This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Hand sewing’s backstitch creates overlapping loops that won’t pull apart easily, while machine sewing’s straight stitch forms tight, secure seams.

Nylon thread offers superior tensile strength, though cotton provides reliable durability for most projects.

Your seam’s strength also relies on proper tension, appropriate stitch length, and secure finishing techniques.

Even basic stitches become remarkably strong when you master the fundamentals – but certain combinations of stitches and threads can handle surprising amounts of stress and strain, making them ideal for projects that require secure seams.

Table Of Contents

Key Takeaways

- You’ll get the strongest hand-sewn seams with backstitch – it creates overlapping loops that won’t pull apart, making it perfect for toys, repairs, and high-stress projects that need to last.

- Machine straight stitch delivers maximum durability – the interlocking upper and lower threads form tight connections that outperform decorative stitches in strength tests.

- Nylon thread offers superior tensile strength – while cotton provides reliable everyday durability, nylon’s molecular structure makes it ideal for heavy-duty applications requiring unbreakable seams.

- Your technique matters more than the equipment – proper tension, consistent stitch length, and secure finishing transform basic stitches into remarkably strong connections that withstand years of wear.

The Strongest Stitches for Hand Sewing: Backstitch

When you need unbreakable hand-sewn seams, backstitch delivers the strongest connection possible.

Master the backstitch—your strongest hand-sewn seam that creates overlapping loops for unbreakable durability.

This foundational technique creates overlapping loops that won’t pull apart, making it essential for toys, repairs, and any project that needs to last.

What is The Strongest Stitch?

When evaluating stitch strength, the backstitch reigns supreme in hand sewing.

This powerhouse creates overlapping loops on the fabric’s wrong side, doubling the thread back on itself for maximum seam strength.

Unlike running stitches that leave gaps, backstitch forms a continuous line without weak spots.

Material influence plays a pivotal role—polyester and nylon threads boost the backstitch’s natural durability, making it perfect for high-stress applications.

How to Work Backstitch: Step by Step Guide

Mastering backstitch transforms your hand sewing from amateur to professional. This fundamental technique creates the strongest possible seam when done correctly.

Start by pinning your fabric pieces together with a small seam allowance. Thread your needle and tie a knot at the end. Push the needle through from back to front, creating your first anchor point.

Here’s your step-by-step process:

- Create the foundation stitch – Make a small forward stitch, then bring your needle up one stitch-length ahead

- Form the backstitch – Insert your needle behind the thread line, going back to where your previous stitch ended

- Maintain consistency – Keep equal distances between stitches and from the fabric edge throughout

Thread tension matters substantially for backstitch success. Too tight creates puckering, while too loose weakens the seam. Fabric choice influences your approach – felt requires different handling than cotton.

To guarantee a polished look, maintain consistent length. Corner backstitching demands extra attention to maintain consistent spacing around curves. Decorative backstitch variations can enhance both strength and visual appeal.

Practice these sewing techniques on scrap material first. Your hand stitches will develop muscle memory, making complex sewing stitches feel natural with repetition.

Tips for Working Backstitch

Three essential techniques will transform your backstitch from amateur to professional.

First, maintain consistent tension throughout your stitching—tight enough to secure the seam, but not so tight that it puckers the fabric.

Second, keep your stitch distance uniform by using your finger as a guide along the fabric edge.

This creates that coveted machine-like appearance.

For corner reinforcement, slow down and pivot carefully, maintaining the same distance from the edge.

Master anchoring techniques by working 2-3 backstitches at the start and end instead of bulky knots.

Your thread choice matters too—polyester threads offer superior strength for functional hand sewing projects.

These sewing techniques guarantee your backstitch delivers maximum durability while looking professionally finished.

Applications of Backstitch

Backstitch transforms ordinary sewing projects into durable masterpieces.

You’ll find this hand sewing technique perfect for plush toy seams that withstand children’s enthusiastic hugs.

Create embroidery embellishments that won’t unravel after countless washes.

Your leatherwork reinforcement benefits from backstitch’s incredible holding power, while denim seam repair becomes foolproof with this sturdy stitch.

