This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

While a regular foot only presses down, leaving the feed dogs underneath to do all the work, a walking foot adds a set of "teeth" on top that move in sync with the bottom feed dogs.

This tag-team approach gives you even feeding from both sides—like having an extra pair of hands holding your fabric.

You’ll notice the difference when sewing multiple layers, quilting, or working with slippery materials.

No more stretched seams or mismatched plaids!

The right foot choice can transform your most frustrating sewing challenges into smooth sailing.

Table Of Contents

Key Takeaways

- You’ll get even feeding from both top and bottom with a walking foot, while a regular foot only presses down from above, letting bottom feed dogs do all the work.

- Your walking foot prevents stretched seams, mismatched patterns, and fabric bunching by moving all layers at the same pace—like having an extra pair of hands.

- You’ll find a walking foot essential for quilting, multiple layers, slippery fabrics, and heavy materials where regular feet struggle to maintain alignment.

- You can choose between open toe walking feet for better visibility during precise work or closed toe models for more stability during general sewing.

Walking Foot Basics

You’ll instantly notice a walking foot is larger and attaches from the back of your sewing machine, with feed dogs on both top and bottom that work together.

Unlike a regular presser foot that just slides along the top fabric, your walking foot moves both layers at the same pace, preventing that frustrating bunching and slipping that can make your projects look homemade rather than handmade.

Feed Dog Function

Ever wonder what those metal teeth hiding under your fabric are actually doing? Feed dogs are the unsung heroes of your sewing machine, playing a vital role in fabric movement.

Here’s how they function:

- Feed dog teeth grip and pull fabric through as you sew

- They work in rhythm with your needle’s up-and-down motion

- Regular foot relies solely on bottom feed dogs for fabric control

- Walking foot (even feed foot) adds top feed dogs for dual feed

Understanding the role of feed dogs in balanced fabric feed is essential for superior sewing performance, and recognizing their importance can help you achieve better results with your sewing machine, making them a crucial part of the sewing process.

Even Stitches Requirement

In order to achieve beautiful, professional-looking projects, you need even stitches throughout your work.

Stitch regulation is essential whether you’re quilting or constructing garments.

| Factor | With Regular Foot | With Walking Foot |

|---|---|---|

| Fabric Tension | Uneven | Consistent |

| Thread Choice | More limitations | Fewer issues |

| Sewing Speed | Must go slower | Can sew faster |

| Needle Selection | More critical | More forgiving |

| Uniform Stitches | Challenging | Reliable |

Your even feed foot creates balanced tension across all layers, producing those perfectly uniform stitches you’re aiming for, which is crucial for achieving professional-looking results.

Fabric Movement

Achieving those even stitches we just talked about depends entirely on how your fabric moves through the machine.

Unlike a regular foot that only presses down from above, a walking foot (sometimes called an even feed foot) controls fabric from both sides.

- Your fabric layers move together in perfect harmony

- Layer alignment stays precise, preventing shifting

- Fabric tension remains consistent throughout

- Feed control stops bunching and stretching

- Fabric flow becomes smooth and predictable

This results in a sewing experience where your fabric moves smoothly, and with the use of a walking foot, you can achieve perfect harmony in your fabric layers.

Regular Foot Limitations

You’ll quickly notice your regular sewing machine foot can be a bit of a troublemaker when working with certain fabrics.

It presses down and slides along your top fabric layer, often causing misalignment issues that’ll have you reaching for your seam ripper more times than you’d care to admit.

Uneven Feeding

Now that you understand how feed dogs work, let’s look at why your regular foot sometimes feels like it’s working against you.

When using a standard presser foot, you’ll notice layer shifting as fabric moves through your machine.

The bottom layer (controlled by feed dogs) moves smoothly, but the top layer often experiences fabric drag.

This uneven feeding leads to fabric bunching and stitch distortion—especially with slippery or thick materials.

To minimize these issues, understanding thread tension basics is essential for achieving smooth fabric feed.

Misaligned Stitches

When uneven feeding occurs, your stitches won’t line up properly.

You’ll notice those annoying misaligned stitches where your pattern suddenly looks like it had too much coffee!

With a regular foot, fabric shifting becomes a real headache, especially when seam matching is critical.

Your presser foot pressure might be perfect, but layer alignment suffers when the top fabric moves differently than the bottom.

Stitch alignment problems are a telltale sign you might need a walking foot.

Fabric Slippage

The nightmare of fabric slippage haunts many sewers using a regular foot.

The nightmare of fabric slippage haunts many sewers using a regular foot.

When your fabric slides around like a fish on ice, your project can quickly transform from masterpiece to mess.

When your fabric slides around like a fish on ice, your project can quickly transform from masterpiece to mess.

This happens because standard feed dogs only grip the bottom layer, leaving the top free to shift.

You’ll notice this especially with silky or slippery fabrics that refuse to stay put.

Walking Foot Advantages

You’ll revolutionize your sewing experience with a walking foot’s ability to move all fabric layers in perfect unison.

Unlike regular feet that can cause puckering and misalignment, walking feet guarantee precise seam matching and prevent fabric stretching.

