This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Yes, you can tie dye nylon with acid dyes, which create the most vibrant, long-lasting results on synthetic fibers.

Yes, you can tie dye nylon with acid dyes, which create the most vibrant, long-lasting results on synthetic fibers.

You’ll need to add white vinegar to help the dye molecules bond properly with nylon’s chemical structure.

All-purpose dyes and food coloring also work, though they produce lighter colors.

The key is using heat and acidic conditions to open nylon’s fiber structure for better dye penetration.

Natural alternatives like coffee and tea can create subtle earth tones, but they won’t give you those bold, Instagram-worthy colors you’re probably after.

The right technique makes all the difference between success and disappointment.

Table Of Contents

Key Takeaways

- You’ll need acid dyes specifically designed for synthetic fibers – regular fabric dyes won’t work on nylon since they’re formulated for natural materials like cotton and wool.

- Add white vinegar to your dye bath – this creates the acidic conditions (pH 4-5) that nylon requires for proper dye bonding and vibrant color results.

- Heat’s essential for success – maintain temperatures between 185-210°F during the dyeing process to open nylon’s fiber structure and ensure the dye penetrates properly.

- You can use alternatives like food coloring or natural dyes – while acid dyes give the best results, household items like coffee, tea, or food coloring will work for lighter, more subtle colors.

Can You Tie Dye Nylon?

You can absolutely tie dye nylon, but it requires specific techniques and dyes to achieve vibrant, lasting results.

Nylon’s synthetic fibers bond best with acid dyes, which create strong chemical connections that won’t wash out or fade quickly, achieving vibrant results.

Use an Acid Dye

Acid dyes reveal vibrant tie-dye possibilities on nylon fabric. These specialized dyes create strong chemical bonds with synthetic fibers, delivering exceptional color retention and dye penetration. Heat setting at 185-210°F guarantees proper dye fixation during the dyeing process.

Unlock nylon’s full color potential with acid dyes that bond permanently for stunning, fade-resistant results.

Essential Acid Dye Tips for Success:

- Pre-wash your nylon to remove sizing that blocks dye absorption

- Add white vinegar to create the acidic pH needed for bonding

- Maintain consistent heat throughout the 30-minute dyeing process

- Stir continuously to prevent uneven color distribution

- Test on scraps first to perfect your technique before dyeing the final piece

Choose an All-Purpose Dye

You’ll find all-purpose dye works wonderfully for nylon tie-dye projects when you follow proper dye selection principles.

These versatile dyes contain leveling agents that help achieve even color distribution across synthetic fibers.

- Fabric prep – Pre-wash nylon to remove finishes

- Dye safety – Use gloves and work in ventilated area

- Color theory – Choose darker shades over existing colors

- Dyeing tips – Maintain consistent heat throughout process

Rit Dye offers excellent all-purpose options that bond well with nylon’s molecular structure, giving you creative freedom to express yourself.

When working with nylon, understanding nylon fabric paint is essential for achieving the desired color and durability.

Opt for Food Coloring

While food coloring offers an accessible alternative to traditional dyes, you’ll need proper dye fixation techniques for lasting results.

Mix 10 drops of food coloring per pound of nylon fabric, understanding that color theory affects your final shade.

KoolAid dye works similarly for tie dye nylon projects. Remember that food dye requires heat setting and careful nylon care to prevent fading.

Test color mixing ratios first, as wet fabric appears darker than dry, creating unexpected colorful patterns.

Pick an Unsweetened Powdered Drink Mix

Several powdered drink mix options work as budget-friendly alternatives to commercial dyes for tie dye nylon projects.

These color choices offer vibrant results when properly applied with heat and acidic conditions for ideal dye fixation.

- Sugar-free packets: Use one packet per pound of nylon fabric for consistent color saturation

- Flavor mixing: Combine different varieties to create custom color palettes and unique hues

- Heat application: Maintain simmering temperatures during the dyeing process for proper penetration

- Permanent results: Colors won’t wash out once set, making careful nylon care essential

Add White Vinegar

When dyeing nylon with tie dye techniques, white vinegar acts as your secret weapon for achieving vibrant, long-lasting colors.

This simple household ingredient creates the perfect acid balance that nylon fabric craves for maximum dye absorption.

