This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A dull rotary blade can ruin your fabric cuts and slow your project to a crawl. You’ll notice ragged edges, skipped threads, and the need to press harder with each pass. These signs mean it’s time to swap that blade out.

Changing a rotary cutter blade takes less than two minutes once you know the steps. The process is straightforward, but it requires attention to safety—you’re handling a razor-sharp cutting tool. With the right technique and a few basic precautions, you’ll keep your cutter performing like new. Lock your cutter, grab your gloves, and get ready to restore those clean, smooth cuts.

Table Of Contents

Key Takeaways

- You’ll know it’s time to swap your rotary blade when you see ragged edges, skipped threads, or need to press harder during cuts.

- Safety comes first: always lock your cutter, wear cut-resistant gloves, work on a stable surface, and handle blades by their dull edges only.

- The blade change process takes under two minutes—lock the cutter face down, remove the retaining nut, lift out the old blade, clean the hub, install the new blade with correct alignment, and test on scrap fabric.

- Extend blade life by cleaning fabric lint after every few projects, using quality self-healing cutting mats, avoiding pins during cuts, and replacing blades as soon as cutting quality declines rather than waiting for complete failure.

Safety Precautions Before Changing Rotary Blades

Changing a rotary cutter blade isn’t difficult, but you’re working with a razor-sharp tool. A few simple precautions will keep your fingers safe and make the job go smoothly.

Before you start, make sure you’ve chosen the right rotary cutter for left-handed users if that applies to you, since blade orientation and handle design affect both safety and control.

Here’s what you need to do before you start.

Wear Cut-resistant Gloves and Eye Protection

Before you touch that blade, slip on cut-resistant gloves made from materials like Kevlar or UHMWPE. They shield your hands from nicks while keeping your grip steady.

Pair them with safety glasses that meet ANSI Z87.1 standards—polycarbonate lenses block flying debris. This hand protection and eye safety combo is non-negotiable. Every blade change demands it, no exceptions.

Lock The Cutter and Work on a Stable Surface

Set your rotary cutter on a flat, sturdy surface with a non-slip mat beneath it. Engage the lock mechanism until you hear a deliberate click—this immobilizes the blade shaft completely.

Position the blade away from your body to maintain a safe corridor. Clear all loose fabrics and clutter that could snag the tool.

Proper surface preparation and cutter stability prevent slips during blade changes. For maximum safety, always consider using personal protective equipment guidelines when performing maintenance tasks.

Keep a Blade Disposal Container Ready

Place a dedicated sharps container within arm’s reach before you begin. A hard plastic or metal disposal bin with a narrow opening and tight lid keeps sharp waste secure. Label it clearly to avoid confusion.

When your container holds about 50 used blades, replace it. This blade safety routine prevents accidental cuts and keeps your workspace organized during every blade replacement.

Handle Blades by Edges Only, Never The Sharp Side

With your disposal container in place, you’re ready for the most critical blade safety tip: grip technique. Always hold blades by the dull edges—never the sharp cutting side. Your fingers belong on the outer rim or central hub only.

- Hold blades by their flat, dull outer edges

- Keep fingers away from the exposed cutting edge

- Don’t slide fingers along any blade surface

- Use cut-resistant gloves for extra protection

- Visually inspect for nicks before handling

This edge handling protocol prevents the cuts that send quilters to urgent care.

Step-by-Step Guide to Changing Rotary Cutter Blades

Changing your rotary blade doesn’t require special skills or tools. The process takes just a few minutes when you follow the right steps.

Here’s exactly how to swap out a dull blade for a sharp one safely.

Lock and Position The Cutter Face Down

Before you touch the rotary cutter, lock it to prevent wheel rotation. Position it face down on a stable, level surface with the blade housing flat. This face down orientation keeps your hands clear of the blade path and exposes the retaining mechanism.

Use a non-slip mat underneath for cutter stability. Always verify the lock engages fully before proceeding.

