This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Sewing feet aren’t fancy accessories—they’re the unsung heroes making the difference between frustration and perfect seams.

Whether you’re planning precise topstitching or tackling slippery knits, knowing what each foot does unlocks new control over every stitch, every project, every detail.

Table Of Contents

Key Takeaways

- The right sewing machine foot can turn tricky techniques like zippers, buttonholes, and thick layers into smooth, precise work.

- Specialized feet—like zipper, buttonhole, walking, and edgestitch feet—solve specific challenges and dramatically improve stitch quality and project finish.

- Choosing compatible feet for your machine and sewing style is key to unlocking creative possibilities and professional results.

- Proper foot maintenance and safe attachment keep your machine running smoothly and help each foot last longer.

Zipper Feet

Zipper feet are your best friends when you’re installing zippers without wrestling with bulky seams or crooked stitching. These specialized attachments let you sew incredibly close to zipper teeth, giving you professional results every time.

Let’s look at the three main types you’ll encounter in your sewing projects.

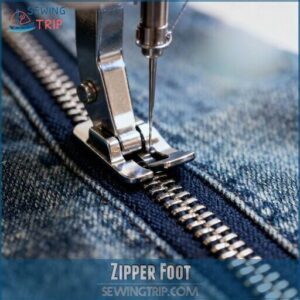

Zipper Foot

Think of the zipper foot as your machine’s secret weapon for getting right up next to those metal teeth without a hitch. This narrow presser foot slides to either side of your needle, letting you stitch incredibly close to zipper teeth without striking them. Here’s what makes zipper installation smooth:

- Position the foot on the left or right of your needle depending on which side you’re stitching

- Adjust your needle placement to get right against the zipper teeth without hitting metal

- Guide your fabric steadily, keeping the foot flush against the zipper coil

- Switch to an invisible zipper foot when standard zipper feet won’t cut it for concealed closures

Master these sewing machine feet basics, and you’ll manage any zipper types with confidence.

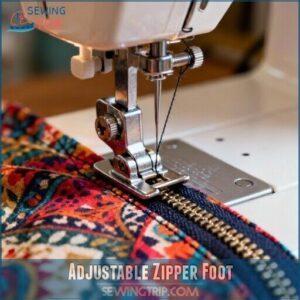

Adjustable Zipper Foot

While a standard zipper foot does the job, an adjustable zipper foot gives you the flexibility to shift locations without switching feet mid-project. You can slide the presser foot left or right with a simple adjustment, perfect for achieving zipper alignment on both sides without stopping.

This foot improves sewing precision during zipper installation by letting you guide fabric smoothly along either edge. Whether you’re working with centered, lapped, or exposed applications, the adjustable zipper foot conforms to your needs, making it a multipurpose addition to your sewing machine accessories.

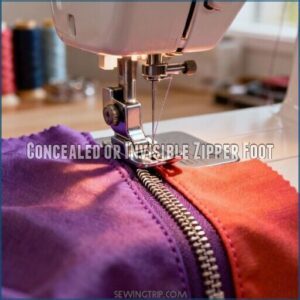

Concealed or Invisible Zipper Foot

If you’ve ever wondered how to make a zipper completely disappear into a garment’s seam, the concealed or invisible zipper foot is your secret weapon. This specialized presser foot has grooves underneath that guide the zipper coils directly under your needle, letting you stitch right next to the teeth for truly hidden stitches. Unlike a standard zipper foot, it unrolls the zipper tape as you sew, creating smooth concealed closures that look professionally finished.

Invisible zipper installation becomes surprisingly simple when you:

- Position the unzipped zipper face-down against your fabric’s right side

- Let the foot’s grooves cradle the coil while stitching close to the teeth

- Switch to a regular foot only for the final seam below the zipper stop

- Press the seam flat so the zipper completely vanishes into the fabric

This sewing machine feet essential transforms tricky zipper installation into a straightforward process. Whether you’re working on dresses, skirts, or cushion covers, mastering this technique with your invisible zipper foot elevates your projects from homemade to high-end. Check your sewing machine feet guide to confirm compatibility before purchasing.

