This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Gently brush away dust, lint, or thread bits from the guide, paying attention to tight spots. A toothpick or compressed air can help tackle stubborn debris.

Once it’s clean, dry the guide thoroughly with the cloth to avoid rust or residue buildup. For metal guides, a tiny drop of machine oil can keep things smooth.

It’s quick, simple, and keeps your sewing projects running like clockwork. Curious how pros handle tougher messes? There’s more to uncover ahead about tougher messes.

Table Of Contents

Key Takeaways

- Use a soft-bristled brush, lint-free cloth, and sewing-safe solution to clean lint or debris from the thread guide.

- Tackle tight spots with a toothpick or compressed air, ensuring all stubborn buildup is removed.

- Dry the guide thoroughly after cleaning to prevent rust or residue, and add a drop of machine oil for smooth operation.

- Regular maintenance of the thread guide ensures better performance and avoids sewing issues like snags or breaks.

Cleaning Thread Basics

You’ll need to understand the basics of thread cleaning to prevent leaks and equipment failure, just like knowing how to floss prevents dental problems.

Your pipes and fittings will thank you with years of trouble-free service when you regularly remove debris, rust, and buildup from their threads, which is a result of proper maintenance.

Importance of Thread Cleaning

Surprisingly, thread cleaning remains the most overlooked maintenance task in plumbing and mechanical work.

Properly cleaned threads guarantee component compatibility and prevent misalignment that causes leaks. You’ll reduce friction between mating parts, preserving structural integrity and extending equipment life.

Clean threads ensure compatibility, prevent leaks, and extend equipment life by reducing friction and preserving structural integrity.

Clean threads create proper seals, prevent costly repairs, and guarantee smooth operation. Think of thread cleaning as preventive medicine – a small effort now saves substantial headaches later.

Tools and Materials Needed

Now that you know why clean threads matter, let’s gather your arsenal.

You’ll need several wire brush types for different threading materials, a thread chaser for stubborn grime, and detailed pipe cleaners for those hard-to-reach spots.

Compressed air benefits include blasting away loose debris, while lint-free cloths prevent new contamination.

Knowing the appropriate brush styles is key for effective cleaning. Many cleaning supplies are common household items you already own.

Remember, having the right materials turns a frustrating job into a quick 10-minute task.

Common Thread Types

Now that you have your tools ready, let’s identify what you’re working with. Common thread types vary by material, size, pitch, and standards.

You’ll encounter UNC/UNF threads on most bolts, NPT on plumbing connections, and metric threads on newer equipment. Metal threads (steel, brass) need different cleaning approaches than synthetic threads.

Understanding your specific thread form makes cleaning more effective and prevents damage during maintenance. Selecting the right thread often depends on thread weight and size for peak performance. This is crucial for ensuring that the threads are used effectively.

How to Clean Threads

You’ll need the right techniques to transform grimy, rusty threads into smooth, functional connections that won’t leak or stick.

With the proper tools and a bit of elbow grease, you can restore those troublesome threads to like-new condition, saving yourself from the frustration of failed connections and costly repairs.

Using a Wire Brush

Now that you have your tools ready, let’s tackle those dirty threads with a wire brush – your best friend for thread cleaning success.

A quality wire brush removes debris with the right technique:

- Choose the correct bristle material (brass for softer metals, steel for tougher rust removal)

- Match brush size to your thread diameter

- Apply consistent cleaning pressure in a circular motion

- Prep the surface by removing loose debris first

Consider using a specialized wire tool for superior cleaning.

Applying Chemical Solutions

While wire brushes handle surface debris, chemical solutions tackle the tough stuff.

For effective thread cleaning, select the right solution: Loctite 7063 for degreasing, isopropyl alcohol for general cleaning, or chemical rust removers for corrosion.

Consider purchasing Loctite products for superior degreasing.

Apply with a brush, spray, or cloth depending on the product, and always prioritize safety by wearing gloves and a respirator when handling chemicals.

Always rinse thoroughly afterward to remove any residue.

Lubricating Threads

Coat your cleaned threads with a thin layer of appropriate lubricant to guarantee smooth connection and prevent future corrosion.

You’ll need to match the lubricant type with your thread material—silicone for plastic, anti-seize for metal.

Apply using a small brush for even coverage. This simple step reduces torque required during assembly and extends thread life.

Remember, compatibility matters—the wrong product can damage certain materials, so it is crucial to choose the right lubricant to ensure the longevity and smooth connection of your threads.

Thread Cleaning Methods

You’ll need different cleaning methods depending on your thread type, from wire brushes for corroded metal threads to gentle pipe cleaners for PVC.

