This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Cotton typically shrinks 3-5%, while wool can reach 8-10% if untreated.

Linen averages 4-6% shrinkage.

In contrast, synthetic materials like polyester and nylon show minimal shrinkage at just 1-2%, thanks to their moisture-resistant properties.

Blended fabrics fall somewhere between, with cotton-polyester blends averaging 2-4% depending on the fiber ratio.

The key difference lies in fiber structure—natural fibers absorb water and swell, causing dimensional changes, while synthetics resist moisture absorption.

Understanding these fabric shrinkage rates comparison patterns helps you choose materials that won’t leave you swimming in oversized clothes or bursting out of shrunken garments after washing, which is a critical consideration for many consumers.

Table Of Contents

- Key Takeaways

- Defining Fabric Shrinkage Rates

- Key Factors Affecting Shrinkage

- Shrinkage Rates in Natural Fibers

- Shrinkage Rates in Synthetic Fibers

- Shrinkage in Regenerated and Blended Fabrics

- Comparing Shrinkage Test Methods

- Directional Shrinkage Patterns in Fabrics

- Techniques for Shrinkage Control

- Practical Implications for Fabric Users

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Natural fibers like cotton (3-5%) and wool (8-10%) shrink significantly more than synthetics due to their water-absorbing fiber structure, so you’ll need to account for this when selecting fabrics for projects that require dimensional stability.

- Synthetic materials including polyester and nylon only shrink 1-2% because they resist moisture absorption, making them your best choice when you need predictable sizing and minimal dimensional changes after washing.

- Cotton-polyester blends offer a middle ground with 2-4% shrinkage rates depending on fiber ratio, giving you better shrinkage control than pure cotton while maintaining some natural fiber benefits.

- Pre-shrinking treatments and mechanical compaction can reduce shrinkage to just 1% maximum, so you should look for treated fabrics or pre-wash untreated materials before cutting to avoid costly sizing disasters.

Defining Fabric Shrinkage Rates

Fabric shrinkage rates measure how much your fabric dimensions change after washing, typically calculated as a percentage of the original size.

You’ll need this data to predict garment fit and select appropriate materials for your sewing projects, utilizing complete concepts to ensure the best results.

Measuring Dimensional Changes After Washing

When measuring dimensional changes after washing, you’ll need precise fabric testing equipment to track shrinkage rates accurately.

Mark your fabric samples before laundering, then measure length and width changes using standard rulers or automated systems.

This dimensional change data reveals how different laundry methods affect fiber analysis results.

Proper fabric relaxation shrinkage measurement requires consistent testing conditions and careful documentation of your fabric density test outcomes.

Calculating Percentage of Size Reduction

Calculating fabric shrinkage percentages is straightforward using dimensional measurements before and after laundering. You’ll measure original length and width, then compare these to post-wash dimensions to determine percentage loss.

Standard shrinkage calculation methods include:

- Original dimension minus final dimension equals dimensional change

- Divide dimensional change by original measurement for decimal value

- Multiply result by 100 to get shrinkage percentage

- Test both length and width directions separately

- Record maximum shrinkage rate for fabric specifications

This fabric testing approach guarantees accurate size reduction data for dimensional stability assessments.

Impact on Garment Fit and Performance

When your fabric shrinks unexpectedly, it’s like watching a perfectly custom-made outfit transform into doll clothes.

Fabric shrinkage turns your custom wardrobe into miniature disappointment

Fabric shrinkage rates directly impact garment sizing and fit issues, causing sleeves to creep up and waistlines to tighten.

This dimensional instability affects textile performance, forcing you to compensate through strategic sewing techniques and garment shrinkage control methods to maintain proper fit.

Importance in Textile Selection

Understanding shrinkage rates helps you make smarter textile choices before diving into your next project.

Quality control starts with knowing how your fabric will behave after washing.

- Garment Durability: Pre-shrunk fabrics maintain better dimensional stability over time

- Fashion Design: Accurate shrinkage data prevents sizing disasters in final garments

- Material Selection: Comparing shrinkage rates guarantees proper fabric quality control for your specific application

Smart textile selection means factoring shrinkage into your design calculations from day one.

Key Factors Affecting Shrinkage

You’ll discover that four primary elements determine how much your fabric will shrink after washing.