Remove The Blade Retaining Nut or Screw

Locate the retaining mechanism on your cutter’s blade hub—most use a hex or spline nut, while others feature a screw with a captive washer.

Once you’ve identified the nut type, consult a guide on rotary cutter anatomy and maintenance to ensure you’re using the right tool for removal without damaging the assembly.

Select a properly sized wrench or driver that fits snugly to avoid stripping. Turn counterclockwise with steady pressure, following torque specifications for your model.

Some safety-oriented designs use left-handed threads, so check your manual for specific blade change instructions and nut removal tips.

For additional guidance on removal direction, consult information about standard rotation and safety precautions.

Lift Out The Old Blade Carefully

Grasp the old blade by its smooth outer edges—never touch the cutting surface. Use your cut-resistant gloves for safe blade removal, then follow these handle techniques:

- Lift the blade straight up without twisting to prevent edge damage.

- Let gravity assist rather than forcing or prying with bare hands.

- Place it immediately into your blade disposal container.

Keep safety shields engaged throughout this blade change process.

Clean The Blade Hub and Remove Debris

A clean blade hub keeps your rotary blades spinning smoothly and prevents frustrating snags. Use a soft nylon brush to sweep loose dust and fabric lint from the hub teeth. For sticky resin, apply a citrus-based cleaner with a microfiber cloth—it dissolves grime without corroding metal. Compressed air blasts out stubborn particles from tight grooves.

| Debris Removal Tool | Best Use |

|---|---|

| Nylon brush | Dislodges fibers between hub teeth |

| Microfiber cloth | Wipes residue without scratching |

| Compressed air | Clears hard-to-reach grooves |

| Citrus cleaner | Dissolves adhesive buildup safely |

Inspect the hub seal for cracks before moving forward.

Install The New Blade With Correct Alignment

A misaligned rotary blade replacement turns every cut into guesswork. Place your new blade flat on the blade hub with the arbor hole centered over the spindle shaft. Match any identification markings on the blade with your cutter’s reference mark. Confirm the blade edge faces the correct cutting direction—look for arrows or lettering stamped on the blade.

- The blade must sit flush against the hub with no gaps

- Rotate the blade by hand to check it spins freely

- Verify the sharp edge clears the safety features without rubbing

Proper blade alignment delivers cutting accuracy and protects your tool maintenance routine.

Reattach and Tighten The Retaining Mechanism

Thread the retaining nut back onto the cutter’s hub until it seats flush against the blade carrier. Tighten snugly—about a snug fit plus an eighth turn—without overtorquing.

Safety locks on many rotary cutter designs won’t engage if you skip this torque setting. Test blade alignment by gently attempting to lift the edge. No movement? You’ve nailed proper mechanism maintenance and secured your rotary blade replacement for clean cuts ahead.

Wipe Down and Test The New Blade

Use a lint-free cloth to remove dust and fingerprints from the blade edge. Run a scrap fabric test across your cutting mat to confirm smooth operation—no skipping or tearing means proper blade alignment and edge sharpness.

Listen for quiet rotation during cutting tests. If you hear grinding, recheck your blade replacement techniques. This safety verification step catches issues before they ruin your project or compromise rotary cutter maintenance.

Top 5 Rotary Cutter Replacement Blades

Not all replacement blades are created equal. The right blade can make your cuts cleaner and last longer between changes.

Here are five top-rated options that quilters trust for consistent performance.

1. Headley Tools Rotary Cutter Blades

Your rotary cutter deserves a blade that won’t quit mid-project. Headley Tools 45mm blades use SKS-7 Japanese steel for long-lasting sharpness. They fit Fiskars and Olfa grips perfectly.

You get 10 blades in a storage box. These blades slice through multiple fabric layers with ease. They work great for quilting and crafts.

