This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

That faded gray shirt hanging in your closet doesn’t have to stay that way. Black dye transforms worn-out clothes into wardrobe staples, and you don’t need professional equipment to get deep, lasting color.

The process works on cotton tees, vintage finds, and even synthetic blends—each fabric just needs the right approach. Your biggest challenge isn’t the dyeing itself but preparing the fabric correctly and choosing a dye that actually bonds with your shirt’s fibers.

Get those two steps right, and you’ll achieve rich black color that holds up wash after wash instead of fading to murky charcoal after three cycles.

Table Of Contents

- Key Takeaways

- Best Fabrics for Dyeing Shirts Black

- Choosing The Right Black Fabric Dye

- Essential Supplies for Black Shirt Dyeing

- Preparing Your Shirt for Dyeing

- Mixing and Applying Black Dye

- Step-by-Step Black Dyeing Methods

- Creative Black Dyeing Techniques

- Fixing and Setting Black Dye

- Washing and Caring for Dyed Black Shirts

- Troubleshooting Common Dyeing Issues

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Natural fibers like cotton and silk absorb black dye easily and create permanent bonds, while synthetic fabrics like polyester require special disperse dyes and high heat to avoid settling for weak charcoal gray instead of true black.

- Proper fabric preparation—prewashing in hot soapy water without fabric softener, removing all stains, and checking water quality—determines whether you get deep, even black or patchy, disappointing results that fade quickly.

- Matching your dye type to your fabric is non-negotiable: fiber-reactive dyes work for cotton and linen, acid dyes handle wool and silk, and synthetics demand products like Rit DyeMore that bond at temperatures above 200°F.

- Post-dye care locks in color permanently—rinse from hot to cold water to seal pigment, use dye fixatives like Retayne for wash resistance, and always wash dyed shirts alone in cold water for the first several cycles to prevent bleeding.

Best Fabrics for Dyeing Shirts Black

Not all fabrics take black dye the same way. Natural fibers like cotton and silk soak up color easily, while synthetics demand different products and techniques.

If you’re unsure which category your material falls into, a fabric dictionary can help you identify its fiber content before dyeing.

Here’s what you need to know about choosing the right fabric for a deep, lasting black.

Natural Vs. Synthetic Fibers

Natural fibers like cotton grab black dye fast, forming strong bonds that lock in color. You’ll get a deeper black shade and solid dye uptake with cellulose fabrics.

If you’re just starting out, working with cotton fabrics gives you the best shot at rich, lasting color without complicated prep work.

Polyester fights back. It needs special disperse dyes and high heat to penetrate that hydrophobic barrier. The difference? Cotton reaches true black in one bath. Synthetics often land at charcoal grey unless you match your dyeing techniques to the material science.

Polyester demands disperse dyes and high heat to achieve true black—cotton succeeds in one bath while synthetics settle for charcoal grey

For best results, consider using disperse dye methods to achieve the desired black shade.

Fabric Preparation Tips

Prewash your shirt in hot, soapy water—no fabric softener. Fabric scouring strips away oils, waxes, and factory residues that block black fabric dye from bonding deep. Remove every stain before dyeing; oil spots resist dye and leave pale rings.

Skipping prewash risks serious headaches later—cotton can shrink over 7% and ruin your fit, so treat fabric prep like a sewing insurance policy before you ever touch scissors or dye.

Check your water quality and pH control—hard water and high alkalinity wreck even coverage. These prewash techniques set you up for true, inky black instead of patchy grey disappointment. Proper scouring fabrics is essential for achieving consistent dye results.

Special Considerations for Blends

Fiber blending throws a wrench in black fabric dye work—cotton polyester blends often land at charcoal instead of midnight. Polyester resists fabric dyeing methods that soak cotton beautifully, so you’ll need DyeMore for Synthetics plus extended heat.

Blend ratios matter: over 35% synthetic fabric demands dual systems for dye penetration. Without fabric modification or proper colorfastness testing, your shirt fades to patchy disappointment.

For pure cotton denim, dyeing denim black at home becomes much simpler since you can skip the synthetic-blend complications entirely.

