This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your seam allowances look perfect from the outside—but flip that garment inside-out and you’ll find raw edges already starting to fray. That’s where a zigzag stitch seam finish becomes your secret weapon.

This simple technique stops fabrics from unraveling wash after wash, and it takes about thirty seconds per seam once you’ve got your machine dialed in. Unlike fancy finishes that need specialized equipment, you can master zigzag finishing with the machine you already own.

Whether you’re sewing cotton dresses, linen tops, or chambray shirts, getting comfortable with this finish means your handmade pieces will hold up just as well as store-bought—maybe even better.

Table Of Contents

Key Takeaways

- A zigzag stitch seam finish prevents fraying by wrapping thread around raw fabric edges, making it the most accessible professional finish for anyone with a standard sewing machine and no serger.

- You’ll need to adjust both stitch width (1.5-4.0mm) and stitch length (1.0-3.0mm) based on fabric weight—lightweight materials need narrower settings while heavy fabrics require wider coverage to prevent puckering or weak edges.

- The technique works best on woven fabrics like cotton, linen, and lightweight wool, especially for garments that get washed repeatedly, but you’ll want French seams for sheer fabrics or flat-felled seams for heavy-duty items like denim.

- Success depends on proper preparation—sew and press your seam first, test settings on scraps, then stitch so the zigzag stitch bites just beyond the fabric edge while maintaining consistent alignment with your presser foot guide.

What is a Zigzag Stitch Seam Finish?

A zigzag stitch seam finish is one of those techniques that separates handmade clothes from homemade ones—it keeps your fabric edges from turning into a frayed mess over time. Think of it as a protective barrier that wraps those raw edges in thread, preventing unraveling and adding durability to every seam you sew.

For a full breakdown of this and other durable finishes, check out this guide on professional seam finishing techniques you can do at home.

A zigzag stitch seam finish is the protective barrier that wraps raw fabric edges in thread, preventing fraying and transforming homemade clothes into durable, professional garments

Let’s look at why this finish matters, when you’ll want to use it, and which fabrics benefit most from this simple technique.

Purpose and Benefits for Garments

The zigzag stitch seam finish brings real staying power to your handmade garments—think of it as armor for those raw edges. This fabric protection method confronts fraying head-on while keeping your sewing techniques beginner-friendly.

Here’s what zigzag finishes do for you:

- Fray prevention – the stitch wraps thread around fabric edges, stopping unraveling after washing and wearing

- Seam reinforcement – distributes stress evenly along edges, preventing weak spots that lead to holes

- Professional edge finishing – transforms homemade pieces into polished garments that rival store-bought quality

This garment-making technique boosts fabric durability without special equipment, making seam finishing accessible for every skill level.

When to Use Zigzag Seam Finishes

You’ll reach for this seam finish when working with woven fabrics prone to fraying, especially cottons, linens, and lightweight woolens. Edge finishing becomes essential for garments washed repeatedly, as seam durability directly impacts longevity. Here’s when the zigzag stitch excels at preventing fraying:

| Scenario | Why Zigzag Works | Fabric Selection |

|---|---|---|

| No serger available | Uses standard sewing machine | Most woven materials |

| Curved seams (armholes) | Flexibility prevents puckering | Medium-weight fabrics |

| Everyday washable clothes | Secures raw edges long-term | Cotton, linen, rayon |

| Quick project turnaround | Faster than French seams | Stable, non-sheer weaves |

| Budget-friendly finishing | No special equipment needed | All fray-prone fabric choices |

This seam finish technique handles most everyday sewing projects without requiring additional machinery. For more tips on achieving a neat and strong finish, check out this resource on.

Types of Fabrics Suited for Zigzag Finish

Most woven fabrics—from quilting cotton to lightweight linen—benefit from zigzag seam finishing. Your fabric choice determines stitch settings and edge finishing success.

If you don’t have a serger, you can still achieve professional-looking edges with simple serger alternatives for seam finishing using your regular sewing machine.

Cotton blends, poplin, and chambray handle standard zigzag widths beautifully, while silk crepe needs narrower settings to prevent fabric fraying. Stretch knits require wider zigzag stitches to maintain seam durability without breaking threads.

Matching your fabric selection to proper stitch configuration ensures lasting results. For a deeper understanding of the basic zigzag stitch technique, review essential machine setup guidance.

Essential Tools and Machine Settings

Getting a clean zigzag seam finish starts with the right setup—trust me, your machine settings matter more than you think.

You don’t need fancy equipment, but using the correct presser foot and dialing in your stitch measurements will make everything easier. Let’s break down exactly what you need to get professional-looking results every time.