- 1 tbsp of white vinegar per cup of water

- Pour the vinegar into the simmering dye bath

- Gently stir before submerging the nylon

Here’s what makes vinegar benefits so powerful for fabric preparation:

- Enhanced color saturation – Vinegar helps acid dyes penetrate deeper into nylon fibers

- Improved color fastness – Your vibrant tie dye patterns won’t fade as quickly over time

- Better dye fixation – The acidic environment guarantees maximum chemical bonding between dye and fabric

This color enhancement technique transforms ordinary nylon fabric dyeing into professional-quality results that’ll make your creative projects pop.

What Can You Use to Dye Nylon?

You’ll find several effective dye options for transforming nylon fabric, each with specific advantages for different projects.

The key is selecting the right dye type that bonds properly with nylon’s synthetic fibers to achieve vibrant, long-lasting colors.

Acid Dye

Acid dyes reveal vibrant, long-lasting colors on nylon through chemical bonding with synthetic fibers.

These professional-grade dyes require heat setting at 185-210°F with white vinegar for maximum dye penetration.

Jacquard Acid Dyes offer 48 colors specifically formulated for nylon dyeing projects, providing an acidic environment that guarantees superior color retention and dye fixation compared to other methods.

For successful dyeing, consider the dyeing methods to achieve the desired results, perfect for tie dye nylon creations.

All-Purpose Dye

All-purpose dyes offer versatility for dyeing nylon, though results differ from specialized acid dyes.

Rit Dye and similar brands work well on nylon blends under 35% synthetic content. These dyes contain leveling agents that help achieve even color distribution during tie dye nylon projects.

Proper fabric prep and dye fixation require adding white vinegar to the dye bath. Color theory suggests darker shades work best when dyeing nylon with all-purpose dye.

Always follow dye safety protocols when working with hot water and chemical solutions. Understanding natural fiber options is essential for achieving the best tie-dye results.

Natural Dyes

Nature’s pharmacy offers powerful plant extracts for nylon dyeing.

Turmeric creates vibrant yellows, while onion skins produce rich oranges.

Coffee and tea deliver earthy browns that smell amazing.

These natural pigments bond with nylon fibers when combined with vinegar for proper dye fixation.

Eco dyes provide excellent color fastness through high-temperature processing.

Natural dyes require longer dyeing times than synthetic options, but fiber reactive compounds in plants create unique, sustainable results.

Your tie dye nylon projects become environmentally friendly masterpieces using these proven dyeing techniques.

The use of natural dye products can enhance the overall quality of the dyeing process, making it more sustainable and environmentally friendly with unique results.

Rit Dye

Rit Dye offers reliable results for nylon dyeing, especially when you understand its specialized formulations. You’ll find Rit All-Purpose Dye works effectively on nylon blends with less than 35% synthetic content.

For higher synthetic percentages, switch to Rit DyeMore, which penetrates synthetic fibers better through high-temperature stovetop methods. When rit dyeing nylon, the fabric absorbs dye quickly and often produces darker shades than expected.

Add white vinegar to your dye bath for improved color uptake and dye fixation. This acid component helps the dye molecules bond properly with nylon fibers.

For nylon preparation, pre-wash your fabric to remove sizing or finishes that block dye absorption. Follow dye safety protocols by working in well-ventilated areas and wearing gloves.

Your color choices will appear more vibrant on nylon compared to other synthetics. Consider using Rit ColorStay Dye Fixative after dyeing to enhance washfastness and prevent bleeding during future washes. To achieve the best results, explore available Rit Dye Products for the most suitable dyeing solutions.

Food Coloring

Beyond traditional methods, food coloring opens up exciting Color Options for dyeing nylon fabric. This household staple creates vibrant hues when combined with white vinegar and heat. The acid helps achieve better colorfastness on synthetic fibers.

Essential considerations for food dye success:

- Mix 10-15 drops per pound of nylon fabric

- Add white vinegar for proper dye uptake

- Maintain simmering temperature for 20+ minutes

- Test Dye Safety on fabric scraps first

Food Dyes work through Color Theory principles – the acidic environment helps synthetic fibers accept pigments. While nylon dyeing techniques using food coloring won’t match commercial acid dyes’ intensity, they’re perfect for experimental tiedye techniques and creative projects. For the best results, understanding food coloring basics is vital to achieve the desired colors.