Felt ornament durability improves dramatically when you use backstitch instead of running stitches.

From delicate dolls to heavy-duty sewing repairs, backstitch delivers professional results every time you pick up needle and thread, providing incredible holding power.

The Strongest Stitch for Machine Sewing: Straight Stitch

When you’re machine sewing, the straight stitch becomes your strongest ally because it creates a tight foundation between the upper and lower threads.

You’ll find this stitch outperforms others in durability tests, making it perfect for seams that need to withstand regular wear and stress.

Why is The Straight Stitch The Strongest?

With machine sewing, straight stitch dominates because it creates an interlocking foundation between upper and lower threads.

This mechanical lock-stitch formation provides unmatched durability that withstands stress better than decorative alternatives.

Key factors that maximize straight stitch strength:

- Thread tension balanced correctly prevents puckering and breakage

- Stitch length shortened to 2-2.5mm increases thread density

- Needle size matched to fabric type guarantees clean penetration

- Seam finishes like backstitching at ends prevent unraveling

Your sewing machine settings directly impact stitch strength and overall sewing performance.

Strengthening Seam Ends With Straight Stitch

When you’re building something that needs to last, strengthening seam ends with straight stitch becomes your secret weapon for bulletproof construction.

This double stitching technique involves running your needle back and forth at the beginning and end of each seam, creating overlapping threads that lock everything in place.

Think of it as insurance for your hard work—those reinforced endpoints prevent unraveling even under serious stress.

Proper thread tension and needle size selection make all the difference in achieving maximum stitch durability.

A shorter stitch length creates tighter reinforcement, while backstitching techniques at seam starts and ends multiply your sewing strength exponentially.

For enhanced durability, consider using upholstery nylon thread.

Key reinforcement benefits:

- Prevents seam failure at stress points where most damage occurs

- Creates professional-grade seam reinforcement that rivals commercial construction

This straight stitch approach transforms ordinary seams into fortress-like barriers against wear and tear, giving your projects the backbone they need for long-term performance and reliability.

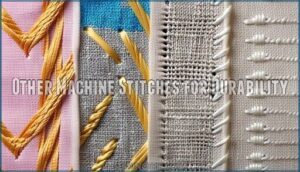

Other Machine Stitches for Durability

When straight stitch isn’t enough, zigzag strength delivers flexibility for stretchy fabrics.

This stitch type strength prevents seam breakage during movement.

Overlock benefits include edge finishing and enhanced stitch durability on knits.

Tricot applications shine in activewear, offering superior stretch resistance.

Industrial machines maximize stitch density for professional results in machine sewing applications.

For maximum durability, consider using a short stitch length.

Strong Threads for Sewing: Nylon and Cotton

Your thread choice directly impacts your project’s durability, with nylon offering exceptional strength for heavy-duty applications. Cotton threads provide reliable performance for everyday sewing while remaining gentle on most fabrics.

Why Nylon Thread is Strong

In terms of thread strength, nylon’s molecular structure creates an almost unbreakable foundation for your projects.

Nylon thread manufacturing involves high-temperature processes that forge incredibly strong bonds between polymer chains, resulting in exceptional thread durability.

This unique composition gives nylon thread superior abrasion resistance compared to cotton or polyester alternatives.

You’ll find that nylon’s chemical resistance makes it perfect for outdoor gear and upholstery projects where exposure to moisture or chemicals is common.

The thread’s high tensile strength means you can use thinner diameters without sacrificing sewing durability.

For projects needing high resistance to sunlight, consider polyester’s UV resistance.

While cost analysis shows nylon costs slightly more than basic threads, its longevity makes it worthwhile for demanding applications requiring maximum thread strength.

Durable Cotton Threads for Strength

While nylon dominates strength categories, cotton thread offers its own durability advantages when you select the right specifications.

Understanding cotton grades and construction methods helps you choose threads that won’t let you down mid-project.

