This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

The answer is yes, it can.

Viscose is prone to burning due to its chemical processing, and it can fray when handled roughly.

Sunlight and harsh detergents can also cause it to fade.

To minimize these issues, you’ll want to handle viscose with care and avoid open flames.

Understanding the properties of viscose is key to working with it effectively, and there’s more to learn about how to make the most of this popular fabric.

Table Of Contents

Key Takeaways

- You’ll want to handle viscose with care, as it can burn quickly, fray easily, and fade over time, so it’s crucial to understand its properties and limitations.

- To minimize fraying, you can use techniques like applying clear nail polish to raw edges, using pinking shears, or reinforcing seams, and for fading, you can wash viscose in cold water and avoid direct sunlight.

- Viscose requires gentle handling, including washing in cold water, avoiding harsh detergents, and ironing at low temperatures, to prevent damage and maintain its quality.

- You should also be aware of the potential hazards associated with viscose, such as flammability, skin irritation, and environmental concerns, and consider eco-friendly alternatives like lyocell or Tencel for a more sustainable option.

Viscose Fabric Overview

You’ll often find viscose in your closet as this semi-synthetic fabric made from wood pulp offers the luxurious drape of silk at a fraction of the cost.

Viscose fabric brings luxurious silk feel at an affordable price

It’s known for its softness and excellent dye absorption, though it requires special care due to its tendency to burn quickly, fray when cut, and fade with prolonged sun exposure.

History of Viscose

The journey of viscose fabric began with early inventions that revolutionized textile production.

You’ll discover its fascinating origins through these key developments:

- Hilaire de Chardonnet created the first "artificial silk" (Chardonnet Silk) in the 18th century, though it was dangerously flammable

- Charles Cross and Edward Bevan invented true viscose in 1892

- The Topham Box enabled mass production at 3000 RPM in 1899

- Global licensing drove production growth to 12,000 pounds daily by the early 1900s

The key milestones in the development of viscose fabric are marked by significant improvements in production technology and mass production capabilities.

Production Process

How does that silky viscose fabric in your closet come to life? The journey from tree to textile involves several chemical-intensive steps.

The journey starts with the extraction of raw materials and goes through various stages, including processing and transformation, which can be summarized as follows:

| Production Stage | Raw Materials | Process | Environmental Impact |

|---|---|---|---|

| Extraction | Wood chips | Pulping | Deforestation |

| Processing | Wood pulp | Chemical treatment | Water pollution |

| Transformation | Cellulose | Fiber extrusion | Chemical waste |

| Finishing | Viscose fibers | Spinning/weaving | Energy consumption |

Manufacturers dissolve cellulose from wood pulp using caustic chemicals, creating a solution that’s forced through tiny holes to form fibers. Viscose, often called artificial silk fabric, offers an inexpensive alternative. Process innovations aim to reduce the environmental footprint.

Properties and Characteristics

When examining viscose fabric properties, you’ll notice its exceptional drape quality and texture softness that rivals silk.

Viscose fabric boasts a silky smooth texture and exceptional drape quality, rivaling the luxury of real silk.

It boasts high viscose absorbency, making it ideal for warm weather, while its natural luster level adds elegance to any garment.

Despite these benefits, viscose has limited fiber strength when wet and requires careful handling to prevent fraying issues and color fading over time.

Does Viscose Burn

You’ll find that viscose fabric burns quickly with a yellow flame and leaves behind a fine gray ash that smells like burnt paper.

This high flammability, even greater than cotton, means you should keep your viscose garments away from open flames and heat sources to prevent potential fire hazards.

Flammability Risks

While viscose offers a silky feel and breathable comfort, it comes with significant flammability risks you should know about.

Viscose burns readily and ignites faster when emollients are present, and loose-fitting viscose garments pose a higher clothing fire hazard than tighter styles.

The U.S. Flammable Fabrics Act specifically regulates viscose due to its burn severity, and for safety, keep viscose away from ignition sources and consider chemical treatments that reduce flammability during safe handling.

Burn Test Procedure

To conduct a viscose burning test, you’ll need a small sample size of 1×1 inch.

Hold the fabric with tweezers over a metal container and apply flame.

Watch for these flame characteristics: yellow flame, quick ignition, and paper-like smell.

The ash residue will be light gray and powdery.

Take safety measures when testing blended fabrics, as chemical treatments can alter the flammability results.