The right technique can save you hours of frustration and prevent those dreaded leaks that always seem to happen at the most inconvenient times, which is why using the right technique is crucial.

Cleaning Corroded Threads

Now that you know the basics, let’s tackle those stubborn corroded threads that can make any plumber curse.

For light rust, grab a wire brush and some WD-40 to work the magic. Natural alternatives include white vinegar or lemon juice for effective corrosion removal.

Dealing with severe corrosion? A flap disc with an angle grinder will do the trick.

A flap disc and angle grinder conquer severe corrosion, transforming rusted threads into smooth, functional connections with powerful precision.

White toothpaste works surprisingly well for gentle thread restoration.

Cleaning Gas Pipe Threads

A plumber’s worst nightmare is a gas leak caused by dirty threads. When cleaning gas pipe threads, thoroughness prevents dangerous situations.

- Remove mill varnish with non-soap cleaners before installation

- Apply degreaser to black pipe to dissolve factory oil coating

- Use a wire brush for light debris without damaging thread profile

- Chase damaged threads with a proper NPT die

- Verify complete thread drying before applying gas-rated sealant

For removing debris, consider using a fitting brush effectively to ensure clean threads and prevent accidents.

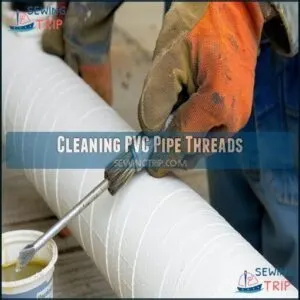

Cleaning PVC Pipe Threads

While gas lines require special care, PVC pipe threads need a gentler approach.

For effective cleaning, scrape away old sealant with a screwdriver tip following the threads.

Apply rubbing alcohol on a cloth for stubborn residue, or use a plastic knife for pipe dope and caulk.

A stiff bristle brush maintains thread integrity without causing damage.

For proper sealing afterward, apply a plastic-friendly sealant like Hercules Megaloc.

Specialized Thread Cleaning

You’ll need specific techniques for materials like galvanized, black, and brass pipe threads, as each requires its own cleaning approach.

When you match the right method to your thread type, you’ll prevent damage and guarantee proper sealing, just like a skilled plumber who knows that one size doesn’t fit all, and this will help you to prevent damage.

Cleaning Galvanized Pipe Threads

When cleaning galvanized pipe threads, protect the zinc layer to prevent damage.

Soak threads in a vinegar solution for 15 minutes, then scrub gently with a wire brush. Finish with compatible lubricants to guarantee a proper seal and prevent rust.

- Vinegar soak time removes stubborn grime.

- Rust prevention ensures longevity.

- Drying methods avoid corrosion.

- Use appropriate cleaning tools carefully.

Cleaning Black Pipe Threads

How do you clean black pipe threads like a pro? Start with cleaning tools like a wire brush for rust removal.

Use acetone or WD-40 to tackle oil contamination. Make sure threads are dry before applying thread sealants for fitting compatibility.

Preventative measures, like inspecting regularly, keep pipe threads in good shape, ensuring secure seals and long-lasting performance.

Cleaning Brass Pipe Threads

Brass pipes might look sturdy, but their threads need careful handling.

For tarnished brass cleaning, wipe loose debris with a soft cloth. Use mild soap or vinegar for brass corrosion removal.

Avoid harsh, abrasive cleaners to prevent brass damage.

After cleaning, apply brass thread lubrication lightly. Specific cleaners designed for brass are ideal, ensuring smooth threads and lasting durability.

Internal Thread Cleaning

Cleaning internal threads doesn’t have to be complicated if you approach it step by step.

By inspecting the threads, prepping the area, and using the right tools, you’ll restore functionality in no time.

Examining Internal Threads

Before using thread cleaning tools, inspect internal threads carefully. Look for damage types like wear or cross-threading and identify obstructions such as rust or debris. Note the material composition to select proper cleaning methods.

- Check threads under good light.

- Use a magnifier for precision.

- Measure threads for consistency.

- Test with a matching bolt.

- Keep specialized tools handy.

Preparing The Area

Start by organizing your workspace; a clutter-free area makes all the difference.

Make certain ample ventilation to avoid fumes. Protect surfaces with a drop cloth or cardboard to catch debris.

Place tools and materials within easy reach—no one likes searching mid-task!

Prioritize contamination prevention by cleaning the area first. It’s your thread guide’s best friend for safety and efficiency.

