This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You pull on your jacket, and the Velcro closure gives way with that familiar ripping sound—except this time, the fabric comes with it. That’s the frustration of poorly attached Velcro, and it’s more common than you’d think. The difference between Velcro that lasts years and Velcro that peels off after a few uses comes down to three factors: the attachment method you choose, how well you prepare the fabric surface, and matching the Velcro type to your material.

Whether you’re repairing outdoor gear, customizing clothing, or crafting from scratch, the right technique ensures your closures stay secure through countless open-and-close cycles. Each fabric presents its own challenges, from slippery nylon that resists adhesives to stretchy knits that pull away from rigid attachments, but once you understand which method works best for your project, attaching Velcro becomes straightforward and reliable.

Table Of Contents

- Key Takeaways

- Essential Tools for Attaching Velcro

- Choosing The Right Velcro for Fabric

- Preparing Fabric for Velcro Attachment

- Cutting Velcro to Fit Your Project

- Attaching Adhesive-Backed Velcro

- Using Fabric Glue to Attach Velcro

- Sewing Velcro to Fabric for Durability

- Velcro Compatibility With Different Fabrics

- Tips for Secure and Lasting Attachment

- Cleaning and Removing Velcro From Fabric

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Velcro attachment success depends on three critical factors: choosing between sew-on, adhesive-backed, or iron-on methods based on your fabric type, properly preparing the surface by cleaning and smoothing it, and matching the Velcro thickness and strength to your project’s stress requirements.

- Sew-on Velcro delivers the most durable bond for high-stress applications and survives repeated washing, while adhesive-backed options work faster on smooth surfaces but may fail on porous, stretchy, or textured fabrics without additional stitching reinforcement.

- Surface preparation determines bond longevity—contaminants like oils or fabric finishes can reduce adhesion by up to 60%, and most fabric glues require 24-72 hours for full cure strength despite setting to touch within minutes.

- Combining attachment methods creates hybrid fastening that outperforms single techniques: layering adhesive with edge stitching distributes stress across wider areas and prevents the peeling that causes most Velcro failures on fabric.

Essential Tools for Attaching Velcro

Before you attach Velcro to any fabric, you’ll need the right supplies within arm’s reach. The tools you choose depend on whether you’re gluing, sewing, or using adhesive-backed strips, so knowing what’s in your toolbox matters.

If you’re planning to stitch it on by hand or machine, check out how to sew Velcro for step-by-step guidance that walks you through the process.

Let’s walk through the essentials that’ll make your project go smoothly from start to finish.

If you’re working with leather, you’ll want to check out these practical tips for sewing leather that cover everything from needle selection to managing tricky seams.

Velcro Types and Sizes

You’ll encounter hook and loop fasteners in two primary forms: sew-on and adhesive-backed Velcro. Hook length usually ranges from 8 mm to 38 mm, with 12–20 mm being ideal for most fabric applications.

For a complete walkthrough of attaching both types to your fabric, check out this step-by-step guide on how to sew on Velcro.

Loop material thickness varies from 1.4 mm to 3.0 mm, affecting both stiffness and holding strength. VELCRO Brand fastener sizes are standardized by width, enabling you to match components precisely for secure closures.

Fabric Glue Vs. Adhesive-backed Velcro

Once you’ve chosen your Velcro type and size, you’ll face a key decision: fabric glue or adhesive-backed Velcro.

Fabric glue offers flexible bond strength but requires longer cure times—often 24 hours—and can degrade without proper fabric prep.

Adhesive-backed Velcro provides faster attachment on smooth surfaces, though Velcro removal may leave residue and adhesive types vary in durability across washing cycles.

Sewing Supplies Needed

If you’re planning to sew your Velcro, you’ll need a few basic sewing notions. A sturdy sewing machine manages most fabric weights, though you can hand-stitch with a sharp needle and thread.

Polyester thread matches Velcro’s strength better than cotton, and choosing thread colors that blend with your fabric creates a cleaner finish. Keep fabric markers handy for placement, and scissors for trimming loose ends.

