This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Understanding how each piece works, from the wire hook to the spring tensioner, gives you control over repairs and replacements. Whether your machine relies on manual threading or boasts an automatic threader, knowing your parts means fewer headaches and smoother sewing sessions ahead.

Table Of Contents

Key Takeaways

- Understanding each threader component—from the wire hook that captures thread to the spring tensioner that controls tension—gives you the power to diagnose problems and make targeted repairs instead of guessing.

- Automatic threaders cut threading time from 30 seconds to under 10 seconds, but when they fail, your entire workflow stops, making regular maintenance essential to prevent costly downtime.

- Most needle threader parts are consumables that manufacturers exclude from warranty coverage, so knowing where to find compatible replacements and understanding compatibility with your specific machine brand saves you frustration and money.

- A bent hook, misaligned lever, or worn spring tensioner won’t just slow you down—it can damage your needle and create stitch quality issues that compromise your entire project.

What Are Sewing Machine Needle Threader Parts?

Before you troubleshoot or replace a needle threader, it helps to know what each part does. Every needle threader has specific components that work together to guide your thread.

Let’s take a closer look at the main pieces you’ll find inside these handy tools.

Overview of Needle Threader Mechanisms

Threader mechanisms stand as a testament to thoughtful design, making Needle Threaders essential for those seeking efficiency. Each mechanism is crafted to simplify Threading Needles, blending precise Needle Alignment with dependable Threading Techniques. Mechanism Design directly impacts Sewing Precision, influencing the final results.

Needle threader mechanisms showcase thoughtful design, blending precision and efficiency to elevate the accuracy and ease of threading needles

These tools are characterized by:

- Fast threading cycles

- Reliable hook action

- Consistent needle alignment

- Easy-to-use actuation

- Emphasis on threader efficiency.

The use of automatic needle threaders can significantly enhance overall sewing performance.

Key Components and Their Functions

A Needle Threader works in harmony, with each piece serving a purpose. The wire hook acts as your Thread Capture tool, sliding through the needle eye for reliable Needle Alignment. Lever Mechanics let you control movement, while quality Hook Materials prevent bending. Tension Control keeps threading smooth.

With these Needle Threaders, threading needles turns from frustration into a fluid sewing machine accessory advantage. Understanding the proper threader mechanism is key to effective use.

Differences Between Manual and Automatic Threaders

Some threaders use a simple wire loop for guiding the thread, while others rely on levers or buttons to push the thread through. Manual models offer better portability and last longer, but threading speed and sewing efficiency are much higher with automatic machines.

If you have trouble getting your needle threaded by hand, automatic threaders dramatically improve user experience and compatibility.

Main Components of a Needle Threader

To understand your needle threader, it’s important to know what makes it work. Each part plays a specific role in helping you thread your sewing machine with ease.

Here are the key components you’ll find in most needle threaders.

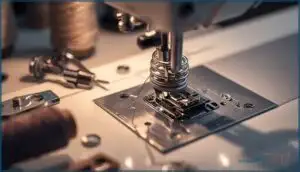

Wire Hook and Its Role

Ever wrestled with a stubborn needle thread? The wire hook is your unsung hero.

Made from hardened steel, this tiny tool slides through the eye, grabs your thread, and pulls it through with ease. Solid hook materials mean strong wire durability, while careful hook maintenance keeps thread capture smooth.

Mastering this threading technique sets the foundation for reliable sewing.

Actuator Lever and Plastic Guide

Lever mechanics make needle threading simple. With a spring-assisted actuator design, you control the wire hook’s movement—accuracy depends on your grip.

Guide materials matter too; thermoplastic guides are light but can bend or break over time.

If you notice frequent threading issues, replacement costs for these sewing machine accessories are low, making them practical sewing tools among essential sewing machine parts.

Spring Tensioner and Mounting Bracket

Spring tensioners are the backbone of thread control in needle threading. Steel alloys give spring durability, while bracket materials like aluminum offer sturdy mounting techniques. You adjust tension for balanced stitches—usually with a dial or screw.

