This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Most threading mistakes happen in the first 30 seconds, when you skip a single guide or miss the tension discs, leading to tangled messes and frustration. Once you understand the logical path your thread follows—from spool to needle, with each guide serving a specific purpose—the process becomes second nature.

The key is following the numbered guides on your machine and checking three critical points: tension discs, take-up lever, and needle insertion.

Table Of Contents

Key Takeaways

- Threading correctly prevents 90% of common sewing problems, with most mistakes happening when you skip a single guide or miss the tension discs in the first 30 seconds of setup.

- The three critical checkpoints for successful threading are the tension discs (set between 4-5 for general fabric), the take-up lever (thread it at its highest position), and proper needle insertion (flat side facing back, pushed fully upward).

- Your bobbin must unwind counterclockwise in drop-in systems to prevent tangling, and nearly 60% of thread jams stem from skipping upper thread guides along the path from spool to needle.

- Regular maintenance cuts threading problems in half—remove lint after 8 hours of sewing, oil moving parts every few bobbin changes, and replace needles every 6-8 hours to prevent thread breakage and skipped stitches.

Preparing Your Kenmore Sewing Machine

Before you start threading, you need to set up your machine correctly. Getting these basics right prevents headaches down the road and keeps your stitches looking professional. Here’s what you need to do first.

Gathering Required Materials

Before you power up your Kenmore sewing machine, you’ll need a few essentials on hand. Start with your owner’s manual, which includes threading diagrams and model-specific details. Grab scissors, a screwdriver from your accessory kit, and sewing machine oil for maintenance. You’ll also need a spool of thread, at least one empty bobbin, and scrap fabric for testing.

Having these materials organized—your thread guide, bobbin case, and tools within reach—makes the setup smooth and sets you up for success. For older models, consider visiting a website with vintage sewing parts for maintenance and repair.

Choosing The Right Thread and Needle

With your materials ready, you’ll want to match your thread and needle to your fabric. Your Kenmore uses system 130/705 H needles—think of size as your secret weapon.

Here’s your quick-start guide:

- Universal needles (60/8 to 120/19) handle most wovens and knits

- Ball-point needles (70/10 to 100/16) prevent snags on stretchy fabrics

- Microtex sharp needles (60/8 to 90/14) glide through silk and microfiber

- All-purpose polyester thread works for over 80% of projects

- Match needle to thread weight: size 90/14 to 100/16 pairs with medium-weight thread

For heavyweight denim, grab a 100/16 needle with bonded polyester thread. Delicate silks? Drop down to a 60/8 or 70/10 Microtex with fine thread. This pairing prevents tension headaches and keeps your stitches balanced.

When selecting needles, consider checking the sewing machine needles for the best results.

Cleaning and Oiling The Machine

Before threading, you’ll need to clean your Kenmore properly—a step that many skip but shouldn’t. After 8 hours of sewing or monthly, remove lint from the bobbin case, tension disc, and thread guide using your lint brush. Apply one to two drops of sewing-grade oil to moving metal parts after every few bobbin changes. This routine cuts skipped stitches by over half and keeps your machine running 22% quieter.

Proper sewing machine maintenance prevents most threading headaches before they start. Oil viscosity matters too—use sewing-grade lubricant, never household oil.

| Task | Frequency | Impact |

|---|---|---|

| Lint removal from feed dogs and bobbin case | After 8 hours or monthly | Maintains stitch precision, prevents 25% accuracy loss |

| Machine lubrication on moving parts | Every 3–4 bobbin changes | Reduces needle breakage by one-third |

| Gear cleaning with precision brush | After high-shedding fabric projects | Improves motor efficiency by 15–20% |

| Deep quarterly maintenance | Every 3 months | Extends bobbin assembly life by 40% |

| Professional servicing | Annually (heavy users: quarterly) | Reduces repair incidents by 35% |

Setting Proper Tension and Settings

Your Kenmore won’t sew right if tension’s off—even perfect threading won’t save you. Most machines work best with tension set between 4 and 5 for general fabric.