They arrive with a light oil coating. Wipe them before use to protect your fabric. They’re sharp and affordable. Keep extras on hand so you’re never stuck mid-cut.

| Best For | Quilters, sewers, and crafters who need sharp, affordable rotary blades that cut through multiple fabric layers without breaking the bank. |

|---|---|

| Blade Size | 45mm |

| Material | Japanese Steel (SKS-7) |

| Pack Quantity | 10 blades |

| Storage Case | Plastic storage box |

| Compatible Brands | Fiskars, Olfa |

| Weight | 1.76 ounces |

| Additional Features |

|

- Made from durable SKS-7 Japanese steel that stays sharp longer than cheaper alternatives

- Compatible with popular rotary cutter brands like Fiskars and Olfa, so no need to buy new handles

- Comes in a pack of 10 with a storage box, giving you plenty of backup blades at a great price

- Blades arrive with an oil coating that must be wiped off before use to avoid staining fabric

- Some users report they dull faster than premium brand-name blades

- Sharp edges require careful handling to prevent accidental cuts during blade changes

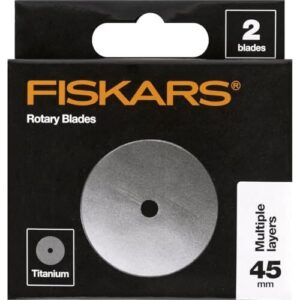

2. Fiskars Titanium Rotary Blades

Fiskars Titanium Rotary Blades outlast standard steel by three times. The titanium coating keeps the edge sharp through hundreds of cuts. You’ll power through denim, canvas, and multiple fabric layers without slowing down.

These 45mm blades snap into most standard rotary cutters. They come two per pack with a storage tray. The precision-ground edge cuts curves and straight lines cleanly. They’re pricier than basic blades, but the durability pays off. Wipe off the factory oil before your first cut.

| Best For | Quilters, sewers, and crafters who cut through thick fabrics or multiple layers regularly and want blades that stay sharp longer. |

|---|---|

| Blade Size | 45mm |

| Material | Titanium |

| Pack Quantity | 2 blades |

| Storage Case | Blade tray |

| Compatible Brands | Fiskars, most 45mm cutters |

| Weight | 0.317 ounces |

| Additional Features |

|

- Last three times longer than standard steel blades thanks to the titanium coating

- Precision-ground edges handle both curved and straight cuts cleanly

- Compatible with most 45mm rotary cutters and snap in and out easily

- Higher price point compared to basic replacement blades

- Come with factory oil that needs to be wiped off before first use

- Extremely sharp edges require careful handling to prevent cuts

3. Headley Tools Titanium Rotary Cutter Blades

Headley Tools offers fifteen titanium-coated blades in one pack for under twenty dollars. These 45mm blades fit Olfa and Fiskars grips without any fuss. The Japanese SKS-7 steel core holds an edge well through fabric, fleece, and vinyl.

You’ll notice the gold coating right away—it fights rust and cuts friction. The blades arrive oily, so wipe them down first. They dull faster than premium options, but at this price you can swap them out guilt-free. Keep extras on hand for big projects.

| Best For | Crafters and quilters who cut through fabric regularly and want an affordable blade pack they can rotate through without worrying about the cost. |

|---|---|

| Blade Size | 45mm |

| Material | Japanese Steel (SKS-7) with Titanium Coating |

| Pack Quantity | 15 blades |

| Storage Case | Plastic storage box |

| Compatible Brands | Fiskars, Olfa |

| Weight | 2.11 ounces |

| Additional Features |

|

- Fifteen blades for under twenty dollars beats most brand-name pricing

- Titanium coating resists rust and reduces drag while cutting

- Fits standard 45mm handles from Fiskars and Olfa right out of the box

- Blades arrive with an oily coating that needs wiping before first use

- Edge dulls faster than premium options, requiring more frequent swaps

- Sharpness demands careful handling to avoid accidental cuts

4. Pavsrmy Rotary Cutter Blades

Pavsrmy delivers ten SK5 Japanese steel blades for steady cutting performance. Each 45mm blade fits most standard rotary cutters, including Olfa and Fiskars models.

