This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

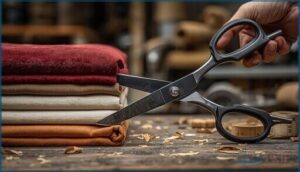

Professional upholstery work lives or dies by the quality of your fabric scissors. Most general-purpose shears won’t survive their first encounter with dense upholstery materials, leather, or multiple fabric layers. The wrong tool leaves you fighting through every cut, fraying edges, developing hand fatigue, and potentially ruining expensive materials with jagged, uneven lines.

Upholstery fabric scissors feature extended blade lengths from 7 to 12 inches, hardened stainless steel or high-carbon construction, and bent handle designs that keep your cutting hand elevated above the work surface for precision control.

Whether you’re tackling furniture restoration projects, cutting drapery materials, or working with carpet and dense textiles, matching your scissors to the specific fabric thickness and application determines the difference between clean, professional results and wasted time correcting poor cuts.

Table Of Contents

Key Takeaways

- Professional upholstery scissors require 7-12 inch hardened steel blades, bent handle designs for tabletop control, and construction rated 53-60 HRC to cut cleanly through dense fabrics like leather, canvas, and multiple textile layers without fraying or dulling quickly.

- Blade length determines your cutting efficiency—7-8 inches handles precision work and tight curves, 9-10 inches suits medium-weight fabrics, and 12 inches delivers speed on wide panels when you need long, straight cuts across thick upholstery materials.

- Regular maintenance extends blade life dramatically: wipe and oil after each use, sharpen every 6-12 months with fine grit whetstones, store in protective sheaths below 60% humidity, and avoid paper cutting or harsh chemicals that destroy cutting edges.

- Match your scissors to fabric thickness and application—lightweight vinyl works with 1.5-1.7mm blades, heavy canvas demands blades over 1.8mm thick, and multi-layer cutting requires convex blade geometry with reinforced pivot joints to prevent bending through stacked materials.

Top 8 Fabric Scissors for Upholstery

When you’re working with heavy upholstery fabrics, standard household scissors won’t give you the precision and power you need to handle thick materials like denim, leather, or multiple layers of canvas. Professional upholstery scissors feature reinforced blades, ergonomic grips, and specialized construction designed to cut through dense textiles without fraying or dulling quickly.

Investing in quality blades pays off over time, especially when you follow proper scissor maintenance and sharpening techniques to keep them performing at their best.

Here are eight top-performing fabric scissors that deliver the cutting power and durability your upholstery projects demand.

1. Professional Heavy Duty Fabric Scissors

You need professional heavy-duty fabric scissors built to power through upholstery work without hesitation. Look for precision-ground blades in forged high-carbon steel, delivering clean cuts through multiple fabric layers while maintaining blade sharpness after repeated use.

For quilters working with delicate or layered materials, specialized quilting scissors offer similar precision-ground construction with ergonomic handles designed for extended cutting sessions.

An ergonomic design with reinforced, slip-resistant grips reduces hand fatigue during extended projects, and rust-resistant coatings protect your investment in humid workshop conditions.

For those working with delicate fabrics, non-sewing hemming techniques pair perfectly with these tools thanks to their adhesive-resistant coating that prevents buildup.

These industrial scissors feature beveled undersides that prevent snagging on thick textiles, making them essential professional sewing tools for serious upholstery cutting and fabric cutting applications.

| Best For | Professional upholsterers, tailors, and serious sewers who regularly cut through heavy fabrics like canvas, vinyl, and denim and need scissors that won’t quit halfway through a project. |

|---|---|

| Blade Material | High carbon steel |

| Total Length | 10 inches |

| Weight | 4.2 ounces |

| Handle Design | Ergonomic rounded |

| Primary Use | Sewing and quilting |

| Color | Black |

| Additional Features |

|

- Precision-ground, forged steel blades slice cleanly through multiple fabric layers without fraying edges, and they stay sharp even after heavy use

- Ergonomic handles with slip-resistant grips keep your hands comfortable during long cutting sessions and give you better control on thick materials

- Rust-resistant coating and durable construction mean these scissors hold up in humid workshops and last through years of demanding upholstery work

- Some models develop issues with screw nuts rusting over time, requiring occasional adjustments to maintain proper tension

- The larger, heavier design might feel awkward or uncomfortable for users with smaller hands

- Limited long-term durability information makes it hard to predict exactly how many years you’ll get out of them with professional-level use

2. LIVINGO Titanium Scissors

LIVINGO Titanium Scissors deliver multi-color titanium coating on durable stainless steel blades, offering excellent blade sharpness and resistance to rust or adhesive buildup during fabric cutting projects.