Choosing a Cleaning Method

Choosing the right cleaning method hinges on a few factors.

Consider these:

- Match cleaning tools to thread size and material compatibility.

- Assess corrosion severity; mild cases need simple cleaning methods, severe ones require advanced tools.

- Factor in accessibility challenges; tight spots need flexible cleaning tools.

- Weigh budget constraints—some thread cleaning methods are costlier but necessary for delicate threads.

Regular maintenance, including monthly lubrication needs, can prevent future issues, and this is crucial for delicate threads and overall maintenance.

Common Cleaning Mistakes

Skipping key steps might seem harmless, but it can cause long-term damage to threads.

Let’s tackle some common mistakes so you can avoid turning a quick cleaning into a costly repair.

Not Removing Debris

Skipping debris removal before cleaning threads can lead to thread damage, sealant failure, and a corrosion risk.

Dirt left behind compromises cleaning effectiveness. Think of debris as the villain of smooth fittings. Always brush or blow debris away before tackling threads.

Use these thread cleaning tips to save time and trouble.

| Tools | Purpose | Best Practice |

|---|---|---|

| Wire Brush | Loosens debris buildup | Gentle scrubbing |

| Compressed Air | Clears fine particles | Short, steady bursts |

| Lint-Free Cloth | Final wipe | Verify threads are dry |

| Thread Chaser | Deeper thread cleaning | Aligns threads evenly |

| Toothbrush | Tight spots cleaning | Back-and-forth motion |

To ensure effective cleaning, it is crucial to follow the best practices outlined for each tool, and remember that cleaning threads is about removing debris to prevent corrosion risk and ensure smooth fittings.

Incorrect Chemical Solutions

Using the wrong chemical solutions can ruin threads faster than you think.

Some solvents cause material degradation, while others leave residue buildup, leading to ineffective cleaning.

Always check the solution compatibility with pipe materials.

Follow safety precautions when handling harsh chemicals.

Missteps here might compromise your cleaning methods and cause more headaches than the dirt you’re trying to remove, which can lead to ineffective cleaning and material degradation.

Insufficient Lubrication

Neglecting lubrication is like forgetting sunscreen—it’s a small step with big consequences.

Without a proper lubricant, you’ll get higher thread friction, reduced thread sealing, and poor corrosion prevention.

Explore lubricant types, and apply a thin, even coat using proven application methods.

This thread cleaning guide emphasizes lubrication as a must-follow for smoother operation and longer-lasting threads.

Don’t skip it, as following these guidelines is crucial for smoother operation.

Thread Cleaning Safety

When cleaning threads, it’s vital to prioritize safety by using proper gear like gloves and goggles to protect from debris and chemicals.

Handle tools and cleaning solutions carefully to avoid accidents or thread damage, ensuring the job gets done right.

Protective Gear

During thread cleaning, proper gear keeps you safe.

Wear gloves made of nitrile or rubber to shield hands.

Eye protection like goggles prevents debris from reaching your eyes.

For respiratory safety, use a mask if fumes arise.

Choose fitted clothing to avoid snags, and sturdy shoes for foot protection.

Protective gear guarantees thread cleaning safety stays in check, ensuring proper gear is essential for the task.

Chemical Handling

Chemical handling isn’t rocket science, but it does demand attention to detail. Always check chemical compatibility and follow safety labels. Good ventilation prevents fumes from becoming a problem. Equip yourself with suitable PPE, like gloves and goggles.

- Store chemicals safely, away from heat.

- Dispose of them properly per local rules.

- Avoid mixing unknown solvents.

- Always prioritize protective gear when handling.

The key to safe chemical handling is to be meticulous and follow established guidelines, ensuring that you handle chemicals with the utmost care and attention to safety labels.

Avoiding Damage

Don’t let thread damage ruin your day—pick the right tools! Select soft brushes over abrasive cleaners, reduce force on delicate materials, and verify compatibility between tools and threads.

Avoid over-tightening, which can cause thread stripping. A little patience and the right thread cleaning techniques go a long way.

Remember, thread cleaning safety is about working smart, not hard. Always unplug the machine for maintenance.

Thread Maintenance Tips

Keeping your threads in top shape isn’t hard if you inspect them regularly and act early.

A little maintenance, like preventing rust and applying lubrication, goes a long way in extending their lifespan.

Regular Inspection

Start your thread cleaning process with regular inspections—it’s like giving threads a routine check-up.

Use inspection tools to assess damage and cleanliness.

Follow these quick steps:

- Check threads for rust, corrosion, or debris as part of frequency guidelines.

- Record findings for better record keeping and preventative measures.