Cutting and Measuring Tools

Before you start sewing, gather precision cutting and measuring tools. A rotary cutter paired with a clear acrylic ruler provides clean, straight cuts through Velcro without fraying edges. Sharp scissors handle detailed trimming, and a seam roller presses adhesive-backed Velcro evenly across uneven surfaces.

Cutting mats protect your work surface, while fabric markers let you mark placement lines that won’t stain.

For more expert advice on preparing your workspace and tools, check out these essential sewing tips for bag making.

Choosing The Right Velcro for Fabric

You can’t just grab any Velcro and hope it works—the type you choose makes all the difference in how well it holds and how long it lasts. Different fabrics and projects need different fastener styles, from permanent solutions to temporary fixes.

Here’s what you need to know about the main types so you can pick the right one for your specific fabric.

Sew-on Vs. Adhesive Velcro

Sewing and adhesive represent two distinct bonding methods for attaching Velcro to fabric, each with clear advantages. Sew-on Velcro offers exceptional durability through repeated opening and closing cycles, making it ideal for high-stress seams. Adhesive variants work faster but may lose grip on porous or stretch fabrics without reinforcement.

- Sew-on installations require stitching access and compatible sewing techniques for long-term stability

- Adhesive-backed options bond directly to surfaces, eliminating the need for needle and thread

- Fabric compatibility plays a key role, as adhesive strength varies notably across different textile types

- Wash conditions and stress levels determine whether you’ll need secondary topstitching for adhesive applications

Iron-on Velcro Options

Iron-on Velcro relies on heat-activated adhesive to fuse directly to fabric, eliminating needlework while maintaining solid Velcro adhesion. You’ll find it in pre-cut strips or rolls, each requiring specific iron temperature settings and a protective cloth to prevent scorching.

Fabric compatibility varies considerably—delicate silks and synthetic blends often resist bonding, while moderate-weight cottons accept the adhesive well.

Bond longevity depends on following brand-specific curing times precisely, though attaching Velcro to fabric this way rarely matches sew-on adhesive strength under repeated stress.

Velcro Thickness and Strength

You’ll notice higher loop pile thickness in Velcro correlates with greater shear strength when attaching Velcro to fabric, particularly under lateral force. Adhesive fasteners usually underperform sew-on hook and loop in tensile testing on flexible textiles, while thin variants peel easily on stretchy materials.

VELCRO Brand fastening systems often specify thickness ratings tied to load class, helping you match material selection to fabric durability requirements and adhesive performance expectations.

Preparing Fabric for Velcro Attachment

Before you stick or stitch Velcro onto anything, you need to prep your fabric properly. A clean, smooth surface makes all the difference between a bond that holds and one that fails in a week.

Here’s what you should do to get your fabric ready for a secure, lasting attachment.

Cleaning and Smoothing Fabric

Before attaching Velcro to fabric, you’ll want a perfectly clean surface—think of it as laying the groundwork for a bond that won’t quit. Debris cleaning and fabric brushing guarantee uniform contact between materials, which is critical for sewing and crafting success.

Follow these textile and fabric care steps:

- Brush or lint removal to eliminate surface dust

- Wipe with a pre-washed microfiber cloth for debris cleaning

- Lightly steam for fiber relaxation and improved surface prep

Marking Attachment Locations

Think of marking as drawing a roadmap before you drive—it prevents costly mistakes. Use marking tools like tailor chalk or fabric-safe erasable markers to identify exact attachment spots.

Align each Velcro strip with reference points or seams, creating parallel markings for corresponding pieces. Symmetry checks guarantee functional closure, and placement guides maintain consistency across your project.

Mark both hook and loop sides distinctly before attaching Velcro to fabric.

Protecting Delicate Textiles

Delicate fabrics like silk demand a softer approach to preserve their beauty. Use gentle adhesives rated for fabric bonding, and apply them with low tension to prevent fiber distortion or pull. Pre-test on hidden areas to check for staining or color transfer.