These upholstery scissors measure 9.5 inches long, featuring a comfort-grip handle design that provides precision control through multiple fabric layers, from lightweight textiles to thick denim.

The ergonomic construction reduces hand fatigue during extended sewing sessions, while the bent blade geometry facilitates smooth tabletop cutting without surface damage.

At 5.4 ounces, you’ll find balanced cutting performance ideal for upholstery work, quilting, and tailoring applications requiring reliable fabric shears.

| Best For | Home sewers, quilters, and crafters who need sharp, rust-resistant scissors for cutting multiple fabric layers without frequent sharpening. |

|---|---|

| Blade Material | Stainless steel |

| Total Length | 9.5 inches |

| Weight | 5.4 ounces |

| Handle Design | Comfort grip |

| Primary Use | All-purpose fabric |

| Color | Black/Red |

| Additional Features |

|

- Multi-color titanium coating resists rust and adhesive buildup while maintaining sharp edges through heavy use

- Ergonomic comfort-grip handles and balanced 5.4-ounce weight reduce hand fatigue during long cutting sessions

- Bent blade design allows smooth tabletop cutting through thick materials like denim without damaging work surfaces

- Weight and size may feel cumbersome for users with weak grip strength or limited hand dexterity

- Cutting smoothness doesn’t match premium Japanese scissors according to some user comparisons

- Limited availability in local fabric and sewing stores means you’ll likely need to order online

3. Wteehn Heavy Duty Fabric Scissors

When Heavy Duty Fabric Scissors feature galvanized manganese blades with a 45° cutting angle, measuring 8 inches long for fast, precise cuts through dense upholstery materials, canvas, and leather. You’ll benefit from the aluminum alloy handle with non-slip grip, reducing hand fatigue during heavy-duty applications while maintaining blade sharpness on multiple fabric layers.

The chamfered edge prevents accidental scratches during fabric cutting, though you should dry these upholstery shears thoroughly after use to prevent rust buildup, as the material requires consistent scissor maintenance to preserve cutting performance in demanding upholstery projects.

| Best For | Professional upholsterers, tailors, and crafters who regularly cut through thick fabrics like canvas, denim, leather, and heavy upholstery materials and need durable scissors with extended blade reach. |

|---|---|

| Blade Material | Galvanized manganese |

| Total Length | 8 inches |

| Weight | 8.1 ounces |

| Handle Design | Aluminum alloy non-slip |

| Primary Use | Tailoring and quilting |

| Color | Black |

| Additional Features |

|

- Ultra-sharp 8-inch galvanized manganese blades with 45° angle cut through multiple layers of dense fabric quickly and accurately

- Ergonomic aluminum alloy handle with non-slip grip reduces hand fatigue during extended cutting sessions

- Chamfered blade edges prevent accidental scratches on delicate fabrics during precision work

- Prone to rusting when exposed to moisture, requiring thorough drying and consistent maintenance after each use

- Finger holes may lack sufficient padding for maximum comfort during prolonged cutting tasks

- Heavier weight compared to standard scissors can cause fatigue during all-day professional use

4. High Carbon Steel Sewing Scissors

High Carbon Steel Sewing Scissors from Homlynn deliver edge retention and sharpness you won’t find in lower-grade alloys, featuring heat-treated blades reaching 60–62 HRC for professional sewing and upholstery applications.

The 9.84-inch steel composition combines rust resistance through protective oil coating with ergonomic handle design, reducing hand fatigue during extended cutting sessions on fabric, leather, and dense textiles.

You’ll maintain cutting performance through regular blade sharpening and proper care, though the handle ergonomics may require size selection based on your hand dimensions for ideal comfort during heavy-duty upholstery projects.

