This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your scissors are tired. After cutting through layers of quilting cotton or wrestling with slippery satin, your hands cramp and your edges look like they survived a tornado. That frayed, uneven mess sitting on your cutting table isn’t just frustrating—it costs you time, wastes fabric, and limits what you can create.

Fabric cutting machines changed everything for crafters and professionals who got sick of wrestling with manual tools. These machines slice through multiple layers in seconds with laser-sharp precision, whether you’re piecing together a quilt, prototyping fashion designs, or cranking out custom patches for your side business.

From budget-friendly die cutters to digital powerhouses that read your designs straight from software, the right machine transforms tedious prep work into the fun part of your project.

Table Of Contents

Key Takeaways

- Fabric cutting machines slash your cutting time by up to 75% and deliver precision down to 0.04 mm—transforming tedious prep work into fast, accurate cuts that manual scissors simply can’t match.

- The right machine depends on your specific needs: manual die-cutters work great for occasional quilters, electric models handle high-volume projects, while digital cutters like Cricut Maker 3 excel at intricate designs across 300+ materials.

- These machines pay for themselves through material savings (reducing waste by 20%), labor efficiency (one operator cuts 100 layers in 20 minutes instead of two hours), and fewer defects (dropping error rates from 5% to 0.5%).

- Regular maintenance—weekly blade cleaning, mat replacement every 18-24 months, and proper storage—extends machine life by 40% and keeps cutting accuracy sharp for years of reliable performance.

Types of Fabric Cutting Machines

Choosing a fabric cutting machine can feel overwhelming when you’re staring at all the options. The good news? They break down into four main categories based on how they work and what kind of power they use.

Let’s walk through each type so you can figure out which one fits your creative vision.

Manual Die-Cutting Machines

When you turn the crank on a manual die-cutting machine like the Sizzix Big Shot, you’re powering through fabric with pure hand strength. Die compatibility matters—Bigz Dies handle thicker materials, but you’ll feel the hand fatigue after a dozen cuts.

These manual die-cutting machines offer total control over cutting pressure and material thickness without electricity, though manual vs electric cutters differ drastically in stamina requirements.

The packaging sector’s high demand drives the need for these machines.

Electric Fabric Cutting Machines

Electric fabric cutting machines flip the script—no more hand-cranking. These plug-in powerhouses deliver cutting precision and automation benefits that manual models can’t touch. With ergonomic design and safety features like blade guards, they’re reshaping market trends in fabric cutting machine reviews.

The global market hit $500 million in 2025, and fabric cutter comparison shows electric models cut three times faster than manual counterparts, slashing labor time dramatically.

The US market is seeing significant market growth due to increasing demand.

Digital and Electronic Cutters

Digital cutting machines and electronic cutting machines like the Cricut Maker and Brother ScanNCut bring software integration into your craft room. You’ll get automation benefits with millimetric cutting precision and impressive material compatibility—from cotton to vinyl. Market adoption jumped 17% last year as hobbyists discovered these machines handle complex patterns effortlessly through computer control, no manual dies needed.

- Upload designs directly from your device for instant cutting

- Cut intricate patterns with 0.01 mm accuracy that scissors can’t match

- Process multiple fabric types without switching equipment

Laser and Automatic Cutters

When precision matters most, laser fabric cutting machines deliver ±0.1 mm accuracy—eliminating fraying entirely. These automated systems dominated 45% of the $3.85 billion market in 2025, with growth accelerating at 7.6% annually.

You’ll see safety standards like Class-1 certification and automatic shutoffs built in.

Automation benefits include 15-30% better material usage and 70% labor savings, transforming how serious creators and manufacturers approach fabric work.

Key Factors When Choosing a Fabric Cutter

Picking the right fabric cutter isn’t just about grabbing the fanciest machine on the shelf. You need to think about how you’ll actually use it, what projects you’re tackling, and what fits your skill level and budget.

Let’s break down the key factors that’ll help you find your perfect match.

Electric Vs. Manual Operation

You’ll face one big question right away: crank by hand or plug it in? Manual die-cutting machines like AccuQuilt give you precision control, but they demand more physical strain—especially if you’re cutting thick fabric stacks. Electric cutting machines triple your cutting speed and slash hand fatigue. Here’s what matters:

- Strength requirement: Manual cutters need elbow grease; electric ones do the heavy lifting.