Choosing The Right Black Fabric Dye

The dye you pick makes or breaks your black shirt project. Your fabric type dictates which dye will actually stick and which will wash right out.

Let’s break down the three main dye categories so you can grab the right product and skip the do-overs.

Fiber-Reactive Vs. Acid Dyes

You’re choosing between two dye chemistry paths: fiber reactive dyes and acid dyes. Fiber reactive dyes bond covalently to cotton and linen, delivering exceptional color fastness and black shade depth through alkaline fixation. Acid dyes target wool, silk, and nylon using ionic fiber binding in acidic baths.

For dyeing clothes black, fiber reactive dyes give cotton shirts the deepest, most wash-resistant results through permanent dye fixation.

Box Dyes (Rit, Dylon, Etc.)

Box dyes like Rit and Dylon put black fabric dye power in your hands—no specialty shops required. When dyeing clothes, these brands deliver solid black shade consistency across cotton, linen, and blends:

- Rit Dye offers all-purpose formulas plus color depth enhancement through doubled doses and salt additions

- Dylon Dye uses fiber-reactive chemistry for permanent fabric dyeing results

- Dye fixative options and dyeing safety precautions boost performance and protect your workspace during the transformation.

Dye Options for Synthetics

Polyester, nylon, and acrylic won’t accept standard all-purpose dye—you need disperse dyes engineered for synthetic fiber dyeing. Rit DyeMore for Synthetics and iDye Poly push dye molecules into polyester blends at high heat, delivering black shade enhancement that standard formulas can’t match.

Here’s your synthetic dye types breakdown:

| Dye Type | Best For | Application Temp | Black Shade Depth | Colorfastness |

|---|---|---|---|---|

| Disperse Dyes | Polyester, Nylon | 95–130 °C | Deep, uniform black | High wash/light resistance |

| DyeMore for Synthetics | Polyester blends | 95 °C (hottest cycle) | Enhanced with intensifier | Good with proper heat |

| iDye Poly | Polyester, Synthetic fabrics | 95 °C, 10+ min | Rich black with auxiliary | Excellent on pure polyester |

| All-Purpose Dye | Natural fibers only | 60–90 °C | Fails on synthetics | Poor on polyester |

| Specialized Disperse | Polyester-Spandex | 80–100 °C | Anti-yellowing formulas | Optimized for blends |

Rit All-Purpose Dye produces pale, washed-out results on synthetic fabrics because polyester fibers repel water-based chemistry. Switch to disperse-based black dye for garments with over 35% synthetic content—anything less leaves you with gray disappointment instead of true black domination.

For poly-blends that fade after dyeing, cutting sleeves off a shirt and pre-treating the exposed edges helps lock in color while maintaining clean lines through proper fabric prep.

Essential Supplies for Black Shirt Dyeing

You can’t dye a shirt black without the right supplies on hand. Getting everything ready before you start saves time and keeps the process smooth from beginning to end.

Here’s what you need to gather for a successful dyeing session.

Dye and Fixatives

You’ll need the right black fabric dye and a solid fixative to lock in that dark, rebellious shade. Here’s your essential arsenal:

- Fiber Reactive dyes for cotton—pair them with soda ash to create those unbreakable covalent bonds that laugh at washing machines.

- Acid Dyes for silk and wool—vinegar drops the pH and drives color deep into protein fibers.

- Rit AllPurpose Dye or ColorStay Dye Fixative—cationic fixatives grab loose dye molecules and prevent bleeding, especially critical for achieving that deep, commanding black you’re after.

Protective Gear (Gloves, Aprons)

You’re going to get messy—own it. Nitrile gloves offer enhanced chemical resistance and puncture protection compared to latex or vinyl, making them your best bet for fabric dyeing. Long-cuff versions shield your forearms from hot dye splashes.

Add a barrier apron to protect your torso from spills, and wear splash-proof safety goggles when mixing concentrated dye—unprotected eyes risk irritation from airborne powder.