Especially when you’re wrestling with those tricky quilting projects or slippery fabrics, walking feet are invaluable.

Precise Seam Matching

Frequently, seamlines refuse to line up with a regular presser foot—those pesky plaids misalign and patterns shift.

Your walking foot comes to the rescue, maintaining perfect seam alignment by controlling fabric tension on both sides.

You’ll nail pattern matching across multiple layers, as the even feed foot guarantees uniform stitch length and quilting accuracy.

It’s like having an extra set of hands managing fabric movement, and utilizing a walking foot for sewing thick layers can substantially improve overall sewing results.

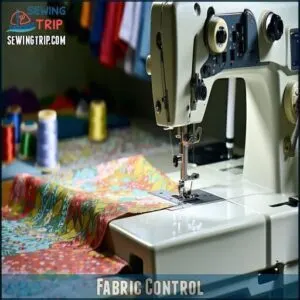

Fabric Control

Beyond perfect seam alignment comes the superpower of total fabric control with your walking foot.

You’ll notice the difference immediately when fabrics that typically slide around stay put under your needle.

- Better fabric tension management prevents puckering and wavy seams

- Enhanced stitch regulation keeps your stitch length consistent

- Improved seam integrity as fabric grain stays aligned properly

Your regular presser foot can’t match this level of control, especially with tricky materials that want to wander off on their own, providing better fabric management and ensuring seam integrity.

Reduced Stretching

While controlling fabric movement is important, your walking foot truly shines when working with stretchy fabrics.

Ever tried sewing a knit only to find the fabric stretched out of shape? Your regular foot can push and drag stretchy materials, distorting them as you sew.

A walking foot prevents this by maintaining even feeding from both top and bottom, keeping your knit fabrics in their original shape as they move through.

Improved Stitch Quality

You’ll notice a dramatic improvement in stitch quality when using a walking foot instead of a regular foot.With even fabric feeding from top to bottom, your stitches look more professional and consistent.

Here are5 stitch consistency benefits:1. Perfectly uniform stitch length2. No more fabric bunching at seams3. Smoother fabric flow for decorative stitches4. Enhanced pattern alignment across multiple pieces5. Balanced layer feeding prevents puckeringA walking foot attachment is especially beneficial for quilting, as it prevents fabric layers from shifting and guarantees precise alignment during stitching.

Walking Foot Applications

You’ll find your walking foot invaluable for tackling quilting projects, multiple fabric layers, and those frustrating slippery or heavy materials that make you want to throw your machine out the window.

It’s your secret weapon when regular feet just can’t handle the job, ensuring your layers move together smoothly without the bunching, puckering, or misalignment that can ruin your carefully planned projects.

Quilting Projects

Quilting becomes a dream rather than a nightmare when you’ve got the right walking foot on your machine.

Your quilting projects will thank you! Unlike a regular presser foot that can create puckered seams, a walking foot keeps all three quilt layers perfectly aligned.

You’ll notice crisp, even stitches without the fabric bunching up – it’s like having an extra pair of hands holding everything in place.

Using the correct sewing machine feet is essential for achieving professional-looking results with the help of the right walking foot.

Multiple Layers

Every sewing project with multiple layers can quickly turn into a bunching nightmare with a regular foot.

When you’re working with interfacing options or thick fabrics, your walking foot (sometimes called an evenfeed foot or dual feed) becomes your best friend.

It maintains perfect layer alignment by moving all fabric thicknesses at the same rate, ensuring consistent seam allowances and successful bonding techniques.

You’ll wonder how you ever managed without it!

Slippery Fabrics

Why do slippery fabrics like silk and satin drive you crazy with their constant shifting?

When you’re working with these slick materials, your regular foot just can’t keep up.

The walking foot (sometimes called an evenfeed or dual feed foot) grips that slippery top layer, preventing bunching and maintaining perfect nap control.

Say goodbye to fabric shifting and hello to beautiful, precise satin stitching without the frustration!

Heavy Fabrics

Heavy fabrics present their own challenges! When you’re wrestling with denim, canvas, or leather sewing, your regular foot might struggle to keep up.

Nothing tames stubborn denim and leather like a walking foot – your heavyweight fabric whisperer!

A walking foot grips and guides these weighty materials evenly, preventing the dreaded "shift and bunch" effect. Unlike a regular foot, it maintains consistent seam allowances even through thick layers.

Your needle selection and thread choice matter less when your dual feed system handles the heavy lifting! The walking foot is particularly useful for sewing thick layers to prevent fabric pushing and shifting, making it ideal for working with heavy materials and achieving professional-looking results with consistent seam allowances.

Choosing Right Foot

You’ll need to match your foot to both your machine and your project for the best results.

Whether you’re wrestling with slippery silk or tackling a quilt sandwich, choosing between an open toe walking foot or regular foot can make the difference between perfectly aligned seams and a frustrating sewing disaster.

Open Toe Walking Foot

Now that you’ve seen how walking feet can transform your sewing projects, let’s check out the open toe walking foot option—it’s a game-changer for visibility!

