This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Betweens needles are shorter, making them perfect for quilting when you need precise, controlled stitches.

Embroidery needles feature larger eyes to accommodate multiple thread strands, and beading needles stay ultra-thin to slip through tiny holes.

Match your needle to fabric weight—cotton works with sizes 8-12, denim needs 14-16, and silk requires delicate 8-10 needles.

Using the right needle turns sewing headaches into satisfying work that looks professional.

Keep your needles organized and swap them out when they get dull—it’s a simple change that makes everything easier.

Table Of Contents

Key Takeaways

- You’ll need to match needle types to your specific project—sharps work best for general cotton sewing, betweens excel at quilting through multiple layers, and specialty needles like beading or glover handle unique materials effectively.

- Choose needle sizes based on fabric weight and thread thickness—lighter fabrics need sizes 8–10, medium-weight cotton uses 8–12, while heavy materials like denim require sizes 14–16 to prevent damage.

- Replace your needles regularly to maintain quality results—watch for warning signs like skipped stitches, fabric snags, thread breakage, or visible damage that can ruin your project’s appearance.

- Store needles properly by organizing them by type and size in magnetic holders, needle books, or labeled compartments to save time and protect your investment in quality tools.

Hand Sewing Needle Anatomy and Sizing

Getting familiar with needle anatomy and sizing helps you match the right tool to your project.

The needle’s point, shaft, eye, and gauge number work together to determine how well it’ll handle your fabric and thread choice.

The needle’s point, shaft, eye, and gauge number work together to determine how well it’ll handle your fabric and thread choice.

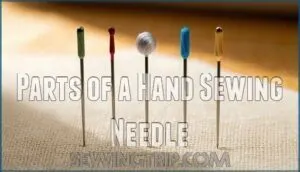

Parts of a Hand Sewing Needle

Every needle has three essential parts that determine its performance. The needle point penetrates fabric, with point shapes varying from sharp to blunt. The needle eye holds your thread, featuring different eye design variations for specific threads. The shaft connects these parts, with diameter and flexibility affecting how it moves through fabric.

- Point and Tip: Sharp points pierce tightly woven fabrics, while blunt tips separate fibers in knits

- Eye and Groove: Wide eyes accommodate thick threads, while groove function guides thread smoothly

- Shaft and Coating: Needle length and coating materials reduce friction for easier stitching

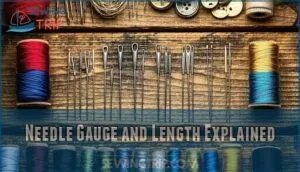

Needle Gauge and Length Explained

Needle gauge corresponds to needle diameter—higher numbers mean thinner needles. You’ll find gauges ranging from 9 (thick) to 24 (ultra-fine). Length varies from 1 to 2.5 inches, affecting control and fabric penetration.

| Gauge | Length Range | Best For | Fabric Type |

|---|---|---|---|

| 9-11 | 1.5-2 inches | Heavy-duty sewing | Denim, canvas |

| 12-14 | 1.25-1.5 inches | General sewing | Cotton, linen |

| 16-18 | 1-1.25 inches | Fine work | Silk, lightweight |

| 20-24 | 1-1.5 inches | Delicate projects | Chiffon, beading |

Project suitability depends on matching needle diameter to fabric weight and thread thickness.

How Eye Size Affects Thread Choice

Thread choice hinges on your needle’s eye size and shape. Matching thread size to needle sizes prevents threading struggles and needle damage.

Your hand sewing needles guide thread material selection perfectly.

- Fine threads: Use smaller needle eye for delicate fabrics like silk

- Heavy threads: Choose larger eye shape for thick materials and upholstery work

- Multiple strands: Wide needle eye accommodates embroidery floss bundles

Essential Types of Hand Sewing Needles

Sewing needles fall into three key categories that every stitcher should know: general-purpose needles like sharps and betweens handle most everyday tasks, embroidery needles such as crewel and milliners excel at decorative work, and specialized options like tapestry, chenille, and glover needles tackle specific materials and techniques.

Each type’s specific design features, from eye shape to point style, directly impact your project’s success and thread performance.

