This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Start by matching your thread type to your fabric: nylon for strength, cotton for breathability, polyester for durability, or silk for luxury projects.

For lightweight fabrics, opt for sizes 60-90 to achieve those smooth, barely-there stitches.

You’ll want to adjust your machine’s tension carefully – too loose and you’ll get loops, too tight and snap goes your thread.

Just like a master chef’s secret ingredients, there’s a whole world of professional techniques waiting to transform your sewing game.

Table Of Contents

Key Takeaways

- You’ll need to match your thread type to your fabric carefully – use nylon for strength, cotton for breathability, polyester for durability, and silk for luxury projects to achieve the best results.

- You’ll want to adjust your sewing machine’s settings by reducing tension to 2-3, using a size 60/8 needle for thin fabrics, and selecting the shortest stitch length to prevent puckering and breaking.

- You’ll find that proper thread storage in cool, dry places away from sunlight and regular rotation every 18-24 months will maintain thread quality and prevent disintegration.

- You’ll achieve the smoothest results by using thread sizes 60-90 for lightweight fabrics, placing tissue paper beneath delicate materials, and maintaining steady, moderate sewing speeds.

Thread Types Overview

You’ll find that mastering thin thread types is like having a secret weapon in your sewing arsenal, with options ranging from sturdy nylon to silky-smooth cotton for your delicate projects.

Whether you’re working with lightweight chiffon or gossamer-thin silk, knowing which thread to choose will help you create those perfectly invisible seams you’ve always dreamed of achieving.

Nylon Thread Properties

In regard to nylon thread properties, you’ll find unmatched strength and elasticity that’s perfect for delicate work.

You’ll appreciate how this versatile thread stretches without breaking, making it ideal for fine thread sewing on lightweight fabrics.

Its superior fiber durability and material resistance mean your stitches will hold up beautifully, while its smooth sewing performance guarantees consistent results.

For superior thin thread sewing, nylon’s your reliable partner.

Cotton Thread Characteristics

While nylon boasts industrial strength, cotton thread’s charm lies in its natural breathability and soft touch.

You’ll find mercerized cotton thread shines with enhanced durability and a subtle luster, perfect for sewing thin threads on delicate fabrics.

Its fiber types vary from long-staple to Egyptian cotton, each offering unique weave patterns and yarn quality.

For everyday projects, soft cotton thread delivers reliable performance without compromising fabric drape.

Polyester Thread Advantages

Polyester thread’s exceptional durability makes it your go-to choice for nearly any sewing project.

You’ll find its strength particularly useful when working with delicate fabrics, as it maintains its integrity even under tension.

Modern polyester threads offer remarkable color retention and fabric resistance, while their smooth texture guarantees sewing ease across various materials.

- Glides through your machine like butter on a warm day

- Holds strong even after countless washes

- Resists fading better than your favorite old jeans

- Stretches just enough to prevent seam puckering

Silk Thread Uses

Silk thread is your secret weapon for sewing fine threads and adding luxury to silk fabric projects.

Its strength and sheen prevent fabric distortion, ensuring smooth stitches. Adjust thread tension carefully—silk sewing tips like this make all the difference!

Perfect for textile arts or fabric blending, it handles delicacy like a pro, mastering even intricate sewing techniques with luxury.

Choosing Right Thread

Choosing the right thread guarantees your stitches hold up beautifully without puckering or breaking.

By matching thread type, weight, and color to your fabric, you’ll avoid frustrating snags and achieve a polished finish every time.

Matching Thread to Fabric

When sewing with delicate thread on fine fabrics, matching thread to fabric is key.

Think about the fiber, weight, and texture.

For lightweight thread sewing, opt for silk on satin or polyester on synthetics—balance strength and flexibility.

Understanding thread basics is essential for choosing the right thread for your project.

Texture contrast methods can avoid puckering.

Fabric-thread compatibility guarantees smooth stitches, showing your mastery in delicate fabric sewing.

Considering Thread Color

Thread color isn’t just decoration—it’s your project’s quiet superhero. Pairing hues with fabric matching is key for color harmony.

