This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your sewing machine hums along perfectly, but something’s off—the stitches look bulky, or they’re almost invisible when they should stand out. The culprit? You’re probably using the wrong thread weight.

Basic thread weights explained comes down to a simple truth: thicker threads create bolder stitches, while finer threads disappear into your fabric. The confusing part isn’t the concept itself, but rather the numbering systems that seem backward—a 50-weight thread is actually thinner than a 30-weight.

Once you understand how these numbers work and which weights match your fabric, you’ll stop fighting with your machine and start getting the clean, professional seams you’re after.

Table Of Contents

Key Takeaways

- Thread weight numbers work backward—higher numbers like 50 wt mean thinner thread, while lower numbers like 30 wt mean thicker, bolder stitches that stand out more on your fabric.

- Match your thread weight to your fabric type: use 60-100 wt for delicate silks and chiffons, 40-50 wt for everyday sewing projects, and 12-30 wt for heavy-duty work like denim or canvas.

- Pair thread weight with the right needle size to prevent problems—fine threads need smaller needles (60/8 to 80/12), medium threads work with 80/12 to 90/14, and heavy threads require larger needles (90/14 to 120/18).

- Polyester thread offers superior strength and colorfastness for durability, while cotton thread provides a natural matte finish and handles heat better, making your material choice just as important as weight selection.

Thread Weight Basics

Thread weight might seem straightforward, but the numbering system works backward from what you’d expect. Higher numbers actually mean thinner thread, which catches most sewers off guard at first.

Let’s break down how thread weight is measured and why understanding these systems matters for your projects.

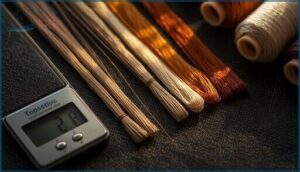

Thread Weight Measurement

How does thread weight actually work? In the fixed-weight system, a 40 wt thread means 40 kilometers of it weigh one kilogram. That’s where the counterintuitive part comes in—lower numbers like 30 wt are thicker because fewer kilometers reach that kilogram. Understanding thread weight helps you predict how your stitches will look. Most digitized embroidery designs are created for 40 weight thread.

- Weight and thickness move opposite to what you’d expect—smaller numbers mean bolder threads

- Thread measurement creates consistency across brands you trust

- Thread weight basics provide professional-looking results every time

- Multi-number notations like 50/3 reveal construction secrets

- Tex vs Denier offer alternative ways to measure what matters

Thread Weight Systems

You’ll run into several thread weight systems depending on where your thread comes from. The U.S. weight number (wt) follows that inverse rule we covered—40 wt is finer than 30 wt. But Tex and Denier flip the script. With Tex, a higher number means thicker thread. Tex 30 weighs 30 grams per 1,000 meters, so it’s actually thicker than Tex 20. Denier applications work the same way, measuring 9,000 meters instead. Metric counts and cotton counts use the inverse approach again, where higher numbers mean finer threads.

Understanding thread weights means knowing which system you’re reading. Thread size affects sewing project outcomes. Thread weight classifications aren’t standardized globally, so Tex conversion charts become your best friend. Older spools might show English Count, making thread weight measurement feel like detective work at first.

Denier and Tex Systems

Let’s look at how Tex and Denier actually work. Tex definition is simple: the weight in grams of 1,000 meters of thread. So Tex 25 weighs 25 grams per 1,000 meters. Denier definition measures 9,000 meters instead—120 denier weighs 120 grams.

Both systems give you direct thread thickness measurements. System conversions are straightforward: multiply denier by 0.111 to get Tex, or multiply Tex by 9 to get denier.

Thread Weight Applications

Once you understand thread weight numbers, the next step is knowing which weights work best for different projects.

Each sewing task has an ideal thread weight range that balances strength, visibility, and compatibility with your fabric.

Let’s look at the most common applications and which thread weights you’ll reach for most often.

General Sewing Thread Weights

Your sewing projects deserve the right thread, and most of your work will rely on medium-weight options. General Sewing Thread Weights center on 40–50 weight threads, which handle everything from shirts to home décor with ease. These weights generally measure Tex 25–40, meaning 1,000 meters weigh between 25–40 grams. You’ll find 50 weight perfect for everyday seams, while 40 weight addresses slightly heavier construction. Most general-purpose spools use polyester or cotton-wrapped polyester for their strength and smooth machine performance.