When attaching Velcro to fabric without sewing, fabric protection starts with choosing textile adhesives designed specifically for delicate handling.

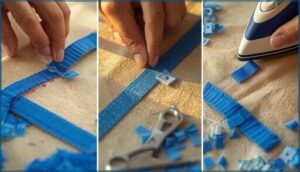

Cutting Velcro to Fit Your Project

You can’t just slap any size Velcro onto your fabric and hope it works. Getting the measurements right and cutting cleanly makes the difference between a closure that holds strong and one that peels off after a few uses.

Here’s how to cut Velcro that fits your project perfectly and stays put.

Measuring Velcro Length

Before you cut, precision matters. Match your Velcro sizing to the fabric opening you’re securing, and mark the exact length carefully. Accurate closure measurement prevents ugly overhangs or gaps that compromise performance.

Here’s what you need to measure:

- Width of the fabric opening or closure area

- Distance from fabric edge to closure endpoint

- Seam allowance, usually 1/4 inch (6 mm)

- Each attachment point separately for symmetry

Record your length calculation for consistent results.

Cutting Techniques for Clean Edges

Once you’ve measured, sharp fabric scissors become your best ally for precision trimming. Hold the scissors perpendicular to the Velcro, and cut in one smooth, decisive motion to prevent fraying and edge curling. For woven fabrics, align your cut with the grain to reduce distortion.

After sewing or fabric shearing, trim any loose threads immediately—this simple edge cutting tip ensures clean attachment surfaces and professional results that last.

Matching Velcro to Closure Size

Now that your edges are clean, you need to match Velcro sizing to your closure’s footprint. Measure the opening width, then select strips that cover at least 50% on each side for reliable hook and loop engagement.

- Choose 1‑inch, 1.5‑inch, or 2‑inch widths based on your closure alignment needs

- Match hook length and loop length to fabric edge measurements

- Avoid exceeding the edge—overhang causes peeling

- Replace old fastening systems with identical dimensions for consistent attachment

Attaching Adhesive-Backed Velcro

Adhesive-backed Velcro saves time when you don’t want to sew, but it only works if you apply it correctly. The backing needs proper pressure and time to bond with your fabric, and different materials require different handling.

Here’s what you need to know for a strong, lasting hold.

Application Tips for Strong Bonding

Strong bonding starts with clean, dry fabric—removing oils or lint guarantees your adhesive grips uniformly and lasts. Inspect the adhesive strength rating on your hook and loop product, then compare your fabric tension and surface prep against these bonding techniques:

| Factor | Best Practice |

|---|---|

| Surface Prep | Brush away dust, guarantee flat attachment area |

| Fabric Tension | Keep fabric taut during application |

| Temperature | Work within adhesive’s recommended range |

| Pressure | Press firmly across entire fastening strip |

Proper technique prevents peeling and maximizes cure times for sewing-free, durable attachment of Velcro to fabric.

Pressing and Curing Adhesive

Patience determines adhesive strength once you’ve positioned your Velcro strip. Apply firm, uniform pressure across the entire surface for at least 30 seconds, using your palm or a rolling motion to activate the bonding techniques.

Most adhesive properties require cure times between 30 minutes and 24 hours—ideal temperature ranges of 60–80°F help your glue reach full strength when attaching Velcro to fabric, so resist tugging or testing prematurely.

Troubleshooting Poor Adhesion

When adhesion failure strikes, diagnosing the root cause saves your project. Surface preparation often determines bond strength—contaminants like oils or fabric finishes can reduce attachment by up to 60%, so thorough cleaning prevents most issues.