- Cutting speed: Electric machines finish jobs three times faster.

- Precision control: Manual offers finer adjustments for delicate work.

- Cost comparison: Electric models cost double upfront but save labor long-term.

- Safety features: Electric cutters include guards and auto-shutoffs to prevent accidents.

If you’re tackling big projects regularly, electric fabric cutting machines reduce strain and boost output—worth every penny.

Multi-Craft Use Vs. Fabric-Only

When choosing between multi-craft and fabric-only systems, think about material versatility first. Multi-craft cutting machines like the Cricut Maker handle 300+ materials—fabric, paper, vinyl, leather—but blades dull faster.

Fabric-only machines like AccuQuilt slice six fabric layers at once, offering better cost analysis for quilters.

Your project complexity and user skill level matter: digital cutters need tech comfort, while die-based options stay simple and space-efficient.

Frequency of Use and Cutting Goals

Your cutting volume shapes which fabric cutting machines work best for you. If you’re tackling 40 to 60 marker plans daily in a production setting, automation impact is huge—sophisticated cutters slash time per marker from 20 minutes down to just 7 minutes.

Consider these project types and goals when choosing fabric cutters:

- Small batches: Manual die-cutters handle 12-20 sessions per day with great desired accuracy

- Medium projects: Semi-automatic machines boost first-pass yield by 12% while cutting material usage waste

- High-volume production: Automatic fabric cutting machines run 18-24 hours, delivering consistent precision within ±1 mm tolerance

Match cutting machine features to your real workload—not wishful thinking.

Ease of Use and Tech Requirements

User interface design on cutting machine software makes or breaks your learning curve. Touch-screen models now let 73% of operators run digital design tasks without prior experience—zero CAD training needed.

Software compatibility matters: 67% require Windows 10 or later.

Training time? You’ll master automated cutters in 2–5 days versus 2–4 weeks for manual systems. Technical skills? They’re optional now.

Budget and Long-Term Value

Initial costs span a wild range—manual machines under $200, electric cutters at $229–$399, industrial laser systems hitting $3,000–$35,000.

But here’s the real turning point: automated fabric cutting machines pay for themselves in 2–2.5 years through 75% labor savings. Lifespan expectations? You’re looking at 5–15 years with proper maintenance. ROI timeframe beats most factory investments hands-down.

Top 8 Fabric Cutting Machines Reviewed

Now that you know what to look for, let’s break down the machines that actually deliver. Each one’s built for different needs—whether you’re cranking out quilts, tackling mixed-media projects, or just getting started.

Here’s what works, what doesn’t, and who each machine is really for.

1. Sizzix Big Shot Express Die Cutter

If you’ve been hand-cranking manual diecutting machines until your wrists ache, the Sizzix Big Shot Express flips the script with electric die-cutting that accommodates the work for you. This motorized powerhouse accepts cutting dies up to 6 inches wide and delivers hands-free operation that’s perfect if you’ve got arthritis or just want speed.

With all-metal gears built for durability that outlast flimsy manual die cutter models, it scores a solid 4.8/5 in user satisfaction.

The crafting versatility spans paper, fabric, and thin metals—making die cutting genuinely enjoyable.

Best For: Crafters who need hands-free die-cutting due to arthritis or limited hand strength, plus anyone tired of manual cranking who wants faster, quieter cuts on multi-layer projects.

- Electric motor handles the work automatically, cutting through paper, fabric, and thin metal with consistent precision—no more hand fatigue from cranking.

- All-metal gears are built to last, with an average service life over five years and less than 2.5% failure rate during warranty periods.

- Compatible with the entire Sizzix product library (except Bigz Plus and Pro dies), so you can use dies and embossing folders you already own up to 6 inches wide.

- Some users report machine failure or malfunction after short-term use, which can be frustrating despite the warranty coverage.

- You have to hold the button down during operation instead of true set-it-and-forget-it automation.

- Cutting pads can warp or curl over time and need replacement every 18–24 months, adding ongoing maintenance costs.

2. AccuQuilt Fabric Cutting System Starter Set

For quilters who want speed without plugging anything in, the AccuQuilt Fabric Cutting System delivers manual die-cutting that’s 90% faster than scissors or rotary cutters. This hand-operated fabric cutting machine slices up to 6 layers of cotton, denim, or fleece in one pass—perfect if your wrists can’t handle repetitive cutting.