Tools and Containers

Your workspace determines whether you nail deep, even black or end up with splotchy chaos. Choose the right arsenal:

- Polypropylene buckets or stainless steel pots (16–24 quart) give fabric room to circulate—cramped containers create uneven color

- Long-handled wooden spoons or stainless tongs keep your hands safe from scalding dye baths

- Digital scales and measuring cups guarantee precise dye-to-fabric ratios for consistent results

Preparing Your Shirt for Dyeing

You can’t skip the prep work if you want a deep, even black that actually lasts. The right setup saves you from patchy color, wasted dye, and frustrating do-overs.

Here’s what you need to handle before your shirt hits the dye bath.

Pre-Washing and Stain Removal

You can’t skip the pre-wash—stains and factory finishes block dye from bonding evenly with your fabric. Wash your shirt in warm water with detergent (skip the softener) to strip away oils and sizing.

For stubborn stains, treat them with enzyme detergent first. This fabric preparation step gives you deep, uniform black instead of blotchy disappointment. Clean fabric takes dye like a dream.

Weighing and Calculating Dye Amount

Once your shirt’s clean, weigh it dry on a digital scale accurate to 0.1 grams—fabric weight determines dye quantity directly.

Deep black demands about 4 percent of fabric weight in dye concentration: for 125 grams of cotton, you’ll need roughly 5 grams of black fabric dye.

This dye chemistry calculation controls color depth and prevents weak, faded results in textile dyeing.

Setting Up a Safe Work Area

Your workspace needs serious airflow to keep dye fumes and powder dust from settling in your lungs—set up cross ventilation with a box fan in one window and crack another opposite it.

Cover your table with a plastic tarp, fill your bucket with hot water, and keep cold water ready nearby. Here’s your safety equipment checklist:

- Rubber gloves to block skin staining

- Safety goggles for powder splash protection

- Particle mask when measuring dry dye

Position chemical storage containers upright on raised surfaces, not directly on floors where spills spread fast.

Mixing and Applying Black Dye

Mixing your dye correctly makes the difference between a rich, deep black and a disappointing gray. The water temperature, additives, and stirring method all affect how well the dye bonds to your fabric. Get these basics right and you’ll nail the color you’re after.

Water Temperature and Ratios

For deep black saturation, heat your dyebath to 140–160°F when working with cotton, linen, or wool—hot water unlocks better dye fixation and retention. Cold water works with fiber-reactive dyes on cotton, but temperature control directly impacts black dye concentration and fixation rates.

Use 10 to 20 times your shirt’s weight in water so the fabric moves freely, preventing patchy results.

Adding Salt or Vinegar for Color Depth

Boost your black intensity by adding 1 cup of salt when dyeing cotton, rayon, or linen—it drives dye molecules from the bath onto fiber surfaces, maximizing color enhancement and dye fixation.

For wool, silk, or nylon, swap salt for 1 cup of white vinegar to create the acidic conditions acid dyes demand.

These fabric dyeing methods deliver deeper blacks and enhanced color retention without extra effort.

Stirring and Soaking Techniques

Keep your fabric moving. Stir continuously for the first 10 minutes in the hot water bucket—wearing rubber gloves—to prevent splotches and guarantee even Black Dye uptake.

Continue agitation throughout 30–60 minute Soaking Times for maximum Dye Fixation and Color Enhancement. Fabric Movement stops dye from pooling in creases.

This method works perfectly for Dyeing Jeans or any garment requiring uniform, deep color.

Step-by-Step Black Dyeing Methods

You’ve prepped your shirt and mixed your dye—now it’s time to actually transform that fabric. The method you choose depends on your setup, your fabric weight, and how much control you want over the process.

Here’s how to tackle black dyeing using three proven techniques that work.

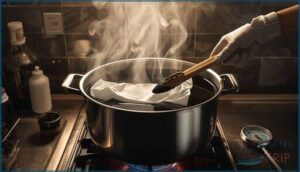

Stovetop Dyeing Process

Fill a large stainless steel pot with enough water to cover your shirt completely, then crank the heat until it hits a rolling boil. Stir in your black dye following package instructions for dye consistency, then reduce heat to maintain a steady dye temperature around 200°F.

