This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Most people assume an embroidery machine can only create decorative designs, logos, and monograms—but that assumption leaves a serious gap in your sewing toolkit. Modern embroidery machines don’t just stitch pretty patterns; they function as dual-purpose workhorses capable of handling the same straight seams, zigzag hems, and buttonholes you’d expect from a standard sewing machine.

Switching between embroidery mode and regular sewing mode takes less effort than most sewers think, and the stitch quality matches what dedicated machines produce. You don’t need two separate machines taking up workspace when one can deliver both functional seams and intricate embellishments.

Understanding how to master your embroidery machine’s full range of stitches means you’ll tackle everything from garment construction to custom embroidery without swapping equipment.

Table Of Contents

- Key Takeaways

- Yes, Embroidery Machines Can Sew Regular Stitches

- How Embroidery Machines Handle Regular Sewing Tasks

- Key Differences Between Embroidery and Regular Stitching

- Common Regular Stitches on Embroidery Machines

- Maximizing Your Embroidery Machine for Both Functions

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Modern embroidery machines function as dual-purpose tools that handle both decorative embroidery and regular sewing tasks like straight seams, zigzag hems, and buttonholes without requiring a separate machine.

- Switching between embroidery and regular sewing modes involves simple mechanical adjustments—detaching the embroidery unit, swapping the presser foot and needle plate, and adjusting tension settings—taking just minutes once you understand the process.

- Regular stitching on embroidery machines delivers the same quality as dedicated sewing machines, with adjustable stitch lengths (2.0-4.0 mm), proper tension control, and feed dog operation that matches fabric weight and thickness.

- Maximizing your machine’s value means knowing when to use each mode—regular sewing for durable seams and garment construction, embroidery for decorative work—while maintaining both functions through consistent lubrication, lint removal, and tension adjustments.

Yes, Embroidery Machines Can Sew Regular Stitches

Yes, your embroidery machine can handle regular sewing stitches—and switching between modes is easier than you might think. Most modern embroidery machines function as dual-purpose tools, letting you sew straight seams, zigzag hems, and standard stitches without needing a separate machine.

If you’re new to the basics, this guide on how to use a sewing machine walks through threading, tension settings, and stitch selection step-by-step.

Here’s what you need to know about how embroidery machines manage regular stitching tasks.

Understanding Embroidery Machine Dual Functionality

Machine conversion in dual mode embroidery machines isn’t magic—it’s mechanical precision. You’re working with equipment that switches from embroidery machine embroidery techniques to sewing machine operations through a single mode change. Here’s what happens when your embroidery machine vs sewing machine debate dissolves:

- The drive system redirects power from stitch interpolation to standard sewing machine embroidery patterns

- Needle plate configuration shifts to accommodate fabric handling without hoop constraints

- Thread management systems adjust tension for seam construction instead of decorative work

- Feed dogs engage to advance material evenly under presser foot pressure

- Software bypasses embroidery controls, activating preprogrammed utility stitches

For an in-depth look at how essential features such as precise needle movement control support these machine operations, examine the fundamentals of embroidery machine engineering. You’re controlling two specialized functions in one frame.

Switching Between Embroidery and Regular Sewing Modes

Power off your embroidery machine completely before you attach or detach the embroidery unit—this mode shift tip prevents port damage and software errors. Once you reconnect the unit securely, access the machine calibration menu to confirm stitch compatibility.

Swap your presser foot and needle plate to match the selected mode, then test fabric handling on scrap material to verify tension and feed dog operation before stitching your project.

What Regular Stitches Are Available on Embroidery Machines

Once you’ve switched modes, explore your embroidery machine’s stitch variety. Most models offer:

- Straight stitch adjustable from 0.0 to 4.0 mm for seams and topstitching

- Zigzag stitch ranging 1.0 to 7.0 mm width for stretch fabrics and edge finishing

- Satin stitch creating dense, glossy fills ideal for lettering

- Buttonhole variations including keyhole and centered styles

Machine settings control stitch length, width, and tension to match thread options and fabric compatibility across embroidery modes and regular sewing tasks.

Adjusting your embroidery machine stitch settings ensures each design element comes out clean, whether you’re working with delicate silk or heavy denim.

Understanding the differences in machine embroidery stitches types can help you select the best options for your project.

How Embroidery Machines Handle Regular Sewing Tasks

When you switch your embroidery machine to regular sewing mode, the setup process mirrors what you’d do on a standard sewing machine. The needle plate, presser foot, and feed dog system all work together to handle fabric just like any conventional machine would.