Address these common problems before reapplying adhesive or glue to fabric:

- Fabric damage from excessive heat scorches delicate textiles during Velcro application

- Incomplete cure times weaken the final bond markedly

- Moisture trapped beneath prevents proper adhesive activation

- Low-porosity synthetics resist most bonding agents

- Stretched fabric during curing creates shear forces that detach faster

Using Fabric Glue to Attach Velcro

Fabric glue offers a permanent attachment method that works well when you can’t or don’t want to sew. The success of this approach depends on choosing the right adhesive for your fabric type, applying it evenly across the Velcro surface, and allowing adequate time for the bond to cure.

Understanding these three factors will help you create a secure, long-lasting connection between Velcro and fabric.

Selecting Suitable Fabric Glues

You want glue types that won’t turn stiff after drying—adhesive strength means nothing if your fabric bonding creates rigid seams. Contact cement provides strong, flexible adhesion for attaching velcro to fabric, curing fully in 24–48 hours.

Silicone-based and acrylic-based flexible glues resist laundering while keeping treated areas soft, making them ideal choices when using adhesives for fabric projects.

Applying Glue for Even Coverage

Think of glue application like buttering toast—too much in one spot creates a mess, too little leaves gaps. Spread a thin, even layer across the fabric surface using a fine-tip applicator or brush for adhesive control.

Work in small sections to maintain wet adhesion, avoiding excessive glue near edges where seepage weakens bonding strength when attaching Velcro to fabric.

Drying and Setting Times

Cure times determine bond strength when attaching Velcro to fabric, so don’t rush the process. Most fabric glues need 2–6 hours for handling, but full adhesive strength requires 24–72 hours depending on adhesive types and drying conditions.

- Adhesive fasteners work best at 20–25°C with 40–60% humidity for ideal setting methods

- Delicate knits may need extra curing time compared to woven materials

- Temperature shifts slow adhesive and fastening systems performance notably

Sewing Velcro to Fabric for Durability

Sewing Velcro to fabric gives you the strongest, most permanent bond you can get, especially for items that’ll face constant wear, washing, or heavy use. You can stitch it by hand if you don’t have a machine, or use your sewing machine with the right settings to make the job faster and more uniform.

The stitch pattern you choose affects how well the Velcro holds, so let’s look at the techniques that’ll keep everything locked in place.

Hand Sewing Techniques

Threading your needle with 18–22 inches of thread keeps things manageable, and tying a knot at the end anchors your work. Use a thimble to protect your fingertips when pushing through multiple layers.

Maintain fabric tension by holding it taut with your index finger perpendicular to the seam—this ensures even stitches and stronger attachment when sewing Velcro to fabric.

Sewing Machine Settings

Your sewing machine needs a few adjustments for reliable velcro fastener installation.

- Set stitch length between 2.5 and 3.0 mm for balanced seams

- Choose a universal 90/14 needle for medium-weight fabrics

- Adjust thread tension to mid-range, around 4–5 on most machines

Test fabric feed and machine calibration on scraps first, keeping your speed moderate to prevent shifting during sewing techniques.

Stitch Patterns for Strength

Once your sewing machine settings are ready, the right stitch pattern makes all the difference. Reinforced stitches at fastener endpoints distribute stress across the seam. A dense zigzag along velcro edges resists peel while maintaining fabric flex and thread grip.

Place short, even increments—around 2 to 3 mm—to improve corner stability, and add a cross-stitch at heavy-load points for lasting durability.

Velcro Compatibility With Different Fabrics

Not all fabrics play well with Velcro, and understanding compatibility from the start saves you from frustrating failures. Some materials naturally grip the hook-and-loop system, while others need extra reinforcement or won’t work at all.

Let’s look at which fabrics give you the best results, which ones require creative solutions, and how to handle stretchy materials that like to misbehave.

Best Fabrics for Velcro Adhesion

You’ll get the strongest Velcro adhesion with tightly woven fabrics like cotton canvas or nylon twill, where stable fiber strength and minimal stretch create reliable fastening points.

Dense weave patterns reduce slippage while improving material durability, making adhesive-backed Velcro bond more securely than on loose textiles.