How to Dye Nylon Using Natural Dyes

You can create beautiful colors on nylon fabric using natural dyes from common kitchen ingredients like coffee, tea, and vegetables.

These chemical-free alternatives offer a safer dyeing method, though the results may be less vibrant than commercial acid dyes, using natural dyes.

Coffee

Despite coffee’s appeal as a natural dye, using it on nylon fabric creates disappointing results.

Coffee grounds produce uneven coffee stains rather than consistent bean hues across your material.

The brew dye process lacks the chemical bonds needed for proper adhesion to synthetic fibers.

For successful nylon fabric dyeing, choose acid dyes instead.

Common issues with coffee dye include:

- Blotchy, uneven roast shades

- Poor colorfastness that fades quickly

- Lingering stale coffee odor

- Unpredictable color outcomes

Natural fibers benefit from natural dye methods to achieve unique colors.

They create vibrant, lasting colors that coffee simply can’t match on synthetic materials.

Tea

Black tea transforms nylon fabric into beautiful earthy shades through natural dyeing processes. You’ll need concentrated tea solution, white vinegar, and patience for desirable results.

The tannins in tea leaves act as natural mordants, binding effectively to synthetic fibers like nylon when combined with acidic conditions.

| Tea Type | Color Result | Steeping Time |

|---|---|---|

| Black Tea | Deep brown to tan | 10-12 hours |

| Green Tea | Light brown to beige | 8-10 hours |

| Herbal Dyes | Variable shades | 6-8 hours |

| Earl Grey | Purple-brown tint | 10-12 hours |

Prepare your dye bath by steeping multiple tea bags in hot water until dark. Remove bags and add vinegar for acidity enhancement. Submerge pre-wetted nylon fabric and maintain temperature for extended periods.

Tea stains develop gradually, creating vintage effects perfect for tie dye projects on synthetic fibers, resulting in unique and beautiful natural dyeing outcomes with extended periods of steeping.

Vegetables

Vegetable dyes reveal creative possibilities for nylon dyeing, though results differ from natural fibers.

You can extract powerful dyes from common kitchen ingredients.

Here’s your vegetable dye toolkit:

- Beet juice – Creates vibrant pink to magenta shades

- Turmeric dye – Produces brilliant yellow tones

- Spinach color – Yields soft green hues

- Red cabbage – Generates purple to blue natural tints

These vegetable dyes require acidic conditions for ideal dye compatibility with nylon’s synthetic structure.

Unlike fiberreactive dyes used on cotton, vegetable dyes bond differently with nylon fibers.

Add white vinegar to your dye bath for better colorfastness.

While these dyeing techniques won’t match commercial acid dyes’ intensity, they offer eco-friendly alternatives.

Pre-mordant your nylon with tannic acid for deeper saturation and improved color retention.

Can You Dye Nylon With Dylon Dye?

Natural dyes offer an eco-friendly approach to coloring nylon, but many wonder if commercial products like Dylon dye work equally well.

Unfortunately, Dylon dye doesn’t effectively bond with nylon fabric due to its chemical formulation.

Standard Dylon products are designed for natural fibers like cotton and wool, not synthetic fibers like nylon.

The dye fixation process requires acidic conditions that Dylon’s standard formulas don’t provide.

When you attempt dyeing nylon with regular Dylon dye, you’ll likely end up with pale, washed-out results or complete color failure.

The synthetic polymer structure of nylon fabric simply won’t accept these dyes without proper chemical bonding agents.

For successful nylon dyeing, you need acid dyes specifically formulated for synthetic materials.

Products like Rit DyeMore or iDye Poly create the chemical bonds necessary for lasting color fastness on nylon.

These specialized dyes penetrate the fiber structure and maintain vibrant colors through multiple washes, unlike standard Dylon formulations that merely coat the surface.

How to Tie-Dye Nylon

Now you’re ready to release your creativity on nylon fabric through tie-dye methods that’ll transform any piece into wearable art. Tiedye nylon requires specific techniques that differ from cotton dyeing, but the results make every step worthwhile.

Here’s your roadmap to successful nylon fabric dyeing:

- Prepare your workspace – Set up in a well-ventilated area with protective gear, including rubber gloves and apron, since dye safety matters when working with acid-based solutions.

- Create your patterns – Bind sections with rubber bands or string after twisting, folding, or scrunching your nylon fabric into desired shapes before applying dye.

