This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

When you wonder how do sewing machines work, picture a carefully choreographed dance.

When you wonder how do sewing machines work, picture a carefully choreographed dance.

Your machine’s needle pierces fabric from above while a rotating hook below catches the upper thread, forming a loop.

The bobbin mechanism feeds bottom thread through this loop, creating an interlocking stitch that’s surprisingly strong.

Feed dogs grip your fabric with tiny teeth, moving it forward in perfect timing with each needle stroke.

It’s like watching gears in a clock—every component moves in harmony.

The motor powers a series of cams and cranks that coordinate these movements with split-second precision.

Understanding each mechanism reveals secrets that’ll transform your sewing experience.

Table Of Contents

Key Takeaways

- You’ll understand that sewing machines create strong stitches through a coordinated dance between the needle above and bobbin below—the needle thread forms a loop that the shuttle hook catches and wraps around the bobbin thread to create interlocking lock stitches.

- You can see how the motor powers a crankshaft that converts rotary motion into precise up-and-down needle movement, while gears and cams synchronize all components including the feed dogs that grip and advance your fabric with perfect timing.

- You’ll appreciate that feed dogs are the unsung heroes of fabric movement—these tiny toothed metal pieces work in sync with the needle and bobbin to grip and advance fabric precisely, ensuring each stitch lands exactly where it should.

- You can troubleshoot and make adjustments more effectively once you grasp these core principles, whether you’re using a basic mechanical machine or a computerized model—the fundamental mechanisms of needle movement, thread interlocking, and fabric advancement remain unchanged.

Sewing Machine Basics

You’ve probably seen sewing machines in action, but understanding their basics can make using one less intimidating.

These machines work by combining a needle, bobbin, and feed dog to create precise stitches, turning fabric into finished pieces with remarkable efficiency.

Types of Sewing Machines

Starting with sewing machine types? Mechanical variety is perfect for beginners, offering simplicity and reliability.

For precision and creativity, explore advanced models like computerized options with programmable stitches. Tackling tough fabrics? Heavy-duty machines are your go-to.

Industrial machines excel at specialized uses, handling high-speed, continuous tasks in textile machinery. Domestic sewing shines with versatility for home projects.

These machines are available for mechanical sewing needs. Choosing the right sewing machine guarantees smoother stitching—so pick wisely for your next masterpiece!

Essential Vs Specialized Machines

Choosing between Beginner Machines and specialized ones depends on your needs.

Beginner options handle Home Sewing with ease, offering:

- Basic features: Perfect for learning machine operation and simple tasks.

- Advanced features: Great for quilting or projects needing precision.

- Cost-effectiveness: Affordable compared to machines for Industrial Applications.

Specialized machines, like Quilting Machines, excel at thick fabrics or intricate stitch formation, but they’re pricier.

Key Components of a Sewing Machine

A sewing machine’s magic lies in its clever components working together.

The presser foot—available in various styles—holds your fabric steady, letting the feed dog, often made of durable materials, glide it forward smoothly.

Beneath, the needle plate guarantees stitching precision, while the bobbin system—powered by efficient shuttle designs—delivers thread flawlessly.

The bobbin winder, perched on top, spins thread effortlessly.

Each part, from the motor types driving the needle mechanism to the feed dog’s rhythm, guarantees seamless stitching with every project.

The Sewing Machine Working Principle

You mightn’t realize it, but a sewing machine’s magic lies in its precise coordination of moving parts.

From the needle’s up-and-down motion to the bobbin’s thread loop, every mechanism works in perfect harmony to create strong, even stitches.

Manual Vs Electric Machines

Manual machines rely on your energy, offering portability and a simple sewing machine mechanism.

They’re reliable, but stitch consistency depends on your rhythm.

Electric machines, powered by an electric motor, bring speed control and a smoother user experience.

While manual machines charm with their independence from a power source, electric machines excel in efficiency, making sewing faster and less tiring.

How Power Moves Gears and Cams

Power flows from the motor to gears, cams, and levers, creating seamless motion.

Timing belts and a camshaft function like a choreographed routine, converting rotary energy into precise, linear movements.