Cutting efficiency meets safety features here: no sharp rotary blades, just consistent accuracy benefits every time. At $649.99, the AccuQuilt Go starter set offers solid product value with 160+ compatible dies. User satisfaction stays high among quilters tackling complicated blocks effortlessly.

Best For: Quilters with arthritis or mobility issues who want to cut fabric 90% faster than rotary cutters while maintaining precision across multiple layers.

- Cuts up to 6 layers of fabric simultaneously with consistent accuracy, eliminating measuring errors and reducing project time significantly.

- Hand-operated design requires no electricity and reduces wrist strain, making it safer and more comfortable than traditional rotary cutters or scissors.

- Compatible with over 160 dies and includes access to 70 free patterns, allowing unlimited creative expansion for quilts, blocks, and appliqué projects.

- Additional dies are expensive, which can add up quickly if you want to expand beyond the included starter pieces.

- Dies are extremely sharp and require careful handling, with some users reporting difficulty removing the protective plastic packaging.

- The system has a learning curve and may not be cost-effective for quilters who work on varied project sizes or only sew occasionally.

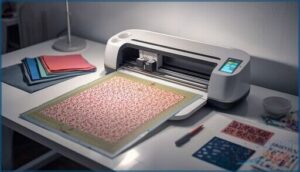

3. Cricut Maker 3 Cutting Machine

If you need a digital fabric cutting machine that truly manages everything, the Cricut Maker 3 dominates with 65% market share for good reason. This powerhouse cuts over 300 materials—cotton, leather, vinyl, even balsa wood—using interchangeable tools and Design Space software that’s surprisingly beginner-friendly.

Material compatibility stretches far beyond fabric cutting machines built for quilters alone. User experience reviews praise its speed boost over earlier models, though you’ll need a device to operate it.

At around $399, sales performance stays strong year-round, especially during holiday peaks.

Best For: Crafters and small business owners who want a versatile machine that cuts hundreds of materials with professional precision, from fabric and vinyl to leather and wood.

- Cuts over 300 different materials with interchangeable tools, making it incredibly versatile for any project you can imagine

- Faster cutting speed than previous models and works with Design Space software that’s easy to pick up, even for beginners

- Dominates the market with 65% share and a huge active user community, so you’ll find plenty of tutorials and support

- Requires a computer or mobile device to operate—you can’t use it standalone

- Price point around $399 is steep compared to basic cutting tools, though it reflects the professional capabilities

- Print Then Cut feature won’t work with reflective materials like metallic or glitter finishes, which limits some design options

4. Cricut FabricGrip Mat 12×24 3 Pack

Your Cricut Maker needs the right partner to shine, and that’s where the FabricGrip Mat 12×24 3 Pack steps in. These pink mats hold cotton, denim, and felt securely without stabilizer in most cases—mat adhesion stays strong through multiple projects before cleaning methods like warm water restore stickiness.

Each 12×24-inch mat accommodates larger quilting patterns, and lifespan factors improve when you alternate between all three.

Fabric compatibility reviews confirm they work brilliantly for face masks and quilt pieces, making project suitability excellent for sewers exploring cutting machine features beyond basic crafts.

Best For: Quilters and sewers who need to cut larger fabric pieces without stabilizer and want mats that last through multiple projects.

- Holds cotton, denim, and felt securely without needing extra stabilizer in most cases

- Three mats let you rotate between them, extending overall lifespan before cleaning is needed

- 12×24-inch size accommodates bigger quilting patterns and face mask layouts

- Mats wear out faster when cutting tougher fabrics like heavy denim

- Cleaning takes effort and time to restore the stickiness properly

- 12-inch width limits cutting size for really large pattern pieces

5. Sizzix Big Shot Plus Die Cutter

The Sizzix Big Shot Plus brings manual cutting machines into bigger territory with its 9-inch opening—perfect when you’re cutting fabric pieces that won’t fit standard die-cutting tools. Die compatibility covers the entire Sizzix library except Bigz Pro dies.

This workhorse accommodates cardstock, felt, and even thin metal while maintaining embossing quality through its sturdy roller system. Material compatibility spans most crafting needs, though cutting pad wear happens faster with heavy use.