Understanding how these components adjust for regular stitching helps you move between embroidery and sewing tasks with confidence.

Needle Plate and Presser Foot Configuration

When you switch your embroidery machine to regular sewing, plate alignment becomes critical—the centered needle hole must line up precisely with your needle path to prevent strikes.

Your presser foot adjustment controls fabric guidance during stitches, while proper needle calibration ensures the foot clears the needle by about one millimeter when raised.

Stitch optimization depends on selecting the right embroidery foot or darning foot for your project.

Stitch Length and Tension Settings for Regular Sewing

Set your stitch length between 2.0 and 3.0 mm for medium fabrics on your embroidery machine during regular sewing, adjusting to 3.0–4.0 mm for heavier fabric types like denim.

Tension balance matters—start at mid-range, around 4 on your tension settings dial. If top loops appear, reduce upper tension; if bobbin thread shows through, increase it.

Always test stitch control on scrap fabric before starting your project.

Sewing Speed and Feed Dog Operation

Control sewing speed using your dial or preset to match fabric weight—slower settings give you precision with delicate materials, while higher speeds suit medium cottons.

Feed dog height directly affects fabric tension and grip; adjust it based on thickness to prevent thread breakage issues.

Regular machine calibration after maintenance keeps stitch quality consistent across regular sewing and embroidery modes, ensuring smooth feed dog operation every time.

Key Differences Between Embroidery and Regular Stitching

Embroidery stitching and regular sewing operate on different principles, even when you’re using the same machine. The setup, thread choices, and needle requirements shift depending on whether you’re creating decorative patterns or constructing functional seams.

Understanding these distinctions helps you switch between modes confidently and get the results you need from each task.

Decorative Vs. Functional Stitch Purposes

Your embroidery machine manages two distinct jobs: decorative stitches bring visual flair through satin stitch, zig zag stitch, and embellishment techniques that improve design considerations, while functional stitches prioritize seam strength and durability.

Thread types differ too—rayon threads deliver sheen for decorative work, while cotton or nylon threads guarantee secure seams.

Fabric choice and stitch variety depend on whether you’re embellishing or constructing, each requiring matched approaches.

Machine Setup Requirements for Each Mode

You’ll handle mode shift tips differently depending on whether you’re decorating or constructing seams. For dual mode optimization on your sewing machine, follow these feed control settings and tension adjustment steps:

- Lower feed dogs and disable automatic patterns for embroidery machine mode

- Raise feed dogs and engage standard stitch parameter controls for regular sewing

- Verify needle plate clearance after each mode switch

- Test tension settings on scrap fabric before production runs

Thread and Needle Selection Considerations

Your thread weight and needle sizes work together like gears in a machine—if they don’t match, you’ll get skipped stitches or fabric damage.

For embroidery thread on delicate fabrics, use size 60/8 to 70/10 needles, while heavier material compatibility demands 90/14 or 100/16.

Match your needle selection to thread type, adjust tension settings accordingly, and always test on scrap fabric first.

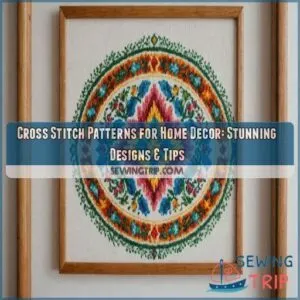

Common Regular Stitches on Embroidery Machines

Your embroidery machine doesn’t just handle fancy decorative patterns—it can execute the same foundational stitches you’d use on a standard sewing machine.

These regular stitches form the backbone of garment construction, repairs, and everyday sewing projects. Let’s look at the specific stitch types your machine can produce when you switch it into regular sewing mode.

Straight Stitch and Running Stitch

You’ll reach for straight stitch when seam strength and durability matter most on your embroidery machine. This workhorse of regular sewing techniques delivers clean, reliable joins and topstitching. Running stitch excels at outline accuracy and basting uses, giving you fine control over fabric handling. Consider these essentials:

- Select a 2.0 to 3.0 millimeter stitch length for standard seams

- Use 80/12 or 90/14 universal needles matched to fabric density

- Balance tension so neither thread pulls through the material

- Adjust presser foot pressure to prevent puckering or skipped stitches

Zigzag and Satin Stitch

When you need edge finishing or applique techniques, zigzag and satin stitches become your go-to tools on any embroidery machine. Stitch density and width settings let you control coverage, while fabric choice determines stabilizer needs.

| Parameter | Zigzag Stitch | Satin Stitch |

|---|---|---|

| Width Setting | 2.0–5.0 mm | 2.0–4.0 mm |

| Length Setting | 1.0–3.0 mm | 0.3–0.6 mm |

| Thread Tension | Medium (4–5) | Medium-high (5–6) |

| Best Applications | Edge finishing, stretch seams | Appliqué borders, lettering |

Match thread tension to your sewing machine’s fabric type for clean, professional decorative stitches without puckering.