These factors work together like a recipe – fiber type sets the foundation, weave structure controls the direction, yarn thickness amplifies the effect, and production processes can either lock in stability or leave room for surprises.

Fiber Composition and Properties

Your fabric’s fiber composition acts like its DNA, determining how much it’ll shrink when wet.

Natural fibers are water-loving troublemakers – cotton’s cellulose structure absorbs moisture enthusiastically, causing 4-10% shrinkage.

Synthetic fibers like polyester resist water absorption, keeping shrinkage rates lower at 4-8%.

Yarn properties and material science principles explain these differences perfectly.

Weave Structure and Fabric Density

Every weave type responds differently to moisture—plain weaves typically shrink less than complex structures like flannel.

Your fabric’s weave structure and fabric density directly influence dimensional stability patterns you’ll encounter.

- Fabric density affects directional shrinkage: Higher warp density increases lengthwise shrinkage, while greater weft density impacts width reduction

- Thread count correlates with fabric stability: Tighter weaves with higher thread counts generally demonstrate better dimensional stability than loose constructions

- Weave types show varying shrinkage patterns: Plain weaves shrink uniformly, while twills and satins may exhibit uneven dimensional changes

- Fabric structure determines shrinkage direction: Knitted fabrics shrink 4-8% due to loop mobility, while tightly woven materials typically shrink under 4%

Yarn Thickness and Twist

Thicker yarns hold more water between fibers, creating higher shrinkage rates compared to fine yarns.

You’ll find that yarn count directly impacts dimensional stability—coarse threads with loose fiber twist absorb moisture differently than tightly twisted, fine threads.

Thread count and yarn density work together: fabrics with heavy yarn weight show increased shrinkage percentages, while higher twist ratios provide better fiber stability and reduced movement during washing.

Understanding fabric weight factors is essential in predicting shrinkage rates and selecting suitable materials for sewing projects.

Production Processes and Finishing

Manufacturing techniques create internal stress that directly affects your fabric’s shrinkage potential.

Tension during weaving and chemical treatments lock fibers into unstable positions, making dimensional stability a key concern.

- Weaving tension stretches yarns beyond natural state, increasing shrinkage rates

- Dyeing methods subject fabrics to heat and moisture, promoting fiber relaxation

- Finishing treatments like calendering compress fibers, affecting fabric density

- Preshrinking processes mechanically compact materials to minimize future shrinkage

Understanding fabric shrinkage rates is essential for superior fabric performance.

Shrinkage Rates in Natural Fibers

Natural fibers present the most significant shrinkage challenges you’ll encounter when working with textiles.

Understanding how cotton, wool, linen, and silk behave after washing helps you make informed fabric choices and avoid costly sizing mistakes in your projects.

Cotton Shrinkage Range

Cotton fabric shrinkage varies dramatically depending on treatment and quality. Your garment’s fate hangs in the balance of these key factors.

Pre-shrunk cotton typically shrinks just 1-3%, while untreated varieties can lose up to 10% of their original size during that first wash cycle.

| Cotton Type | Shrinkage Rate | Post-Wash Impact |

|---|---|---|

| Pre-shrunk Commercial | 1-3% | Minimal size change |

| High-Quality Treated | 3-4% | Slight dimensional loss |

| Standard Untreated | 4-8% | Noticeable size reduction |

| Raw/Unprocessed | 8-10% | Significant shrinkage |

| Lightweight Untreated | Up to 10% | Dramatic size change |

Cotton Care becomes essential for Shrinkage Control success. Fabric Testing reveals cotton shrinkage rate patterns across different weaves and finishes. Cotton Blends typically perform better than pure cotton fabric, with polyester blends showing 3.5-5.5% textile shrinkage rates.

Fiber Analysis demonstrates that mercerized cotton maintains superior dimensional stability compared to standard varieties. Understanding cotton fabric shrinkage is essential to minimize loss and maintain garment size.

Wool Shrinkage Patterns

Pure wool shrinks dramatically—expect 8-10% fabric shrinkage rate after washing.

The felting process transforms wool fiber structure permanently, making shrinkage control critical.

Yarn thickness and fabric density amplify wool shrinkage patterns.

Unlike cotton’s predictable textile shrinkage, wool fabric characteristics create unpredictable dimensional changes.