Add color fixative and submerge your shirt, stirring constantly for maximum dye absorption. This stovetop method demands vigilant heat control and stovetop safety awareness.

Bucket Dyeing Process

Grab a large bucket and fill it with three gallons of hot water—around 140°F works perfectly for most black dye dissolution. Dissolve your dye in two cups of very hot water first, then pour it into the bucket.

Submerge your pre-washed shirt, stir constantly for ten minutes, then agitate every fifteen minutes for the next hour. This bucket setup gives you total control over color fixation without needing a stovetop method.

Washing Machine Dyeing

Your washing machine can handle black dyeing techniques if you respect its limits. Pre-wet your shirt, toss it in the drum, add dissolved Rit dye, then run a full 40°C cotton cycle—no eco settings allowed.

- Set water levels to maximum for proper dye circulation around fabric dyeing and clothes

- Select standard cycles over quick washes for even black dye saturation

- Add detergent (5 mL) to prevent streaking during the dyeing process

- Run a second hot cycle with bleach afterward to flush machine residue

Creative Black Dyeing Techniques

Black doesn’t have to mean boring. You can create custom patterns and effects that transform a plain shirt into something completely your own.

Here’s how to break the rules and make black work for you.

Tie-Dye and Pattern Effects

Black dye transforms ordinary tie-dye into dramatic art. Spiral patterns gain punch with black accents radiating between bright wedges. Shibori folding creates geometric blocks, while crumple techniques yield galaxy effects with irregular dark zones. For web designs, twist from off-center points to build spider-like arms.

| Pattern Type | Binding Method | Black Placement |

|---|---|---|

| Spiral | Twist from center, secure with intersecting bands | Apply to back or alternate wedges |

| Shibori | Accordion-fold in two directions | Fill selected geometric segments |

| Galaxy/Nebula | Random scrunch into flattened mound | Concentrate over lighter base colors |

| Spider Web | Half-folded off-center spiral | Radiate alongside contrasting hues |

Cure tied shirts 24–48 hours above 70°F for deep blacks in fabric dyeing techniques.

Dip-Dye and Ombre Styles

Ombre techniques let you command gradient effects by controlling how deep each shirt section sits in black dye. Dip the hem for 10 minutes, lift gradually to expose the middle for 5, then barely touch the top—this staged immersion builds color shift from intense black to barely tinted fabric.

Pre-wet your shirt and keep it moving constantly during textile dyeing to avoid harsh lines in dip dyeing experiments.

Reverse Dyeing With Bleach

Where ombre builds depth, reverse dyeing with bleach strips it away to carve patterns from dark fabric. Mix household bleach with water at a 3:2 ratio, bind your shirt with rubber bands for reverse tie effects, then brush or spray the solution onto cotton. Watch for 10-15 minutes until you see color removal, rinse thoroughly, and soak in a 1:10 hydrogen peroxide solution for dye neutralization—this step prevents fabric damage from residual oxidants still eating your fibers.

Essential reverse bleach dyeing steps:

- Wear gloves and work outdoors when handling bleach to avoid skin contact and chlorine vapor exposure.

- Use only 100% cotton shirts because bleach destroys wool, silk, and most synthetics beyond repair.

- Monitor bleaching closely since stronger concentrations accelerate both color removal and fiber breakdown.

- Rinse until water runs clear, then neutralize with a hydrogen peroxide bath before washing.

- Never skip neutralization—residual bleach continues weakening dyed fabric and clothes long after rinsing.

Fixing and Setting Black Dye

Getting the dye to stay put is where most people mess up. You need to lock in that black color so it doesn’t wash out after a few rounds in the machine.

Here’s how to fix and set your dye properly so your shirt stays dark and bold.

Rinsing and Temperature Control

After your shirt’s soaked up all that rich black dye, the rinse is where you lock it in or lose it—and temperature’s your secret weapon. Start with hot water to flush loose dye particles, then switch to cold for color setting and dye fixation. This temperature shift tightens fibers and seals pigment deep into the fabric.