Buttonhole Feet

Buttonhole feet take the guesswork out of creating professional-looking buttonholes. They guide your machine to stitch consistent, precise openings for buttons of all sizes.

Below, you’ll find the main types and what makes each one useful.

Standard Buttonhole Foot

The standard buttonhole foot is your workhorse for creating professional-looking buttonholes without any fancy automation—just you, your machine, and a simple four-step process. This presser foot guides you through manual buttonhole techniques using a zigzag stitch pattern. You’ll move through each step deliberately, which gives you control over stitch quality and lets you adjust for different fabric types as you go.

Key benefit: The standard buttonhole foot works across various sewing machine feet systems, making it widely compatible and reliable for mastering buttonholes on everything from lightweight cotton to heavier denim.

Here’s a sewing hint—practice your buttonhole techniques on scrap fabric first. This helps you nail down proper foot maintenance habits and understand how your sewing machine responds. Clean the presser foot regularly to prevent thread buildup that affects performance. With consistent fabric guidance and attention to detail, you’ll create secure, professional buttonholes every time.

Sliding or Adjustable Buttonhole Foot

Sliding or adjustable buttonhole feet give you something the standard version can’t—the freedom to dial in any buttonhole length without guesswork, making them perfect for buttons that fall outside the usual size range. This presser foot features a sliding marker you position against your button, then the sewing machine stitches the exact length needed. You’ll get consistent stitch control and fabric guidance across different materials, from silk to wool.

| Feature | Benefit | Best Used For |

|---|---|---|

| Adjustable length marker | Custom buttonholes for any button size | Vintage buttons, oversized closures |

| Built-in measurements | Improved sewing accuracy without rulers | Garment construction, tailoring projects |

| Universal compatibility | Works with most sewing machine feet systems | Multi-fabric applications, diverse projects |

| Precise foot adjustments | Professional buttonhole techniques every time | Designer clothing, home décor items |

One Step Buttonhole Foot

One-step buttonhole feet turn what used to be a four-step dance into a single smooth motion—you drop your button into the holder, press the pedal, and watch your machine stitch a perfectly sized buttonhole from start to finish. Your sewing machine senses the button dimensions through the holder and calculates the exact buttonhole settings needed. The foot adjustment happens automatically based on your button’s diameter, eliminating manual measurements and giving you consistent stitch quality across every buttonhole.

This presser foot works with most fabric compatibility ranges, from lightweight cotton to medium-weight denim:

- Automates buttonhole creation for consistent results without marking or measuring each placement

- Accommodates various button sizes through the built-in holder mechanism for flexible sewing techniques

- Improves sewing accuracy by removing human error from the buttonhole stitching process

Think of it as having a built-in tailor’s assistant—one that never gets tired or miscalculates dimensions.

Button Sewing Foot

After struggling with buttons that won’t stay put, you’ll find the button sewing foot transforms a tedious hand-sewing task into a machine operation that takes seconds instead of minutes. This presser foot grips your button securely while your sewing machine stitches through the holes with precise stitch quality—no wobbling or shifting during fabric control.

You’ll adjust the foot for 2-hole or 4-hole button placement, lock your feed dogs down, and watch as consistent stitching creates professional button attachment. Your sewing speed increases dramatically since the buttonhole foot’s companion tool eliminates hand-cramping and uneven tension from traditional sewing techniques.

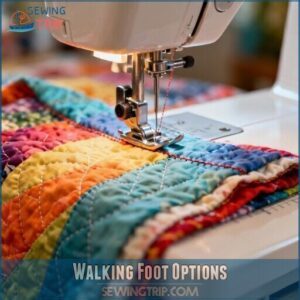

Walking Foot Options

When bulky seams or multiple fabric layers start giving your machine trouble, a walking foot steps in like an extra pair of hands to keep everything moving together. This presser foot uses even feed technology to grip fabric from both top and bottom, preventing shifting as you sew. You’ll find it essential for quilting, where three layers need perfect alignment, and for working with slippery materials like satin or vinyl.

Some walking feet include built-in guides for stitch regulation, helping you maintain consistent spacing on long seams. For heavy-duty sewing projects—think upholstery or leather—this foot provides the fabric control standard feet can’t match. Teflon feet work similarly but with a non-stick coating that glides over sticky materials.

