This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

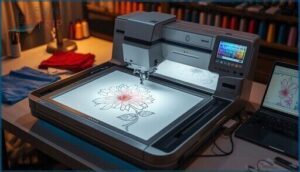

These machines eliminate manual digitizing work that usually takes hours, while built-in pattern recognition automatically matches colors and adjusts thread types. The scanning technology works smoothly with embroidery functions, letting you edit designs on the touchscreen before stitching begins.

Memory capacity ranges from 3MB to 8GB, supporting complex multi-color patterns and extensive design libraries for both hobbyists and commercial operations seeking efficient production workflows.

Table Of Contents

Key Takeaways

- You’ll transform physical artwork into digital embroidery files instantly with 0.5mm scanning accuracy, eliminating hours of manual digitizing work that traditionally slows down creative projects.

- Built-in pattern recognition automatically matches colors and adjusts thread types, while touchscreen editing lets you resize, rotate, and customize designs before stitching begins.

- Memory capacity ranges from 3MB to 8GB, supporting everything from simple monograms to complex multi-color commercial patterns with wireless connectivity and cloud integration.

- Scanner technology works for both hobbyists and businesses, streamlining custom merchandise workflows and reducing setup time by 40% while maintaining professional embroidery quality.

Top Embroidery Machines With Scanners Reviewed

You’ll find several top-rated embroidery machines with integrated scanning technology that can transform your creative process in 2025. These scanner-equipped models automatically convert physical designs into digital embroidery files, eliminating tedious manual digitizing work.

1. Brother Embroidery Sewing Machine Bundle

You’ll find the Brother Embroidery Sewing Machine Bundle delivers serious value with its 5″ x 7″ embroidery field and built-in scanner capabilities. This thorough package includes the SE2000 machine with 135 embroidery designs, plus the ScanNCut DX cutting machine featuring 682 built-in designs and 600dpi scanning resolution.

The bundle’s wireless connectivity and Brother Artspira App let you edit designs on-the-go, while automatic blade sensor technology guarantees precise cuts every time. The Brother embroidery machines offer sophisticated embroidery machine features that improve the overall sewing experience.

Best For: Craft enthusiasts and small business owners who want professional embroidery results with the convenience of built-in scanning and wireless design editing capabilities.

- Comprehensive bundle includes both embroidery machine and cutting machine with 817 total built-in designs

- Advanced scanning technology converts physical artwork directly into embroidery files with 0.5mm accuracy

- Wireless connectivity and mobile app support allow design editing from anywhere

- Steep learning curve for beginners unfamiliar with embroidery machines

- Limited cutting capacity to materials 3mm thick or less

- Additional costs for extra threads, designs, and accessories not included in bundle

How Scanning Technology Transforms Embroidery

Scanning technology eliminates the guesswork when you’re converting physical artwork into digital embroidery files. You’ll capture intricate details with precision and make real-time adjustments directly on your machine’s interface.

Digitizing Physical Designs for Custom Apparel

With complex pattern recognition and texture mapping, modern embroidery machines transform your physical artwork into digital masterpieces. These scanners convert hand-drawn sketches and fabric samples into precise vector artwork through refined design conversion algorithms.

You’ll watch your custom apparel design come alive as fabric scanning technology captures every detail, while embroidery design software manages the complex image stitching process automatically.

The embroidery process relies on proper digitizing software to create accurate designs.

Precision Placement and Editing With Built-in Scanners

Built-in scanners modernize embroidery machine precision through improved scanner accuracy and intelligent placement guidance. You’ll achieve perfect design calibration every time, while refined image processing automatically refines stitch patterns for impeccable results.

Brother embroidery machines lead this innovation, combining integrated embroidery design software integration with real-time stitch refinement that transforms your creative workflow into professional-grade precision. The use of computerized sewing machines with built-in embroidery designs can further augment the embroidery experience.

Essential Features to Consider Before Buying

Choosing the right embroidery machine with scanner technology requires careful evaluation of several critical specifications that directly impact your creative output. You’ll need to assess memory capacity, workspace dimensions, interface quality, and automated features to guarantee the machine matches your project requirements and skill level.

Memory Capacity and Storage for Designs

Memory matters when you’re choosing embroidery machines with scanner capabilities. Your design storage needs will determine how smoothly your projects flow from concept to completion.