Understanding Thread Weights helps you match Material Type Uses to your fabric:

- 50 weight polyester – Your go-to for most woven and knit garments

- 40 weight cotton – Natural-fiber projects needing matte finishes

- Tex 30 thread – Standard all-purpose weight for domestic machines

- Machine Compatibility – Works with universal 80/12 or 90/14 Needle Size

- Stitch Formation – Balanced tension without bulk in seams

Quilting Thread Weights

When you’re ready to quilt, your thread choice shapes every stitch’s performance and appearance. Weight vs. density matters—40 wt quilting thread creates visible, decorative lines ideal for showcasing your work, while 50 wt blends subtly for texture-focused designs. Visual stitch impact increases with heavier 28–30 wt threads, perfect for bold motifs. Fiber type affects durability: polyester resists fading and laundering stress, while cotton grabs fabric to prevent slippage. Quilt size influences thread consumption—bed-sized quilts need 500–900 yards. Machine performance improves when you match needle size to thread weight for quilting, preventing tension issues and breakage.

| Thread Weight | Best Application |

|---|---|

| 28–30 wt | Bold decorative quilting, outlining |

| 40 wt | General quilting, visible stitching |

| 50 wt | Piecing, subtle background fills |

| 60 wt | Dense micro-quilting, detail work |

| Polyester 40 wt | High-strength functional quilting |

Heavy Duty Thread Weights

For heavy fabrics like denim, canvas, and upholstery, you’ll need threads between 12 wt and 30 wt—remember, lower numbers mean thicker, stronger thread. Polyester delivers superior tensile strength for industrial applications, while nylon stretches before breaking, perfect for flexible materials. Denim topstitching commonly uses Tex 60 to Tex 120, though premium designs now specify Tex 150 for bolder seams. Outdoor gear benefits from weather-resistant finishes.

As market growth drives demand in automotive interiors and technical textiles, upholstery threads like Tex 500 handle extreme load-bearing applications where standard thread weight simply won’t hold up.

- Canvas projects: Tex 70-135 powers through heavy bags and outdoor gear

- Denim topstitching: 12-28 wt masters thick seams with visible definition

- Upholstery threads: V92-V138 secures furniture under constant stress

- Industrial applications: Tex 150-600 delivers unmatched strength for demanding projects

Choosing Thread Weight

Picking the right thread weight isn’t about guessing—it’s about matching your thread to your fabric and project goals. Your fabric type sets the foundation for which weight will work best, from sheer silks to heavy canvas.

Let’s break down how to choose thread weight based on what you’re sewing.

Thread Weight for Delicate Fabrics

When you’re working with silk, chiffon, or organza, think of your thread choice like choosing the right brush for watercolor—too heavy, and you’ll lose that beautiful drape.

Delicate fabrics like silk and chiffon demand fine thread the way watercolor demands the right brush—too heavy, and the drape disappears

Fine weight threads in the 60-100 weight range create nearly invisible seams that won’t pucker or distort delicate fabrics. Pair them with microtex needles (size 60/8 to 70/10) and reduce your tension adjustment by about 10-15% for smooth, professional results.

Thread Weight for General Sewing

For most of your projects, 40–50 wt threads are the workhorse you’ll reach for again and again. This Everyday Thread range delivers the perfect balance of weight, visibility, and seam durability across cotton, polyester, and blends. Here’s why it works so well:

- Tension Balance: These medium thread weights require minimal adjustments on your machine, making them reliable for consistent stitching.

- Needle Matching: Pair with 80/12 needles for typical fabrics—it’s a combination that rarely fails.

- Versatility: Thread weight for general sewing means one spool addresses garments, crafts, and everyday mending without switching.

Master thread weight basics, and you’ll simplify your entire workflow.

Thread Weight for Heavy Duty Projects

When canvas, upholstery, or leather demands won’t bend, you need heavy weight threads built for the job. Tex 70 works for most home machines on fabric thickness up to 14 oz canvas, while industrial projects may require Tex 90–135 for strength requirements. Pair these heavy duty thread weights with 100/16–120/19 needles to prevent shredding.

Stitch visibility increases with heavier thread—perfect for decorative topstitching on heavy fabric projects.

Thread Types and Quality

Thread weight is only part of the equation—what your thread is made of matters just as much as how thick or thin it is. Cotton and polyester each bring their own strengths to the table, and details like finish and color can make or break your project.

Let’s look at how these factors work together to help you pick the right thread every time.

Cotton Thread Characteristics

Cotton thread stands out because of its natural fiber structure—those twisted, ribbon-like cotton fibers create a soft, matte finish that feels comfortable in your hands. Mercerization effects boost strength by 20–30% and add a silk-like luster, making mercerized cotton perfect for decorative stitching.

While tensile strength runs lower than polyester, cotton withstands heat beautifully, tolerating pressing temperatures up to 180°C without melting. Just remember: cotton shrinks above 40°C, so pre-wash matters.