Cotton thread strength depends heavily on fiber quality and manufacturing processes. Here’s what to look for:

- Long staple cotton – Extra-long fibers (like Egyptian cotton) resist breaking and fraying better than short-staple varieties

- Mercerization process – This chemical treatment strengthens fibers by up to 20% while adding lustrous thread finishes

- Thread ply construction – Multi-ply twisted threads (2-3 plies) provide superior tensile strength compared to single-ply options

- Weight selection – Choose 30-weight for heavy fabrics, 40-weight for general use, maintaining proper thread durability

- Quality brands – Invest in mercerized cotton from reputable manufacturers for consistent sewing thread strength

The mercerization process also reduces lint production and improves dye retention, making these threads ideal for projects requiring both strength and appearance longevity.

For general use with medium-weight cottons, a thread weight of 40-50 is typically recommended.

Considerations for Thread Strength

Thread selection impacts your project’s durability substantially. Understanding thread fiber types helps you choose wisely—nylon offers superior strength while cotton provides natural flexibility.

Your thread choice becomes the backbone of every project—choose nylon for unbreakable strength, cotton for reliable everyday durability.

Thread ply impact affects thickness; multiple plies create stronger bonds. Thread treatment effects like resin coating add resilience against wear.

Needle size matters for proper thread accommodation, preventing breakage. Maintaining tension balance guarantees consistent stitch quality and prevents thread snapping during construction.

| Factor | Impact on Strength |

|---|---|

| Material Type | Nylon exceeds cotton in tensile strength |

| Thread Thickness | Larger sizes provide greater breaking force |

| Coating Treatment | Resin coating increases abrasion resistance |

| Ply Construction | Multiple plies enhance overall durability |

| Environmental Exposure | UV resistance varies by thread properties |

General Sewing Tips for Stronger Seams

Beyond mastering individual stitches and threads, you’ll need proper preparation techniques to create seams that truly last.

Your attention to details like stitch placement, length selection, and seam finishing can make the difference between projects that hold up for years versus those that fall apart after minimal use, which is crucial for seam finishing.

Marking Stitching Lines

Marking stitching lines transforms amateur sewing into professional-quality work. When you take time to mark precise guidelines before threading your needle, you’ll discover the difference between random stitching and masterful craftsmanship.

Creating Guidelines: Use washable fabric markers or tailor’s chalk to draw clear, visible lines on your fabric surface.

Precise Marking: Measure each point carefully, guaranteeing consistent spacing between planned stitch locations for uniform results.

Stitching Accuracy: These marked guiding lines serve as your roadmap, keeping stitches straight and preventing costly mistakes.

Line Placement: Position marking tools strategically, especially when working with intricate patterns requiring exact alignment.

Pattern Alignment: Match your markings to design elements precisely, creating polished, professional-looking finished products.

Your sewing guide becomes invaluable when you’ve invested time in proper preparation.

Quality marking tools make the difference between guesswork and precision. Consider using specialized marking pens for best results. Whether you’re adjusting sewing machine settings or hand-stitching delicate fabrics, consistent seams start with well-planned stitching lines.

This foundation guarantees your strongest stitches maintain their integrity throughout the entire project.

Choosing Stitch Length for Strength

Selecting the right stitch length transforms your sewing from amateur to professional.

Shorter stitches create stronger seams by distributing stress across more connection points, while longer stitches work faster but sacrifice durability.

For guidance, consider a detailed stitch guide when choosing your settings.

| Stitch Length | Best For |

|---|---|

| 1.5-2mm | Heavy fabrics, high-stress seams |

| 2-2.5mm | Standard weight fabrics, everyday projects |

| 2.5-3mm | Lightweight fabrics, temporary basting |

| 3-4mm | Gathering, decorative topstitching |

Your fabric type determines ideal length—dense materials need shorter stitches for proper penetration, while delicate fabrics require longer stitches to prevent damage.

Adjust stitch density based on seam reinforcement needs, considering tension impact on final strength.

This adjustment ensures a professional finish and prevents seam damage.

Proper settings lead to a more durable result.

Finishing Seams for Added Durability

Seam allowances need protection to prevent unraveling over time. Proper seam finishes transform weak points into strong, lasting connections that won’t fail under stress.

