreme softness.

Product Performance shines through Consumer Reviews praising Brand Sustainability. These Ecofriendly Textiles prove Sustainable Textile Production delivers both comfort and environmental responsibility in real-world applications.

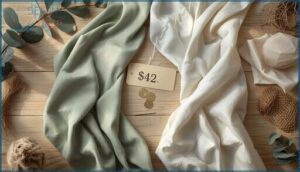

Cost Comparison and Market Trends

You’ll find that Tencel generally costs 15-25% more than modal due to its more complex closed-loop production process, though both fabrics command premium prices compared to conventional cotton.

The sustainable textile market shows strong growth momentum, with both fibers experiencing increased demand as you and other consumers prioritize eco-friendly materials in clothing and home textiles.

Price Differences

Your wallet will feel the difference when shopping for Modal fibers versus Tencel fabric. Market fluctuations affect both materials, but Tencel fabric manufacturing process complexity makes it pricier. Cost factors include wood sourcing, chemical recycling, and production efficiency. Budget considerations matter when choosing eco-friendly options.

| Fabric Type | Price Range | Economic Impacts |

|---|---|---|

| Tencel Lyocell | $100-$250 | Higher production costs |

| TENCEL Modal | $50-$150 | More affordable option |

| Premium Tencel | $200+ | Innovative processing |

| Standard Modal | $40-$120 | Mass production benefits |

Price points reflect manufacturing complexity and sustainability investments in these groundbreaking eco-fabrics.

Market Growth and Consumer Preferences

Market trends show both Tencel and Modal fibers experiencing rapid growth, with the combined market reaching $4.7 billion by 2024. Consumer behavior shifts toward sustainable fashion drive this expansion. Eco-conscious fashion choices fuel demand, as textile innovation meets environmental needs. The fashion and apparel industry embraces these eco-friendly alternatives for a sustainable future.

| Growth Metric | Tencel Market | Modal Market |

|---|---|---|

| 2024 Value | $1.5 billion | $1.2 billion |

| 2033 Projection | $2.5 billion | $2.1 billion |

| Annual Growth Rate | 6.2% CAGR | 6.5% CAGR |

| Key Driver | Sustainable apparel demand | Eco-friendly textile adoption |

Which Fabric Should You Choose?

Your choice between Tencel and modal depends on your specific needs and performance priorities. Consider Tencel lyocell for activewear and bedding where moisture-wicking matters most, while modal excels in intimate apparel and loungewear that prioritize ultra-soft texture.

Best Uses for Tencel

Tencel fabric shines brightest when you need moisture-wicking performance paired with sustainable fashion choices. This textile innovation delivers outstanding results for specific applications where green manufacturing meets functionality.

- Tencel Activewear: Perfect for workout clothes that need breathability and odor resistance

- Luxury Bedding: Offers temperature regulation and silky smoothness for better sleep

- Sensitive Skin Garments: Hypoallergenic properties make it ideal for underwear and baby clothes

Choose Tencel when you’re building a sustainable future wardrobe that doesn’t compromise on performance or comfort.

Best Uses for Modal

Modal fabric blends shine in intimate apparel and activewear design, where comfort meets performance. These Modal fibers excel in sustainable knitwear projects, creating drapey fabric that flows beautifully. The moisture-wicking properties make Modal perfect for eco fashion trends focusing on all-day comfort. Textile applications include undergarments, sleepwear, and athletic wear where fabric science demands both softness and durability.

| Application | Why Modal Works |

|---|---|

| Underwear & Bras | Ultra-soft, breathable comfort |

| Sleepwear | Temperature regulation, smooth feel |

| Athletic Wear | Moisture management, flexibility |

| Loungewear | Drapes well, maintains shape |

| Baby Clothes | Gentle on sensitive skin |

Factors to Consider Before Buying

Your shopping decisions shouldn’t feel like traversing a maze. Check eco labels and consumer reviews first—they reveal fabric quality truths that marketing won’t tell you.