You’ll get clean cuts through fabric, paper, and light leather without tugging or fraying. The blades stay sharp for six to eight hours of heavy quilting work.

They come in a durable plastic case with a secure clasp—perfect for safe storage. At 1.4 ounces, they won’t weigh down your tool kit. Keep a few spares ready for marathon sewing sessions.

| Best For | Quilters and crafters who need affordable replacement blades that stay sharp through multiple projects. |

|---|---|

| Blade Size | 45mm |

| Material | SK5 Japanese Steel |

| Pack Quantity | 10 blades |

| Storage Case | Durable plastic case |

| Compatible Brands | Olfa, Fiskars, most 45mm cutters |

| Weight | 1.4 ounces |

| Additional Features |

|

- SK5 Japanese steel construction delivers clean cuts through fabric, paper, and light leather without fraying

- Fits most standard 45mm rotary cutters including popular Olfa and Fiskars models

- Comes with durable plastic storage case and ten blades for long-term value

- Some users report they’re not as sharp as premium brands right out of the package

- Can only cut through 4-5 layers of cotton at once, limiting bulk cutting

- Blade sharpness varies depending on materials used and handling care

5. Iegremar Rotary Cutter Replacement Blades

Precision-ground high carbon steel puts these blades in a league of their own. Each 45mm Iegremar blade slices through fabric with minimal fraying, thanks to SKS-5 steel construction. You’ll fit them on most standard cutters without hassle.

The ten-pack includes a secure storage case to prevent dulling between uses. These blades maintain their edge through multiple cutting sessions before showing wear. At 1.13 ounces, they won’t add bulk to your sewing kit. Stock up and swap them out the moment your cuts lose crispness.

| Best For | Quilters, crafters, and sewers who need reliable replacement blades for high-volume cutting projects involving fabric, paper, leather, or vinyl. |

|---|---|

| Blade Size | 45mm |

| Material | Steel (SKS-5) |

| Pack Quantity | 10 blades |

| Storage Case | Secure storage case |

| Compatible Brands | All 45mm handles |

| Weight | 1.13 ounces |

| Additional Features |

|

- High-quality SKS-5 steel construction maintains sharpness through multiple cutting sessions

- Universal 45mm size fits most standard rotary cutter handles

- Includes storage case to protect blades and prevent dulling between uses

- Blades require frequent replacement as they’re consumable items

- Some users report these aren’t as sharp as premium competing brands

- Minor size variations (up to 0.12 inches) possible due to manufacturing tolerances

Maintenance Tips to Extend Blade Life

Your rotary blade doesn’t have to wear out as fast as you think. A few simple habits can double or even triple its lifespan, saving you money and keeping your cuts sharp.

Here’s what you need to do to get the most from every blade.

Clean Fabric Lint Regularly From Blade Area

Fabric fibers cling to your blade hub like dust bunnies under a bed. Clean the blade area after every 2 to 3 meters of dense fabric or at the end of each project session.

Here’s your lint-free cutting routine:

- Use a stiff brush to dislodge lint without touching the sharp edge

- Blast tight corners with compressed air

- Wipe the hub with a soft microfiber cloth

- Extract stubborn fibers with a wooden toothpick

- Inspect for remaining lint before your next cut

Regular blade care prevents heat buildup and keeps your cuts crisp.

Use Quality Cutting Mats and Avoid Pins

Your cutting mat acts as a shock absorber for every blade strike. Invest in a self-healing mat made from layered vinyl at least 3mm thick. The smooth surface reduces drag and prevents microchips that dull your rotary cutter faster than heavy use alone.