An open toe walking foot offers:

- Clear needle visibility when attaching the foot

- Better stitch accuracy when following marked lines

- Improved fabric guidance without metal obstructing your view

You’ll love how it helps you see exactly where your needle lands, especially for detail work. The open toe design is ideal for Open Toe Foot care and maintenance to guarantee peak performance.

Closed Toe Walking Foot

While open toe walking feet give you clear visibility, the closed toe walking foot has metal strip(s) between the toes that can obstruct your view of the needle.

This foot comparison shows closed toe designs often present toe alignment challenges when matching patterns or stitching in the ditch.

You’ll notice reduced stitch visibility and potential needle clearance issues, especially when trying to follow chalk lines for precise work.

Understanding proper closed toe maintenance is vital for peak performance.

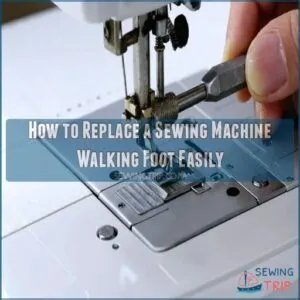

Machine Compatibility

Not every walking foot will fit your sewing machine.

Before purchasing, check your machine model and compatibility with different foot types. Many manufacturers offer machine-specific attachments to prevent compatibility issues.

Your sewing machine manual should list approved presser foot types and proper attachment methods. Some newer models even feature built-in dual feed systems that eliminate the need for separate walking foot attachments.

Understanding sewing foot compatibility is essential for superior machine performance and to ensure you choose the right sewing foot.

Fabric Type Considerations

Now that your machine compatibility is sorted, let’s talk fabrics. Your walking foot isn’t just a cool accessory—it’s your best friend for certain materials that make regular feet throw tantrums.

When deciding between walking and regular feet, consider these fabric characteristics:

- Slippery fabrics like silk that love to play hide-and-seek under your needle

- Stretchy fabrics that need gentle handling to prevent unwanted stretch

- Heavy fabrics with extra thickness that regular feet struggle to climb over

- Materials with texture or nap that need consistent feeding to maintain appearance

Frequently Asked Questions (FAQs)

What is a walking foot?

A walking foot is a specialized sewing machine attachment that adds upper feed dogs to move your fabric’s top layer at the same rate as the bottom, preventing slippage and ensuring even stitches.

It prevents slippage and ensures that the fabric layers move in sync, which is crucial for achieving professional-looking results in sewing projects.

Why do feet ache after standing or walking?

Like a balloon under too much pressure, your feet ache after standing or walking because of increased stress on bones, muscles, and joints.

Proper footwear and regular breaks can help reduce discomfort.

Is there a right or wrong type for walking feet?

Yes, there are two main types: open toe and closed toe walking feet.

Open toe offers better visibility and precision for detailed work, while closed toe provides more stability for general sewing.

What is the difference between an open toe and a walking foot?

The astronomically important difference is that an open toe walking foot lacks metal between the toes, giving you clear needle visibility.

This helps with precise stitching, while a regular walking foot has metal that partially blocks your view, which is a significant consideration for clear needle visibility.

Which walking foot should I Choose?

An open toe walking foot is your best bet.

You’ll get better visibility for precision work, easier alignment with markings, and it’s ideal for quilting projects.

One foot does it all!

How does a walking foot work?

To put it simply, your walking foot works by adding feed dogs on top of your fabric.

These move in sync with the bottom feed dogs, helping all fabric layers move evenly through your machine together.

Can I use a walking foot for regular sewing?

You can absolutely use a walking foot for everyday sewing.

It’ll give you better results on tricky fabrics, though it might slow you down a bit on simple projects where a regular foot works fine.

Why would you use a walking foot?

Nearly 70% of quilters report frustration with fabric shifting.

You’d use a walking foot for even feeding of multiple layers, preventing puckering and misalignment when sewing slippery fabrics, or matching patterns precisely, which helps in preventing puckering.

How to identify a walking foot?

You’ll spot a walking foot by its larger size and additional feed dogs on top.

It attaches from the back of your machine and has a distinctive arm that connects to the needle bar.

Can you zigzag with a walking foot?

Yes, you can zigzag with a walking foot.

Your machine’s powerful walking foot handles zigzag stitches beautifully while keeping your fabric layers perfectly aligned.

Just adjust your stitch settings and sew with confidence.

Conclusion

The jaw-dropping difference between walking foot and regular foot can revolutionize your sewing game overnight.

You’ll wonder how you ever managed with just a regular foot as your projects transform from frustrating to flawless.

Whether you’re tackling quilts, slippery fabrics, or multiple layers, your walking foot will become your new best friend.

Don’t let uneven stitches or fabric puckering hold you back—make the switch today and watch your sewing skills soar with the help of your walking foot.

- https://sewcanshe.com/walking-foot-sewing-machine/

- https://madamsew.com/blogs/sewing-blog/why-and-when-to-use-a-walking-foot-on-your-sewing-machine

- https://www.goldstartool.com/blog/walking-foot-vs-regular-foot-whats-the-difference.htm

- https://www.craftsy.com/post/how-to-use-a-walking-foot-for-garment-sewing

- https://mellysews.com/how-to-use-a-walking-foot-for-sewing/