At 16.5 pounds, user fatigue stays low thanks to smooth cranking action that fabric cutting machines should deliver effortlessly.

Best For: Quilters, fabric artists, and serious crafters who need to cut larger materials and want a reliable manual machine that handles everything from paper to thin metal.

- 9-inch opening handles bigger projects like fabric squares and full-page designs that smaller machines can’t accommodate

- Works with the entire Sizzix die library (except Bigz Pro) and cuts multiple layers in one pass, speeding up production work

- Smooth manual operation reduces hand fatigue even during long crafting sessions, and the machine stays dependable for years with basic maintenance

- Weighs 16.5 pounds and takes up permanent counter space since it doesn’t fold for storage

- Cutting pads wear out faster with heavy use (every 500-1,000 cuts) and need replacing, adding to ongoing costs

- Higher price point than standard Big Shot models, and Plus-specific accessories cost more too

6. Sizzix Big Shot Plus Adapter G

With die versatility on your mind, the Sizzix Big Shot Plus Adapter G unlocks AccuQuilt compatibility for your manual cutting machines without buying separate systems. This 8¾” x 15″ polypropylene plate lets you sandwich AccuQuilt GO! dies between cutting pads—but only standard sizes work (sorry, Studio dies won’t fit).

User experiences consistently praise clean fabric cutting results, though adapter limitations include spotty market availability. You’ll save 15–20% on die costs long-term, making this hard-to-find accessory worth hunting down if you’re expanding your die-cutting arsenal.

Best For: Quilters and fabric crafters who already own a Sizzix Big Shot Plus and want to expand their cutting options by using AccuQuilt GO! dies without investing in a second machine.

- Enables use of popular AccuQuilt GO! dies on your existing Sizzix Big Shot Plus, saving you from buying another cutting system

- Delivers clean, accurate fabric cuts that match the quality you’d get from the original manufacturer’s setup

- Reduces long-term die costs by 15–20% since you can mix and match dies across brands

- Only works with standard AccuQuilt GO! dies—larger Studio dies aren’t compatible

- Frequently out of stock at retailers, making it frustratingly hard to find when you need it

- Requires precise sandwich layering with cutting plates, which adds an extra step to your workflow

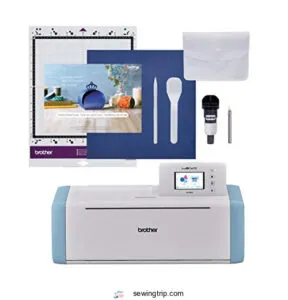

7. Brother ScanNCut DX Cutting Machine

The Brother ScanNCut DX stands out as the only fabric cutting machine with a built-in scanner, perfect for turning your hand-drawn sketches into clean cuts. Its Auto-Blade tech detects material thickness automatically, handling everything from delicate fabric to 3mm foam.

You’ll get 1,163+ built-in designs and 17 fonts on the 5-inch touchscreen, plus material compatibility that makes multi-craft projects a breeze.

Regular maintenance tips include cleaning the scanning plate and replacing mats to keep cutting machine features performing smoothly.

Best For: Crafters and small business owners who want an all-in-one machine that can scan hand-drawn designs and cut multiple materials without manual adjustments.

- Built-in 600 DPI scanner lets you turn sketches into cut files instantly—no computer needed

- Auto-Blade sensor adjusts to material thickness automatically, so you’re not constantly tweaking settings

- Massive design library with 1,163 patterns and 17 fonts saves you from hunting down files online

- Replacement mats run expensive compared to other brands

- Takes up serious counter space with its 21-inch width

- Some users find the adhesive mats too sticky and need to modify them for delicate materials

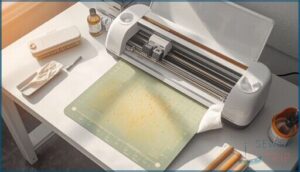

8. Silhouette Cameo 4 Die Cutting Machine

The Silhouette Cameo delivers an impressive 5,000 grams of cutting force—twenty times more powerful than older models—making it a beast for cutting fabric, vinyl, and cardstock up to 3mm thick. You’ll breeze through projects three times faster than previous versions, with no subscription required for core features.

Material versatility shines here: fabric, heat transfer vinyl, even felt. Software compatibility covers both Windows and Mac, though beginner tutorials scattered across forums mean there’s a learning curve.