- Binding edges with bias tape creates professional-looking seam reinforcement

- Serged edges using overlocking stitches prevent fraying while adding stretch resistance

- Taped seams apply fusible interfacing strips for heavy-duty strength

- Flat felled seams encase raw edges completely for maximum durability

Smart sewers know that overcasting methods work wonders for seam encasing. For enhanced durability, consider that the backstitch offers strength similar to a machine stitch.

You’ll find that sewing finishes like zigzag stitching along raw edges stops threads from pulling loose. Seam fraying prevention becomes automatic when you trim seam allowances to quarter-inch width, then overcast immediately after stitching your main seam.

Frequently Asked Questions (FAQs)

What is the strongest stitch you can sew by hand?

Backstitch stands as your strongest hand-sewing option. It creates overlapping loops that double the thread’s strength, making it perfect for durable seams on toys, repairs, and decorative projects.

How strong are hand sewing stitches?

Hand stitches pack surprising punch.

You’ll find backstitch reigns supreme, creating overlapping loops that rival machine strength.

With polyester thread, your seams withstand serious stress, making handwork surprisingly durable for toys and repairs.

What is the strongest sewing thread?

Kevlar thread stands as the toughest option you’ll find, but polyester and nylon threads offer excellent strength for most projects.

You’ll get durability that handles stress while remaining workable for your sewing needs.

What is strong hand sewing?

You want strong hand sewing?

Use a backstitch with polyester or nylon thread.

Keep your stitches close and tension steady, like a tightrope walker balancing above the crowd.

Reinforce corners, anchor your thread, and your seams won’t budge.

Why do you need a strong hand sewing technique?

Strong hand sewing creates unbreakable bonds when life pulls your projects apart.

You’ll need durable techniques for toys that’ll survive countless hugs, repairs that last years, and seams that won’t split under stress or daily wear.

Which stitch pattern is strongest?

The backstitch reigns supreme as the strongest hand-sewing stitch you’ll master.

Its overlapping loops create unbreakable bonds, while machine straight stitches dominate for their lock-like thread interweaving that’ll outlast your favorite jeans.

Is hand sewing as strong as a machine?

Hand sewing can match machine strength when using backstitch with quality thread.

Your technique matters more than the method—consistent stitches, proper tension, and strong thread create durable seams regardless of whether you’re stitching by hand or machine.

What is the strength of stitching?

Think of stitching as your fabric’s backbone – it’s what holds everything together when life gets rough.

Backstitch creates the strongest hand-sewn connection, while machine straight stitch offers superior durability through interlocked threads that won’t easily break, providing durability.

Is sewing a good exercise?

Sewing provides excellent fine motor exercise, strengthening hand muscles and improving dexterity.

You’ll enhance hand-eye coordination while sitting comfortably.

However, it’s primarily sedentary, so you won’t get cardiovascular benefits like running or swimming would provide, which affects overall cardiovascular health.

How strong is sewing thread?

You’ll find polyester and nylon threads are incredibly tough, with backstitch creating virtually unbreakable bonds that outlast many machine stitches. These synthetic powerhouses resist stretching, tearing, and wear.

Conclusion

Surprisingly, the strength of your sewing depends more on technique than expensive equipment.

When you understand how strong is sewing, you’ll realize that proper backstitch application and quality thread selection create seams that withstand years of stress.

Your mastery of fundamentals—correct tension, appropriate stitch length, and secure finishing—transforms basic techniques into remarkably durable connections.

You’ve learned that nylon thread offers superior strength, while cotton provides reliable everyday durability.

Now you can confidently tackle projects requiring secure seams.

- https://www.linkedin.com/posts/saadmk_seam-strength-is-a-critical-factor-in-activity-7290367039913832449-v9SK

- https://medcraveonline.com/JTEFT/influence-of-different-sewing-parameters-on-seam-quality.html

- https://abcseams.com/what-is-the-most-durable-stitch-and-stitch-stypes/

- https://www.faa-design.com/files/7/22/7-2-yasen.pdf

- http://article.sapub.org/10.5923.j.textile.20200901.04.html