This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A single embroidery machine can execute 1,000 stitches per minute with positional accuracy measured in tenths of a millimeter, transforming a flat piece of fabric into dimensional artwork through controlled needle penetration and thread manipulation. This precision stems from the synchronized operation of mechanical components—needle bars, rotary hooks, tensioning discs—and digital control systems that interpret vectorized design files.

Understanding how an embroidery machine works reveals the engineering behind automated textile decoration, from the servo motors that govern XY-axis hoop movement to the optical sensors that detect thread breaks mid-cycle.

The process combines material science principles with programmable motion control, allowing you to reproduce identical designs across dozens of garments or experiment with custom digitized patterns that push the boundaries of what thread and fabric can achieve together.

Table Of Contents

- Key Takeaways

- What is an Embroidery Machine?

- Core Components of Embroidery Machines

- How Digital Designs Become Stitches

- The Embroidery Process Step by Step

- Types of Embroidery Machines

- Choosing Threads and Needles for Embroidery

- Importance of Stabilizers and Hoops

- Common Features and Automation

- Troubleshooting Embroidery Machine Issues

- Maintaining Your Embroidery Machine

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Embroidery machines synchronize servo motors, rotary hooks, and digital control systems to execute 1,000 stitches per minute with sub-millimeter positional accuracy, converting vectorized design files into dimensional textile artwork through programmable motion control.

- The core mechanical architecture consists of three interdependent systems—needle and thread delivery mechanisms, movable hoop assemblies that secure fabric with precise tension, and calibrated tension discs that regulate thread friction to prevent breakage and puckering during high-speed operation.

- Digitizing software transforms bitmap images into machine-readable stitch files (PES, DST, JEF formats) by assigning fill types, stitch densities, and color sequences, while the controller interprets X-Y coordinates to orchestrate synchronized needle movements and real-time tension adjustments.

- Machine selection hinges on needle configuration (single versus multi-needle systems), production scale (home models with 1-2 needles versus industrial units with 4-20+ heads), and the critical pairing of thread type, needle size, and stabilizer material to match fabric weight and prevent distortion during stitch formation.

What is an Embroidery Machine?

An embroidery machine converts digital designs into precise, stitched patterns on fabric using computerized controls and mechanical systems working in tandem. Unlike standard sewing machines that join fabric pieces together, embroidery machines create decorative surface designs through coordinated needle movements and automated threading mechanisms.

These specialized machines serve applications ranging from personal craft projects and custom apparel to large-scale commercial textile production, transforming how we approach decorative stitching across multiple industries.

Definition and Purpose

An embroidery machine is a specialized device that automates decorative stitching according to digital designs, allowing you to reproduce complex, repeatable motifs with precision your hands alone can’t match.

The programmable mechanism moves fabric and operates needles to execute patterns from files stored via USB or built-in memory, transforming textile customization from laborious handwork into efficient automated stitching that maintains embroidery machine mechanics across multiple items.

Key Differences From Sewing Machines

While conventional sewing machines guide fabric past a stationary needle for garment construction, embroidery machine mechanics operate through a movable hoop system that secures fabric with extreme accuracy beneath specialized embroidery heads containing multiple needles.

You’ll notice this inverted fabric guidance paradigm facilitates complex stitch density patterns, maintains precise thread tension across color changes, and interprets digitized coordinates rather than relying on manual needle dynamics during decorative stitching.

Applications in Textile Arts

Beyond garment decoration, you’ll discover machine embroidery driving significant Textile Innovation across contemporary art practices. Artists leverage Digitizing software to translate visual concepts into programmable surface decoration, transforming quilts, gallery installations, and experimental fabric interaction into reproducible textile art forms:

- Intricate motifs with precision fills elevate art quilting and wall hangings

- Industrial-grade frames accommodate large-format installation textiles

- Digitized heritage patterns support cultural preservation and reinterpretation

- Unconventional threads enable experimental fabric embellishment techniques

- Embroidery machines execute gallery-ready pieces with consistent quality

These embroidery techniques and tips merge digital weaving principles with mechanical execution, expanding creative boundaries in surface decoration. Mastering fabric preparation techniques for embroidery helps preserve these intricate digital designs through proper stabilization and handling.