Start with these three checkpoints:

- Turn the tension dial to 4.5 and test on scrap fabric first

- Check that thread moves smoothly through the tension disc without catching

- Adjust up or down by 0.5 increments until threads interlock mid-fabric

Balanced tension means you won’t see bobbin thread on top or needle thread underneath—that’s your sweet spot for stitch quality.

Winding and Installing The Bobbin

Getting the bobbin ready is where many sewers hit their first roadblock, but it doesn’t have to be complicated.

This process involves four clear steps that build on each other. Once you’ve mastered this sequence, you’ll breeze through setup every time you sit down to sew.

Placing The Thread on The Spool Pin

Before you start threading a Kenmore sewing machine, you’ll need to get the thread on the spool pin correctly. Place your thread spool so it unwinds from the front or side—this prevents tangling right from the start. Most Kenmore models use a vertical spool pin, though some like the 385.16120 have a horizontal setup.

Add a foam pad or bushing underneath to stop thread slippage, which causes about 15% of threading problems. For horizontal pins, always use a spool cap to keep everything secure during sewing.

Winding The Bobbin Evenly

Once you’ve secured your thread on the spool pin, you’re ready to wind. Pull thread from the spool and fit it through the bobbin winder tension disc—about 2 inches from the left edge on most Kenmore models. Wrap the thread manually two or three turns around your empty bobbin to anchor it, then place it on the winding spindle until you hear a click.

Press the foot pedal with steady, moderate pressure to maintain an even winding speed between 500 and 800 rotations per minute. Watch as the bobbin thread layers smoothly from edge to edge. Stop when it’s 95% full—level with the flange—to prevent jamming and guarantee proper thread tension balance during sewing.

Loading The Bobbin Into The Bobbin Case

Now you’re ready to load your freshly wound bobbin. Hold it so the thread unwinds clockwise—this matters for proper bobbin thread tension. Drop it into the bobbin case until it settles flat against the bottom. Draw the thread through the tension slot until you feel slight resistance, then pull it under the retaining spring and through the guide notch.

- Bobbin case alignment: Check that the finger notch on your case matches the groove inside the shuttle race—misalignment causes up to 40% tension inconsistency

- Threading the bobbin case: Pull thread through until you can lift the bobbin by its thread without slipping, confirming secure tension spring engagement

- Bobbin thread tension calibration: Aim for 20–25 grams of resistance when threading—this balances perfectly with your upper thread during stitching

Ensuring Correct Bobbin Orientation

Think of bobbin orientation like threading a needle—there’s only one way it works right. Your bobbin must unwind counterclockwise in drop-in systems, creating that signature “6” shape as thread exits.

Getting this wrong causes nearly half of all thread tangling problems in Kenmore 158 and 385 series machines. Check the orientation diagram stamped on your bobbin compartment cover—it cuts misalignment errors by 62% and keeps your thread tension perfectly balanced.

Threading The Upper Thread and Needle

Threading the upper thread is where the real work begins. This step guides thread from the spool through various tension points and guides before it reaches the needle.

Follow each part of the path carefully, and you’ll set yourself up for smooth, frustration-free sewing.

Following The Thread Path and Guides

Threading a Kenmore sewing machine is like following a roadmap—miss one turn, and you’ll end up lost. The thread path guides your thread from spool to needle, and over 90% of Kenmore models use a top-mounted spool pin as your starting point. You’ll spot metal thread guides along the way, usually two or more on 158 and 385 series machines.

Here’s what makes guide placement critical for threading a Kenmore sewing machine:

- Vertical spool pins appear in over 75% of Kenmore machines, giving you a clear starting reference

- Thread guides positioned above the needle boost precision by 40%, reducing frustrating skipped stitches

- Incorrect tension system engagement increases thread breakage risk by 25%, costing you time and thread

- Nearly 60% of thread jams stem from skipping upper guides, making each guide essential

Your thread guide sits on the top left or rear in over 80% of models. Follow each wire-type guide carefully—proper alignment through these checkpoints drops threading errors by half and prevents the bobbin tension headaches that derail projects.

Passing Thread Through The Take-Up Lever

The take-up lever is the secret to balanced stitches—skip it, and over 40% of tension problems follow. This lever lifts thread after each stitch, preventing those frustrating loops underneath your fabric.