Subtle tints blend seamlessly, while bold hues pop for contrast. Explore thread dyeing tricks or test samples first; fabrics vary under light.

Proper hue selection even hides mistakes. Nailing thread selection sparks creativity, even when sewing with delicate thread!

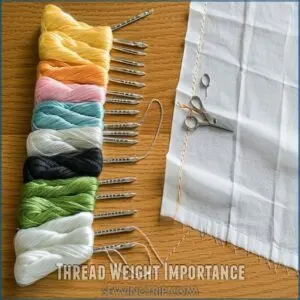

Thread Weight Importance

Choosing the right thread weight guarantees smooth stitching and prevents fabric mishaps. Thin threads work best for delicate fabrics, while heavier threads handle tougher projects.

To achieve superior results, understanding the needle selection process is vital for selecting the right thread.

Keep these in mind:

- Match thread sizes (like tex or denier) to fabric thickness.

- Avoid thread breakage with proper tension.

- Confirm fabric stability by testing thread weights.

- Prioritize sewing precision.

- Adjust for fabric stretch.

Fabric Care Instructions

Before stitching, pre-wash and iron your fabric to prevent unexpected shrinkage later.

Proper fabric care, like gentle washing and thoughtful storage, helps maintain thread durability and avoids thin thread problems.

For sewing thin fabrics, finish seams neatly to prevent fraying.

Simple steps like this make fabric washing and ironing your secret weapon for smooth sewing and long-lasting results, using proper fabric care.

Thread Size Selection

Choosing the right thread size is key to flawless stitching, especially with thin fabrics that demand precision.

If your thread’s too thick or too thin, your project might turn into a tangled mess or a stretched-out disappointment.

Thread Size for Lightweight Fabrics

When sewing thin fabrics, the thread size matters. For lightweight materials like chiffon or silk, choose thread sizes between 60-90 for smooth, delicate stitches.

A thinner thread diameter reduces puckering and keeps sewing tension balanced. Using silk thread can also provide strong and smooth results.

Test on scraps to avoid thin thread problems, ensuring your lightweight thread sewing results in crisp, clean seams without breaking or tangling.

Thread Size for Heavyweight Fabrics

Tackling heavyweight fabrics? You’ll need a thread size that matches their bulk.

Opt for thicker threads like sizes 30 or 40—these provide the thread strength and thread durability required for heavy-duty sewing.

Fabric weight demands a thread diameter that holds seams together securely, avoiding any weak points. Remember, lightweight thread sewing isn’t effective here; the fabric thickness demands tougher threads!

Thread Color Impact

Thread colors do more than just blend; they can transform your project.

Choosing sewing threads that create color harmony or fabric contrast affects thread visibility and overall impact.

Test dye lots to avoid mismatches and guarantee colorfastness, especially for bold hues.

Remember: sewing with thin threads requires careful thread selection, as the wrong shade could overshadow delicate fabrics.

Sewing Machine Setup

Getting your sewing machine setup right makes working with thin threads much smoother and less frustrating.

With a few simple adjustments, you can avoid skipped stitches, snapped threads, and fabric damage.

Setting Up for Thin Fabrics

Before sewing thin fabrics, take a moment to prep your sewing machine.

Start by ensuring the needle matches your delicate thread selection—think sharp, fine needles for smooth stitches.

Adjust your machine’s settings for lighter tension.

Keep fabric handling soft and precise to avoid puckering while working with sheer fabrics.

These simple adjustments simplify sewing lightweight threads beautifully.

Thread Tension Adjustment

Nail your tension control when sewing thin fabrics by fine-tuning your machine calibration. Light fabrics call for lower thread tension to avoid puckering or thread breakage.

Test before you sew—always! Understanding thread tension is essential for perfect stitches.

- Too loose? Loops form on the fabric’s back.

- Too tight? Snap—thread breaks at speed.

- Find balance to keep your delicate thread sewing flawless.