- Identify damages early to fine-tune your thread cleaning techniques.

Consider using drawer dividers to maintain thread order.

Preventing Corrosion

Corrosion weakens thread integrity, so take steps to stop it early.

Use protective coatings or lubricants to keep moisture at bay. Choose materials resistant to environmental factors, like stainless steel, to avoid galvanic corrosion.

Applying inhibitors after thread cleaning also helps. Remember, thread maintenance isn’t magic—it’s good habits and the right tools.

Prevention always saves headaches later!

Extending Thread Life

Taking care of threads goes beyond cleaning.

Regular inspection catches wear early, saving time and money.

Use proper lubrication to reduce friction and preserve thread integrity.

Stick to gentle cleaning methods to avoid damage, and always consider material compatibility.

Don’t forget correct torque during assembly—it maintains longevity.

These thread cleaning best practices guarantee a longer thread lifespan and better performance.

The reorganization highlights the importance of regular inspection in maintaining thread quality.

Frequently Asked Questions (FAQs)

How to clean internal threads?

Ignoring debris in internal threads is like wearing muddy shoes indoors—it causes problems.

Inspect threads, use a matching bolt with lubricant to loosen grit, clean with a wire brush, and dry thoroughly to avoid corrosion.

How to clean internal threads without a tap?

Use a soft wire brush or pipe cleaner to remove debris gently, rotating evenly.

A degreaser or vinegar can help loosen grime.

Rinse thoroughly, let it dry, and apply lubricant for smooth threads.

How to clean pipe threads?

Grab a wire brush or a toothbrush, scrub gently to remove debris, and use a degreaser if needed.

For stubborn grime, a thread chaser works wonders.

Always dry thoroughly before applying sealant or tape.

How do you clean threads?

Inspect the threads for debris or corrosion, then gently scrub with a wire brush or thread chaser.

For tougher grime, apply a lubricant or cleaning solution, let it sit, and rinse thoroughly.

Dry completely, ensuring the area is free of moisture to prevent corrosion.

How do you clean internal threads with a wire brush?

Cleaning internal threads with a wire brush is like combing tangled hair—go slowly, applying consistent pressure.

Insert the brush, rotating gently to clear debris.

Always rinse thoroughly, ensuring threads are clean and damage-free.

What tools do you need for thread cleaning?

You’ll need tools like a wire brush, thread chaser, or tap and die set.

Add compressed air for blowing debris, a lint-free cloth for wiping, and lubricants or cleaning solutions for stubborn grime.

How to clean threads in hard-to-reach spaces?

It’s like threading a needle in dim light—use a flexible pipe cleaner or a toothbrush with a long handle.

Add a bit of lubricant, twist carefully, and rinse debris with compressed air.

What environmental factors affect thread cleanliness?

Dust, humidity, and temperature swings can mess with thread cleanliness.

Moisture promotes rust, while dirt and oils attract debris.

To keep threads in good shape, store them dry, clean, and away from harsh environments, which helps maintain clean threads.

How to safely clean antique or delicate threads?

Treat antique threads like fragile treasures; gently brush away debris with a soft-bristle toothbrush or pipe cleaner.

Avoid water-based solutions—use mild solvents sparingly.

Inspect often, ensuring cleanliness without damaging delicate materials or historical integrity.

What’s the lifespan of cleaned threads after maintenance?

Well-maintained threads can last indefinitely with regular care, but neglect leads to corrosion and wear.

Frequent cleaning, proper lubrication, and avoiding over-tightening guarantee longevity.

Think of it as giving threads a spa day—they’ll thank you!

Conclusion

Did you know even a small buildup of lint in your thread guide can reduce sewing efficiency by 20%?

Keeping your thread guide clean guarantees smooth stitching and avoids frustrating snags or thread breaks.

With the right tools, a steady hand, and regular maintenance, you’ll keep your sewing projects on track effortlessly.

Apply these pro secrets, from proper cleaning techniques to lubrication, and you’ll master how to clean thread guide effectively for long-lasting, flawless results every time.

- https://www.youtube.com/watch?v=MoimFvHaB1Q

- https://www.quora.com/How-can-I-clean-rusty-threads-on-pipe-fittings

- https://terrylove.com/forums/index.php?threads/cleaning-dressing-old-pipe-threads.28870/

- https://www.garagejournal.com/forum/threads/how-to-clean-iron-pipe-fitting-threads-on-old-plumbing-work.516305/

- https://www.reddit.com/r/HomeImprovement/comments/27mgc5/cleaning_up_pipe_dope/