Polyester Thread Characteristics

When you need thread durability that outlasts natural fibers, polyester delivers. Spun polyester in Tex 40 provides around 3.3 pounds of Tensile Strength—far stronger than cotton at similar thread weights. You’ll appreciate its 12–22% Elongation, which flexes under stress without snapping.

Polyester Thread Characteristics include excellent Chemical Resistance to detergents, outstanding Colorfastness that survives repeated washing, and Dimensional Stability with minimal shrinkage. Plus, it melts at 250–260°C, so your seams won’t deform during pressing.

Thread Finish and Color

Your thread’s surface finish shapes how it performs. Mercerized cotton gains 10–20% more strength and a polished look, while glazed finishes resist abrasion during hand quilting. Synthetic threads with smooth, lubricated surfaces run cleaner at high speeds.

Thread color matters beyond looks—polyester’s better colorfastness keeps hues vivid through repeated washing, while neutral tones blend across fabrics. Consider both finish and color when selecting thread materials for lasting visual durability.

Thread Weight and Needle Compatibility

Getting thread weight right is only half the battle—you also need the right needle to make everything work together. The needle you choose affects how smoothly your thread feeds through the fabric and whether your stitches turn out clean or messy.

Let’s look at how needle size, machine tension, and specialty options match up with different thread weights.

Needle Size and Thread Weight

Why does pairing your thread weight and needle size correctly matter so much? The needle’s eye should be about 40% larger than your thread diameter—think of it as giving the thread room to breathe. This simple fabric-needle matching principle prevents fraying and skipped stitches.

Follow this thread compatibility chart for smooth results:

- Fine threads (100wt–60wt) pair with 60/8 to 80/12 needles

- Medium threads (50wt–40wt) work with 80/12 to 90/14 needles

- Heavy threads (30wt–20wt) need 90/14 to 100/16 needles

- Extra-heavy threads (12wt–6wt) require 100/16 to 120/18 needles

- Industrial bonded threads demand specialized sizing

Thread Size and Machine Tension

Your machine’s tension dial becomes the critical control center once you’ve matched the needle to the thread. Most home machines range from 0 to 9, with mid-settings around 4–4.5 calibrated for everyday 40wt threads. Here’s where thread size and machine tension work together: heavier threads increase friction through the thread path, so you’ll often need to lower tension settings despite what feels obvious.

For practical adjustments, test each thread–fabric combination on scraps first.

| Thread Weight | Recommended Tension Range |

|---|---|

| Fine (60wt) | 3.5–4.5 |

| Medium (40wt) | 4–5 |

| Heavy (30wt) | 3–4.5 |

| Extra-heavy (12wt) | 2.5–4 |

Tension troubleshooting starts with checking your thread path and bobbin tension before adjusting machine tension for different fabric weight combinations.

Specialty Needles and Threads

Beyond standard applications, specialty threads require precision matching to perform reliably. Metallic threads—prone to friction and shredding—demand topstitch or metallic needles in 90/14 with elongated eyes.

Embroidery needles (75/11–90/14) reduce thread breakage when working with rayon or polyester decorative thread types.

For technical applications involving heavy 30wt topstitching, you’ll need 100/16 needles whose deeper grooves protect thick thread bundles from abrasion and performance impacts.

Selecting Best Thread Weight

You’ve learned how thread weights work with different needles and fabrics, but choosing the right thread for your project involves more than just matching numbers. Your selection should consider the thread’s material, the brand’s reputation, and whether you’re willing to test different options.

Let’s look at three key factors that will help you select the best thread weight for any sewing project.

Considering Thread Weight and Type

Fiber properties and elasticity factors matter just as much as the number on the spool. Understanding thread weights means pairing thread types with your project requirements for ideal thread performance. Cotton threads offer breathability for quilting cottons, while polyester’s stretch suits knits. Blends considered for thread applications can combine strengths—like polyester-wrapped cotton cores that balance durability with natural handling.

- Match thread weight applications to fabric weight (60-80 wt for silks, 12-30 wt for canvas)

- Choose fiber type based on fabric content (cotton for natural weaves, polyester for synthetics)

- Consider elasticity needs (stretchy threads prevent breakage on knits and activewear)

Considering Thread Brand and Quality

Brand reputation speaks volumes when choosing thread for sewing. Gutermann, Mettler, and Aurifil deliver consistent fiber construction and colorfastness that cheaper threads can’t match. You’ll notice better lint reduction and fewer breaks mid-seam.