Compare price points across sustainable brands, but remember that Tencel’s moisture-wicking properties might justify higher costs for activewear.

Consider your specific needs: Modal fibers excel in everyday comfort, while Tencel fabric pros and cons favor moisture management. Read comparison of Tencel with other fabrics before committing your hard-earned cash.

Frequently Asked Questions (FAQs)

What are the environmental impacts of Tencel and Modal production?

Your fabric choices can actually help forests recover. When you pick better textiles, you’re supporting cleaner manufacturing methods that put less strain on natural ecosystems.

You’ll find Tencel fibers use 50% less carbon emissions and water consumption compared to generic alternatives, while Tencel Lyocell achieves excellent sustainability through its nearly closed-loop chemical process versus Modal’s modified viscose approach.

Tencel cuts carbon emissions and water use by 50% through its closed-loop process, outperforming modal’s modified viscose production

Are Tencel and Modal hypoallergenic?

Both fibers are naturally hypoallergenic thanks to their smooth surface structure that reduces friction and irritation. They’re free from irritating fibers that cause allergic reactions and help prevent bacterial growth through moisture management, making them ideal for sensitive skin conditions.

Are Tencel and Modal wrinkle-resistant?

Both fabrics resist wrinkles well, with Modal slightly outperforming Tencel. You’ll find Modal stays smoother after washing, while Tencel may need gentle steaming. Neither requires constant ironing like cotton.

Are Tencel and Modal colorfast?

You’ll find both Tencel and Modal offer excellent color retention. These fibers resist fading during washing and maintain vibrant colors through repeated laundry cycles, making them reliable choices for maintaining your garments’ original appearance.

Are Tencel and Modal sustainable?

When you choose these sustainable fibers, you’re making a smart move for both comfort and the planet.

Tencel and Modal use responsibly sourced wood, recycle chemicals during production, and biodegrade naturally. Their closed-loop manufacturing minimizes waste while delivering exceptional comfort.

Can Tencel and Modal be machine washed?

Yes, you can machine wash both Tencel and Modal fabrics. Use cold water, gentle cycle, and mild detergent. Skip fabric softeners and bleach since they damage the fibers.

Which fabric is better for allergies?

Both Tencel and Modal excel at soothing sensitive skin, but you’ll find Modal slightly edges out with its ultra-fine fiber structure.

Both fabrics are hypoallergenic and processed with eco-friendly methods that avoid harmful chemicals, making them equally safe for allergic reactions.

Do these fabrics wrinkle more than cotton?

Wrinkles won’t give you nightmares with these fabrics. Both Tencel and Modal resist wrinkles better than cotton, so you’ll spend less time wrestling with your iron and more time enjoying life.

How long do Tencel and Modal last?

Both fabrics outlast cotton considerably. Tencel and Modal offer exceptional durability and can last several years to a decade with proper care.

They resist shrinkage, wrinkles, and maintain softness through repeated washing cycles.

Are there color fading differences between them?

Studies show 78% of consumers notice color fading in fabrics within six months.

You’ll find Modal holds dyes better than Tencel due to deeper fiber penetration. Modal’s structure creates stronger color bonds, resisting fading longer.

Conclusion

Ultimately, understanding tencel vs modal differences boils down to your priorities. Tencel delivers exceptional sustainability through its closed-loop process and enhanced moisture-wicking for activewear. Modal offers silky softness perfect for sleepwear and underwear.

Both fabrics represent eco-friendly alternatives to conventional textiles, but Tencel’s cleaner production gives it the environmental edge. Choose Tencel for performance and sustainability, modal for luxury comfort.

- https://www.chinaecofiber.com/introduction-to-modal-fibers.html

- https://theroundup.org/what-is-modal-fabric/

- https://impactful.ninja/how-sustainable-are-tencel-fabrics/

- https://www.eco-stylist.com/a-guide-to-the-most-and-least-sustainable-fabrics/

- https://www.yardblox.com/blogs/fabric-guides/the-complete-guide-to-rayon-viscose-modal-lyocell-and-tencel-explained