Pre-treatment reduces but won’t eliminate this natural behavior, and it’s essential to understand the impact of felting process on wool fabric.

Linen and Silk Shrinkage Characteristics

Linen shrinkage rates typically range from 5-10%, though some fabrics reach 15% without proper treatment.

High-quality linen with careful silk finishing techniques shows better dimensional stability, shrinking only 3-4%. Yarn tension during production substantially affects fabric relaxation patterns.

Key linen care considerations:

- Pre-wash treatment – Reduces fabric shrinkage rate through controlled moisture exposure

- Heat sensitivity – Both linen and silk require gentle drying to maintain textile stability

- Weave density – Tighter fabric structure provides better dimensional control

- Blended compositions – Mixed fibers offer improved shrinkage resistance over pure materials

Shrinkage Rates in Synthetic Fibers

Synthetic fibers offer superior dimensional stability compared to natural materials, making them your best choice when shrinkage control matters most.

You’ll find polyester shrinking just 1-3%, while nylon and acrylic typically stay under 2%, thanks to their engineered molecular structure that resists water absorption and maintains shape retention.

Polyester and Nylon Shrinkage

Beyond their reputation for durability, synthetic fibers like polyester and nylon deliver impressive dimensional stability.

Polyester shrinkage typically stays below 2%, while nylon fabric shrinks 1-3% during standard washing.

These synthetic blends resist moisture absorption, making them ideal for performance wear.

Heat-setting treatments further reduce shrinkage rates, with proper fabric treatment keeping dimensional changes under 1.5% in controlled textile science applications.

Acrylic and Other Synthetics

Among synthetic fibers, acrylic typically shrinks 2-4%, making it more stable than cotton but less predictable than polyester.

You’ll find acrylic’s shrinkage varies substantially based on yarn properties and fabric structure.

Textile science shows that acrylic care requires gentle handling since heat can cause permanent dimensional changes.

Fabric blends containing acrylic often demonstrate improved dimensional stability compared to pure natural materials, which highlights the importance of dimensional stability.

Heat Resistance and Dimensional Stability

Synthetic fibers excel in thermal insulation and heat resistance compared to natural materials.

You’ll find polyester maintains dimensional stability up to 200°C, while nylon resists heat treatment without significant dimensional change.

Stability testing reveals synthetic fabrics achieve shrinkage rates below 2% after heat exposure.

This superior heat resistance makes synthetics ideal for applications requiring fabric durability under extreme temperatures, as textile science research consistently demonstrates.

Shrinkage in Regenerated and Blended Fabrics

Regenerated and blended fabrics present unique shrinkage challenges that you’ll need to understand for successful sewing projects.

Viscose can shrink up to 13% due to its high moisture absorption, while cotton-polyester blends typically shrink 3.5% to 5.5% depending on their fiber ratio.

Viscose, Modal, and Lyocell Shrinkage

Regenerated fibers occupy a unique position between natural and synthetic materials regarding fabric shrinkage behavior. Viscose demonstrates the highest shrinkage rates among this fiber family, typically ranging from 2% to 8% after washing.

Modal exhibits superior dimensional stability with shrinkage rates of 1% to 3%, while lyocell performs best with minimal shrinkage under 2%. Understanding fabric shrink rates is essential for choosing the right materials.

- Viscose’s amorphous structure makes it most vulnerable to dimensional changes during laundering

- Modal’s stronger hydrogen bonding reduces fiber movement and associated shrinkage patterns

- Lyocell’s stable crystalline structure provides exceptional dimensional stability compared to other regenerated fibers

- Laboratory tests using AATCC 135 protocol confirm lyocell’s superior performance under wet conditions

- Pre-finishing treatments like sanforization can reduce shrinkage rates across all three fiber types

Cotton-Polyester and Other Blends

Cotton-polyester blends revolutionize fabric shrinkage through strategic fiber mixing.

You’ll find these textile hybrids shrink just 3.5% to 5.5%, substantially less than pure cotton’s 4-10% range.

The polyester component acts like an anchor, providing dimensional stability while cotton offers comfort.

Material science shows blended fabrics balance performance and wearability, making cotton polyester blends ideal for everyday garments requiring predictable shrinkage rates.

Performance of Specialty Fabrics

Smart materials and high-tech fabrics revolutionize dimensional stability through textile innovation.