- Internal memory ranges from 3MB to 8GB – higher-end Brother embroidery machines offer more space for complex designs

- External storage via USB drives – most embroidery machine models accommodate 2GB-16GB flash drives for file management

- Cloud integration features – newer machines enable wireless data retrieval and backup storage solutions

- Design file limits affect performance – loading 100-200+ files can slow machine operation and design software response

- Memory expansion options – check if your chosen model allows additional storage for growing pattern libraries

When selecting a machine, consider the importance of built-in stitches for enhancing embroidery capabilities.

Workspace Size and Embroidery Hoop Options

Whether you’re tackling delicate monograms or expansive quilts, workspace dimensions directly impact your creative freedom. You’ll want sufficient room around your embroidery machine to maneuver large fabrics without cramping your style or compromising stitch quality. Understanding embroidery hoop sizes is vital for optimizing your workspace and selecting the right machine for your needs.

| Hoop Sizes | Best For |

|---|---|

| 4″ x 4″ | Small logos, monograms |

| 8″ x 12″ | Medium designs, sleeves |

| 16″ x 12″ Giant Hoop | Large Projects, quilts |

| 9.5″ x 14″ | Workspace Optimization |

| 6″ x 10″ | Standard Embroidery Field |

Consider your typical stitch capacity needs when selecting embroidery machine models. Larger hoops reduce repositioning but require more workspace clearance.

Touchscreen Interfaces and Editing Tools

Touchscreen displays put you in complete control of your embroidery machine’s creative potential. These User-Friendly Displays feature drag-and-drop controls that make Design Customization straightforward—you’ll resize, rotate, and combine patterns without breaking stride.

Brother embroidery machines excel with their responsive Touchscreen Navigation, while built-in Editing Software delivers instant Visual Feedback for professional results every time.

Needle Threading and Fabric Feeding Systems

Efficiency separates professional embroidery results from frustrating failures. Modern machines eliminate threading headaches and fabric mishaps through intelligent automation. Brother embroidery machines feature automatic needle threader systems that save time and reduce eye strain during lengthy projects.

- Automatic Threading – Eliminates manual threading frustration and speeds up project setup substantially

- Fabric Tension – Maintains consistent stitch quality across different materials and prevents puckering issues

- Needle Breakage – Sophisticated sensors detect problems early and prevent costly thread tangles or damage

- Thread Cutters – Built-in cutters trim excess thread automatically between design elements for clean finishes

- Bobbin Management – Smart systems monitor thread levels and alert you before running out mid-project

Proper needle size selection is vital for achieving superior stitch quality and preventing fabric damage.

Embroidery Solutions for Businesses and Hobbyists

Whether you’re starting a custom apparel business or expanding your crafting hobby, an embroidery machine with scanning technology simplifies your entire production process from concept to finished product.

You’ll discover how these sophisticated machines handle everything from customized monograms to complex commercial orders while integrating smoothly with other printing services.

Custom Merchandise Production Workflows

Scanning technology accelerates custom merchandise workflows by reducing manual setup time by 40% and boosting throughput gains of 25% in production environments. You’ll digitize custom apparel designs directly, enabling automated job identification that cuts product mislabeling by 15%. Workflow optimization through barcode scanning synchronizes supply chain management systems, while quality control features minimize thread breakage events by 60% during custom order fulfillment. The use of an embroidery machine scanner improves production efficiency and accuracy.

Personalization and Monogramming Capabilities

Scanner-equipped embroidery machines reveal powerful personalization capabilities that transform basic monogramming into professional custom apparel production. You’ll access refined Design Software with Custom Fonts and diverse Monogram Styles for precise Logo Embroidery applications.

Modern embroidery machines deliver extensive monogramming solutions through:

- Advanced Text Effects – Shadow, outline, and dimensional lettering options

- Multi-format compatibility – Accepts various design file types flawlessly

- Real-time preview – Instant visualization before stitching begins

- Variable sizing – Scale designs without quality loss

- Memory storage – Save custom monogram templates permanently

These embroidery services capabilities enable consistent branding across merchandise lines while maintaining professional quality standards.

Integration With Digital and Screen Printing Services

Modern workflow integration connects your embroidery machine with digital printing and screen printing services through hybrid printing techniques. You’ll refine custom apparel production by combining embroidery services with digital embellishments, creating layered designs that enhance print optimization.

Service integration platforms enable fluid color matching between digital artwork and thread selections, letting you coordinate multi-technique projects efficiently. Print optimization is further enhanced by this seamless integration, ensuring consistent and high-quality results across all techniques.