Core Components of Embroidery Machines

Every embroidery machine depends on three interconnected systems that work together to transform digital instructions into precise stitched patterns. Understanding these core components—the needle and thread delivery mechanism, the embroidery arm and hoop assembly, and the tension control system—gives you the foundation to operate any machine effectively. Proper thread quality and storage play a huge role here—check out this embroidery machine thread guide to avoid common tension and breakage issues.

Let’s examine each component and how it contributes to successful embroidery execution.

Needle and Thread System

Your machine’s needle and thread system forms the mechanical heart of stitch formation, where upper thread from the spool interlocks with bobbin thread beneath the fabric. Regular maintenance like replacing dull needles and proper oiling helps prevent common thread tension and jamming issues that disrupt smooth stitch formation.

The needle carries thread through material while the presser foot maintains steady downward pressure, ensuring precise needle movement. For complex patterns, pairing quality hoops with the right stabilizers prevents fabric puckering and keeps detailed work crisp from start to finish.

Proper thread tension and needle selection prevent skipped stitches, making thread and needle management essential for quality needlework and consistent bobbin management. Machines with advanced tension systems and versatile needle compatibility, like those featured in top-rated Juki sewing machine reviews, help eliminate these common stitching problems.

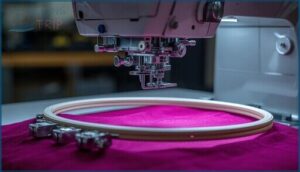

Embroidery Arm and Hoop

The arm provides vertical and horizontal motion that carries the needle across your fabric, executing design coordinates from the digitizing file. Meanwhile, the hoop maintains fabric stretch and position, ensuring embroidery alignment throughout stitching.

You’ll find four critical arm and hoop functions in every embroidery machine:

- The arm houses the needle bar and holds bobbin case placement during operation.

- Hoop clamping mechanisms determine fabric tension uniformity across the design area.

- Magnetic hoops simplify quick hooping for lightweight materials in commercial workflows.

- Stabilizers work with hoops to prevent distortion under hoop pressure and needle penetration.

Proper mounting reduces vibration, enhancing stitch quality at higher speeds.

Tension Discs and Regulators

Thread tension control separates impeccable embroidery from frustrating thread breaks and puckered fabric. Your tension discs apply calibrated pressure on the top thread, regulating sliding friction as the needle executes stitches per minute during machine embroidery techniques.

Proper thread regulation prevents loop formation, while worn discs cause uneven stitch tensioning. Regular disc maintenance and regulator calibration guarantee consistent embroidery machine operation, especially when switching thread weights or adjusting tension for delicate materials.

To achieve ideal results, understanding methodological rigor is essential in evaluating the performance of embroidery machines.

How Digital Designs Become Stitches

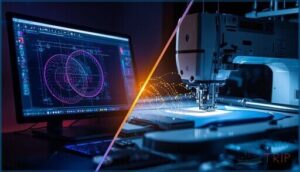

The transformation from digital artwork to precise stitches represents the technological core of embroidery machines, relying on specialized software and standardized file protocols to guarantee accurate reproduction. You can’t simply upload a JPEG and expect perfect results—the design must first be converted into a language your machine understands, complete with stitch coordinates, thread color sequences, and tension parameters.

This section explains how digitizing software processes images, which file formats deliver the best compatibility across different machine brands, and the exact mechanics that translate those digital instructions into controlled needle movements.

Digitizing Software Explained

Digitizing software transforms your artwork into machine-readable instructions through vector conversion, which traces bitmap images into clean, editable paths.

You’ll use stitch editing tools to assign fill types, set densities, and control stitch angles, while thread management features map specific colors to each design segment.

Design optimization algorithms adjust compensation values for pull and distortion, ensuring the embroidery design creation process yields professional results when your digitizing tools generate the final stitch file.

File Formats Used (PES, DST, Etc.)

Your embroidery machine reads proprietary formats that encode stitch coordinates, color changes, and trim commands into machine-specific instructions. PES caters to Brother machines, DST manages commercial Tajima systems, while EXP bridges Melco formats, JEF targets Janome equipment, and HUS accommodates Husqvarna Viking models.

File conversion tools within embroidery software guarantee format compatibility across brands, maintaining stitch editing parameters, thread management data, and design optimization settings throughout the digitizing workflow.

