This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

The numbers might look confusing at first, but they’re actually telling you something simple: how much the front is pulling compared to the back. Once you understand what those numbers mean and how to adjust them for different fabrics, you can turn problem projects into professional results.

Table Of Contents

Key Takeaways

- Differential feed is a ratio system that controls how front and back feed dogs pull fabric at different speeds, letting you prevent wavy seams on knits, puckering on lightweight materials, and create decorative gathers when you want them.

- Settings below 1:1 slow the front feed dogs to prevent stretching on knits and delicate fabrics, while settings above 1:1 speed them up to control slippery materials and create ruffles—neutral 1:1 works best for stable woven fabrics.

- Test every differential feed adjustment on scrap fabric first to see how your specific setting performs before cutting into your real project, since thread tension, fabric weight, and needle choice all affect your final seam quality.

- Regular maintenance of your feed dogs through gentle brushing and proper lubrication keeps them working smoothly, and most differential feed problems stem from incorrect settings, worn feed dog teeth, threading errors, or tension imbalances rather than machine failure.

Differential Feed on Serger Machines

If you want smoother seams and better control over your fabric, understanding differential feed is key. This feature changes how your serger treats different materials.

Here’s what you need to know before you start adjusting your machine.

How Differential Feed Works

Ever wonder why some fabrics glide through your serger without bunching or stretching, while others seem to misbehave no matter what you do? Differential feed is the answer. It lets you control fabric movement by adjusting feed ratio. Here’s what it does:

- Feed dog action

- Fabric movement control

- Feed ratio impact

- Preventing distortion

- Achieving balance

Components Involved in Fabric Feeding

If you want to know how your serger moves fabric so smoothly, it helps to look at the feed dogs and the presser foot working together under the needle. The front and rear feed dogs pull fabric at different rates.

The throat plate and needle plate guide the layers, while the looper system forms stitches.

Each part aids precise fabric feed and differential feed control.

Key Benefits for Sewing Projects

When all those parts work together, you get better sewing results. Differential feed gives you real control over your fabric. That means no more wavy edges on jersey knit or puckered seams on lightweight material. Here’s what you gain:

- Fabric Control and Stretch Management: You prevent fabric stretching on knits and keep seams flat

- Decorative Resourcefulness: You create fabric gathers, ruffles, or lettuce edges with simple dial adjustments

- Efficiency Gains and Seam Durability: Your projects finish faster with stronger seams that won’t break under stress

Differential feed helps you work with different fabric types without frustration. Whether you’re sewing project quality matters for yoga pants or home décor, this feature saves time and improves results. Modern sergers use independent front and back feed dogs.

Adjusting Differential Feed Settings

Getting your differential feed right is where the magic happens. The dial on your serger isn’t just a random knob—it’s the control center for how your fabric behaves under that presser foot.

Let’s break down what those numbers mean and how to pick the perfect setting for whatever you’re sewing.

Understanding Feed Ratio Numbers

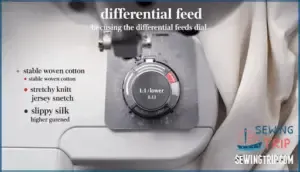

The numbers on your serger’s differential feed dial aren’t there to confuse you—they’re actually a simple ratio that tells you exactly how fast one set of feed dogs moves compared to the other. A setting of 1:1 means both sets move at the same speed—what goes in comes out unchanged.

Numbers below 1 (like 0.7) slow the front feed dogs down, stretching your fabric. Numbers above 1 (like 2.0) speed them up, pushing more fabric through and creating gathers.

Setting for Different Fabric Types

Your fabric type dictates your differential feed setting—and getting it right makes all the difference. Lightweight fabrics like organdy work best at 0.5 to 1.0, while medium fabrics such as broadcloth stay flat at 1.0. Heavy fabrics like denim need 1.0 to 2.2 for clean seams. Knit fabrics require 1.0 to 1.5 to prevent stretching.

Rolled hems on delicate weaving call for 0.5 to 0.7 for perfect edges.

When to Use 1:1, Lower, or Higher Ratios

Knowing when to dial that ratio up or down is like knowing when to ease off the gas or hit the brakes—it keeps your fabric moving exactly how you need it to.

Use 1:1 for standard sewing on stable woven fabrics. Drop below 1:1 for knit fabrics and lightweight materials—preventing puckering keeps seams smooth. Crank it above 1:1 for decorative gathers and controlling slippery fabrics. Understanding differential feed means adjusting the feed ratio to match what your project demands.