- Apply heat for dye fixation – Use temperatures between 185°F-210°F with slightly acidic conditions (pH 4-5) to confirm proper bonding between dye molecules and nylon fibers.

Color theory plays a vital role in dyeing nylon since synthetic fibers accept dyes differently than natural materials. The chemical structure of nylon requires extended processing times but rewards you with vibrant, long-lasting results. Understanding fabric dyeing techniques is essential for achieving the desired outcome and exploring various creative possibilities with nylon fabric.

Top 5 Acid Dyes for Dyeing Nylon

You’ll need top-quality acid dyes that bond effectively with nylon’s synthetic fibers to achieve vibrant, long-lasting colors.

These five acid dyes offer the best chemical compatibility and color retention for your nylon tie-dye projects, ensuring long-lasting results.

Rit DyeMore Liquid Dye Super Pink

Dyeing nylon fabric with Rit DyeMore Liquid Dye transforms ordinary materials into vibrant pink masterpieces.

This synthetic-specific formula penetrates nylon fibers effectively, creating lasting color saturation.

You’ll achieve consistent pink shades through proper dye mixing and temperature control.

The liquid formula simplifies color fixing on nylon blending projects.

Rit Dye’s specialized synthetic formula guarantees superior adhesion compared to standard dyes.

Your tie dye nylon creations will maintain their brilliance through multiple wash cycles when using this dyeing nylon fabric solution, which ensures lasting color saturation.

Dylon Machine Dye Pod Olive Green

Most crafters discover that Dylon Machine Dye Pod Olive Green won’t deliver the vibrant results you’re hoping for on nylon fabrics.

While Dylon pods excel with natural fibers like cotton and linen, they’re not formulated for synthetic materials requiring acid dyes. You’ll get unpredictable, often disappointing color fixing when dyeing nylon with these pods.

Here’s what you need to know about machine dyeing nylon with Dylon pods:

- Limited Color Absorption – Nylon fibers resist Dylon’s alkaline formula, resulting in patchy green shades

- Poor Washfastness – Colors fade quickly without proper acid dye bonding to synthetic fibers

- Inconsistent Results – Machine dyeing synthetic fabrics requires specialized dyes designed for nylon dyeing

For successful tie dye projects on nylon, skip the Dylon pods and choose acid dyes specifically engineered for synthetic materials. These create lasting, vibrant olive dye effects that won’t wash out after your first laundry cycle.

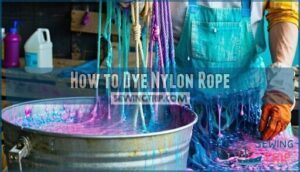

How to Dye Nylon Rope

When tackling rope dyeing projects, nylon rope transforms beautifully with proper technique and patience. The synthetic fibers require specific approaches for ideal dye penetration and color fixing results.

Here’s your essential rope dyeing process:

- Prepare the dye bath – Heat water to a simmer, add acid dye, then incorporate white vinegar for proper fiber treatment

- Submerge and agitate – Keep the nylon rope moving constantly during the 30-minute dyeing process for even color distribution

- Rinse thoroughly – Use cool water until it runs clear, ensuring excess dye won’t transfer later

Acid dyes create the strongest chemical bonds with nylon fibers, delivering vibrant, lasting colors. You’ll need adequate space in your dye bath for the rope to move freely – cramped conditions lead to uneven results. The vinegar acts as a vital mordant, helping the dye molecules bond permanently with the synthetic material.

Remember that tightly braided rope may resist dye penetration in inner fibers, so consider loosening sections beforehand. Proper nylon care during this process maintains your newly colored rope’s strength and flexibility, and this will help to achieve the best possible outcome.

Dyeing Nylon Backpack

Your backpack’s transformation starts with proper preparation and the right dye selection. Pre-wash your nylon fabric thoroughly to remove manufacturing residues that block dye penetration.

Choose acid dyes like Rit DyeMore for synthetics rather than all-purpose options – they create stronger chemical bonds with nylon fibers. Heat your dye bath to 185-210°F and maintain constant stirring for even color distribution.

Tape off zippers and hardware before dyeing nylon. The dyeing process requires 30-60 minutes for ideal dye fixation and color retention. Remember that polyester threads won’t absorb dye, creating interesting multi-tone effects.