Nano fibers enhance fabric durability while maintaining low shrinkage rates. Memory foam textiles exhibit 1-2% shrinkage, while moisture-wicking synthetics stay below 3%.

Performance fabrics combine synthetic fibers with specialized treatments, delivering superior fabric performance. These advanced materials resist shrinkage better than traditional textiles, making them ideal for technical applications.

Comparing Shrinkage Test Methods

When you’re testing fabric shrinkage, you’ll encounter two main approaches: wet processing tests that simulate real washing conditions and dry heat tests that measure thermal dimensional changes.

Automated shrinkage measurement systems now provide precise data collection, replacing manual methods and reducing human error in calculating percentage changes across warp and weft directions.

Wet Processing and Dry Heat Tests

You’ll encounter two primary shrinkage testing methods when evaluating fabric performance.

Wet processing tests measure how fabrics react to moisture effects through washing cycles, while dry heat tests assess thermal shrinkage during drying methods.

These complementary approaches reveal different aspects of fabric relaxation and shrinkage control, helping you predict real-world behavior and choose appropriate heat resistance levels for your projects.

Understanding fabric shrinkage rates is essential for selecting the right materials.

Automated Shrinkage Measurement

Modern textile labs have moved beyond manual measurements to embrace automated shrinkage measurement systems.

These sophisticated setups use fabric sensors and machine learning algorithms to track dimensional changes with unprecedented precision.

Here’s what automated testing brings to your fabric analysis:

- Real-time monitoring – Fabric sensors continuously measure length and width changes during wash cycles, providing instant shrinkage rate data

- Predictive modeling – Machine learning algorithms analyze historical shrinkage patterns to forecast fabric dimensional stability before production

- Standardized precision – Automated testing eliminates human error in textile shrinkage tests, delivering consistent results across multiple samples

These systems transform how you’ll understand fabric behavior, making shrinkage modeling more reliable than traditional methods.

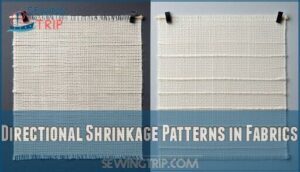

Directional Shrinkage Patterns in Fabrics

Fabric shrinkage doesn’t occur uniformly in all directions, and understanding these patterns helps you predict how your finished garments will behave after washing.

The warp and weft directions often shrink at different rates, while knitted fabrics present their own unique dimensional challenges that require careful consideration during pattern layout and construction.

Warp Vs. Weft Shrinkage Differences

You’ll notice fabric shrinkage varies dramatically between warp and weft directions.

Weft shrinkage typically exceeds warp shrinkage due to lower weaving tension during production.

While warp threads face higher fabric tension, creating stability, weft yarns remain more flexible, and this yarn elasticity difference means weft shrinkage rates can reach 61%, while warp stays below half that figure.

Your fabric’s weave patterns and fiber orientation directly influence these shrinkage direction variations.

Bias and Stretch Fabric Considerations

When you cut fabric on the bias, you’re working at a 45-degree angle to the grain lines, creating natural stretch and drape.

This diagonal cutting technique affects fabric stability substantially, as bias-cut pieces exhibit different shrinkage patterns compared to straight-grain cuts.

- Fabric Bias cutting increases stretch factors by 30-50% compared to straight grain

- Grain Lines determine shrinkage direction – bias cuts distribute tension evenly

- Cutting Techniques on bias require extra seam allowances for fabric relaxation

- Fabric Tension varies between woven fabrics and knitted fabrics when cut diagonally

- Fabric Stability decreases on bias, making pre-washing essential before construction

Dimensional Stability in Knits

Knit fabrics present unique dimensional stability challenges due to their loop structure.

Knit Fabric Behavior differs from woven textiles, with shrinkage rates typically reaching 4-8%.

Yarn Elasticity and Fiber Blending affect how loops contract during washing.

Textile Relaxation occurs as stretched yarns return to their natural state.

Stretch Recovery varies by fiber type, impacting overall fabric shrinkage and dimensional stability in finished garments.

Techniques for Shrinkage Control

You can prevent fabric shrinkage through several industrial and home treatment methods. Pre-shrinking, chemical stabilization, and heat-setting processes reduce dimensional changes by up to 85% compared to untreated fabrics.