Keep your rubber gloves on throughout—dyeing fabric and clothes gets messy. Rinse until water runs clear, applying color theory and application principles for maximum depth.

| Stage | Water Temperature | Purpose |

|---|---|---|

| Initial Rinse | Hot (120-140°F) | Removes excess dye, opens fibers |

| Mid Rinse | Warm (90-110°F) | Continues flushing loose particles |

| Final Rinse | Cold (60-70°F) | Locks color, tightens weave |

| Bucket Soak | Hot initially, then cold | Complete dye fixation process |

Using Dye Fixatives

Once your rinse is complete, take control with a fixative—it’s your insurance policy against future fading. Products like Retayne or ColorStay Dye Fixative lock black dye into cotton and rayon by binding loose pigment molecules to fabric fibers, boosting wash resistance dramatically.

Soak your shirt in hot water (140°F minimum) with one teaspoon per yard for 20 minutes. This simple step transforms color fastness, keeping your black bold through countless washes.

Preventing Color Bleeding

You’ve locked in the dye—now keep that black where it belongs instead of watching it bleed onto your favorite white towels.

Bleed prevention demands three non-negotiable fabric treatment steps:

- Wash solo for 3-5 cycles – Color retention stays strongest when black dye stabilizes without interference from other garments.

- Add vinegar to rinse water – One cup per load enhances fabric sealing and color fixation.

- Cold water only – Heat reopens fibers and triggers bleeding you just worked to prevent.

Washing and Caring for Dyed Black Shirts

You’ve put in the work to get that perfect black, so don’t let it fade on you now. How you wash and care for your newly dyed shirt makes all the difference between color that lasts and color that disappears down the drain.

Here’s what you need to know to keep your black shirt looking fresh.

First Wash Instructions

The first wash separates the pros from the amateurs. Wash your dyed shirt alone in cold water to prevent color bleeding onto other garments. Skip hot water; it’ll strip the dye fixation you worked hard to achieve.

Choose a gentle wash cycle—no heavy-duty pounding needed. Use mild detergent and keep fabric separation strict.

If you used ColorStay Dye Fixative, your shirt’s ready for proper fabric care and maintenance.

Long-Term Color Maintenance

Keeping your black shirt looking sharp for years demands consistent attention to washing habits and storage choices. Turn garments inside out before washing to protect fibers from direct agitation and color fading. Cold water preserves dye stability and prevents fabric wear.

Store shirts away from sunlight to maintain dark color achievement. These maintenance tips support color preservation and sustainable fashion practices, keeping your garment rich and intense through repeated use.

Avoiding Fading and Bleeding

Vigilance protects your dark color achievement from laundry damage and preserves intensity through every cycle. Use these proven fiber reactive dyes and color enhancement methods to maintain black richness:

- Wash in cold water on gentle cycle to minimize dye solubility

- Apply ColorStay Dye Fixative or dye fixatives for color retention

- Turn shirts inside out for fabric protection

- Avoid harsh detergents that strip DyeMore for Synthetics

- Use color catcher sheets to prevent bleeding

Troubleshooting Common Dyeing Issues

Even experienced dyers run into problems when working with black dye. Your shirt might come out patchy, faded, or refuse to take color at all.

Here’s how to fix the most common issues and get the deep black you’re after.

Achieving Deep, Even Black

Deep Color Theory tells you this: jet black demands more dye than you think. Double your concentration for 100% cotton, especially when dyeing denim. Fiber reactive dyes need precise water ratios—use hot water and stir constantly for even dye distribution.

The Back to Black Kit simplifies this, while ColorStay Dye Fixative locks in color fastness. Don’t settle for charcoal when you want true black shade variation.

Fixing Patchy or Faded Results

Patchy black happens when dye compatibility fails. Start with a second dye reapplication using the correct acid dyes for your fabric blending composition. Pre-soak thoroughly, then stir constantly during the textile dyeing process to prevent patch fixing nightmares.

For clothing restoration and repair, target faded zones with a concentrated dye solution. Color correction demands patience—natural dyeing methods take longer but deliver even results. Control fading prevention by heat-setting immediately after.