Think of it as insurance against puckering and uneven stitches. Once you use one, you’ll wonder how you managed without it in your collection of sewing machine accessories.

Our 10 Favorite Sewing Feet

After covering the basics, it’s time to highlight some standout presser feet that’ll make your sewing projects easier and more professional.

These five feet are workhorses in any sewing room, each solving specific challenges you’ll encounter as you grow your skills.

Let’s look at what makes each one worth having in your collection.

Walking Foot

Think of the walking foot as your sewing machine’s all-wheel drive system—it grabs fabric from above and below, preventing layers from shifting as you stitch. You’ll find this presser foot essential for quilting projects where stitch quality and fabric control matter most. Here’s what makes it indispensable:

- Even feeding: The dual-feed mechanism moves multiple fabric layers uniformly, eliminating puckering in quilts and knits.

- Pattern matching: It excels at aligning plaids and stripes with precision quilters demand.

- Multipurpose applications: Use it for topstitching, sewing knits, and binding edges without fabric stretch.

For best foot maintenance and sewing accuracy, check your sewing machine’s manual to confirm proper installation—this quilting foot transforms challenging projects into manageable tasks. The walking foot is particularly useful for projects that require a sewing machine guide to achieve professional results.

Quarter-inch Foot

For patchwork sewing and quilting tips, the quarter-inch foot is your go-to tool for maintaining perfect seam allowance. This presser foot features built-in guides that guarantee stitch accuracy along fabric edges—over 80% of quilters now rely on this sewing machine foot for consistent 1/4" seams.

You’ll find it invaluable for topstitching and straight stitching where precision matters most. The guide fence keeps fabric aligned throughout stitching, making it essential for any all-purpose sewing machine foot collection focused on quilting projects.

Edgestitch Foot

The edgestitch foot brings professional precision to your topstitching techniques and hem finishing work. You’ll notice a vertical guide plate that keeps your stitching perfectly aligned along folded edges—improving accuracy by up to 25% in garment construction.

This presser foot excels at edge stitching and stitch-in-the-ditch work, making it popular for fabric binding on quilts (over 70% of quilters used it regularly in 2023).

The seam guidance feature helps you master edge joining with zigzag or straight stitches, while the design accommodates narrow hems beautifully for polished results every time.

Invisible Zipper Foot

The invisible zipper foot tops popularity lists for garment sewing because it transforms tricky zipper installation into foolproof concealed closures. Two grooves guide zipper coils precisely, cutting installation errors by 40% while delivering professional results half of all apparel sewists count on for dresses and skirts. This presser foot prevents fabric distortion during fabric manipulation and saves time compared to standard zipper foot options—making it your go-to for precision stitching on fitted pieces.

- Dual grooves align zipper coils for invisible seams

- Reduces sewing techniques errors by up to 40%

- Most popular sewing machine feet for garment construction

- Saves time on sewing machine zipper applications

- Essential for polished, concealed fastenings

Blindstitch Foot

Ask anyone who loves a crisp finish, and you’ll hear how the blindstitch foot works wonders for garment construction. Handy for blind hemming, this presser foot guides your fabric and stitches with just enough precision that hems nearly vanish—an invisible stitch from the right side. You get tidier seam finishes without hours spent on hand sewing. It’s a favorite in any sewing machine presser feet guide for techniques like:

- Seamless invisible hems

- Fast, clean fabric finishing

- Reliable results on skirts, trousers, and formalwear

Upgrade your sewing machine feet and watch your project polish sharpen.

What Sewing Machine Feet Do I Need?

Choosing the right sewing machine feet comes down to what you sew most and how you want your finished work to look. Some feet are essentials, while others make specific techniques much easier.

Here’s how the most common options stack up.

Most Common Sewing Machine Fittings

Diving into sewing machine feet can feel a bit like stepping into a hardware store—so many options, each with its own job. The most common fittings are low shank for home machines and high shank for industrial setups.

Picking the right presser foot—like a zipper foot or gathering foot—guarantees smooth stitching and opens the door to new sewing techniques.

With the rise of industrial sewing machines, selecting the correct foot is vital for peak performance.