Pre-shrinking and Mechanical Compaction

Pre-shrinking and Mechanical Compaction eliminate fabric shrinkage before garment construction.

These Pre Treatment methods control dimensional stability through controlled moisture and pressure. Mechanical Finishing processes compress fibers permanently, reducing post-wash movement. Compaction Methods achieve consistent Shrinkage Control across production batches.

5 Key Mechanical Compaction Techniques:

- Sanforization – Steam and pressure rollers compress cotton fabrics to 1% shrinkage maximum

- Compressive shrinkage – Heated blankets force controlled Fabric Relaxation under tension

- Palmer method – Moist heat treatment followed by mechanical compression cycles

- London shrinking – Wet fabric pressed between heated metal plates repeatedly

- Decatizing – Steam pressure treatment that sets wool fibers permanently in position

These preshrinking processes prevent the 4-10% shrinkage rates typical in untreated cotton. Mechanical compaction works by forcing fibers into their natural relaxed state before consumer use, basically "pre-shrinking" the material through controlled industrial processes.

The use of Sanforization machines is vital for achieving consistent results in textile manufacturing.

Chemical Stabilization Methods

Beyond mechanical compaction, chemical treatments offer another pathway to control fabric shrinkage.

Resin Treatments and Crosslinking Agents create permanent bonds between fibers, reducing dimensional changes during washing. Formaldehyde Alternatives like DMDHEU provide safer crosslinking options.

Enzyme Applications modify fiber surfaces, while Nanotechnology Finishes create protective barriers that minimize shrinkage rates effectively.

To explore options for resin fabric finishing, various suppliers offer specialized products.

| Treatment Type | Shrinkage Reduction | Durability Rating |

|---|---|---|

| Resin Finishing | 70-85% reduction | Excellent |

| Enzyme Processing | 40-60% reduction | Good |

| Nano Coatings | 60-75% reduction | Very Good |

| Crosslinking Agents | 80-90% reduction | Excellent |

Heat-setting and Sanforization

Heat-setting benefits synthetic fabrics by achieving shrinkage reduction below 2% through controlled temperature and tension.

The sanforization process mechanically pre-shrinks cotton fabrics, delivering dimensional stability with residual shrinkage under 1-5%.

To further prevent issues, consider gentle detergent options.

These fabric finishing techniques provide dimensional control, transforming unruly textiles into predictable materials that maintain their shape through countless wash cycles.

Practical Implications for Fabric Users

Understanding fabric shrinkage rates helps you make informed decisions about textile purchases and care routines.

You’ll save money and avoid frustration when you factor shrinkage into your project planning and garment sizing choices, which is crucial for making the right decisions.

Care Labels and Shrinkage Prevention

Why decipher care labels like ancient hieroglyphs when they’re your roadmap to fabric longevity?

Label interpretation reveals washing techniques, drying methods, and ironing impact limits.

Follow these fabric care tips religiously—cold water reduces shrinkage rates substantially, air-drying prevents heat damage, and proper storage solutions maintain dimensional stability.

Smart fabric washing and shrinkage prevention start with understanding those tiny symbols.

Sizing and Fit Considerations

When selecting fabric for your project, you’ll want to account for potential size changes during fabric washing.

Smart sewers build shrinkage allowances into their calculations before cutting:

- Pattern Alterations – Add 2-3% extra length to pattern pieces for cotton fabrics

- Garment Ease – Include additional wearing ease to compensate for dimensional stability issues

- Body Measurements – Cross-reference size charts with expected shrinkage rates when determining fabric requirements

Economic Impact of Fabric Shrinkage

Fabric shrinkage hits your wallet hard through multiple channels. Consumer Costs spike when you replace shrunken garments, while manufacturers absorb 5-7% higher production expenses.

Fabric shrinkage turns your perfect fit into an expensive mistake—spare yourself the heartache and plan ahead

Retail Losses from returns damage profits, and Production Waste forces companies to buy extra fabric—costs ultimately passed to you.

| Cost Category | Impact Range | Your Reality |

|---|---|---|

| Consumer Replacement | $20-200 per item | Shrunken favorites = shopping trips |

| Manufacturing Overhead | 3-7% fabric increase | Higher retail prices |

| Return Processing | 15-25% profit loss | Fewer sales, higher costs |

Industry Standards requiring strict shrinkage rates below 3% drive up testing costs, affecting final prices you pay.