If your sewing machine parts feel loose, inspect the mounting bracket. Reliable tension adjustment keeps your sewing tools and accessories working smoothly among essential sewing notions.

Types of Needle Threaders for Sewing Machines

Needle threaders come in several styles, each built for a specific task. You’ll find options for standard use, specialty needs, and different machine brands.

Here’s how the main types compare and what you should know about each one.

Standard Vs. Automatic Needle Threaders

Why settle for slow threading when you can boost sewing efficiency? Standard needle threaders rely on manual skill, while automatic models offer speed and ease. Here’s what sets them apart:

- Threading Speed: Automatics finish in seconds; manuals take longer.

- Needle Compatibility: Automatics work best with standard sizes.

- User Experience: Automatics reduce frustration, but durability can vary.

Specialty Threaders (Looper, Yarn, Double Needle)

Need precision for tricky seams or fancy threads? Looper threaders drive Sewing Efficiency in industrial machines, handling up to 3,000 stitches per minute for strong Double Stitch seams.

Yarn threaders manage Yarn Tension with metallic or heavy threads, boosting Thread Durability.

Double needle threaders let you run parallel lines, but require manual threading for perfect results—no shortcuts here.

Compatibility With Different Machine Brands

Brand Interoperability isn’t one-size-fits-all in the sewing world. Machine Compatibility hinges on Threader Standards unique to each brand—Singer, Janome, or Bernina, for example.

Universal Fitments like Clover and Dritz aim for broad reach, but true Cross Branding success still requires close attention to your machine’s fitment chart. Even trusted sellers like Sewing Parts Online call this step non-negotiable.

Replacement and Maintenance of Threader Parts

Keeping your needle threader in good shape means watching for signs of wear and knowing when it’s time for a switch. You’ll also want a clear plan for replacing parts when the need comes up.

Here’s what you should look for and expect along the way.

Signs Your Needle Threader Needs Replacement

Ever notice your sewing machine threader acting up? Threader failure often shows through missed threading attempts, bent hooks, or strange noises. If you spot these warning signs, don’t ignore them:

- Threading issues or repeated failures

- Misaligned hook causing needle damage

- Audible grinding or lagging movement

- Visible breakage or loose parts

Replacement costs rise fast if left unchecked.

How to Replace Needle Threader Components

If your needle threader’s hook is bent or the actuator jams, it’s time to swap it out. Start by turning off the machine and removing the needle. Use a Phillips screwdriver or Allen key for Threader Removal Tips. Align the new unit, listen for a “click,” and test with your Needle Inserter.

Here’s a quick reference:

| Step | Tool Needed |

|---|---|

| Power off machine | None |

| Remove needle | Needle Holder |

| Unscrew assembly | Phillips/Allen key |

| Align threader | Tweezers |

| Test threading | Needle Inserter |

Cost and Availability of Replacement Parts

Once you’ve swapped out a faulty threader, you’ll notice part pricing varies. Supply chain issues have nudged costs up, but global sourcing keeps options open. Discount options appear in bulk packs, while Sewing Parts Online’s Needle Threader Collection offers fair rates. Refund policies support returns, and customer service helps you find the right fit.

- Online sewing supplies

- Repair service support

- Flexible refund policies

Where to Buy Sewing Machine Needle Threader Parts

Finding the right needle threader parts can feel tricky if you aren’t sure where to look. Here are some things to keep in mind as you shop for replacements. You’ll want to know your options before making a decision.

Online Retailers and Sewing Supply Stores

Across online shopping platforms, the market size for sewing supplies is massive, with broad product selection from brands like Nifty Notions and Sewing Parts Online.

You’ll notice consumer trends shifting toward bulk purchases and repeat orders. Geographic distribution means global access, while logistics support ensures quick delivery.

For specialized sewing accessories and parts, these retailers make finding what you need straightforward.

Factors to Consider When Purchasing

When picking needle threader parts, start with Model Compatibility—most only fit certain sewing machines. Material Durability matters, too; aluminum threaders last longer. Factor in Maintenance Needs and Cost Analysis, especially if you sew often. User Preferences count, so look for ergonomic designs.