Many sewers invest in specialized fabric scissors for home use to ensure clean cuts across different materials without compromising blade longevity.

| Best For | Professional tailors, dressmakers, and upholsterers who need durable, sharp scissors for cutting heavy fabrics, leather, and upholstery materials throughout long workdays. |

|---|---|

| Blade Material | High-carbon steel |

| Total Length | 9.84 inches |

| Weight | 11.6 ounces |

| Handle Design | Ergonomic |

| Primary Use | Professional tailoring |

| Color | Black |

| Additional Features |

|

- High-carbon steel blades heat-treated to 60–62 HRC maintain sharpness longer than standard scissors, reducing how often you need to sharpen them

- Ergonomic handle design minimizes hand fatigue during extended cutting sessions, making them comfortable for professional and heavy-duty use

- Protective oil coating helps prevent rust and corrosion, extending blade life with minimal maintenance

- Not ideal for small, detailed cutting work due to the 9.84-inch size and blade design

- Handle size may not fit all hand sizes comfortably, so you’ll need to check dimensions before buying

- Requires regular sharpening and maintenance to keep the blade performing at its best

5. Professional Tailor Scissors

Professional tailor scissors bring precision-ground blades and ergonomic shears designed for detailed fabric cutting in upholstery and tailoring applications. They feature balanced weight distribution, hardened alloy steel construction for extended edge retention, and grips sized around 8 to 9 inches for controlled sewing techniques.

Keeping your fabric scissors for dressmaking sharp and well-maintained ensures they deliver clean cuts through delicate materials for years to come.

You’ll achieve clean cuts through fine fabrics with reduced hand fatigue during extended sessions, maintaining performance through regular scissor maintenance, including honing and proper storage. Screw-adjustable tension ensures consistent cutting action across professional sewing projects requiring accuracy and reliability.

| Best For | Professional tailors, upholsterers, and serious craft enthusiasts who need precision cutting through multiple fabric layers and dense materials during extended work sessions. |

|---|---|

| Blade Material | High carbon steel |

| Total Length | 9 inches |

| Weight | 7.2 ounces |

| Handle Design | Ergonomic rounded |

| Primary Use | Sewing and crafting |

| Color | Black |

| Additional Features |

|

- Precision-ground blades with hardened alloy steel deliver clean, accurate cuts through fine fabrics and heavyweight materials like canvas and leather without fraying or snagging

- Ergonomic bent-handle design and balanced weight distribution reduce hand fatigue and wrist strain during long trimming sessions while allowing stable tabletop cutting

- Screw-adjustable tension and durable construction maintain consistent cutting performance across professional projects with proper maintenance and care

- May require initial cleaning due to factory oil residue and some models show crude grinding marks or lower-quality finishes

- Handle sizing can feel tight for users with larger hands, potentially limiting comfort during extended use

- Not ideal for heavy-duty industrial applications or those seeking absolute top-tier professional equipment

6. Professional Fabric Sewing Scissors

You’ll find professional fabric sewing scissors equipped with high carbon steel blades reaching HRC 58–64 hardness, delivering blade sharpness that slices cleanly through multiple fabric layers without fraying edges.

These upholstery scissors feature ergonomic grips, often offset or bent to minimize wrist strain during extended cutting techniques, with blade lengths from 7 to 12 inches suited for fabric selection in professional scissors applications.

Reinforced pivot joints and thick blade stock support sewing shears performance, while protective sheaths maintain edge quality between sewing scissor selection tasks requiring precision fabric shears selection.

| Best For | Tailors, dressmakers, quilters, and crafters who need reliable scissors for cutting fabric, leather, and paper across long sewing or upholstery projects. |

|---|---|

| Blade Material | High carbon steel |

| Total Length | 10 inches |

| Weight | Not specified |

| Handle Design | Soft-grip ergonomic |

| Primary Use | Professional cutting |

| Color | Bk-10 |

| Additional Features |

|

- Ultra-sharp high carbon steel blades (HRC 58–64) cut cleanly through multiple fabric layers without fraying

- Ergonomic soft-grip handle reduces hand fatigue during extended cutting sessions

- Heavy-duty construction with reinforced joints ensures long-lasting performance for professional use

- Requires regular maintenance with oil to prevent rust since the blades aren’t stainless steel

- Right-handed design only, so left-handed users will find them awkward to use

- May arrive with oil on the blades that needs to be wiped off before first use

7. LIVINGO Professional Fabric Scissors

You’ll appreciate the LIVINGO Professional Fabric Scissors for upholstery fabric cutting with their 8.07-inch stainless steel blades featuring rust-resistant construction and mirror finish, maintaining blade sharpness through forged press manufacturing that produces high-density steel for consistent cutting techniques across multiple fabric layers.

The bent handle ergonomic design aids tabletop work in fabric selection and sewing scissor selection tasks.