Translating Designs to Machine Movements

Once your digitizing software completes design conversion, the embroidery machine controller interprets X and Y coordinates to orchestrate needle movement across the hoop. Real-time sensors monitor thread tension and fabric slack, while machine calibration ensures stitch optimization through synchronized timing. This process transforms digital designs into precise mechanical actions:

- Needle drop timing matches thread consumption rates

- Hoop positioning constrains pattern alignment within the embroidery area

- Feedback loops adjust movements to preserve stitch density and quality

The Embroidery Process Step by Step

Once you’ve prepared your design file, you’re ready to execute the actual embroidery operation on your machine. The process follows a precise sequence of mechanical and material preparation steps, each contributing to the final stitch quality and design accuracy.

Let’s walk through the four critical stages that transform your digital file into a finished embroidered piece.

Setting Up The Machine

Before you can watch your first stitch form, you need a stable foundation. Position your machine on a level surface near a power outlet, confirm the display and ports are debris-free, and guarantee adequate lighting for precise work. This power setup, combined with proper machine calibration and hoop alignment, sets the stage for impeccable embroidery.

| Setup Task | Key Requirement |

|---|---|

| Surface & Power | Stable, level workspace with accessible outlet |

| Machine Condition | Clean USB port, unobstructed display, unplugged for adjustments |

| Environment | Well-lit area, lint-removal tools nearby for maintenance |

Threading The Needle and Bobbin

With your machine ready, mastering thread pathways determines stitch formation quality. Thread your needle through each guide in the thread path, seating it fully to prevent slippage and skipped stitches, then position the needle at its highest cycle point to shield the eye.

Wind your bobbin evenly with consistent tension, inspect the bobbin case for burrs, and align the thread take-up lever for synchronized needle alignment and balanced thread tension throughout operation.

Hooping The Fabric Properly

With thread pathways secured, you’ll achieve embroidery accuracy through proper hoop selection and fabric tension control. Center your fabric within the hoop’s embroidery field, layer appropriate stabilizer beneath to prevent puckering, then tighten the outer ring until the material sits drum-taut without overstretching.

This stabilizer choice and hooping technique establishes the foundation for precise stitch placement, transforming thread management into impeccable textile artistry.

Starting and Monitoring The Stitching

Once you press start, the embroidery machine executes rapid, controlled needle penetrations to establish stitch initiation, locking thread tension at approximately 40-60 grams for consistent fabric alignment.

Your LCD screen displays realtime monitoring of stitch progress, remaining bobbin thread, and design completion percentage, allowing you to catch tension imbalances or misalignments early—critical factors that separate perfect machine embroidery from distorted output requiring complete rework.

Types of Embroidery Machines

Embroidery machines aren’t one-size-fits-all—different models serve distinct purposes, from casual hobbyist work to high-volume commercial production. Understanding the variations in needle configuration, functionality, and scale helps you match machine capabilities to your specific textile projects.

The distinctions below outline how design, operational capacity, and intended application separate these machine categories.

Single-Needle Vs. Multi-Needle

When selecting embroidery machines, you’ll face a critical choice between single-needle and multi-needle systems. Single-needle systems operate with one active needle, requiring manual thread management for color changes. In contrast, multi-needle systems deploy 4 to 20+ needles, automating color transitions through digitizing software.

Multi-needle systems offer faster embroidery speed and reduce production costs in commercial settings. However, single-needle machines provide affordable entry points for small-scale work.

Embroidery-Only Vs. Combo Machines

Your workflow dictates whether you select an embroidery-only unit or a combo sewing and embroidery machine system, each offering distinct advantages in machine selection and comparison. Embroidery-only machines prioritize dedicated embroidery machine usage, optimizing hoop sizes, thread capacity, and stitch quality for specialized projects. Conversely, combo models integrate both functions, addressing needle variance and expanding creative flexibility:

- Embroidery-only models deliver faster embroidery rates, specialized bobbin systems, and 1-6 needles for focused applications.

- Combo machines combine sewing stitches with 1-4 needles, balancing versatility against footprint constraints.

- Price considerations reflect needle count, software compatibility, and industrial-grade capabilities across both machine comparison categories.