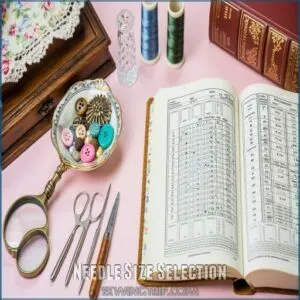

Needle Size Selection

Choosing the right needle size guarantees smooth sewing precision and minimizes thread breakage. A fine thread needle, matched to your thread weight and fabric, is key. Sharp needle tips improve stitch quality and prevent snags.

Consider this quick reference: Understanding sewing techniques is important for achieving professional results.

| Fabric Type | Thread Sizes | Needle Sizes | Needle Material |

|---|---|---|---|

| Lightweight | 60-90 | 8-10 | Steel or Titanium |

| Medium Weight | 50-60 | 11-14 | Chrome-Plated |

| Heavyweight | 30-40 | 16+ |

Stitch Length Variation

After selecting the right needle, stitch length sets the tone for sewing thin fabrics. Longer stitches reduce puckering, while shorter ones boost seam stability.

Adjust sewing machine settings to balance needle movement and fabric stretch.

- Test stitch lengths: Try on fabric scraps first.

- Match stitch length to thread weight: Thin threads need shorter stitches.

- Check thread tension: Avoid fabric pulling.

Thread Care Essentials

Taking care of your thread mightn’t sound exciting, but it’s the secret to smooth, snag-free sewing.

Keep your spools clean, dry, and rotated regularly, and you’ll dodge those annoying breaks and tangles mid-stitch.

Storing Threads Properly

Keeping thread storage neat isn’t just about appearance—it saves your sanity later.

Smart organization guarantees hassle-free sewing sessions! For easy thread selection, organize spools by type or color.

Store spools in a cool, dry spot, far from sunlight and moisture to maintain thread quality and fiber protection. Closed containers work wonders for spool management, blocking dust and preserving thread.

Preventing Thread Disintegration

A bad storage environment can weaken sewing threads before you even begin. Prevent thread disintegration with these tips:

- Avoid direct sunlight exposure to protect thread strength.

- Control humidity to stop brittleness or mold.

- Store in cool temperatures to preserve materials.

- Inspect threads for fuzz or fading—signs of trouble.

Take care, and your threads will last, ensuring proper storage to maintain their quality.

Rotating Old Threads

Thread Revitalization isn’t just about storage – it’s about smart rotation. You’ll want to refresh your thread collection every 18-24 months to maintain peak sewing performance.

Here’s a quick guide to thread aging signs:

| Age Indicator | Action Needed | Impact on Sewing | Prevention Tips |

|---|---|---|---|

| Visible Fading | Replace Thread | Weak Stitches | Store in Dark Place |

| Brittle Texture | Immediate Replace | Thread Breaks | Use Sealed Containers |

| Lint Build-up | Quality Check | Tension Issues | Regular Cleaning |

| Color Transfer | Replace Similar | Staining Risk | Separate Storage |

Handling Thread With Care

Now that you’ve refreshed your thread collection, let’s talk about proper thread handling – it’s like giving your threads a five-star hotel treatment. You’ll want to keep these tiny textile champions in peak condition for flawless stitching results.

- Store spools horizontally in a cool, dark place to prevent thread breakage and maintain tension control

- Clean your thread guides regularly to avoid lint buildup

- Handle thread ends with care to minimize fabric fraying

- Keep thread quality intact by avoiding exposure to direct sunlight and high humidity

Thin Thread Sewing Tips

You’ll discover that working with thin threads isn’t as tricky as it seems once you’ve got the right techniques down pat.

Whether you’re crafting delicate heirloom pieces or working with lightweight fabrics, these proven tips will help you master the art of sewing with thin threads without the usual tangles and tension troubles.

Handling Delicate Fabrics

When working with delicate fabrics like chiffon or silk, you’ll need a gentle touch and the right tools.