Skip pins entirely during fabric cutting. Pins create invisible nicks in seconds.

| Mat Material | Blade Longevity Benefit | Safety Impact |

|---|---|---|

| Self-healing vinyl | Absorbs impact, reduces dulling | Prevents blade rebounds |

| 3mm thickness | Distributes pressure evenly | Stops cut-throughs |

| Non-slip backing | Maintains cutting accuracy | Reduces hand slippage |

| Smooth surface | Minimizes fabric snagging | Fewer sudden blade catches |

| Grid markings | Eliminates pin positioning | Removes scattered sharps |

Follow basic mat maintenance to protect your blade care investment. Wipe down with mild soap after messy projects. Store flat to prevent warping that throws off your cutting accuracy. A clean mat means fewer fabric fibers trapped under your blade during precision work.

Store Blades in Protective Cases

Tossing loose blades in a drawer invites accidents and rust. Your rotary cutter blade needs proper safety precautions and moisture control the moment you remove it. Invest in rigid protective cases with snap locks—they’re not just about blade storage, they’re about edge protection and cutter maintenance that extends tool life.

- Choose impact-resistant polycarbonate cases with clear lids for quick inventory checks

- Use individual pockets to prevent blade edges from touching during storage

- Add desiccant packets inside cases to control humidity and prevent rust

- Store used blades in dedicated sharps containers with sealed openings

- Label each case with blade size and replacement date for efficient tracking

Replace Blades When Cutting Quality Declines

Your rotary cutter blade won’t announce its retirement—you’ll feel it. When resistance spikes or frayed edges appear, blade wear signs demand attention.

Uneven cuts and reduced cutting edge geometry mean it’s time for blade replacement techniques. Test sharpness on scrap fabric; if you’re pushing harder than usual, rotary cutter maintenance calls for a fresh cutter blade. Don’t compromise your fabric cutting tips waiting for complete failure.

Apply Proper Cutting Pressure to Prevent Strain

A sharp rotary blade shouldn’t require force—if you’re pushing hard, something’s wrong. Apply smooth, steady pressure rather than hard bursts to maintain blade contact.

A sharp rotary blade cuts smoothly with steady pressure—excessive force signals something’s wrong

Let the cutter blade do the work while you guide it. Proper cutting techniques and pressure control prevent strain on both you and your rotary cutter, extending blade life and keeping your fabric handling safer.

Frequently Asked Questions (FAQs)

How often should you change your rotary cutter blade?

Think of your blade like a chef’s knife—it only performs its best when sharp.

Replace your rotary cutter blade every 2 to 5 projects with lightweight fabrics, or sooner when you notice skipping cuts.

How often should I replace my rotary blade?

Your cutting frequency determines replacement schedules. Daily cutters need fresh blades every 2-3 projects.

Weekly hobbyists should swap after 8-12 hours. Watch for frayed edges—that’s your blade wear signs telling you it’s time.

Can I sharpen a dull rotary cutter blade?

Most blades aren’t designed for edge restoration and sharpening can void warranties.

Blade replacement techniques yield safer, cleaner cuts. Some users report temporary improvements, but results vary and durability suffers quickly.

What size blade does my cutter need?

Your rotary cutter‘s manual or label shows the blade diameter you need. Most quilters use 28 mm or 45 mm blades, while heavy-duty cutters take 60 mm sizes for thicker materials.

Are rotary blades compatible across different brands?

Most 45mm blades fit standard grips from major brands like Fiskars and Olfa.

However, some manufacturers use proprietary arbors that prevent cross-brand use. Always verify compatibility to maintain safety features and warranty coverage.

How do I dispose of old blades safely?

Like tossing daggers into a steampunk vault, place your rotary cutter blade in a sharps container or blade bank.

Seal it tightly, then follow local metal waste programs for safe disposal or blade recycling.

Conclusion

Most people fear the blade change more than the actual cutting. Yet how to change rotary cutter blades proves simpler than threading a needle.

You’ve now got the process down: lock, remove, clean, replace, test. Sharp blades don’t just cut fabric—they cut frustration from your projects.

Keep spares on hand and swap them without hesitation. Your next quilt deserves edges so clean they look laser-cut, not chewed by dull steel.