Safety Precautions

Take five simple safety precautions when conducting a viscose burning test. Always work in a well-ventilated area to avoid chemical exposure.

Keep water nearby for fire prevention. Use metal tweezers, never your fingers, to handle samples.

Place burning fabric in a metal container to prevent clothing hazards. If you have skin sensitivity, wear gloves as fabric residue may cause irritation.

Workplace safety should always come first and be the top priority, ensuring that safety precautions are in place to protect against potential hazards.

Viscose Fraying Issues

You’ll notice your viscose garments tend to fray at the edges due to the fabric’s weak fibers and loose thread structure.

When you cut viscose, especially looser weaves, the material often unravels at the seams unless you take preventive measures like using fabric glue or pinking shears.

Causes of Fraying

Beyond the burning risks we’ve discussed, fraying is another common issue with viscose.

Your fabric’s edges unravel because of viscose’s inherent fiber weakness.

The looser weave density makes threads separate easily when cut or rubbed.

Friction against rough surfaces, improper cutting techniques, and abrasion damage all contribute to viscose fraying issues.

Even regular washing can cause edge finishing to deteriorate, leading to those frustrating loose threads you often find on your favorite viscose garments, which can be a result of the fabric’s inherent fiber weakness.

Prevention Methods

Now that you understand why your viscose fabrics fray, let’s arm you with practical prevention methods.

You’ll save both your garments and sanity with these five fray prevention techniques:

- Apply clear nail polish to raw edges

- Use pinking shears for zigzag cuts that resist unraveling

- Reinforce seams with French seams or flat-felled construction

- Add fusible interfacing to stabilize delicate areas

- Finish edges with bias tape for both functionality and style

To further protect your fabrics, consider products for fray prevention to enhance your fabric care and prevent damage.

Repairing Frayed Edges

Once fraying appears, you’re not out of luck. Apply clear nail polish to seal raw edges or use fabric glue for immediate reinforcement.

You can address this with nail polish fray.

For more permanent solutions, try invisible mending techniques with a fine needle and matching thread.

Edge reinforcement with bias tape works wonders for severe fraying.

As a last resort, patch application can cover damaged areas while adding decorative elements to your viscose garments.

Viscose Fading Problems

You’ll notice your favorite viscose garments may lose their vibrant colors over time when exposed to sunlight and harsh detergents.

The combination of UV rays and chemical washing agents breaks down viscose dyes, causing gradual fading that’s particularly noticeable in darker-colored items, which can be described as a gradual process.

UV Resistance

Most viscose fabrics offer surprisingly poor UV resistance, with standard varieties scoring UPF values as low as 2.5.

When exposed to sunlight, UV degradation occurs faster in viscose than in polyester or wool.

However, specially treated viscose can achieve UPF ratings between 33-39.5.

Dark-colored viscose typically provides better protection against UV rays than lighter shades, with black and navy offering the strongest defense against fading, due to their natural UV resistance.

Dye Loss and Fading

While UV rays can damage viscose fibers over time, poor dye retention remains the primary culprit behind fading.

You’ll notice color bleeding during washing, especially with bright hues.

Harsh detergents strip dyes from viscose’s cellulose structure, accelerating fading, and machine washing on hot cycles dramatically reduces colorfastness.

Even spills (particularly alcohol or perfume) can cause permanent discoloration, as viscose’s high absorbency works against it when containing dyes.

Color Preservation Tips

Now that you understand what causes your viscose garments to lose their brilliance, let’s save those vibrant colors.

To improve dye retention, wash your viscose in cold water with mild detergents free of bleach.

Skip fabric softeners and dry your clothes inside-out, away from direct sunlight as UV rays accelerate fading.

For storage solutions, hang dark viscose items in cool, dark closets.

When dealing with stains, treat them immediately without rubbing to prevent color loss.

Viscose Static Electricity

You’ll notice your viscose garments might cling to your body or deliver tiny shocks due to the wood pulp composition that encourages static electricity buildup.

You can reduce this annoying static cling by wearing a slip under your clothing or applying a small amount of talcum powder to minimize friction between the fabric and your skin.

Causes of Static

Several factors contribute to static electricity in your viscose garments.

The wood pulp fiber composition naturally attracts electrical charges, while low humidity levels intensify this effect.

Fabric friction during movement creates the perfect storm for static buildup.

Chemical treatments used in manufacturing can either worsen or reduce this tendency.