Natural fibers in basket or plain weaves pass adhesion tests better than brushed surfaces, giving you predictable, long-lasting attachment.

Challenging Fabrics and Workarounds

Not all fabrics cooperate with standard Velcro methods. Velvet adhesion struggles because pile fibers resist bonding, so you’ll need sewing with velcro or specialized adhesive fasteners instead.

Satin protection requires barrier layers to prevent residue transfer, while upholstery attachment works best with VELCRO Brand sew-on options.

Synthetic fur demands heat-sensitive approaches that won’t melt fibers during textile attachment.

Reinforcing Knit or Stretchy Materials

Elasticity demands extra care when working with jersey and lycra. You’ll need interfacing options behind your VELCRO Brand Fasteners to maintain fabric stability and prevent puckering during textile attachment. Stretch stitching with zigzag patterns allows movement without thread breakage, while reinforcement patches distribute load across knit support areas. Test your adhesive fasteners or sewing with velcro on samples first to preserve the fabric’s natural give.

| Reinforcement Method | Best For |

|---|---|

| Knit-friendly interfacing | Jersey, lightweight stretch fabrics |

| Zigzag or stretch stitch | All knit materials requiring movement |

| Reinforcement patches | High-stress closure points |

| Sample testing | Verifying elasticity retention |

Tips for Secure and Lasting Attachment

Getting Velcro to stick is one thing, but keeping it there through repeated use, washing, and wear takes a few extra steps. The difference between a fastener that lasts six months and one that holds strong for years often comes down to how you reinforce the attachment.

Here’s what you need to know to prevent peeling, strengthen vulnerable edges, and combine methods for maximum durability.

Preventing Velcro From Peeling

Preventing peeling starts with adhesion testing on a small fabric sample before committing to your full project. Clean and dry the fabric surface completely, since dirt or moisture compromises bond strength from the start.

Apply adhesive-backed Velcro or sew-on Velcro with firm, consistent pressure across the entire attachment area. For fabrics prone to shifting, combine adhesive technology with a few strategic stitches to boost peel resistance.

Edge Reinforcement Methods

Durability improves dramatically when you anchor Velcro edges against stress. Edge stitching around the entire Velcro field prevents corner peel, while fabric interlining underneath distributes pulling forces across a wider area. Consider these reinforcement strategies:

- Secure raw edges with bias tape or serging to stop fraying

- Add heat sealing to adhesive-backed Velcro for clean, permanent borders

- Position reinforcement patches perpendicular to Velcro strips

- Layer interlining between fabric and fastening surfaces for load distribution

Combining Adhesives and Stitching

When you layer adhesive and stitching, you engineer hybrid fastening that outperforms either method alone. Bond strength multiplies as adhesive layers lock surfaces together, while stitch patterns create mechanical anchors, each compensating for the other’s weaknesses under fabric tension.

| Method | Primary Function | Best Application |

|---|---|---|

| Adhesive-backed Velcro | Chemical adhesion | Non-stretch zones |

| Fabric glue + sewing | Combined bonding | High-stress closures |

| Zigzag over adhesive | Mechanical fastening | Edge reinforcement |

| Sequential layering | Load distribution | Heavy-duty projects |

| Scrap testing | Bond verification | Before final attachment |

Start with clean fabric, apply adhesive fastening first, then reinforce edges with compatible stitching for weaving together maximum durability.

Cleaning and Removing Velcro From Fabric

Even the best Velcro attachment won’t last forever, and you’ll eventually need to clean or remove it from your fabric. Lint, pet hair, and debris can weaken the hook-and-loop bond over time, but a few simple techniques can restore its grip.

When it’s time to remove Velcro completely, you’ll want methods that protect your fabric from damage or residue.

Methods for Cleaning Velcro Strips

Over time, lint and debris clog Velcro hooks, weakening their grip. Strip Cleaning restores Hook Restoration effectively with these methods:

- File card or pet brush – Run it across VELCRO Brand hooks to lift embedded fibers and maintain adhesive-backed Velcro performance.