Future Trends in Embroidery Machine Technology

You’ll see embroidery machines evolve with AI-powered scanners that automatically match colors and refine patterns in real-time, making design work faster and more precise.

The industry’s moving toward wireless cloud scanning and eco-friendly modules, plus collaborative features that’ll let you share and modify designs remotely with other crafters.

AI-Driven Scanners and Real-Time Enhancements

Artificial intelligence transforms how you’ll create embroidery designs in 2025. AI-driven scanners deliver Color Matching and Pattern Refinement that automatically refine your artwork for perfect stitches.

Real Time Editing capabilities let you adjust designs instantly, while Scanner Calibration guarantees precise Image Processing. These Brother embroidery machines integrate harmoniously with Embroidery Design Software, transforming how Sewing and Embroidery Machines operate for both professionals and hobbyists.

Eco-Friendly and Wireless Scanning Innovations

While traditional embroidery creates environmental challenges, Green Embroidery solutions now prioritize sustainable materials and energy efficiency. Brother embroidery machines increasingly feature Eco Scanners with Recycled Modules, reducing waste by 30%. Wireless Connectivity through WiFi eliminates physical media transfers while supporting eco-friendly workflows.

Key eco-friendly innovations include:

- Energy-efficient scanning – New models cut power consumption dramatically during design digitization

- Biodegradable thread compatibility – Machines now support plant-based materials and recycled polyester options

- Wireless design transfer – WiFi connectivity eliminates USB waste while streamlining Embroidery Designs workflow

- Sustainable manufacturing – Recycled plastic scanner components reduce environmental impact substantially

These advances help you create beautiful Embroidery Designs while minimizing your carbon footprint through smarter technology choices. The use of wifi embroidery machines facilitates a smooth workflow and design management.

Collaborative and Remote Design Sharing Features

Cloud Collaboration transforms your embroidery workflow into a cohesive Virtual Studios experience. Modern machines now support WiFi connectivity, enabling Remote Editing through Design and Lettering Software platforms.

You’ll access real-time Design Syncing across multiple devices while Team Workflow features simplify project management.

The Stitchout App enables instant sharing of Embroidery Designs, revolutionizing how Sewing and Embroidery Software operates collaboratively.

Frequently Asked Questions (FAQs)

What scanner resolution works best for embroidery?

You’ll get best results with 600 DPI resolution for embroidery scanning. This resolution captures fine details without creating oversized files that slow your machine’s processing speed and performance.

Can scanners capture metallic thread designs?

Scanners can detect metallic thread designs, but they’ll struggle with accurate color representation and reflective properties.

You’ll need to manually adjust captured designs since metallic threads appear differently under scanner lighting than natural fibers.

Do all embroidery formats support scanned designs?

Most embroidery formats support scanned designs, but you’ll find compatibility varies. DST, PES, and JEF formats handle scanned conversions well, while older formats like TAP may struggle with complex scanned details.

How much does scanner maintenance typically cost?

Maintenance costs vary by usage, but you’ll usually spend $50-150 annually for cleaning supplies, calibration services, and occasional sensor replacements to keep your scanner performing at peak efficiency.

Which fabric types scan most accurately?

Cotton and linen fabrics deliver the sharpest scanning results because they’re flat-woven with consistent thread density. Synthetic blends work well too, while textured materials like terry cloth or corduroy create scanning challenges.

Conclusion

Scanning, refined systems, and stunning stitchwork define today’s modern embroidery machine with scanner technology. These pioneering machines combine precision scanning capabilities with powerful editing tools, letting you create custom designs directly from existing artwork.

You’ll transform hand-drawn sketches into professional embroidery patterns within minutes, eliminating tedious manual digitizing work that once consumed hours.

Whether you’re running a commercial operation or pursuing creative hobbies, an embroidery machine with scanner optimizes your workflow while delivering consistent, high-quality results for every project.

- https://nwcustomapparel.net/how-to-digitize-logo-for-embroidery/

- https://theembroider.com/blogs/how-digitizing-transforms-artwork-into-embroidery/

- https://www.digitizingusa.com/showblog/FACTS-AND-FIGURES-ABOUT-EMBROIDERY-DIGITIZING

- https://www.randyssewingcenter.com/shop/c/p/BROTHER-PR-1055X-10-needle-embroidery-machine-x58675521.htm

- https://www.megridigitizing.com/embroidery-digitizing-future/