Choosing The Right Sewing Machine Foot

Your presser foot makes all the difference—trust me, the wrong one turns zigzag finishing into a wonky mess. Here’s what you need to know about foot compatibility:

- Overedge foot (or overcast foot) keeps raw edges aligned with a built-in guide for perfect positioning

- Universal foot works in a pinch but requires more attention to edge alignment

- Snap-on vs. screw-in shank styles—check your sewing machine’s foot system first

- Clear feet let you see exactly where the needle hits the fabric edge

- Adjustable guides help maintain consistent seam allowances during edge stitching

Test different presser foot types on scraps to find what clicks with your machine.

Recommended Stitch Width and Length

Before you even touch fabric, dial in the right numbers—stitch width between 1.5 mm and 4.0 mm, stitch length from 1.0 mm to 3.0 mm. Lightweight fabrics need narrower settings to prevent puckering, while heavier materials benefit from wider coverage.

Thread tension control and sewing machine calibration directly impact edge finish quality, so test your zigzag stitch on scraps first. Small adjustments change everything.

Step-by-Step Guide to Zigzag Seam Finishing

Now that your machine is set up, it’s time to actually finish those seams. I’ll walk you through each step so you can get clean, professional edges without any guesswork.

Here’s exactly what you need to do from start to finish.

Preparing Seams and Fabric Edges

Before you even touch that zigzag stitch, your seam needs proper prep—think of it as setting the stage for a perfect performance. Start with your basic seam sewn using the pattern’s seam allowance, then press it flat following the directions.

Here’s your fabric preparation checklist for finishing seams:

- Sew your seam first using the correct seam allowances from your pattern

- Press the seam to set the stitches and flatten raw edges

- Trim excess bulk from seam allowances if they’re too wide or uneven

- Test zigzag settings on fabric scraps to dial in perfect stitch alignment

- Align edges carefully before starting—this prevents wonky fray prevention later

Stitching Along The Raw Edge

Now comes the fun part—actually stitching that zigzag seam finish. Guide your fabric’s raw edges under the presser foot, keeping edge alignment consistent with your foot guide. The zigzag stitch should bite just beyond the fabric edge, creating seam reinforcement without excessive fabric fraying.

Watch your thread tension and stitch density as you go—these determine whether your finishing seams look professional or puckered.

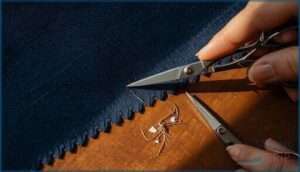

Securing and Trimming Threads

You’ve finished zigzag stitching—great! Now secure those thread ends with a short backstitch inside the seam allowance, ensuring thread management doesn’t unravel your hard work. Trim tails to 2-3 mm using sharp snips, which prevents bulk while maintaining fray prevention.

For edge finishing excellence, tuck loose ends into the seam allowance or use a needle to weave them invisibly into the fabric—these sewing techniques and tips transform amateur work into professional seam finishing.

Tips for Neat and Durable Zigzag Finishes

You’ve got the basics down, but a few simple tweaks can take your zigzag finishes from “homemade” to “store-bought quality.” The difference between a messy edge and a professional one often comes down to tension, alignment, and how you handle your fabric.

Let’s walk through the finishing touches that’ll make your seams look crisp and last through countless washes.

Maintaining Even Stitching and Alignment

Stitch regulation starts with your machine setup—calibrate the needle position so the zigzag center line runs exactly along the edge. Fabric tension matters too; let the machine feed smoothly instead of pulling.

For edge control, use a presser foot with seam guidance and test your stitch width and stitch length on scraps first. Alignment techniques like grain marks keep your zigzag seam finish straight and professional.

Adjusting for Different Fabric Weights

Your fabric weight considerations drive every zigzag seam finish decision—because what works on cotton won’t work on denim. Dial in these fabric-specific adjustments on your sewing machine for clean edges every time:

- Lightweight fabrics: Use a 2.0–3.5 mm stitch width, size 70/10 needle, fine thread, and lower presser foot pressure to prevent puckering.

- Medium-weight fabrics: Set width to 3.0–4.0 mm with an 80/12 needle and standard thread tension settings for balanced seam finishing.

- Heavy fabrics: Max out stitch width to 5.0 mm, switch to a 90/14 needle, and increase foot pressure for even feeding.

- Needle size selection matters: Smaller needles prevent holes in delicate weaves; larger ones penetrate thick layers cleanly.

Pressing and Final Touches

After your zigzag seam finish cools down, press those edges flat using moderate steam and gentle pressure—this is where fabric relaxation meets edge finishing magic.

Allow each pressed seam to rest briefly before handling; rushing this stage creates puckering you can’t undo.

Run your final inspections now: check for uniform stitching, trim any thread tails close, and admire your professional garment shaping.

Comparing Zigzag With Other Seam Finishes

You’ve mastered the zigzag finish—but is it always your best option? Knowing when to choose this method over other techniques can save you time and give you better results.

Let’s compare zigzag with sergers, French seams, and flat-felled seams so you can pick the right finish for every project.