User perception confirms what testing shows: quality thread runs smoother through your machine. Types of sewing threads vary, but premium brands balance thread weight with durability, making thread selection easier and your results more professional.

Experimenting With Thread Weights

Think of experimenting with thread weights like taste-testing ingredients before you cook a full meal. Start by limiting your tests to two adjacent weights—say, 40 wt versus 50 wt—on identical fabric scraps. This side-by-side comparison reveals how each weight affects stitch visibility and coverage without overwhelming you with variables.

Fabric matching matters: try 50 wt or finer on delicate cottons, then switch to 30 wt on denim to observe seam durability differences.

Document your needle pairings and tension adjustments for each weight—40 wt generally needs an 80/12 needle, while 30 wt works better with 90/14. These records become your personal reference guide for selecting best thread weight in future projects, helping you master thread weight applications with confidence.

Frequently Asked Questions (FAQs)

Which is heavier, 40 wt or 50 wt thread?

The 40 weight thread is heavier than 50 weight thread. In thread weight systems, lower numbers mean thicker threads with more mass per length.

When comparing denier conversion and spool length, 40-weight packs fewer yards per cone.

What do different thread weights mean?

Understanding thread weight systems is counterintuitive—higher numbers mean finer threads. A 50 wt thread is thinner than 30 wt.

Thread thickness follows inverse numbering: lower weight numbers indicate heavier, more visible threads for your projects.

What is the difference between 30 wt and 40 wt thread?

The lower the thread number, the thicker the thread—so 30 wt is noticeably heavier than 40 wt.

This thickness comparison affects everything from stitch visibility to needle sizes you’ll need for smooth stitching.

What is the difference between 60 wt and 90 wt bobbin thread?

Bobbin thread weight differences matter for machine compatibility and visual outcomes. 60wt bobbin thread suits general embroidery work, while 90wt’s finer thread diameter suits micro-detail projects.

Fine weight threads require specific tension adjustments and machine calibration.

Can different thread weights mix in same project?

You’ll discover remarkable creative freedom when you blend thread weights intentionally. Pair heavier decorative threads with lighter bobbins to achieve dimensional visual effects while maintaining seam performance, stitch balance, and structural integrity—just adjust tension and match needle size to your thread weight applications.

How does thread weight affect washing durability?

Thread weight directly impacts washing durability. Heavier threads maintain better seam strength through repeated laundering, while polyester fiber types outperform cotton in colorfastness and abrasion resistance.

Proper thread-to-fabric matching prevents seam efficiency loss and fabric damage over time.

What causes thread weight inconsistencies between brands?

Measurement variations, fiber differences, and construction methods create inconsistencies. Cotton swells differently than polyester, twist levels alter thread thickness, and manufacturing tolerances vary.

Labeling practices don’t always reflect actual thread measurement standards.

Does thread weight impact embroidery hoop selection?

Yes, it does. Heavier threads increase tension and design density, demanding smaller hoop sizes for fabric stability and firmer stabilizer choice.

Proper tension control prevents puckering, especially on delicate machine embroidery projects with intricate thread-weight-dependent designs.

Can vintage thread weights match modern equivalents?

Vintage thread labels used different weight systems than today’s standards, but you can find modern equivalents. Cotton ticket numbers and tex values help bridge the gap, though aged cotton threads may have lost strength over time.

How should I store different thread weights?

You might think all thread needs the same treatment, but thread storage actually varies by fiber type. Store cotton and linen in moderate humidity (40–55%) to prevent mildew; polyester needs less fuss but still benefits from dust protection and cool, dry conditions.

Keep spools in thread storage boxes away from light exposure to extend thread lifespan. Pair bobbins with matching spools for easy identification.

Check humidity control with a hygrometer if you’re serious about thread care and thread maintenance—proper thread storage tips really do make a difference.

Conclusion

Think of thread weight like choosing the right sword for battle—match it to your opponent, and you’ll win every time. Now that basic thread weights explained has armed you with the knowledge of numbers, fabrics, and needle pairings, you won’t second-guess your spool drawer.

Test different weights on scrap fabric, trust what you’ve learned about that backward numbering system, and watch your projects transform from frustrating experiments into confident, professional results that actually look finished.

- https://www.servicethread.com/blog/industrial-sewing-thread-sizes-explained

- https://www.mh-chine.com/blog/products/tex-mean-in-thread

- https://www.magnetichoop.com/blogs/news/thread-weight-mastery-essential-guide-for-sewing-and-embroidery-success

- https://www.czsewingthread.com/blog/understanding-thread-weight-what-do-30-40-and-50-mean.html

- https://peekaboopatternshop.com/our-blog/guide-to-thread-for-sewing-beginners