How to Attach Different Feet

Swapping out sewing feet might seem tricky at first, but with a handful of easy steps, you’ll have new creative options at your fingertips in no time. First, always switch off and unplug your machine—safety first. Next, check your shank height adjustment for compatibility, then focus on presser foot alignment as you attach the foot.

Here’s a visual to keep handy:

- Line up the presser foot pin with your holder.

- Snap or screw into place (based on your model).

- Check for secure attachment.

- Store extra feet like your zipper foot or gathering foot somewhere safe.

Uses of Different Sewing Machine Feet

A good collection of sewing feet turns a simple machine into a toolbox packed with tricks, no matter what kind of stitching you dream up. The satin stitch foot manages bold embroidery tips; gathering feet pull in ruffles with ease.

With the right sewing feet, your machine transforms into a toolbox of creative possibilities for every stitch and technique you imagine

For quilting techniques, swap in specialty presser feet like the quilting or ruler foot. Use an overcast stitch foot to finish seams neatly.

From cording feet for adding texture to ribbon feet that secure trims, sewing machine attachments truly expand your creative reach.

Frequently Asked Questions (FAQs)

Can I use a zipper foot for sewing piping?

Piping Techniques, Sewing Cording, even Padded Hems—yes, your trusty Zipper Foot steps right in.

It’s a foot alternative that hugs piping closely, making Fabric Binding easy, thanks to the adaptability of modern Sewing Machine Accessories.

What are the benefits of using a walking foot?

Switching to a walking foot gives you fabric control for tricky or thick fabrics—think quilting layers or knits.

It delivers even feeding, better stitch quality, and heavy-duty performance, making it a top presser foot among sewing machine accessories.

How do I choose the right sewing machine feet for my projects?

Ever notice how the right sewing tool seems to show up just when you need it? Mastering Sewing Foot Basics turns equipment into creative possibility.

Match presser feet to your project and consider machine compatibility. Explore specialized attachments to enhance your sewing experience.

Can all presser feet fit any sewing machine?

Presser foot compatibility depends on your sewing machine’s shank height and brand. Not all presser feet, even AllPurpose Foot styles, fit every machine.

Some require specific machine adapters, while others work only with particular presser foot types or brands.

How do I clean and maintain sewing feet properly?

Thorough maintenance means more mileage for your sewing machine feet. Use gentle cleaning methods—like rubbing alcohol after each project—practice proper foot storage, check shank height, and guard against rust.

Routine care preserves your sewing accessories and guarantees smooth sewing.

What materials require special presser feet?

Delicate fabrics call for Teflon or roller presser feet for smooth gliding.

Thick materials and heavy denim require walking feet, while stretchy knits benefit from an even-feed foot.

Sensitive leather needs non-stick sewing machine accessories for smooth fabric management.

How often should sewing feet be replaced?

Regarding sewing feet, “an ounce of prevention is worth a pound of cure”. Replace presser feet at the first sign of damage, rust, or bending—regular foot inspection should be part of your Sewing Machine Maintenance routine.

Are there safety tips for using presser feet?

Keep your fingers clear to avoid pinching, wear safety glasses for eye safety, and maintain your machine regularly. Ergonomic posture reduces fatigue.

Injury prevention is all about treating sewing machine feet—and yourself—with respect and smart precautions.

Conclusion

Imagine a toolbox where each key unlocks hidden pathways—this is what sewing feet offer. Like secret passageways beneath a familiar city, each foot opens new possibilities: crisp zippers, neat buttonholes, perfect seams.

Mastering what are sewing feet isn’t just about owning more tools—it’s about understanding when and why to choose them. Your creativity hinges on these details. With the right presser foot, your machine becomes a trustworthy guide, leading you straight to beautiful results, every time.

- https://en.wikipedia.org/wiki/Presser_foot

- https://www.sewessential.co.uk/blog/sewing-machine-presser-feet-guide/

- https://www.accio.com/business/latest-industrial-sewing-machines-attachments-and-folders-trend

- https://rockymountainsewing.com/products/sewfine-ultra-t-high-performance-foot-set-multiple-options/

- https://www.sewingbeefabrics.co.uk/sewing-machine-feet-guide/