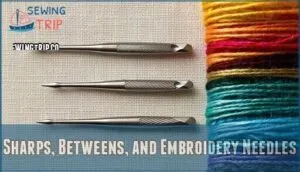

Sharps, Betweens, and Embroidery Needles

Now you’ll meet the workhorses of hand sewing needles. Sharps needles offer exceptional versatility for general sewing tasks, while betweens needles excel in quilting with their short, precise design. Embroidery needles accommodate multiple floss strands through wider eyes.

| Needle Type | Best Use | Key Feature |

|---|---|---|

| Sharps | General sewing, fine seams | Thin shaft, round eye |

| Betweens | Quilting, appliqué | Short length, sharp point |

| Embroidery | Decorative stitching | Wide, elongated eye |

These three types of hand sewing needles form your essential toolkit foundation.

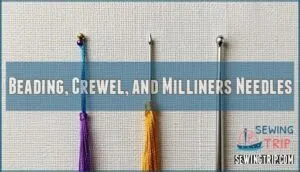

Beading, Crewel, and Milliners Needles

Beading needles feature ultra-thin, flexible shafts with long eyes perfect for threading through tiny beads and sequins.

Crewel needles sport wider, elongated eyes that accommodate multiple embroidery floss strands for rich crewel stitches.

Milliners needles bring remarkable length and thinness, making them ideal for gathering, pleating, and hat-making applications where precision matters most.

Specialty Needles: Tapestry, Chenille, Glover

Beyond basic needles, specialty hand sewing needles tackle unique projects with precision. Tapestry needles feature blunt tips for counted-thread work on tapestry fabrics without splitting fibers. Chenille needles offer sharp points and large eyes for chenille embroidery through dense materials. Glover needles use triangular points for glover leatherwork applications. One should also consider the needle material, as gold-plated options are hypoallergenic.

- Tapestry needles – Blunt tips protect delicate counted-thread fabrics

- Chenille needles – Sharp points penetrate tightly woven materials

- Glover needles – Triangular geometry pierces leather cleanly

These needle types require specialty storage to maintain their unique points and threading capabilities.

Matching Needles to Fabrics and Projects

Matching your needle to fabric weight and project type makes all the difference in your results.

Choose sharps for cotton and general sewing, betweens for quilting dense layers, and glover needles for leather work that won’t tear or skip stitches.

Best Needles for Cotton, Denim, and Silk

Cotton fabrics work best with sharps needles in sizes 8-12 for thread compatibility and stitch quality.

Denim requires heavy-duty sharps or glover needles, sizes 14-16, to penetrate thick weaves.

Silk demands delicate handling—use fine sharps or betweens, sizes 8-10, preventing snags.

Match your needle types to fabric weight for professional results.

Choosing Needles for Quilting and Appliqué

When you’re working on quilts and appliqué, your needle choice makes all the difference. Heavier fabrics and thicker batting call for larger needles, while delicate work needs finer ones.

Betweens needles are your best friend for quilting—their short design gives you excellent control over stitch length as you work through multiple layers. Plus, that shorter length means less strain on your hand during those long quilting sessions.

For appliqué work, sharp needles or embroidery needles provide clean fabric penetration. Thread compatibility matters—match your needle size to thread weight for peak results.

Needle Selection for Leather, Beading, and Heavy-Duty Use

Diamond-point leather needles slice through thick hides, while glover needles handle softer leather projects. For hand sewing leather, match needle size to material thickness—use size 2-4 for thin leather, size 000+ for heavy-duty applications.

Beading needles require precise eye size matching; sizes 10-15 accommodate delicate beads.

Heavy-duty gauges aid specialized materials in upholstery and repair applications. Matching the needle and thread ensures strong and durable stitches.

Practical Uses and Techniques for Each Needle

Different needle types become powerful allies when you know their specific strengths. Each one serves a distinct purpose – from delicate silk threads to heavy canvas work.

These hands-on applications bridge the gap between knowing your tools and using them effectively, whether you’re fixing a favorite shirt, adding sparkle with beads, or tackling that worn-out chair cushion.

Mending, Dressmaking, and Decorative Embroidery

Your mending techniques start with sharp needles for fabric repair and darning needles for holes.

Dressmaking demands precision—sharps handle seams while betweens create fine hems.

Decorative embroidery transforms fabric using embroidery needles for floss and crewel needles for thick threads.

Hand sewing needles make each needlepoint project successful when matched correctly to your fabric weight.

Beading and Ribbon Embroidery Applications

Beyond traditional embroidery, beading needles excel at delicate work with tiny seed beads and ribbon embroidery applications. You’ll want beading needles for projects requiring precise bead size compatibility and consistent stitch tension.