Solutions for Synthetic Fabrics

Synthetic fabric dyeing demands DyeMore for Synthetics—your weapon against polyester’s dye resistance. Heat matters: boil acrylic blends for 40-60 minutes to force color fastness. Test dye compatibility on fabric blending compositions before committing.

Nylon? Switch to acid dyes for enhanced results. Skip the Back to Black Kit on synthetics—it won’t hold.

Elastic treatment requires gentle handling to prevent fiber damage during high-heat processes.

Frequently Asked Questions (FAQs)

What type of clothing is best suited for dyeing black?

Cotton, linen, and silk clothing grabs dye best for deep black shades. Natural fibers deliver excellent color fastness and dye compatibility compared to synthetics.

Your material choice determines whether you’ll achieve rich black or disappointing gray tones.

How long should the fabric be left in the dye bath?

Your fabric soaking time in the dye bath runs 30 to 60 minutes for most natural fibers, while wool needs just 20 to 30 minutes to prevent oversaturation and achieve even black shade duration.

Is it necessary to use a dye fixative?

You don’t need a Dye Fixative for every project, but it’s your best tool for Color Fastness and Dye Stability.

Fixatives lock color into fibers, giving you better Color Retention and Fabric Protection against bleeding.

Can the same dyeing process be used for faded black clothes?

Yes, you can rescue those ghost-gray relics using standard black revival methods. Natural fibers like cotton respond beautifully to fiber-reactive dyes, restoring deep color through heat and proper agitation for sustainable fashion wins.

Is it possible to dye denim black?

You can absolutely transform denim black using Fiber Reactive dyes. Pure cotton denim takes Back to Black Kit beautifully, while polyester blends demand DyeMore for Synthetics to nail that deep Black Shade Depth despite Denim Dye Challenges.

Can I dye a shirt with graphics or logos?

You can dye shirts with graphics, but logos may resist dye uptake or show color bleeding. Test fabric saturation on a hidden spot first—heat-set designs often create halos during clothing upcycling with acid dyes.

How long does black dye last on shirts?

The proof is in the pudding—your shirt’s dye longevity depends on fabric type and care.

Fiber-reactive dyes on cotton deliver 20–40 washes of wash resistance, while polyester blends fade faster, around 15–30 cycles, affecting dye stability.

Is dyeing a shirt black safe for skin?

When handled properly, most commercial fabric dyes pose minimal skin risks.

Wear gloves and long sleeves during dyeing to prevent irritation or allergic reactions, and rinse any spills immediately to protect your skin.

Can I re-dye a previously dyed black shirt?

Black over black sounds simple, but fabric aging and dye layering create shade variations. Color stratification steps help achieve uniform depth, though expect subtle changes from previous layers—perfect for revitalizing worn shirts.

Whats the best water type for dyeing shirts?

Softened or distilled water gives you better dye uptake than hard tap water. Minerals mess with pH levels and block natural dyes from penetrating fibers, leaving you with weak, patchy results instead of deep black.

Conclusion

You might think learning how to dye a shirt black requires artistic talent, but it’s pure technique. Match your dye to your fabric, prep the material correctly, and control your water temperature. That’s the entire formula.

The shirts you’ve been ready to toss can become pieces you’ll actually reach for. Black dye doesn’t just cover mistakes—it gives you the power to rebuild your wardrobe exactly how you want it.

- https://www.dharmatrading.com/cgi-bin/procion_yields.cgi?colornumber_inp=1&colornumber=6A&weightozs=7.05&weightlbs=0.44&weightgrams=200&action=Get+Estimate

- https://www.reddit.com/r/sewing/comments/nbj4u1/can_you_dye_fabric_with_just_acrylic_paint_and/

- https://www.thecreativefolk.com/dye-clothes-with-acrylic-paint/

- https://digitalcommons.newhaven.edu/cgi/viewcontent.cgi?article=1034&context=honorstheses

- https://www.nbinno.com/article/disperse-dyes/why-choose-disperse-dyes-for-polyester-focus-on-black-ex-sf-wy