Reliable sewing accessories and notions save headaches, and sewing machine repair services can guide your choices.

Customer Support and Warranty Policies

Confidence in your purchase starts with clear Customer Support and knowing Policy Exclusions. Warranty Claims for needle threader parts rarely succeed—brands like Brother and Singer exclude these as consumables.

Customer Service, though, offers Support Options such as troubleshooting guides and repair processes.

Satisfaction Guarantee and Money Back Guarantee policies help, but Customer Satisfaction and Returns often rely on retailer flexibility, not manufacturer promises.

Frequently Asked Questions (FAQs)

How do you thread a sewing machine needle?

To thread a needle on your sewing machine, guide the thread through the thread guides, adjust thread tension, align the needle, and use a needle threader or inserter if needed. Proper alignment prevents skipped stitches and thread breakage.

How does the madamsew ultimate needle threader work?

The Madam Sew Premium Needle Threader streamlines the threading process by securely holding the needle for perfect alignment.

Its ergonomic design guides thread through the eye with a spring-loaded pin, improving user experience for anyone struggling with manual threading.

How many PCs are in a needle threader set?

When you compare Threader Set Sizes on the market, most Needle Threader Packs include 3 to 50 pieces per set.

Multi Pack Options and Threader Kit Contents usually range from 10 to 25, perfect for sewing notion variety.

Where can I buy threaders – sewing tools?

You’ll find threaders at Online Marketplaces like Amazon, eBay, and Etsy. Specialized Sewing Accessories and Supplies shops, Sewing Communities, and local stores also stock Needle Threading Made Simple tools, plus Needle Holders and other Sewing Notions and Tools.

Where is the needle inserter on a sewing machine?

Picture the needle inserter as a navigator—its Best Placement is just above or beside the Eye of Needle. This Accessibility Design lets you Insert a Needle with ease, adapting across Machine Variations for Needle Threading Made Simple and ergonomic use.

How do needle threader parts affect sewing speed?

Automatic threaders cut threading time from 30 seconds to under 10 seconds, boosting efficiency over 50%. But malfunctions halt sewing entirely. Regular maintenance prevents failures that slow your work by 20-30%.

Are needle threader parts safe for children?

An ounce of prevention is worth a pound of cure. Needle threaders pose choking hazards and material toxicity risks for children. Keep these sewing machine parts away from kids under three. Regulatory compliance helps, but injury prevention requires vigilant supervision.

Can damaged threader parts harm sewing machines?

Yes, damaged threader parts cause thread breakage risk and stitch quality issues. Bent hooks or misaligned guides increase machine downtime by 15-20% daily. Repair costs mount quickly, leading to user frustration across sewing operations.

What materials are used in threader part manufacturing?

The delicate needle eye demands strong materials. Manufacturing processes rely on metal alloys like steel and stainless steel for springs, while plastic polymers such as polypropylene form actuator levers.

Component coatings improve material durability throughout sewing machine parts.

Do threader parts require regular lubrication or cleaning?

Needle threader maintenance focuses on cleaning, not lubrication. Use a soft brush or compressed air to clear lint after every few projects.

Regular debris removal prevents jams and extends your machine’s threading mechanism lifespan considerably.

Conclusion

A broken threader can turn a five-minute project into an all-day ordeal. Now that you understand sewing machine needle threader parts—from wire hooks to spring tensioners—you won’t be left guessing when something fails.

You’ll spot the problem, order the right component, and get back to work. That knowledge transforms frustration into confidence.

Keep your threader maintained, replace worn pieces promptly, and you’ll spend less time troubleshooting and more time creating exactly what you envision.

- https://sewingmachineman.substack.com/p/broken-needle-threaders

- https://www.hooptalent.com/blogs/news/embroidery-needle-threaders-ultimate-guide-to-durable-picks-and-pro-techniques

- https://www.maggieframes.com/blogs/embroidery-blogs/thread-needle-tool-mastery-essential-techniques-and-pro-solutions-for-effortless-threading

- https://www.youtube.com/watch?v=8UF8sGwcECU

- https://www.futuremarketinsights.com/reports/sewing-machine-components-market