- Lower settings stretch your fabric for flattering curves on jersey knits

- Neutral ratios deliver precision when you need clean, professional seams

- Higher settings create volume transforming plain edges into beautiful ruffles

Test-Stitching for Optimal Results

Before you stitch a real seam, scrap fabric tells you everything you need to know about how your settings will perform. Test stitching on fabric swatches reveals seam appearance issues before you cut into your good material.

Test drive different ratios using test samples to see how stitch length impact and tension fine-tuning change everything. Iterative adjustments on scrap fabric save you from ripping out bad seams later.

Preventing Fabric Stretching and Gathering

You’ve adjusted your differential feed settings. Now it’s time to put them to work preventing the most common fabric problems.

Here’s how to address stretching, gathering, and tricky fabrics that misbehave under your presser foot.

Avoiding Wavy and Stretched Seams

When your serger seam looks like a stretched-out slinky or waves like a flag in the wind, you know something’s off with your differential feed setting. Fabric distortion happens when the feed dog ratio doesn’t match your material.

Lower the differential feed for wavy seams on knits. Raise it to stop fabric stretching on lightweight materials. Tension balance matters too.

Test your serger settings on scraps first for consistent stitching without seam puckering.

Creating Gathers and Ruffles

You can turn your serger into a gathering machine by cranking up the differential feed setting to 2:1 or higher. The front feed dogs push more fabric under the needle than the rear ones pull through. This creates uniform ruffles without hand-basting.

Your fabric choice affects ruffle density. Test on scraps to dial in the perfect gather for decorative effects on skirts and sleeves.

Differential Feed for Knit and Lightweight Fabrics

Knit fabrics and lightweight materials demand precise adjustments to avoid common serger headaches. Here’s your quick guide to mastering differential feed settings:

- Knit fabric settings: Use ratios between 1.0 and 1.5 to stop stretching on spandex blends

- Lightweight fabric settings: Drop to 0.5–1.0 for chiffon to prevent puckering

- Preventing wavy seams: Test on scraps and adjust one click at a time

- Decorative lettuce hems: Push above 1.5 for controlled gathering effects

Adjusting differential feed transforms tricky fabrics into professional finishes. Understanding how to adjust the serger’s feed dogs is key for preventing fabric distortion.

Techniques for Quality Serger Seams

Getting quality results from your serger comes down to mastering how you control fabric movement through the machine. The differential feed is your main tool for this—it’s what keeps seams flat, prevents distortion, and lets you add decorative effects when you want them.

Master your serger’s differential feed to keep seams flat, prevent distortion, and unlock decorative effects that transform your fabric

Here’s how to put it all together for professional-looking work.

Achieving Flat Overcast Seams

A flat overcast seam is what separates a messy edge from a professional-looking finish, and your differential feed setting is the tool that makes it happen.

Start by matching your differential feed to your fabric weight—heavier fabrics need higher ratios, lighter ones need lower. Your needle choice and feed pressure matter too. Set tension balanced so threads lock smoothly without puckering.

Test-stitch on scraps first. Adjust gradually until that seam lies flat and smooth.

Decorative Effects With Differential Feed

Once you’ve mastered flat seams, it’s time to flip the script and use that same differential feed to create texture and visual interest instead of just preventing problems.

Here’s where decorative effects shine:

- Ruffle creation — Crank your differential feed to 2:1 or higher. The front feed dogs move faster, bunching fabric into soft, gathered waves.

- Gathering techniques — Lower settings compress fabric tightly. Perfect for shirring or creating dense texture on lightweight materials.

- Lettuce edges — Use higher ratios with decorative stitches to curl fabric edges while adding ornamental detail simultaneously.

- Fabric manipulation — Mix settings mid-seam. You’ll build visual interest and control where gathers land for intentional design.

Test on scraps. This texture enhancement takes practice, but once you dial it in, your serged pieces jump from functional to stunning.

Controlling Fabric Movement for Precision

Precision doesn’t mean rigidity—it means understanding exactly how your fabric moves through the machine so you can guide it exactly where you want it to go. Your feed dogs are the muscle here. They pull fabric forward at different speeds depending on your differential feed setting.