Embroidery needles handle wider ribbon width beautifully, while tapestry needles work perfectly for color harmony in open-weave fabrics.

Project ideas include silk ribbon roses, beaded jewelry, and mixed-media textile art combining both techniques.

Upholstery, Darning, and Bookmaking Uses

Tough jobs call for tough needles. Upholstery needles pierce thick materials with ease, while curved needles navigate awkward angles during bookmaking projects. Darning techniques bring worn fabrics back to life using specialized darning needles and bodkins for material repair.

- Use upholstery needles for heavy fabrics and furniture restoration work

- Apply darning needles with traditional weaving motions for hole repairs

- Choose curved needles for bookbinding stitches and tight corner work

Organizing, Storing, and Replacing Needles

Sharp needles and good organization go hand in hand. Store them by type and size in a proper system, and your projects will flow much better.

Replace dull or bent needles immediately to prevent fabric damage and frustrating snags that can ruin hours of careful work.

Needle Storage Solutions and DIY Needle Books

Smart needle storage protects your investment and saves frustration. Try DIY needlebooks using felt pages in decorative covers, or magnetic holders that grab needles instantly. Antique cases add charm while keeping needles organized.

Modern needle organizers feature compartments for different types. Remember safe disposal for bent needles—wrap in tape before tossing to prevent injuries.

Organizing by Type and Size

Good needle organization methods prevent frustration and save time. Sort your hand sewing needles by type first—sharps in one section, beading needles in another. Within each type, arrange by size from smallest to largest.

Use small containers or DIY organizers with labeled compartments. Keep an inventory list noting needle sizes and uses for quick reference during projects.

When to Replace Needles for Optimal Results

When your needle starts fighting you, it’s time for a change. Dull needle signs include fabric damage, thread breakage, and poor stitch quality that makes your work look sloppy.

Here are 5 clear signals for needle replacement:

- Skipped stitches – Your needle can’t pierce fabric cleanly anymore

- Snagged threads – A burr or bend catches and pulls fabric fibers

- Popping sounds – The needle forces through instead of gliding smoothly

- Frayed thread – Sharp edges cut your thread during sewing techniques

- Visible damage – Bent tips, rust spots, or worn eye edges

Needle lifespan varies by use, but replacing needles every 8-12 hours of sewing ensures best results. Don’t let a worn needle ruin your project.

Frequently Asked Questions (FAQs)

What needle thread combinations prevent fabric damage?

Match your thread weight to your needle size—fine threads need thin needles, heavy threads require larger ones. You’ll prevent snags and puckering when the combination flows smoothly through fabric.

How do you sharpen dull sewing needles?

Like finding an old family recipe, you can sharpen dull needles using emery boards. Push the needle through an emery strawberry in one direction or use a whetstone by turning back and forth until sharp.

Which needles work best for stretch fabrics?

You’ll

What causes needles to bend during sewing?

You’re likely forcing the needle through fabric too quickly or using the wrong needle size. Thick fabrics, rushing your stitches, or pulling thread too tight can bend needles.

How do you remove broken needle fragments?

Congratulations, you’ve joined the exclusive "broken needle club!"

First, stop sewing immediately. Use needle-nose pliers or tweezers to carefully grasp the visible fragment and pull straight out. Check for remaining pieces before continuing.

Conclusion

Picture a master tailor reaching for the perfect tool—just as carpenters select specific hammers for different jobs, experienced sewers know their needle choice determines project success.

Experienced sewers know their needle choice determines project success, just as carpenters select specific hammers for different jobs

Know your needles, and your sewing suddenly clicks. The right needle prevents fabric damage, reduces thread breaks, and makes every stitch cleaner.

It’s the difference between wrestling with your project and watching it come together smoothly.

Keep quality needles organized, replace them regularly, and watch your stitching skills flourish with proper tool selection.

- https://threadsmonthly.com/hand-sewing-needles/

- https://www.mhthread.com/blog/products/types-and-sizes-of-hand-sewing-needles

- https://www.longancraft.com/blogs/sewing-tips/hand-sewing-needle-sizes3a-types-of-hand-sewing-needles

- https://www.blog.wawak.com/post/choosing-the-right-hand-sewing-needle-for-your-project

- https://en.wikipedia.org/wiki/Sewing_needle