Gears and cams work in sync, driving the needle and feed dog with perfect timing.

This efficient power distribution guarantees every stitch is consistent, making your sewing machine a marvel of engineering ingenuity.

The Role of The Handwheel and Treadle

The handwheel function lets you manually control the needle’s movement, perfect for precision tasks like starting stitches or turning corners.

Paired with the treadle, which powers older sewing machines through foot motion, it highlights the historical significance of early sewing machine operation.

Together, they offered speed regulation and a hands-on feel, making the sewing machine mechanism both practical and user-friendly.

Sewing Machine Operation

You’ll need to set up the sewing machine properly to get it running smoothly, starting with threading the needle and winding the bobbin.

Once everything’s in place, installing the needle and beginning your project becomes a straightforward and satisfying process.

Setting Up The Machine

Creating the perfect sewing machine setup starts with Workspace Ergonomics—ensure your table’s height feels comfortable.

Choose the right sewing machine needle and thread types for your project.

Insert the needle securely, then check thread tension for smooth stitching.

Threading The Needle and Winding The Bobbin

Threading the needle and winding the bobbin can feel tricky, but it’s simple with practice.

Follow needle threading steps carefully, ensuring the thread flows smoothly through the guides.

For bobbin winding, use the spool pin and tension disc to maintain thread tension balance.

Choose the right thread type—too thick or thin causes issues—and troubleshoot any uneven winding.

Some users find it easier to use specialized threading devices for assistance.

Installing The Needle and Starting a Project

Installing a sewing machine needle is surprisingly simple but vital for smooth stitching. Always insert it flat-side back, tightening the wingnut securely.

Choose the right needle for your fabric selection—it’s a game-changer! Once threaded, test stitch on scrap material to check alignment. Proper sewing requires specialized needle types for different materials.

Ready? Let your project planning guide you as the sewing machine hums to life.

- Needle Insertion: Flat side faces the correct direction.

- Fabric Selection: Match the needle type to fabric.

- Threading Machine: Make certain the needle thread flows smoothly.

- Test Stitch: Check tension and alignment.

- Project Planning: Organize steps before starting.

Needle Mechanism and Movement

You’ve probably noticed how the needle moves up and down with perfect rhythm, but there’s a lot happening behind the scenes to make that possible.

Powered by a crankshaft, the needle’s motion is carefully synchronized with other parts to guarantee smooth and precise stitching.

The Shaft and Wheel

Think of the shaft and wheel as your sewing machine’s heartbeat.

The shaft materials affect durability, while the wheel diameter influences torque transmission and speed regulation.

Keep the mechanical system well-oiled for smooth operation.

Here’s a quick guide:

| Component | Function | Tip |

|---|---|---|

| Shaft | Transfers motion | Use high-quality lubrication. |

| Wheel | Regulates speed | Check for wear regularly. |

| Handwheel | Manual control | Turn gently to avoid strain. |

| Bearings | Reduce friction | Clean and oil periodically. |

| Screws | Hold parts together | Tighten if loosening occurs. |

Smooth shafts, sturdy wheels—efficiency guaranteed!

The Crankshaft and Needle Movement

Picture the crankshaft as the heart of your sewing machine, tirelessly converting motor rotation into precise up-and-down needle motion.

This Crankshaft Function guarantees smooth Needle Synchronization with other sewing machine mechanisms, like the feed dogs, for Movement Precision.

As the crankshaft powers the needle, it drives the needle thread through fabric layers, creating flawless stitches.

Whether your needle’s crafted from steel or specialized Needle Materials, this motion keeps your sewing efficient and consistent.

It’s like a perfectly choreographed dance—motor conversion fuels the crankshaft, and the crankshaft guarantees every stitch lands exactly where it should, making sewing feel almost effortless.

Synchronization With The Bobbin Mechanism

As the crankshaft drives the needle’s motion, perfect timing adjustments guarantee the bobbin and shuttle align seamlessly.

When the needle thread loops, the shuttle hook grabs it, wrapping it around the bobbin thread.

This synchronization, paired with proper tension balance, guarantees stitch quality. Without it, your lock stitch would unravel faster than a distracted feed dog chasing a squirrel, highlighting the importance of perfect timing.