However, regular scissor maintenance and proper fabric shears selection remain essential for peak upholstery scissors performance, with some users noting comfort limitations during extended professional scissors applications requiring precise upholstery fabric cutting control.

| Best For | Home sewers, quilters, and hobbyists who need reliable fabric scissors for upholstery projects, multi-layer cutting, and general crafting without breaking the bank. |

|---|---|

| Blade Material | Stainless steel |

| Total Length | 8.07 inches |

| Weight | 4.8 ounces |

| Handle Design | Standard |

| Primary Use | Sewing and tailoring |

| Color | Silver |

| Additional Features |

|

- Rust-resistant stainless steel blades with a mirror finish stay sharp longer thanks to the forged press manufacturing process

- 8-inch bent handle design makes tabletop cutting easier and works well for both left- and right-handed users

- Versatile enough to cut through thick materials like upholstery fabric, canvas, vinyl, and leather in multiple layers

- Some users experience hand discomfort or pain during extended cutting sessions due to limited ergonomic features

- Blades require regular sharpening and maintenance to keep peak performance, especially with heavy use

- Not ideal for precision work on delicate fabrics or professional-grade tasks requiring exact cuts

8. eZthings Heavy Duty Upholstery Shears

You’ll find the eZthings Heavy Duty Upholstery Shears deliver industrial textile cutting performance with their 12-inch hardened stainless steel blades, providing outstanding scissor sharpness for heavy materials like carpet, leather, and thick upholstery fabric cutting applications.

The bent handle ergonomics support tabletop cutting techniques, while blade durability benefits from nickel plating that resists corrosion during heavy duty cutting tasks.

However, the riveted construction between handle and blade affects long-term upholstery shears performance, and some users report reduced cutting efficiency with challenging fabric selection choices requiring sustained industrial-grade precision.

| Best For | Crafters, tailors, and upholstery professionals who regularly cut thick fabrics, leather, or carpet and need heavy-duty shears that can handle multiple layers at once. |

|---|---|

| Blade Material | High carbon steel |

| Total Length | 10.2 inches |

| Weight | 11.6 ounces |

| Handle Design | Rubberized ergonomic |

| Primary Use | Upholstery and sewing |

| Color | Black |

| Additional Features |

|

- 12-inch hardened stainless steel blades with nickel plating cut through dense materials like upholstery fabric, leather, and carpet backing with ease

- Bent handle design lets you cut comfortably on flat surfaces while keeping your hand elevated, reducing wrist strain during long sessions

- Balanced weight distribution and contoured grips make extended cutting tasks less tiring on your hands

- Riveted construction (rather than one-piece design) may loosen over time with heavy use, affecting durability

- Not designed for left-handed users, which limits accessibility

- Some users report the blades losing sharpness faster than expected, especially when cutting particularly tough materials

Key Features of Upholstery Fabric Scissors

You need scissors built to handle the toughest upholstery jobs without hesitation. Professional-grade upholstery scissors deliver cutting power through specific design features, material choices, and construction methods that separate them from standard fabric shears.

Understanding these key features helps you select tools that won’t fail when you’re working with heavy materials, multiple layers, or all-day cutting sessions.

Extra-Long Blade Length and Cutting Power

When you’re cutting upholstery foam or thick canvas, blade sharpness and cutting efficiency depend on length—7 to 12 inch upholstery scissors deliver the reach and cutting power you need for heavy materials. Extra-long blades provide key advantages for industrial textile cutting:

- Extended reach reduces repositioning on large fabric panels

- Straight, clean cuts through multiple layers without blade drift

- Enhanced scissor durability when paired with reinforced construction

- Efficient heavy-duty cutting on dense textiles like leather and denim.

For best results, consider the importance of methodological rigor in your cutting process.

Bent Handle Design for Tabletop Cutting

Your forearm stays relaxed, and your blade glides flat across the table—that’s the bent handle advantage. This angled grip reduces wrist deviation by 15 to 25 percent, positioning the blade shaft parallel to your work surface for stable, accurate cuts.