When you walk across carpet in viscose clothing, you’re basically becoming a human battery, ready to discharge at the next metal doorknob, which can lead to an unpleasant shock from electrical charges.

Reducing Static Cling

Now that you know what causes static in viscose, let’s tackle the problem.

You can reduce static cling by keeping humidity levels higher in your home. Try layering viscose garments over natural fibers instead of synthetics.

When washing, skip harsh detergents and add a quarter cup of white vinegar to your rinse cycle – it works better than fabric softeners without damaging the delicate fibers.

A light misting of water can also provide quick static relief. You can also use a metal clothes hanger to neutralize static.

Anti-Static Treatments

Now that you’ve learned how to reduce static cling, let’s explore specialized anti-static treatments for your viscose garments.

Professional products effectively prevent static electricity buildup in your favorite fabrics:

- ATC-ANTISTAT provides excellent lubricity without yellowing viscose

- Graphene-infused poly/viscose blends disperse electric charge

- Fabric softeners create a thin protective layer that minimizes friction

- Static sprays offer immediate relief when you’re already dressed

To address this, consider using viscose static spray for quick solutions. Natural remedies like vinegar rinses during washing also prevent the annoying cling without harsh chemicals, providing a gentle and effective way to manage static in your garments.

Viscose Care and Maintenance

You’ll need to handle your viscose garments with specific care to maintain their silky texture and prevent damage.

Proper washing, ironing, and storage techniques will extend the life of your viscose items and keep them looking their best, which is crucial for viscose garments.

Washing and Drying

Caring for your viscose requires gentle handling during washing. Always use cold water and mild detergents to prevent color fading.

Hand washing is ideal, but if machine washing is necessary, use a delicate cycle in a mesh bag. Never wring viscose—instead, lay flat to dry away from direct sunlight to control shrinkage.

For stain removal, treat spots immediately with diluted mild soap rather than harsh chemicals, and remember to always handle your viscose with cold water.

Ironing and Steaming

Now that you know how to wash viscose, proper ironing and steaming techniques are just as important to prevent fabric damage.

When ironing viscose, remember these key points:

- Use low temperature settings (rayon/viscose setting) to avoid scorching

- Iron while slightly damp for best wrinkle removal

- Turn garments inside-out to prevent viscose color fading from iron heat

- Consider gentle steaming instead of direct ironing for delicate pieces

Storage and Handling

Three key principles guarantee proper viscose storage: hang on padded hangers to prevent stretching, avoid direct sunlight to minimize UV ray fading, and maintain moderate humidity control.

When folding viscose, use acid-free tissue between layers for wrinkle prevention.

Store in breathable cotton bags rather than plastic to protect from moths and dust while allowing fabric to breathe.

Don’t crowd viscose garments in your closet to ensure they remain in good condition and to prevent damage, making proper viscose storage a priority.

Viscose Sewing Tips

You’ll need specific techniques to successfully sew with viscose due to its tendency to fray and slip under the presser foot.

Using a fine needle, lightweight thread, and proper stabilizers will help you manage this delicate fabric and create beautiful, professional-looking garments.

Choosing The Right Needle

Needle selection makes all the difference when sewing with viscose fabric. Choose the right needle to prevent damage and guarantee professional results.

Viscose’s delicate nature requires careful consideration.

- Use fine needles (60/8 or 70/10) for lightweight viscose

- Select universal point styles for standard weaves

- Sharp needles work best to prevent fraying edges

- Match needle size to fabric weight (smaller for sheerer material)

- Replace needles frequently as dull points can snag viscose, which is why using the right needle is critical.

Thread Selection

Now that you’ve got the right needle for your viscose fabric, selecting the proper thread is your next step.

For viscose, which can fray easily, the right thread guarantees seam strength and durability.

| Thread Type | Fabric Weight | Recommended Use |

|---|---|---|

| Polyester | Light to Medium | Everyday garments |

| Cotton | Light | Delicate pieces |

| Silk | Medium | Special occasion wear |

Choose thread that’s slightly lighter than your fabric to prevent puckering. Thread color should match or complement your viscose to minimize appearance of any potential fading.

Interfacing and Stabilizers

After finding the right thread, you’ll need proper support for viscose’s delicate nature. Lightweight fusible interfacing works best for viscose weight concerns, preventing the dreaded fray while maintaining drape.

Apply stabilizers to areas prone to stretching, like necklines and buttonholes. Remember, heat management is key—excessive iron heat can "burn" fusible options.