For small businesses, ROI analysis shows you’ll break even after just 50–100 products.

Best For: Small business owners, serious crafters, and DIY enthusiasts who need professional-grade cutting power without ongoing subscription fees.

- Cuts through thick materials up to 3mm with 5,000 grams of force—twenty times more powerful than older models

- Completes projects three times faster than previous versions, with speeds up to 30 cm/second

- No subscription required for core features, saving you money compared to competitors like Cricut

- Steeper learning curve with tutorials scattered across different forums rather than one central resource

- Can struggle with cheaper paper or materials, requiring higher-quality supplies for best results

- Software glitches reported with certain versions and Mac compatibility issues

Benefits of Using Fabric Cutting Machines

Switching to a fabric cutting machine can completely change how you work with textiles. You’ll notice the difference right away—cleaner cuts, faster projects, and way less frustration than wrestling with scissors and rulers.

Here are five solid reasons why these machines are worth considering for your sewing room or studio.

Precision and Consistency

You know what’s game-changing? Cutting accuracy down to 0.04 mm. That’s what modern fabric cutting machines deliver—repeatability benchmarks that turn every piece identical. No more wonky edges or uneven shapes.

Developed digital cutters slash defect rates from 5% to just 0.5%, while slicing material waste by over 20%. Quality assurance becomes automatic, and your fabric cutting techniques reach precision you simply can’t achieve by hand.

Time and Labor Savings

Imagine slicing your cutting time by 75%—that’s the automation impact you’ll see with modern machines. One operator finishes 100 fabric layers in just 20 minutes instead of two hours, unlocking efficiency gains that transform your entire workflow.

- Production speed jumps 4–6 times faster than manual methods

- Quilting time reduction lets you complete more projects weekly

- Workforce reallocation shifts skilled hands to creative tasks

- Cost reduction saves small factories around $20,000 yearly

Enhanced Safety Features

Modern fabric cutting machines transform workshop hazards into a thing of the past. Blade guards and emergency stops slash injury risk by 92%, while sensor integration detects jams before accidents happen.

Ergonomic design reduces strain by 40%, and training standards make sure you’re confident from day one.

These cutting tools protect your hands so you can focus on creating—not worrying about your next trip to urgent care.

Creative Design Possibilities

Beyond protection, you gain creative freedom you couldn’t dream of before. With over 3,500 applique shapes and design software that cuts pattern complexity down to size, you’re making custom designs 38% faster. Material versatility means cutting through cotton, denim, even leather—opening doors to artistic innovation.

Here’s what becomes possible:

- Intricate quilt design with sub-millimeter precision for haute couture-level detail

- Multi-layer cutting patterns that handle 5-10 fabrics simultaneously for bold experimentation

- Print-and-Cut technology turning digital prints into physical customization options instantly

Reduced Fabric Waste and Cost

All that creative power pays off in your wallet, too. AI optimization and marker efficiency slash fabric waste by up to 20%, turning scraps into savings. Accurate cuts mean fewer do-overs, while defect management spots flaws before you cut.

AI-optimized fabric cutting slashes waste by 20%, turning scraps into savings and cutting mistakes into profit

One factory dropped waste from 15% to 5%, saving $30,000 yearly on material alone—your fabric cutting system becomes an investment, not just a tool.

Maintaining and Maximizing Your Fabric Cutter

You’ve invested in a fabric cutter, and now it’s time to keep it running like a dream. A little care goes a long way—clean blades cut cleaner, fresh mats grip better, and smart storage means you won’t be hunting for parts when inspiration strikes.

Let’s walk through the simple maintenance steps that’ll help your machine deliver perfect cuts for years to come.

Cleaning and Replacing Blades and Mats

Your cutting mats and blades need regular love to keep your fabric cutting machines running smoothly. Weekly cleaning frequency boosts blade lifespan by 25–35%, while daily attention can bump cutting accuracy by 15–20%. Mat cleaning with vinegar and water works wonders. Maintenance scheduling every six months prevents problems.

This performance impact means sharper cuts, less waste, and more time creating instead of troubleshooting.

Accessory Storage and Organization

Once your blades and mats are clean, smart storage solutions keep all those accessories from vanishing. Drawer organizers slash accessory loss by 37% and trim setup time by 43%. Your cutting machines deserve better than cluttered chaos.