Let’s explore essential fabric handling techniques that’ll make your sewing journey smoother: To achieve perfect stitches, mastering sewing hacks is important for handling various fabric types.

| Fabric Type | Handling Method | Thread Choice |

|---|---|---|

| Chiffon | French seams | Size 60-70 polyester |

| Silk | Rolled hems | Fine silk thread |

| Organza | Stay-stitching | Lightweight nylon |

Keep your hands clean and dry while handling these fabrics, and use tissue paper underneath to prevent slipping during stitching.

Preventing Puckering and Distortion

After mastering delicate fabric handling, let’s tackle those pesky puckering issues.

Start by reducing your upper thread tension and making small adjustments to your bobbins tension.

Test these settings on scrap fabric first. You’ll want to choose finer thread weights that complement your lightweight materials and avoid multiple stitch rows.

Remember to keep your machine clean to prevent any unwanted fabric snags.

Using Right Needle and Thread

Selecting the right needle and thread combination becomes your secret weapon for flawless stitches. Remember, proper thread selection and needle size work together like a well-choreographed dance for perfect results.

For delicate projects, pair fine thread types with smaller needle sizes (60/8 or 70/10).

Your thread weight should match your fabric’s characteristics – lighter threads for silk and chiffon, medium-weight for cotton. Working with thin threads requires careful consideration of needle size and thread weight to achieve the desired stitch quality.

Sewing Speed and Tension Control

Fine-tune your sewing speed and thread tension like a pro for flawless results with thin threads.

Keep your machine calibrated at a moderate pace—rushing only leads to skipped stitches.

When working with lightweight fabrics, dial down your thread tension slightly and maintain steady fabric control.

You’ll know you’ve got it right when your stitch regulation produces even, balanced seams without puckering or loops.

Frequently Asked Questions (FAQs)

What is thin thread used for?

You’ll find thin threads perfect for delicate fabrics like silk and chiffon.

They create fine, nearly invisible seams and work beautifully for detailed embroidery work, heirloom sewing, and intricate decorative stitching.

How do you set a sewing machine to thin fabric?

Reduce tension to 2-3, use a size 60/8 needle, and select the shortest stitch length. Lower presser foot pressure slightly. Test settings on scrap fabric first for perfect results.

Does thread matter when sewing?

Thread choice can make or break your entire sewing project.

It’s absolutely vital to match your thread weight and type to your fabric – this affects your seam strength, stitch quality, and overall results.

How to sew flimsy fabric?

Use tissue paper beneath delicate fabrics for stability while sewing.

You’ll want to adjust tension settings lower, choose a fine needle, and take it slow.

Pin generously to prevent shifting and puckering.

How to prevent thread tangling during high-speed sewing?

Keep your machine well-oiled, adjust tension settings properly, and don’t rush the start.

You’ll want to hold both thread tails when beginning to sew, preventing those pesky backlash tangles at high speeds.

Can thin threads be used for buttonhole stitching?

Thin threads aren’t ideal for buttonholes, as they lack the strength to withstand repeated stress.

You’ll get better results with medium-weight thread that’s specifically designed for buttonhole stitching and heavy wear.

What causes thin threads to break while backstitching?

Nearly 70% of thread breakage occurs during backstitch moves. You’re likely experiencing breaks due to excessive tension, a dull needle, or incorrect thread weight for your machine’s capabilities and settings.

Should thin threads be pre-treated before delicate embroidery?

Pre-treating your threads isn’t necessary for delicate embroidery, but you’ll want to handle them with care.

Keep your threads away from moisture and test them on scrap fabric before starting your project.

When to switch between thin and regular threads?

Switch to thin threads for delicate fabrics and detailed work, while regular threads work best for everyday sewing.

You’ll want to match thread weight to your fabric’s thickness and your project’s requirements.

Conclusion

As swift as a TikTok trend, mastering sewing with thin threads transforms your projects from amateur to artisan.

You’ll find that precise tension control, proper thread selection, and mindful machine setup create flawless results every time.

Whether you’re crafting delicate lingerie or haute couture pieces, these techniques will elevate your sewing game.

Remember, practice makes perfect – start with simple projects and gradually tackle more challenging ones. Soon you’ll be creating pieces that rival professional work.