Free-Motion Stitching Capabilities

Freemotion embroidery transforms your embroidery machine into a freehand drawing tool once you lower the feed dogs and attach a free motion foot. You control stitch length through hand speed and fabric movement, not the machine’s automated settings.

Here are three Free Motion Tips for better Stitch Control:

- Machine Calibration: Slow motor speed while maintaining consistent rotation creates smoother lines

- Fabric Choice: Use stabilizers with cotton or linen to prevent puckering during complex patterns

- Thread Management: Balance tension between bobbin and needle thread to eliminate looping

Practice simple loops first, keeping wrists relaxed for even stitch flow across your sewing machine work.

Maximizing Your Embroidery Machine for Both Functions

Owning an embroidery machine that can sew regular stitches gives you a two-in-one tool, but you’ll get the most out of it by knowing when to switch modes and how to keep everything running smoothly.

The key isn’t just understanding what your machine can do—it’s learning when to use each function and how to combine them without wearing down your equipment.

The real value of a dual-purpose machine isn’t its features—it’s knowing when to switch modes and how to preserve both functions

Here’s how to make the most of your machine’s dual capabilities.

When to Use Regular Stitching Mode

You’ll want regular sewing mode when your project demands durable seams rather than decorative flair. Repairs, alterations, and functional hems on woven fabrics benefit from this shift, preserving seam strength without embroidery stabilizers. Fabric selection and tension control matter here—your embroidery machine delivers consistent stitch quality at standard lengths of 2.5 to 3.0 mm, ideal for garment construction and quick fixes where mode shift takes seconds.

| Project Type | Best Stitch Mode |

|---|---|

| Garment repairs | Regular sewing |

| Simple hems | Regular sewing |

| Basting seams | Regular sewing |

| Trial construction | Regular sewing |

| Functional topstitching | Regular sewing |

Combining Regular and Decorative Stitches

You build visual depth by layering base seams first, then adding decorative stitches on top. Stitch integration starts with straight or zigzag stitches to anchor fabric layers, followed by satin stitch borders or motif embellishments on your sewing machine.

Thread management remains critical—switch to polyester or rayon for decorative work while keeping bobbin tension balanced.

Design optimization means planning where each stitch type sits, preventing fabric puckering and ensuring embellishment techniques shine without distorting your seams.

Machine Maintenance for Dual-Purpose Use

With alternating loads from regular sewing and machine embroidery, your sewing machine demands consistent care. Lubrication schedules every 8 to 12 hours of heavy use keep metal joints smooth, while daily lint removal from bobbin areas prevents stitch defects.

Maintenance logs track oil type, needle care intervals, and thread management patterns, ensuring stabilizer selection and tension adjustments stay ideal across dual-purpose sessions.

Frequently Asked Questions (FAQs)

Are buttonholes possible on embroidery machines in sewing mode?

Absolutely—buttonhole techniques on embroidery machines in sewing mode basics are surprisingly sturdy.

Toggle your embroidery machine into regular sewing mode, attach the buttonhole foot, select your stitch, and you’re ready to create precision holes every time.

How do embroidery machines handle thick fabrics when sewing?

Your embroidery machine adjusts presser foot pressure, slows stitch speed, and switches to longer stitch lengths when sensing thick fabrics.

Use heavy duty settings, fabric stabilizers, and size 90/14 needles for bulk stitching without puckering.

Conclusion

You’ve probably been working twice as hard as necessary. Your embroidery machine already holds the answer to whether embroidery machines can sew regular stitches—swap the presser foot, adjust your tension settings, and you’re running straight seams within minutes.

Stop treating it like a specialty tool that sits idle between decorative projects. Master both modes, maintain your needle plates properly, and you’ll eliminate the need for duplicate equipment while expanding what you can accomplish in a single workspace.