Matching interfacing weight is essential for fabric balance. Water-soluble stabilizers offer temporary support that washes away, solving many viscose sewing challenges, and ensuring a good fabric balance with the right viscose weight.

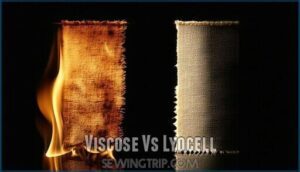

Viscose Vs Lyocell

You’ll notice significant differences between viscose and lyocell when choosing fabrics for your wardrobe.

While both are cellulose-based fibers, lyocell uses a more environmentally friendly production process and offers superior strength and durability compared to traditional viscose, with superior strength being a key advantage.

Production Differences

While sewing with viscose requires careful handling, understanding the differences in how viscose and lyocell are made is equally important.

When comparing these fabrics, their production processes differ substantially in environmental impact and resource use.

Both viscose and rayon, often used interchangeably, share similar properties.

| Process Stage | Viscose | Lyocell |

|---|---|---|

| Pulp sourcing | Often from non-certified forests | Sustainably managed forests |

| Chemical usage | Harsh chemicals (carbon disulphide) | Non-toxic solvents |

| Waste management | Often discharged into waterways | Closed-loop system (95% recycled) |

| Energy consumption | Higher energy requirements | More energy efficient |

| Production scale | Large industrial facilities | Smaller batches possible |

They are even considered the same fabric by the FTC, highlighting the need for sustainable management and non-toxic solvents in fabric production, which affects the overall production scale and energy consumption.

Property Comparison

When comparing viscose and Lyocell properties side by side, you’ll notice significant differences in performance and feel.

Both fabrics originate from wood pulp but behave quite differently in daily use.

| Property | Viscose | Lyocell |

|---|---|---|

| Strength | Weaker (especially when wet) | Stronger and more durable |

| Texture | Silkier, smoother | More cotton-like feel |

| Moisture Wicking | Good absorption, poor wicking | Excellent absorption and wicking |

| Flammability | Burns quickly (similar to cotton) | Less flammable |

Sustainability Factors

When comparing viscose and lyocell’s sustainability factors, you’ll find significant differences in their environmental footprints.

Lyocell outperforms traditional viscose across multiple sustainability metrics.

| Factor | Viscose | Lyocell |

|---|---|---|

| Forestry | Often uses endangered forests | Responsible forestry certified |

| Chemical Process | Toxic chemicals | Closed-loop, 99.8% recovery |

| Water Usage | High consumption | 50% less water needed |

| Energy | Fossil fuel dependent | Lower energy requirements |

| Waste | Significant pollution | Minimal waste, circular economy |

Eco-friendly viscose alternatives like ECOVERO are bridging the sustainability gap, but lyocell remains your best choice for sustainable fabric options.

Viscose Environmental Impact

You’ll be surprised to learn that your favorite viscose garments contribute to the cutting of over 150 million trees each year.

The production process also releases harmful chemicals into waterways, affecting both factory workers and surrounding communities, which is a significant issue related to the production process.

Deforestation Concerns

While Lyocell offers sustainability benefits, viscose production takes a devastating toll on our forests.

Your stylish viscose shirt comes at a high environmental cost, with over 200 million trees logged annually for production.

Here’s how viscose drives deforestation:

- Ancient forests in Indonesia, Canada, and Brazil being cleared for wood pulp

- Habitat loss threatening countless wildlife species

- Indigenous communities losing their homes and livelihoods

- Carbon sequestration capabilities diminished with each tree felled

Look for FSC-certified viscose to guarantee responsible sourcing.

Chemical Pollution

While forests disappear for viscose production, the chemical pollution created is equally concerning.

The process releases carbon disulphide, a toxic chemical that endangers worker safety and nearby communities.

You’ll find sodium hydroxide and sulfuric acid also contaminate water sources, harming aquatic life.

Untreated wastewater from viscose factories often ends up in local lakes.

Though newer methods like Lyocell’s closed-loop system reduce environmental pollution, viscose’s chemical footprint remains significant.

Sustainable Alternatives

Looking for safer alternatives to traditional viscose? Several eco-friendly options have emerged in response to environmental concerns about conventional production methods.