Home Vs. Industrial Models

Production scaling determines whether you invest in a home model or an industrial embroidery machine, each addressing distinct machine selection and comparison criteria. Home models have limitations, including 1–2 needle configurations and compact hooping areas. In contrast, commercial embroidery systems deploy multi-needle setups with 4–20+ heads for industrial applications, delivering higher stitch rates and continuous operation.

| Feature | Home Models | Industrial Embroidery |

|---|---|---|

| Needle count | 1–2 needles | 4–20+ needles |

| Production capacity | Light-to-moderate volume | High-volume continuous runs |

| Automation level | Basic thread trimming | Enhanced batch automation |

Choosing Threads and Needles for Embroidery

Your thread and needle choices directly impact stitch quality, fabric integrity, and the longevity of your finished embroidery work. Understanding the compatibility between thread weight, needle size, and fabric type prevents common issues like thread breakage, fabric puckering, and needle deflection during high-speed stitching.

The following sections break down the technical specifications you need to match materials correctly and achieve professional results with every project.

Embroidery Thread Types

Your choice of embroidery thread materials defines how your design looks and also how long it lasts through wash cycles and light exposure. Consider these primary fiber classifications when selecting threads for your embroidery machine:

- Polyester: High tensile strength, colorfastness up to 60°C laundering, ideal for commercial applications

- Rayon: Lustrous sheen with moderate colorfastness, prone to fading under prolonged sunlight

- Cotton: Matte finish, good washability threshold, suitable for natural fabric blends

- Specialty threads: Metallic, variegated, and UV-reactive options require careful tension control adjustments

Match thread weight (generally 40-weight for general embroidery) to your fabric density and digitizing specifications, ensuring compatibility between fiber blends and stabilizer selection for best stitch formation.

Selecting Needle Sizes and Types

Needle selection is crucial for achieving crisp embroidery designs and preventing distorted stitches. It’s essential to match needle material, size, and type with your fabric weight and thread characteristics. For instance, ballpoint needles are ideal for knits, sharp needles for wovens, and embroidery needles with enlarged eyes for metallic threads. Regular needle maintenance is also vital, with replacements recommended every 8 hours to avoid breakage and skipped stitches.

| Needle Size | Fabric Type | Thread Compatibility |

|---|---|---|

| 65/9 – 70/10 | Lightweight silks, chiffon | Fine polyester, rayon threads |

| 75/11 – 80/12 | Cotton, cotton blends | Standard 40-weight embroidery thread |

| 90/14 – 100/16 | Denim, canvas, heavy materials | Thick threads, metallic varieties |

| Ballpoint (various) | Knits, jersey, stretch fabrics | Polyester for elasticity retention |

| Embroidery (75/11) | General embroidery applications | Rayon, polyester, novelty threads |

Stitch density plays a significant role in needle choice, particularly when working with heavy fabrics and dense fill stitches. In such cases, larger needle sizes are necessary to minimize thread friction and prevent needle deflection during high-speed sewing techniques.

Matching Materials to Needles and Threads

Your embroidery success hinges on precise material matching, where thread compatibility directly influences needle sizing and tension control. Polyester threads pair well with sharp needles featuring smaller eyes to minimize linting, while rayon requires larger needle eyes for smooth feeding.

Consider fabric selection alongside thread type—lightweight silks demand 65/9 needles with fine threads, whereas denim needs 90/14 needles with thicker varieties. Proper stabilizer use prevents puckering, ensuring your digitizing translates into impeccable stitches.

Importance of Stabilizers and Hoops

Your embroidery machine’s precision means nothing if the fabric shifts, puckers, or distorts during stitching, which is where stabilizers and hoops become non-negotiable components of the process.

Stabilizers provide the structural support that prevents fabric movement and maintains stitch integrity, while hoops secure the material with consistent tension across the embroidery field.

Understanding which stabilizer type to select, when magnetic hooping systems offer advantages, and how to prevent distortion will determine whether your designs emerge crisp and professional or compromised by mechanical stress.

Types of Stabilizers (Cut-Away, Tear-Away)

Stabilizers provide the fabric support and embroidery tension control your machine needs to execute clean designs without distortion. You’ll encounter two primary stabilizer materials in your embroidery workflow, each engineered for specific fabric stabilization requirements and hoop techniques.

Cut-away stabilizers are permanent aids removed after embroidery finishes, offering:

- Nonwoven, film, or foam-backed composite construction

- Application to dense or stretch-prone surfaces

- Prevention of distortion during stitching

- Ideal use for knits, sweatshirts, and intricate designs

Tear-away stabilizers remain in place after stitching, removed by tearing along perforations. They’re preferred for woven fabrics where cutaway could leave visible marks, ensuring superior thread management while minimizing stiffness on lighter materials and delicate threads.