Ergonomic shears minimize muscle strain during extended sessions, so you’ll maintain cutting accuracy on dense upholstery fabrics without fatigue. To improve your cutting techniques, consider exploring language patterns for better understanding of complex designs.

| Feature | Ergonomic Benefits | Performance Impact |

|---|---|---|

| 25–30° Handle Angle | Natural hand position, reduced pronation | Enhanced wrist support during tabletop cutting |

| Blade Alignment | Shaft parallel to surface | Stable cuts across multiple fabric layers |

| Handle Materials | Comfortable grip contours | Sustained cutting accuracy on heavy-duty materials |

| Bent Trimmer Shears Design | Minimized forearm effort | Improved control with upholstery scissors |

| Ergonomic Shears Construction | Lower muscle fatigue | Consistent performance in heavy-duty cutting |

Hardened Stainless Steel Construction

Steel hardness between 53 and 60 HRC gives your upholstery scissors edge retention that lasts through dense canvas and synthetic blends.

Hardened stainless steel construction maintains corrosion resistance even in humid workshops, preventing rust buildup while you cut multiple fabric layers.

Blade sharpening intervals stretch longer because heat-treated alloys—like 440C—resist micro-chipping, delivering consistent cutting performance with durable materials that match heavy-duty demands.

Nickel-Plated Steel for Added Durability

Beyond hardness ratings, nickel-plated steel adds a protective layer that boosts corrosion resistance and rust prevention in damp workshop conditions.

You’ll find this metal plating reduces friction at the pivot, keeping blade sharpness consistent through repetitive heavy-duty cutting.

The durable materials stay cleaner and simpler to maintain, so your upholstery scissors deliver reliable stainless steel performance across dense textiles without frequent honing.

Multi-Layer Cutting Capability

When you stack layered fabric three to five layers deep, blade sharpness and rigidity become critical. Thicker blades over 1.2 mm resist bending through dense material thickness, while reinforced ground edges maintain precision across every ply.

Ergonomic grips reduce fatigue during heavy-duty cutting, and convex blade geometry minimizes fraying in upholstery scissors designed for industrial scissors and shears performance across heavy-duty sewing and fabric cutting techniques.

Choosing The Right Upholstery Scissors

Selecting the right upholstery scissors requires matching specific features to your cutting tasks, as the wrong tool can slow your work and damage expensive materials. You’ll need to evaluate blade length, construction materials, handle design, and intended use level to find scissors that deliver clean cuts through your fabrics.

The following considerations will help you choose scissors that meet your project demands and workspace requirements.

Blade Length Considerations (7″ to 12″)

Blade length directly impacts cutting efficiency and control. Your ideal scissor blades depend on project scale and fabric tension demands. For balanced performance across most upholstery tasks, consider these length guidelines:

- 7–8 inches – Precision work on small panels, tight curves, and multi-layer control

- 8 inches – All-purpose default for general upholstery scissors and heavy-duty cutting

- 9 inches – Faster traversal on medium-weight textiles without sacrificing maneuverability

- 10–11 inches – Bulk trimming of thick materials, requiring increased wrist stabilization

- 12 inches – Long, straight cuts across wide panels, best with bent-handle upholstery shears for tabletop support

Blade balance and scissor ergonomics improve as you match length to fabric thickness and cutting techniques.

Material Types and Their Benefits

Your choice of material cutting tools determines sharpness factors and rust resistance across daily textile cutting. Stainless steel alloys in fabric shears deliver corrosion protection for upholstery fabric work, while high-carbon steel upholstery shears maintain exceptional edge retention.

Titanium blade coatings reduce friction during repeated cuts, and chrome-plated options balance material durability with workshop-ready performance, ensuring your tools handle dense textiles reliably.

Handle Style and Ergonomic Comfort

When you’re powering through yards of upholstery fabric, ergonomic design separates comfortable tools from hand-cramping disasters. Bent-handle upholstery shears place your wrist in neutral posture during tabletop cuts, while soft-grip handle materials cushion pressure points across extended sessions.

Spring-assisted sewing scissors reopen automatically after each cut, slashing repetitive strain. Lightweight ergonomic hand tools with balanced weight distribution deliver fatigue reduction you’ll feel after hours at the cutting table.

Professional Vs. Heavy-Duty Vs. Industrial Use

Your cutting demands determine which tool tier delivers the best return. Professional cutting scissors maintain 60–65 HRC blade hardness for consistent edge retention during high-volume upholstery work, while heavy-duty cutting tools balance durability with affordability for home craftspeople.