- Lyocell production uses closed-loop systems that recycle 99% of chemicals and water

- TENCEL™ and bamboo fabric require substantially less water than conventional viscose

- Organic cotton and recycled viscose offer reduced environmental impacts without compromising quality

These alternative fibers support fashion sustainability while maintaining the comfort and drape you love.

Viscose Safety Precautions

You’ll need to handle your viscose garments with extra caution since they burn quickly and can cause skin irritation in sensitive individuals.

Keep them away from open flames and wash them before first wear to remove any remaining chemicals from the manufacturing process, which can help prevent irritation and ensure they are safe to wear.

Fire Hazards

Viscose fabric poses significant fire hazards you shouldn’t ignore.

This highly flammable material catches fire rapidly and burns even faster than cotton, potentially causing severe burn injuries.

Keep viscose away from ignition sources like candles, stoves, and cigarettes.

While some manufacturers add flame retardants to meet clothing regulations, most viscose remains dangerously combustible.

For safe handling, store viscose garments away from heat sources and never leave them near open flames.

Skin Irritation

While viscose fabric is generally soft, some people experience skin irritation when wearing it.

Your body may react to chemical residues from production, certain dyes used, or even the fiber’s roughness.

If you notice redness, itching, or rashes after wearing viscose, you might’ve chemical sensitivities or viscose allergies.

Loose weave irritation can also occur when fibers rub against sensitive skin.

Proper Disposal Methods

While some synthetic fabrics can irritate skin, proper disposal of viscose requires equal attention.

When it’s time to part with your viscose items, consider these eco-friendly options:

- Recycling Viscose through textile collection programs

- Composting Viscose in home systems (if untreated)

- Repurposing into cleaning rags to avoid Landfill Impact

- Donating wearable items to extend their lifecycle

Remember that viscose will eventually biodegrade, unlike pure synthetics, though chemical treatments may slow this process considerably, and this is an important factor to consider for proper disposal.

Frequently Asked Questions (FAQs)

How to stop viscose fraying?

You can prevent fraying by using scotch tape, fabric glue, or sewing stitches to secure loose threads, and consider using pinking shears for angled cuts to minimize fraying.

Does viscose fabric fade?

You’ll find that viscose fabric can fade over time, especially when exposed to UV rays, wear, and tear, or harsh chemicals, causing gradual color loss and discoloration slowly.

What are the disadvantages of viscose?

You’ll face drawbacks like poor durability, fading, and fraying, as well as static issues and a tendency to burn quickly, making it a high-maintenance fabric choice.

What are the hazards associated with Viscose fabric?

You’ll encounter hazards like flammability, fraying, and fading with Viscose fabric, which can be mitigated with proper care and handling techniques to minimize risks.

How can I prevent static electricity in Viscose fabric?

You can minimize static in Viscose by wearing a slip, using talcum powder, or avoiding frequent rubbing to reduce buildup and cling.

What type of fabric does a burn test identify?

You’ll identify fabrics like cotton, viscose, or linen with a burn test, which reveals unique characteristics, such as a yellow flame and burnt paper smell, through simple experimentation.

What is the difference between Tencel and Lyocell?

You’ll find Tencel and Lyocell are similar, but Tencel is a branded form of Lyocell, known for its eco-friendly production and higher quality fabric with improved durability and softness.

Can viscose be used for outdoor upholstery?

Like a fleeting sunset, viscose’s charm fades quickly; you’ll want to reconsider using it for outdoor upholstery due to its susceptibility to fading, fraying, and burning.

Is viscose suitable for people with sensitive skin?

You should be cautious, as viscose can irritate sensitive skin due to its semi-synthetic nature and potential chemical treatments during production.

How does viscose react to extreme cold temperatures?

You’ll be shocked to know viscose doesn’t handle extreme cold well, it can become brittle and prone to breaking, losing its softness and durability in freezing temperatures suddenly.

Conclusion

You’ve learned the shocking truth: viscose can indeed burn, fray, or fade.

To minimize these issues, handle it with care. Understanding does viscose burn, fray, fade is key to working with this popular fabric effectively, so you’ll make informed decisions and enjoy your viscose garments for years to come, with proper care and maintenance, and have a good understanding.

- https://www.sciencenewsforstudents.org/article/explainer-how-and-why-fires-burn

- https://en.wikipedia.org/wiki/Viscose

- https://www.theguardian.com/sustainable-business/zara-h-m-fashion-sustainable-forests-logging-fabric

- https://pubmed.ncbi.nlm.nih.gov/5488690/

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3299826/