After nylon backpack dyeing, rinse thoroughly in cold water until clear, then machine wash separately. Apply waterproofing spray afterward since tiedye processes can reduce water resistance.

Your backpack care routine should include gentle washing to maintain the vibrant results of your nylon dyeing project.

How to Dye Nylon Yarn

Moving from backpack dyeing to working with individual strands, nylon yarn presents unique opportunities for creative color expression. Start by pre-washing your nylon yarn to remove manufacturing finishes that can block dye penetration. This yarn preparation step guarantees even fiber reaction across all strands.

For superior nylon yarn dyeing results, select acid dyes like Jacquard or Rit DyeMore specifically formulated for synthetic fibers. Create your dye bath by heating water to 200°F, then add one teaspoon of white vinegar per cup of water. The acidic environment promotes proper color fixation to nylon fibers.

Submerge your pre-wetted yarn into the simmering dye bath. Stir gently every five minutes for thirty minutes, allowing complete dye penetration throughout each strand. Remove the yarn with tongs and rinse in cool water until it runs clear.

Consider these creative techniques for stunning results:

- Gradient effects – Dip portions at different intervals for ombre coloring

- Shibori-inspired patterns – Bind sections before dyeing for unique designs

- Multi-color blending – Layer different acid dyes for complex hues

- Experimental combinations – Try Procion MX dyes with mordants for unexpected results

- Temperature variations – Adjust heat levels to control color intensity

When working with nylon, understanding nylon fabric painting techniques can also enhance your projects.

Frequently Asked Questions (FAQs)

Will tie-dye work on nylon?

Yes, tie-dye works beautifully on nylon.

You’ll need acid dyes instead of regular fabric dyes, plus heat and vinegar to chemically bond the colors to synthetic fibers for vibrant, lasting results, using acid dyes.

What dye works best on nylon?

Acid dyes work best on nylon because they form strong chemical bonds with synthetic fibers.

You’ll get vibrant, long-lasting colors that won’t fade easily.

Use heat and slightly acidic conditions for ideal results.

Can 100% nylon be dyed?

You can absolutely dye 100% nylon successfully.

Acid dyes work best, creating strong chemical bonds with nylon fibers for vibrant, long-lasting colors.

Heat-setting at 185-210°F guarantees proper dye penetration and retention, which is a critical step for achieving vibrant colors.

Can you dye nylon with Rit?

Standard Rit dye won’t work on 100% nylon since it’s formulated for natural fibers. You’ll need Rit DyeMore, which contains acid dye specifically designed for synthetic materials like nylon and polyester.

Does nylon fabric shrink during dyeing process?

Nylon fabric typically shrinks when exposed to high temperatures during the dyeing process. You’ll need to monitor heat carefully and follow manufacturer instructions to minimize shrinkage and fabric distortion.

Can you overdye already colored nylon items?

Over 80% of synthetic fabrics can be successfully overdyed, and you’re in luck with nylon.

You can absolutely overdye colored nylon items, but remember the cardinal rule: you can only go darker, never lighter.

The existing pigments won’t magically disappear.

What temperature water works best for nylon?

For ideal results, you’ll want to heat your dye bath to 185-210°F (85-99°C).

This temperature range guarantees the acid dye bonds properly with nylon fibers, giving you vibrant, long-lasting colors that won’t fade easily.

How long does nylon dye take to cure?

Patience isn’t just a virtue—it’s absolutely essential when dyeing nylon.

You’ll need to let your dyed nylon cure for 24-48 hours after heat-setting to achieve maximum color intensity and permanence, which is crucial for maximum color intensity.

Will nylon dye bleed onto other fabrics?

Properly dyed nylon won’t bleed onto other fabrics when you’ve followed correct heat-setting procedures.

However, you’ll want to wash newly dyed items separately for the first few washes to prevent any residual dye transfer.

Conclusion

Like a chameleon transforming colors, nylon readily accepts dye when you understand the science behind it.

You can tie dye nylon with acid dyes, all-purpose dyes, or even natural alternatives like coffee and tea.

The key lies in creating proper acidic conditions with white vinegar and applying heat to open the fiber’s molecular structure.

Whether you’re dyeing rope, backpacks, or yarn, the chemical bond between dye molecules and nylon’s polymer chains determines your success.

Follow the correct pH levels and temperature requirements for vibrant, lasting results.