When you nail the fabric feed balance, you prevent distortion before it starts. Lower ratios slow the front dogs, giving stretchy knits room to breathe without puckering. Higher ratios speed them up, controlling fabric movement through specialty sewing without bunching. Adjust one notch at a time. Test on scraps.

Achieving smoothness comes from precise fabric control and patience—dial in your differential feed, and your seams stay flat every time.

Troubleshooting and Maintenance Tips

Even the best sergers need a little attention to keep running smoothly. When your differential feed isn’t working right, the problem usually comes from one of a few common culprits.

Let’s walk through what to check and how to keep your machine in top shape.

Common Differential Feed Issues

Most differential feed problems stem from four culprits: incorrect settings, feed dog wear, timing misalignment, and fabric mismatches. When you set ratios wrong—below 0.8 causes stretching, above 1.2 creates wavy seams on knits—you’ll see puckering or distorted edges.

Feed dogs wear down after heavy use, causing inconsistent fabric advance. Maintenance lapses compound everything. Start by adjusting differential feed carefully for your fabric type, then inspect feed dogs for tooth rounding.

Checking Threading and Tension

Before you blame the machine for acting up, thread tension and threading path issues are usually the real troublemakers lurking behind most serger problems. Start by checking that your thread aerial is up and presser foot is down.

Then verify each thread weaves correctly through the tension discs—this is where most threading issues hide. Improper tension settings create puckering or loose stitches. Make sure threads sit snugly in their discs.

Run a test seam on scrap fabric to confirm everything works smoothly before moving forward with your project.

Cleaning and Maintaining Feed Mechanisms

Think of your serger’s feed dogs like the tires on a car—they need regular care to keep rolling smoothly and doing their job right. Dirt and lint build up over time and mess with how fabric moves through your machine. Here’s what you need to do:

- Feed Dog Cleaning: Use a small brush to gently remove lint and thread bits from around the feed dogs. Get into those tight spots where debris hides.

- Machine Oil Checks: Apply a tiny drop of machine oil to the feed mechanisms where they pivot. Don’t overdo it—too much oil attracts dirt.

- Bobbin Case Maintenance: Clean out the bobbin case spring and surrounding area. Thread path clearance matters more than you’d think for smooth differential feed operation.

Regular serger brushing keeps everything moving freely. When your feed mechanisms work right, your differential feed adjustments actually do what they’re supposed to.

Practice and Skill Development

You’ll find that getting comfortable with differential feed takes time, and that’s perfectly normal—nobody masters it on the first try. Building skill means working through practice exercises and sewing drills that teach your hands and eyes what good fabric management looks like.

Start simple. Use scrap fabric to test adjusting differential feed settings on knit fabrics and woven materials. Each drill builds machine familiarization. Notice how fabric moves at different ratios. Creating fabric gathers and perfecting serger techniques for knit fabrics becomes natural through repetition, not theory.

| Practice Focus | Fabric Type | Differential Setting | Expected Result | Skill Level |

|---|---|---|---|---|

| Basic Threading | Woven Cotton | 1:1 | Flat Seams | Beginner |

| Gathering Technique | Lightweight Knit | 2:1 | Controlled Ruffles | Intermediate |

| Stretch Prevention | Jersey Knit | 0.7:1 | Smooth Edge | Intermediate |

| Decorative Effects | Silk Charmeuse | 2:1+ | Artistic Gathers | Expert |

| Speed Control | Mixed Fabrics | Variable | Precision Edges | Expert |

Conclusion

The truth is simple: your serger’s differential feed isn’t magic—it’s mechanics. When you understand what those numbers mean and match them to your fabric, you stop fighting your machine.

Whether you’re working with stretchy knits or delicate silk, mastering serger sewing machine differential feed settings transforms problem projects into confident stitches.

The key is testing, adjusting, and trusting the process. Your seams will thank you.

- https://support.brother.com/g/b/faqend.aspx?c=us&lang=en&prod=hf_air1800eus&faqid=faqh00000588_004&pfs=1

- https://www.simplesimonandco.com/2014/06/understanding-differential-feed-sergers.html/

- https://www.instagram.com/reel/DPe5MnsClbO/

- https://www.youtube.com/watch?v=7kXfRQN-7t0

- https://threadistry.com/blog/serger-troubleshooting/?srsltid=AfmBOop7nuwZpRi3_KeA3z4QznMmNOCb6C6P_50JcVDfGtj9M6p3rJB6