- Professional use: Warranty-backed precision for daily fabrication cycles requiring exceptional cutting efficiency

- Heavy-duty sewing: Reinforced grips and blades up to 3mm thick for weekend upholstery projects

- Industrial sewing: Corrosion-resistant coatings, lifetime service plans, and ergonomic design for factory environments

- Material compatibility: Steel variants optimized for specific fabric densities affect blade durability and user safety across categories

Matching Scissors to Fabric Thickness

You’ll notice fabric thickness dictates blade selection more than any other factor. Heavy-duty cutting through canvas or denim demands blades ≥ 1.8 mm thick, while medium-weight vinyl works best with 1.5–1.7 mm fabric shears.

Material compatibility protects your investment—mismatched upholstery shear maintenance accelerates dulling. Test cutting techniques on fabric corners before committing to full passes, and proper scissor maintenance preserves edge performance across weaving and upholstery and furniture making projects.

Best Uses for Upholstery Fabric Scissors

Upholstery scissors deliver their best performance when you match them to the right cutting tasks, from heavy furniture fabrics to layered materials that demand precision and power. Understanding where these specialized tools excel helps you optimize their cutting capability and protect your investment in quality equipment.

The following applications represent the core uses where upholstery scissors outperform standard fabric shears, giving you the control and cutting force needed for professional-grade results.

Cutting Upholstery and Furniture Fabrics

You’ll encounter every challenge upholstery throws at you—dense canvas, layered velvet, and stubborn leather—so your fabric shears need serious cutting power. Proper fabric preparation and edge finishing start with the right heavy-duty cutting tools matched to material thickness.

- Canvas and duck cloth: Use 10-12″ hardened steel blades for straight, clean cuts across wide panels

- Velvet and boucle: Apply steady, tensioned cuts to prevent fiber lifting and snagging

- Leather upholstery: Select shears with reinforced, beveled edges to slice through without chipping

- Wool blends: High-carbon steel maintains sharpness through repeated cuts on dense weaves

- Multi-layer cutting techniques: Bent-handle designs keep fabric flat while you work through stacked materials

Drapery and Curtain Material Cutting

Drapery and curtain materials demand precision fabric cutting techniques that keep edges clean and patterns aligned. Always cut parallel to the grain, add 1/2 to 1 inch seam allowance for hem finishing, and use a straight edge to prevent waviness in your upholstery and drapery projects.

You’ll need fabric scissors with 10-12″ blades for long, straight runs across lightweight polyester blends and linen panels.

Carpet and Dense Textile Applications

When you tackle carpet cutting or bulky microfiber, you’ll need industrial scissors with hardened blades that resist dulling on dense fabric. Bent grips give you leverage for tabletop work, while 10-12″ nickel-plated blades slice through multiple layers without snagging.

For upholstery tools that handle textile tools demands, choose heavyweight shears with micro-serrated edges—blade sharpness determines clean cuts on dense piles.

Denim and Heavy-Duty Fabric Projects

Heavy-duty sewing on denim demands scissors built for fabric selection challenges—10-12 ounce weights resist blade deflection during textile cutting. For denim crafting and upholstery tools accuracy, reinforced stainless steel edges prevent fraying across grain lines.

Master these sewing techniques:

- Pin patterns securely to prevent shifting

- Start cuts from the top layer downward

- Maintain consistent blade pressure through all plies

- Clean lint buildup after each heavy-duty cutting session

- Test edge sharpness on scrap swatches first

Multiple Layer Cutting Techniques

When you’re stacking fabrics for upholstery or heavy-duty sewing projects, reduce blade load progressively to prevent snagging upper layers. For dense materials, use staggered cuts at varied cutting angles to minimize compression.

Check your blade sharpness every 2–3 passes—uniform seam allowances depend on edge alignment across all fabric thickness levels. Contrasting guide marks guarantee consistent depth, keeping long-lasting scissors performing through layered fabric and heavy-duty cutting.

Maintaining Your Upholstery Scissors

Your upholstery scissors are a serious investment, and proper maintenance keeps those blades cutting like new for years. Without regular care, even the toughest hardened steel will lose its edge, collect rust, or suffer premature wear from fabric lint and environmental damage.

Here’s how you’ll protect your cutting tools and maintain their precision through every project.

Cleaning and Preventing Rust Buildup

Keep your upholstery scissors performing at their peak by protecting those sharp blades from rust and corrosion. Regular blade maintenance ensures stainless steel scissors maintain maximum cutting power through proper humidity management and corrosion control.