When to Use Magnetic Hoops

You’ll select magnetic hoops when working with delicate woven fabrics, lightweight cottons, or knits that require rapid production cycles and minimal hoop burn risk. Magnetic hoop benefits include even fabric grip without metal ring pressure, reducing perforations and distortion common with traditional hooping methods.

Pair your magnetic hoops with appropriate stabilizers to maintain embroidery efficiency, and inspect magnetic alignment regularly during hoop maintenance to verify consistent holding force across repeated use.

Preventing Fabric Distortion

You’ll minimize fabric distortion by balancing three interrelated factors: fabric tension during hooping, stabilizer type matched to fiber content and stitch density, and thread management through calibrated upper and bobbin tension settings.

Proper hoop selection distributes pull evenly across the embroidery area, while underlay stitches stabilize stretch-prone zones before dense fills.

Test tension adjustments on scrap samples before executing final digitizing instructions on your embroidery machines.

Common Features and Automation

Modern embroidery machines aren’t just mechanical workhorses—they’re equipped with automation features that optimize your workflow, reduce manual intervention, and give you precise control over every aspect of the stitching process.

These built-in capabilities distinguish contemporary models from their predecessors, allowing you to focus on creative decisions rather than repetitive adjustments.

Understanding these three core automation features will help you boost efficiency and achieve consistent, professional results in your embroidery projects.

Automatic Thread Cutting

Modern embroidery machines rely on automatic thread cutting to improve stitch efficiency and minimize manual intervention. When you reach a color change or complete a sequence, a small powered blade integrated with the carriage severs the top thread cleanly, synchronized with the controller to prevent fabric snag.

This precision cutting mechanism, central to computerized embroidery and multi-needle systems, eliminates tedious trimming tasks and maintains consistent thread management throughout complex designs.

Speed and Stitch Control

Beyond automatic cutting, you’ll find that embroidery machines let you adjust stitch rate—measured in stitches per minute (SPM)—to balance speed limits against thread tension and feed rate precision. SingleNeedle systems and MultiNeedle systems alike use acceleration profiles to prevent fabric distortion, while digitizing and design software often recommends ideal speeds.

Machine comparison reveals three critical controls:

- Maximum SPM settings for dense fills versus delicate details

- Thread tension adjustments during high‑speed runs

- Feed rate synchronization to maintain uniform stitch formation

On-Screen Editing and Preview

Before your computerized embroidery machine cuts thread, you can use on-screen design editing to adjust placement, thread optimization paths, and color management within the preview modes.

Stitch simulation displays how digitizing software will translate your embroidery design into needle movements, letting you tweak software and file formats—PES, DST, or JEF—and verify hoop alignment before the first puncture.

Troubleshooting Embroidery Machine Issues

Even well-maintained embroidery machines encounter operational challenges that disrupt your workflow, from snapped threads mid-design to puckered fabric that ruins hours of work.

These issues stem from specific mechanical or setup problems, each requiring targeted diagnostic approaches to restore peak performance.

Understanding the root causes of common malfunctions—and implementing systematic correction methods—will minimize downtime and protect your investment in materials and machine components.

Thread Breakage Solutions

Thread breakage stems from mismatched needle-thread pairings, improper tension settings, or accumulated lint in the hook area.

You’ll need to verify needle size compatibility with your thread weight, adjust both top and bobbin thread tension systematically, and clean debris from tension discs regularly.

Replace needles after each project to prevent burrs that snag thread, and lower stitching speed on specialty fabrics to reduce mechanical stress during stitch formation.

Fixing Tension Problems

Imbalanced tension reveals itself as loose loops on fabric surfaces, puckered stitchwork, or irregular stitch density across your embroidery field. You can resolve these issues through systematic tension adjustment and needle calibration procedures:

- Top tension correction: Increase dial settings incrementally if bobbin thread shows on fabric surface, or decrease settings when top thread appears excessively tight.

- Bobbin case inspection: Clean tension springs, verify proper bobbin insertion direction, and confirm consistent thread delivery.

- Thread path verification: Re-thread entirely, checking each guide point and tension disc engagement to eliminate routing errors that compromise balanced stitch formation.

Avoiding Design Misalignment

Misaligned patterns stem from hoop alignment errors, inadequade fabric tension, or thread synchronization failures in multi-needle embroidery machines.