Bobbin and Shuttle Mechanism

You’ve probably wondered how the bottom thread gets pulled into the stitching process—this is where the bobbin and shuttle mechanism shines.

It uses precise timing and a rotating hook to catch the needle thread, creating a secure lock stitch every time.

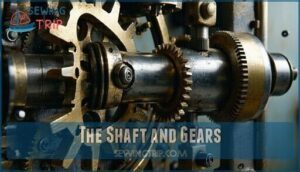

The Shaft and Gears

Underneath the sewing machine’s hum lies the magic of shafts and gears, driving its precision.

- Gear Ratios: Fine-tune speed and torque transmission.

- Shaft Materials: Durable metals guarantee mechanical efficiency.

- Lubrication Systems: Keep gears spinning smoothly, like a well-oiled clock.

- Alignment: Misaligned shafts? Say goodbye to flawless stitching!

Treat these parts well—they’re the backbone of your machine’s reliability.

The Hook and Loop Creation

The shuttle hook timing is key to loop formation.

As the needle pierces fabric, it pulls the needle thread, creating a loop.

The hook swiftly grabs this loop, wrapping it around the bobbin thread.

This precise dance of threads forms the lock stitch, a hallmark of modern stitching.

Innovations in hook design guarantee smoother stitch formation and fewer loop formation issues.

The Shuttle and Bobbin Housing

The shuttle and bobbin housing keep your sewing machine humming smoothly.

Proper bobbin tension guarantees even stitches—adjust the tiny screw on the bobbin case carefully. Different shuttle types and housing materials suit various machines, so know yours.

Bobbin winding prepares thread for flawless stitching, while a clean case prevents snags and jams.

- Check bobbin tension regularly

- Match housing materials to your machine

- Wind bobbins evenly

- Inspect the shuttle hook for wear

- Keep housing clean for smooth operation

Feed-Dog Mechanism and Stitch Formation

You’ve probably noticed those tiny, toothed metal pieces under the presser foot—they’re called feed dogs, and they’re the unsung heroes of fabric movement.

Working in sync with the needle and bobbin, they grip and advance the fabric precisely, ensuring each stitch lands exactly where it should, making them crucial for fabric movement.

The Lever and Crank

The lever and crank in your sewing machine are like a synchronized team, converting rotary motion into precise fabric movement.

These parts guarantee the feed-dog mechanism advances fabric smoothly, adjusting stitch length with ease.

By leveraging mechanical advantage, they boost efficiency, whether you’re using a mechanical sewing machine or exploring free-motion techniques.

Crankshaft function keeps everything running seamlessly, stitch after stitch, with a focus on precise fabric movement.

Synchronization With The Needle and Bobbin

To create a flawless lock stitch, timing precision is everything.

The needle and bobbin must work like dance partners—perfectly synchronized.

As the needle pierces the fabric, the shuttle grabs the thread loop, wrapping it around the bobbin thread.

Proper thread tension and needle alignment guarantee stitch consistency.

Without this harmony, your sewing machine’s magic would unravel.

Adjusting Stitch Length and Free-Motion Sewing

Free-motion sewing lets you express creativity by ditching feed dog control.

- Drop the feed dogs and use free-motion feet for better visibility and fabric feed control.

- Balance your sewing machine speed with hand movement for consistent stitch length—ideal for quilting applications or darning techniques.

- Practice on scrap fabric to fine-tune stitch length control and explore new designs effortlessly, which helps to master free-motion sewing.

The Lock Stitch and Sewing Process

You’ve probably heard of the lock stitch, but did you know it’s the backbone of most sewing machines.

By interlocking two threads—one from the needle and one from the bobbin—it creates durable, precise stitches that hold your fabric together seamlessly, which is the key to understanding how the lock stitch works in sewing.

The Top and Bottom Threads

Getting the top and bottom threads to cooperate is essential for perfect stitch formation.

The top thread follows a precise thread path, while the bobbin thread waits below.

Proper thread tension guarantees smooth lock stitch formation—too tight, and you risk thread breaks; too loose, and stitch quality suffers.