Tips for Minimizing Shrinkage at Home

Properly caring for your fabrics at home substantially reduces unwanted fabric shrinkage. Smart fabric care starts with understanding your materials and following proven techniques that preserve dimensional stability.

You can also find a suitable mild detergent for washing.

- Gentle Washing: Use cold water and delicate cycles to minimize fiber stress

- Pre-Washing: Test new fabrics separately before incorporating into projects

- Air Drying: Skip the heat and hang fabrics naturally for best results

- Cool Ironing: Apply low temperatures to prevent heat-induced shrinkage

- Fabric Softeners: Use sparingly as they can affect fabric structure

Frequently Asked Questions (FAQs)

What is fabric shrinkage rate?

Shrinkage rate measures how much your fabric contracts after washing, expressed as a percentage of its original size.

You’ll see cotton shrink 3-10%, while synthetics typically shrink 4-8%, depending on fiber type and weave density.

Why do different fabrics have different shrinkage rates?

Don’t think fiber type alone determines shrinkage—it’s actually about water absorption and structural stability.

Natural fibers absorb more moisture, causing greater swelling and contraction, while synthetic fibers resist water absorption and maintain dimensional stability.

What is shrinkage rate?

You’re looking at the percentage reduction in fabric dimensions after washing or treatment. It’s calculated by comparing original size to post-laundering size, typically ranging from 3-15% depending on fiber type.

Can fabric shrink?

Like Cinderella’s gown at midnight, fabrics transform when water meets fiber.

You’ll see cotton shrink 3-10%, wool 8-10%, and viscose up to 13% after washing, depending on fiber composition and treatment methods.

How does the finishing process impact shrinkage?

Finishing processes directly control your fabric’s final shrinkage rate. Pre-shrinking treatments, tension adjustments during dyeing, and mechanical finishing can reduce post-laundering shrinkage to just 1-3% for most treated fabrics.

How does density affect shrinkage rates?

Higher fabric density creates tighter yarn spacing, which increases shrinkage potential.

Dense weaves trap more tension during production, and when you wash them, fibers release this stress, causing greater dimensional change than looser constructions, due to the increased tension.

Whats the typical shrinkage rate for synthetics?

Synthetic fibers typically shrink 4% to 8% after washing. You’ll find they’re more dimensionally stable than natural fibers, making them reliable choices for garments requiring consistent sizing and shape retention.

Why test for shrinkage?

Don’t let shrinkage catch you off-guard—testing prevents costly mistakes. You’ll avoid dimensional disasters, confirm proper fit, and calculate pre-washing requirements. Testing protects your investment and guarantees professional results.

What causes uneven shrinkage across fabric?

Uneven shrinkage happens when you’ve got inconsistent fiber tension, varying weave density, or mixed fiber content across the fabric. Different areas absorb moisture unevenly, creating that frustrating puckered effect.

How does water temperature affect shrinkage?

Water temperature directly impacts shrinkage rates—hot water causes fibers to swell more than cold water, increasing dimensional changes.

You’ll see cotton shrink up to 10% in boiling water versus 3-4% in cool temperatures.

Conclusion

Like traversing a textile minefield, understanding fabric shrinkage rates comparison empowers you to make smarter purchasing decisions.

Natural fibers demand respect—cotton’s 3-5% shrinkage and wool’s potential 8-10% can transform your favorite shirt into doll clothes.

Synthetics offer predictable 1-2% shrinkage, while blends split the difference.

Armed with this knowledge, you’ll pre-shrink when necessary, choose appropriate sizes, and select fabrics that maintain their dimensions through countless wash cycles, saving money and wardrobe disasters.

- https://www.oxfordfabric.net/news/what-is-the-shrinkage-rate-of-textile-fabrics.html

- https://fashinza.com/fabric/fabric-types/textile-fabrics-and-how-they-may-shrink-while-processing/

- https://www.ageberry.com/do-cotton-polyester-fabrics-shrink/

- https://www.sciencedirect.com/science/article/pii/S209012321930013X

- https://medcraveonline.com/JTEFT/investigation-of-the-change-of-the-shrinkage-properties-in-contradiction-to-the-change-of-the-composition-of-cotton-polyester-spandex-denim-fabrics.html