- Clear bins boost workspace by 18% through space optimization

- Vertical shelving maximizes wall area for inventory management

- Rolling carts hold 60+ tools while improving efficiency improvements and loss prevention

Tips for Prolonging Machine Life

When you treat your cutter like a teammate—not a tool—it thrives for years. Regular cleaning, blade maintenance, and software updates form your core trio. Add operator training and environmental control for serious performance gains. Cutting machines drop failures by 40% with quarterly staff sessions, while fabric cutting machines last 36 months longer when you log every maintenance action.

| Maintenance Task | Impact on Longevity |

|---|---|

| Weekly surface cleaning | 40% longer lifespan |

| Monthly software updates | 28% fewer digital errors |

| Blade checks every week | 1,000+ cutting cycles per blade |

| Quarterly operator training | 40% fewer breakdown incidents |

| Temperature/humidity control | 14% fewer electrical failures |

Frequently Asked Questions (FAQs)

What is the best tool for cutting fabric?

The best tool depends on your project complexity and skill level needed. For simple quilts, rotary cutters work great. Intricate designs? Fabric cutting machines like Cricut Maker 3 deliver precision every time.

Which fabric cutting method is best?

Your skill level and volume needs matter most. Material compatibility, budget constraints, and cutting precision all play a role in choosing the right fabric cutting techniques, from manual to automated types of cutting machines.

Which type of cutting machine is best?

Your skill level and project complexity matter most. Manual cutting machines work great for beginners, while electronic cutting machines handle intricate patterns.

Consider your budget constraints, cutting volume, and fabric types you’ll use regularly.

Which Cricut machine cuts fabric the best?

The Cricut Maker series dominates fabric cutting projects with its rotary blade benefits and 4 kg cutting force. Material versatility shines—over 300 textiles cut cleanly. Pair it with a FabricGrip mat for unbeatable precision.

Can fabric cutters handle patterned or textured fabrics?

Yes, sophisticated fabric cutters excel with patterned or textured materials. Digital machines offer pattern alignment within ±2 mm, handle fabric distortion automatically, and provide edge sealing on stretchy textiles—boosting material compatibility while reducing waste through smart cutting fabric techniques.

How often do cutting blades need replacement?

Blade material, fabric type, and usage frequency determine replacement timing. Most cutting tools need new blades every 3-6 months with regular use.

Proper maintenance of cutting mats extends lifespan and reduces costs considerably.

Can multiple fabric types be cut simultaneously?

High multi-layer cutters handle different fabric types—cotton, polyester, denim—in one batch. You’ll adjust blade selection and machine settings for material thickness variations.

This fabric compatibility saves time and reduces waste when cutting fabric pieces together efficiently.

What fabrics work best with cutting machines?

Most cutting machines handle cotton compatibility brilliantly—it’s the ideal. Synthetic handling works great with laser cutters, while delicate fabrics need rotary blades. Heavy materials like denim? Stack ’em up!

Can fabric cutters handle thick or layered materials?

Think fabric cutters are wimps that fold under pressure? Think again. Industrial machines power through 20–100 layers at once, while laser and electric models conquer denim, leather, and foam effortlessly.

How do I choose the right dies?

Start with die compatibility—check your machine’s specs before buying. Then consider fabric layers, shape accuracy for your projects, and waste minimization. Safety handling matters too, especially with sharp custom dies.

Conclusion

Consider this: a quilter in Texas once measured her scissor time at 40% of every project—just cutting. She grabbed a die cutter and reclaimed those hours for actual stitching.

That’s the real magic of fabric cutting machines. They don’t just slice cleaner lines—they hand you back your creative time.

Whether you’re piecing quilts or launching a patch business, the right cutter stops being a tool and starts being your creative partner.

- https://www.futuremarketinsights.com/reports/fabric-cutting-machines-market

- https://www.globalinsightservices.com/reports/fabric-cutting-machines-market/

- https://www.marketresearchfuture.com/reports/fabric-cutting-machine-market-40609

- https://insights.made-in-china.com/Advancements-in-Fabric-Cutting-Machines-and-Evolving-User-Needs_tGuAPLvbmQia.html

- https://www.archivemarketresearch.com/reports/electric-fabric-cutter-464344