Zigzag Vs. Serger (Overlock) Finish

Your serger and regular machine handle seam finishing differently—and knowing when to pick one over the other saves time and delivers better results. A serger trims as it wraps multiple threads around the edge, creating a narrow, flexible finish perfect for knits and high-wear areas. Zigzag stitching on your standard machine doesn’t trim, so you’ll keep the full seam allowance visible.

Here’s what sets them apart:

- Edge Finishing: Sergers produce a rolled, professional edge that resists fraying longer, while zigzag stitching wraps the raw edge without trimming excess fabric.

- Machine Settings: Zigzag requires only minor stitch width and length adjustments on your regular foot, but overlocking needs multi-thread setup and looper alignment.

- Seam Durability: Overlocking edges withstand repeated washing and stretch better on knits, while zigzag finishes may loosen over time on lightweight or heavily stressed seams.

- Fabric Selection: Sergers excel on delicate silks and stretchy jerseys, but zigzag stitching works well for medium-weight cottons and linens when stitch quality is carefully managed.

When to Choose French or Flat-Felled Seams

Beyond overlocking and zigzag, you’ll sometimes need seam finish types that fully encase raw edges. French seams work beautifully on lightweight silks and sheers—your chiffon blouse deserves that flawless interior. Flat felled seams bring garment durability to denim and workwear, offering edge finishing that withstands heavy laundering.

Here’s when each sewing technique shines:

| Seam Finish | Best Fabric Weight & Use |

|---|---|

| French Seam | Lightweight sheers, delicate silks, heirloom garments |

| Flat Felled Seam | Heavy denim, twill, sturdy cotton workwear |

| Zigzag Finish | Medium-weight cottons, linens, general garments |

| Serger Finish | Knits, jerseys, high-stretch fabrics |

| Pinked Edges | Non-fraying wovens, interior seams, quick projects |

Choose French seam finishing when transparency matters and you want hidden raw edges. Opt for flat felled seams on jeans or shirts where that visible topstitch adds classic style—and the double-stitched construction prevents fraying under stress. Zigzag finishes remain your go-to for everyday sewing techniques and methods when fabric weight falls between sheer and heavyweight.

Pros and Cons of Zigzag for Seam Edges

Each seam finishing technique brings trade-offs you need to weigh. Zigzag offers excellent edge stability on your sewing machine without extra equipment—that’s your biggest win.

Fabric selection stays flexible from lightweight cotton to medium denim. Thread tension matters more here than with sergers, and stitch visibility runs higher. Seam durability holds strong, though seam allowances may show more bulk than overlock finishes.

Frequently Asked Questions (FAQs)

How to finish seams with zig zag stitch?

Most sewn seams fray within the first three washes without proper edge treatment.

To finish seams with zigzag stitch, align raw edges under your presser foot, adjust stitch width and stitch length on your sewing machine, then stitch evenly.

Will zig zag stitch stop fraying?

Yes, a zigzag stitch effectively stops fraying by catching and encasing raw fibers along the fabric edge.

Proper stitch width and tension guarantee edge stability, fabric durability, and seam reinforcement without serging equipment.

What is a zig zag finish?

A zigzag finish uses angled thread patterns along raw fabric edges to lock down fraying fibers, creating edge protection that flexes with the material—essential for seam finishing on woven fabrics and fabric selection requiring gentle hemming methods.

Can I use zigzag finish on knit fabrics?

Like a safety net catching fabric fibers, zigzag works beautifully on knit fabric types—just adjust your zigzag stitch width between 0–5mm and maintain fabric stretch control for edge stability tips and knit seam durability.

How do I prevent fabric puckering while zigzagging?

Adjust your fabric tension first—it’s often the main culprit. Then check your needle selection and stitch density.

Using edge stabilizers underneath lightweight fabrics makes a huge difference, and proper seam allowance prevents pulling.

Should I finish seams before or after sewing?

Most sewers finish after construction—it preserves your seam allowance for accurate fitting and lets you test the garment first.

Pre-finishing works when fabric frays heavily during handling, giving better edge control upfront.

What thread type works best for zigzag finishes?

For most seam finishing, polyester all-purpose thread in 40 to 50 weight gives reliable results. Cotton thread offers a softer hand on natural fibers, while nylon monofilament reduces bulk on lightweight fabrics.

How do I zigzag finish curved seam allowances?

Those tricky curves need a gentle touch—start your zigzag just inside the fabric edge, pivot slowly, and shorten your stitch length on tight bends.

This keeps coverage smooth without puckering or distorting your curved seam allowance.

Conclusion

Think of your zigzag stitch seam finish as the backup parachute on every garment you make—it won’t steal the show, but you’ll be grateful it’s there when stress hits those edges.

Now that you’ve walked through width settings, foot position, and fabric adjustments, you’re ready to finish seams that actually last. Your next project deserves edges that won’t fray apart mid-wear, and you’ve got the skills to deliver exactly that.