Mastering this balance is like tuning an instrument—tricky at first, but it makes the sewing process seamless and requires understanding of thread tension.

The Loop and Hook Mechanism

Your sewing machine’s loop-and-hook dance creates perfect stitches through precise coordination.

The shuttle hook catches your needle thread loop at exactly the right moment, while proper bobbin thread tension guarantees smooth operation.

Here’s how this mechanism works:

- Shuttle Hook Timing synchronizes with needle movement for consistent catches

- Loop Size Control prevents thread bunching and skipped stitches

- Hook Material Impact affects durability and stitch quality

- Bobbin Thread Tension balances top and bottom threads perfectly

The Lock Stitch Formation and Strength

Why does the lock stitch dominate sewing? It’s all about thread tension balance creating unbreakable bonds.

Here’s how lock stitch formation works:

- Stitch Tension: Perfect balance between needle and bobbin threads prevents puckering.

- Thread Types: Cotton, polyester, and silk each affect seam durability differently.

- Fabric Impact: Thick materials need adjusted tension for proper lockstitch variations.

- Seam Durability: Proper sewing machine stitching process creates lasting connections.

Frequently Asked Questions (FAQs)

How did the sewing machine work simple?

Coincidentally, like your morning routine, you’ll find sewing machines follow simple steps. You guide fabric while the needle moves up-down, catching thread from below to create locked stitches automatically.

Why do sewing machines need two threads?

Two threads create a lockstitch that won’t unravel.

Your needle thread from above catches the bobbin thread below, wrapping around it to form interlocked stitches that hold fabric pieces securely together.

What is the mechanism of a sewing machine?

Your machine’s crankshaft converts the motor’s rotary motion into the needle’s up-and-down movement. Meanwhile, gears drive the shuttle faster than the needle, while cams control the feed-dog’s synchronized fabric advancement.

What is a good sewing machine for a beginner?

You’ll want a mechanical sewing machine as your first choice.

They’re simple, reliable, and don’t overwhelm beginners with fancy features.

Basic models offer essential stitches while you’re learning the fundamentals of sewing.

How to operate a basic sewing machine?

Thread your needle and load the bobbin first.

Place fabric under the presser foot, lower it down, then gently press the foot pedal.

Guide fabric straight while the machine stitches automatically.

What are some tips for using a sewing machine?

Start with proper tension settings and quality thread.

Keep your machine clean and oiled regularly.

Practice on fabric scraps first, and use the right needle for your fabric type.

Don’t rush—steady speed produces better stitches.

How do you thread a sewing machine?

First, you’ll wind thread onto the bobbin and insert it into the machine’s lower compartment.

Next, pull the upper thread through guides, tension discs, and the needle’s eye, following your machine’s numbered threading path diagram.

How does a sewing machine work step by step?

Your machine’s needle dances down through fabric, catching bobbin thread below.

The shuttle hook grabs this loop, wrapping threads together while feed dogs nudge fabric forward, creating perfect lockstitches with each rhythmic cycle, utilizing the shuttle hook.

How does a sewing machine sew clothes explain?

Your sewing machine creates clothes by interlocking two threads—one from the needle above, one from the bobbin below.

As you guide fabric through, the needle pierces, hooks catch loops, forming lockstitches that join pieces together.

How do mechanical sewing machines work?

You operate a mechanical sewing machine using manual controls and mechanical components.

The crankshaft converts your motor’s rotation into needle movement, while gears synchronize the bobbin shuttle and feed-dog mechanisms for consistent stitching, utilizing the crankshaft to achieve this functionality.

Conclusion

Despite seeming complex at first glance, understanding how do sewing machines work isn’t rocket science.

You’ve discovered that synchronized mechanisms create those perfect stitches—needle bars, bobbins, and feed dogs working together like clockwork.

Your machine transforms simple up-and-down needle movement into interlocking thread loops through precise timing.

Whether you’re using a basic straight-stitch model or computerized embroidery machine, these core principles remain unchanged.

Now you can troubleshoot problems, make adjustments, and appreciate the engineering marvel sitting on your sewing table.