Run a design preflight check to verify stitch optimization parameters, confirm your hoops clamp securely without wobble, and verify stabilizers match fabric weight specifications.

Pause mid-stitch if distortion appears during digitization execution, re-hoop immediately, and document troubleshooting adjustments to prevent recurring registration defects.

Maintaining Your Embroidery Machine

Your embroidery machine’s performance depends on consistent maintenance routines that prevent mechanical failures and preserve stitch quality. Regular cleaning removes lint accumulation from critical components, while proper lubrication reduces friction on moving parts, and both procedures extend your machine’s operational lifespan.

The following maintenance protocols guarantee your equipment continues producing precise, professional-grade embroidery across thousands of stitching cycles.

Cleaning and Oiling Procedures

Your embroidery machine operates like a precision instrument, demanding consistent care to maintain peak performance. Effective sewing machine maintenance begins with establishing cleaning schedules that align with your operational intensity, usually after every 8 to 10 hours of machine embroidery to prevent lint accumulation in the bobbin hook, feed dogs, and tension discs.

Machine lubrication follows, applying lightweight oil exclusively to manufacturer-specified critical joints using a precision dropper, avoiding electronic components and the needle bar. After oiling, run test stitches on scrap fabric to distribute lubricant and verify smooth operation—these maintenance routines form the foundation of troubleshooting and prevention.

Regular Needle Replacement

A dull needle compromises stitch quality faster than most operators realize, requiring timely replacement every 8 to 12 hours of machine embroidery to prevent thread tension anomalies and fabric damage. You’ll notice needle wear through pulled threads, bird-nesting at the needle point, or recurrent thread breakage—clear indicators that replacement shouldn’t be delayed.

Proper needle selection matters too: use sharp needles for woven fabrics, ballpoint for knits, and reinforced needles for heavy materials like denim.

Incorporating needle replacement into your maintenance schedules, alongside recording replacement dates, ensures your embroidery machine delivers consistent performance while troubleshooting issues before they compromise your work.

Frequently Asked Questions (FAQs)

Can embroidery machines work on leather or vinyl?

As the saying goes, “measure twice, cut once”—you can embroider leather or vinyl with proper material preparation, needle selection, and stabilizers.

Reduce speed, use leather needles, and apply cut-away stabilizers for best results.

How do you resize designs without distortion?

Maintain aspect ratio by locking proportions in your digitization software, ensuring embroidery machines read vector formats accurately.

Verify stitch density after scaling to prevent thread overfill, and validate resized digital designs against your target hoop dimensions.

Whats the maximum embroidery area for home machines?

Like a painter’s canvas, your embroidery field determines creative boundaries. Most home machines accommodate 4×4 to 6×10 inch hoops, with entry models starting at 100×100 mm and high-end units reaching 150×260 mm maximum size for fabric capacity.

Do embroidery machines require special electrical outlets?

Most embroidery machines don’t require special electrical outlets, operating on standard 110-120V household power in North America.

However, industrial models and international voltage requirements may necessitate dedicated circuits or power adapters for electrical compatibility.

How long does a typical embroidery design take?

Picture a clock ticking through stitches—design runtime spans 15 to 60 minutes on multi-needle embroidery machines, influenced by stitch complexity, thread management, fabric selection, and production planning demands in machine embroidery workflows.

Conclusion

Mastering how an embroidery machine works means you’ve threaded together mechanical precision with digital intelligence—no small feat in textile engineering. Each stitch represents synchronized motion control, material interaction, and vectorized instruction execution working in perfect harmony.

You now possess the technical foundation to adjust thread tension, select appropriate stabilizers, and troubleshoot breakage patterns before they compromise your designs. That knowledge transforms you from machine operator into an informed practitioner who understands the engineering principles beneath every programmed needle penetration.

- https://www.linkedin.com/posts/bohdanlukianets_tasks-study-research-activity-7373377539521667072-UTEi

- https://www.gauthmath.com/solution/1837934067002466/2-Main-point-1-Subpoint-2-Subpoint-3-Subpoint

- https://elsevier.blog/sub-points-outlining-organization/

- https://github.com/tugcekonuklar/msc-computer-science-notes/blob/main/research-methods/Home.md

- https://www.thinkpro.net/blog/2017/evolution-of-machine-embroidery/