- Duct tape – Press sticky side onto hooks, peel away debris for quick Adhesive Removal.

- Multisurface cleaner – Dampen cloth, wipe gently for Fabric Protection during Velcro Maintenance.

Regular Cleaning prevents permanent damage.

Safe Velcro Removal Techniques

Removing Velcro without causing Velcro Damage starts with Gentle Detaching. Use a plastic card to lift edges gradually along the weave, not straight away from the fabric.

If adhesive remains after closure removal, soften it with a hair dryer held at a safe distance before peeling. Test hidden areas first to prevent fabric repair issues, ensuring adhesive removal and residue cleaning won’t affect color or finish.

Repairing Fabric After Velcro Removal

Once you’ve pulled off the Velcro, adhesive removal becomes your priority. Here’s how to restore the fabric without damage:

- Apply citrus-based cleaner or isopropyl alcohol to residue, testing a hidden spot first for colorfast testing.

- Trim fringe repair areas where loose threads remain.

- Press a matching patch over weakened spots for clothing repair.

- Reinforce with interfacing if patching holes appear.

Frequently Asked Questions (FAQs)

Can Velcro be attached to any type of fabric?

Velcro works on most fabrics, but delicate, highly stretchable, or coated materials need specialized attachment methods.

Rough textures reduce adhesive grip, while extremely lightweight fabrics may require reinforcement for lasting durability.

Can Velcro be attached to leather?

Yes, you can attach Velcro to leather using sew-on or adhesive-backed options. Surface prep with isopropyl alcohol improves adhesion, while stitching offers greater durability for load-bearing applications compared to adhesive methods alone.

Can Velcro be attached to a curved surface?

You can attach Velcro to curved surfaces, though adhesive-backed versions may struggle on tight curves.

Sew-on Velcro works best since stitching follows fabric contours naturally, ensuring flexible, durable fastening on curved fabric solutions.

Can Velcro be removed from fabric?

Like peeling a bandaid, careful technique makes all the difference. You can remove Velcro from fabric using removal safety precautions, though adhesive residue cleaning and fabric damage prevention remain essential for successful fastener extraction and Velcro reusability.

How long does it take for fabric glue to dry?

Most fabric glues set to touch within 15 to 60 seconds, but you’ll need to wait 24 to 72 hours for full curing strength, depending on the adhesive type and fabric density.

Can Velcro be washed in the machine?

Most sewn Velcro fasteners tolerate gentle machine wash cycles when you turn fabric inside out, use mild detergent, and skip fabric softener.

Adhesive-backed types need hand washing since water weakens the bond over time.

How long does adhesive Velcro typically last?

Ironically, the “permanent” adhesive on Velcro fasteners usually holds just 6 to 12 months with regular DIY use.

Bond strength weakens faster on textured fabrics, making adhesive longevity depend heavily on surface preparation and fabric adhesion quality.

Does Velcro damage fabric over time?

Over time, Velcro hook surfaces can cause fiber damage through abrasion on delicate fabrics. Adhesive residue attracts lint and may tear material during removal.

Proper fastening techniques greatly extend fabric longevity.

Can you reuse Velcro after removing it?

Yes, you can reuse Velcro after removal, but adhesive-backed versions often lose their tack. Sew-on Velcro holds up better across multiple uses, especially on sturdy fabrics, though hook damage and fabric residue affect reattachment success.

What temperature should iron-on Velcro use?

Set your iron between 250°F and 350°F, depending on the Velcro brand and fabric type. Medium heat with no steam works best, activating the adhesive without scorching delicate textiles during application.

Conclusion

Does Velcro really need special treatment, or can you just slap it on and hope for the best? The answer lies in matching method to material—adhesive fails on textured fabrics, while stitching prevents peeling on high-stress closures.

When you understand how to attach Velcro to fabric using the right combination of preparation, attachment method, and reinforcement, you create closures that withstand years of use. Your next Velcro repair won’t need another repair.