- Wipe blades clean with a lint-free cloth after each use, then apply light mineral oil to cutting edges and pivot points.

- Control workshop humidity below 60% using dehumidifiers to minimize rust formation on metal surfaces.

- Inspect regularly for early rust spots, treating immediately with non-abrasive metal polish before reapplying protective oil coating.

Proper Storage With Protective Sheaths

Store your scissors in protective sheaths that shield blades from moisture and accidental contact, ensuring rust prevention and safe handling. Quality sheath materials with corrosion-resistant coatings maintain blade integrity, while handle guards protect cutting edges from environmental damage.

Choose storage solutions with belt clips or drawer organizers to keep your sewing tools accessible yet secure, and label each sheath to prevent misuse of specialized sewing accessories.

Regular Sharpening and Honing Techniques

Sharpen your blades every 6–12 months using a fine grit whetstone or dedicated honing stone, applying light mineral oil to reduce friction and heat buildup during edge refining. This honing frequency maintains cutting efficiency without altering blade geometry, ensuring your cutting instruments deliver precision through multiple upholstery projects.

Wipe blades dry after blade maintenance to prevent corrosion and preserve sharpness between scissor and shear maintenance sessions.

Avoiding Harsh Chemicals and Temperatures

To enhance chemical resistance and temperature regulation in your upholstery fabric cutting tools, you must shield blades from conditions that compromise rust prevention and corrosion protection during sewing and fabric cutting tasks.

Here are the key steps to follow:

- Skip chlorine-based cleaners on stainless steel sewing scissors reviews consistently highlight—they pit cutting edges and destroy blade maintenance efforts

- Keep temperatures below 140–F to prevent warping heat-treated components

- Apply pH-neutral lubricants exclusively for best corrosion protection

- Store away from direct sunlight and heat sources that degrade ergonomic hand tools

- Rinse blades after solvent or dye exposure, drying promptly for lasting rust prevention

Extending Blade Life in Humid Environments

Humidity above 60% accelerates rust on stainless steel blades, so you’ll need aggressive rust prevention to maintain sharpness. Wipe your ergonomic hand tools dry after fabric cutting, apply protective blade coatings, and use storage solutions with silica gel packs to control moisture.

Sewing scissors reviews confirm dehumidifiers and sealed containers deliver long-lasting scissors performance in coastal or damp workshops where sewing and fabric cutting happen daily.

Frequently Asked Questions (FAQs)

Can upholstery scissors cut leather and vinyl?

Standard upholstery scissors can handle vinyl effectively, but leather usually requires specialized shears with hardened steel blades.

For thicker hides beyond 5 mm, you’ll want dedicated leather cutting tools to prevent blade damage.

Whats the difference between bent and straight handles?

Bent grips keep blades flat on your work surface for smooth, long cuts and better visibility, while straight grips give you tighter control for precision trimming and curved seams.

Are left-handed upholstery scissors widely available?

You’ll find fewer left-handed upholstery scissors than right-handed models, but several manufacturers offer ambidextrous options and ergonomic designs with reversed cutting edges, giving left-handed sewers workable choices for their projects.

How often should I sharpen upholstery scissors?

You’ll want to sharpen your upholstery scissors every 6 to 12 months with regular use.

Daily cutting of dense fabrics demands sharpening every 3 to 6 months for peak edge retention and cutting efficiency.

Can I use upholstery scissors for paper cutting?

You shouldn’t use upholstery scissors for paper cutting. Paper dulls blades quickly, reducing cutting precision and blade durability.

Stick to crafting scissors for paper to preserve your fabric cutting shears and avoid potential fabric damage.

Conclusion

Think of your scissors as the foundation of every upholstery project—when that foundation crumbles, everything above it suffers.

Selecting the right fabric scissors for upholstery means matching blade length, material composition, and handle design to your specific cutting demands. Whether you’re working with leather, dense textiles, or multiple fabric layers, the right tool transforms challenging cuts into clean, controlled precision.

Your investment in quality scissors pays dividends through every project you complete.

- https://www.academia.edu/129757331/Ergonomic_investigation_of_bent_handle_fabric_scissors

- https://www.fiskars.com/en-us/special-feature/how-to-choose-scissors

- https://www.facebook.com/groups/tchibohomeaccessories/posts/747611762108675/

- https://madamsew.com/products/spring-scissors

- https://www.n-ccarpet.com/index.php?route=product%2Fproduct&product_id=891