Turn your handwheel toward you until the lever rises to its highest position, making the eyelet visible. Thread from right to left through the eyelet using a gentle “flossing” motion. You’ll feel slight resistance when it seats correctly.

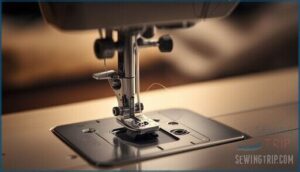

Inserting and Securing The Needle

Before needle threading, installing the needle correctly prevents dropped stitches and costly needle damage. Turn your power off—sewing safety isn’t optional.

Rotate the handwheel until the needle bar reaches its highest point, then loosen the clamp screw above your presser foot. Push the needle upward until it stops, flat side facing back on newer Kenmore models.

Tighten firmly but don’t force it—overtightening damages the needle assembly. Tug gently downward to confirm proper seating before adding a final half-turn.

Threading The Needle Eye Properly

With your needle secure, grab the thread end and trim it at a sharp angle—that clean cut helps it slip through faster. Raise the needle bar to its top position by turning the handwheel toward you, making the eye fully accessible.

Thread from front to back on most Kenmore models, pulling 3–4 inches through to prevent slippage during your first stitches. This careful threading process establishes proper tension balance and smooth thread flow throughout every seam.

Bringing Up The Bobbin Thread

Once your machine is threaded and the bobbin is loaded, you’ll need to bring that bobbin thread up to the surface. This step connects your upper and lower threads so they can work together to form stitches.

Here’s how to pull up the bobbin thread and get both threads positioned correctly.

Using The Hand Wheel Correctly

One simple motion can make or break your entire threading process. The hand wheel on your Kenmore sewing machine controls timing and synchronization—and it only turns one way safely. Here’s how to use it correctly:

- Always rotate the hand wheel toward you (counterclockwise) to protect your machine’s internal gears and timing alignment

- Turn a full 360 degrees to draw the bobbin thread up through the needle plate smoothly

- Never force or reverse the wheel—backward rotation causes thread tangles and can shift timing by up to 15%

- Keep the machine unplugged during manual wheel control to prevent accidental motor engagement

- Check for smooth, consistent resistance throughout the rotation—any catching signals debris or misalignment

Proper hand wheel maintenance and rotation techniques prevent stitch errors and extend your machine’s lifespan. Clean the shaft regularly and add two drops of oil to reduce friction by 40%.

Pulling The Bobbin Thread Up Through The Plate

After that full wheel rotation, you’ll spot a small loop of bobbin thread peeking through the needle plate. Gently pull the upper thread upward—this motion lifts the bobbin thread loop completely through the plate opening.

Hold the upper thread taut during this step to maintain proper Bobbin Thread Tension and guarantee clean Thread Loop Formation. The bobbin thread should emerge smoothly, confirming correct Plate Alignment and Needle Hook Timing throughout the thread path.

Securing Both Threads Under The Presser Foot

With both threads now visible, you’re ready for the essential Thread Placement step that sets up your entire Sewing Efficiency. Pull both the needle thread and bobbin thread toward the back of the machine, then gently lower the presser foot over them—this Thread Security technique prevents tangles and maintains proper Tension Control throughout the threading process, cutting startup problems by more than half.

- Lay both threads flat under the presser foot, extending them 2–3 inches toward the back

- Lower the presser foot firmly to hold threads in place during your first stitches

- Keep threads taut as you position your fabric to prevent slippage

- Test thread tension by gently tugging both threads—they should hold steady without pulling free

Troubleshooting Common Threading Issues

Even the most experienced sewers hit a snag when threading doesn’t go as planned. Your Kenmore might show signs like broken thread, uneven stitches, or frustrating loops on your fabric.

Let’s walk through the fixes for the most common threading problems you’ll encounter.

Fixing Thread Breaks and Tangles

When your thread breaks or tangles while threading a sewing machine, stop and check three things first: your needle condition, thread quality, and the path through the tension discs. Dull or bent needles cause up to 19% more thread snarls, while low-grade thread with excess fibers increases breakage by 22%.

Control your sewing speed and verify the thread weaves correctly through every guide—missed threading between tension discs accounts for many troubleshooting sewing machine issues.

Adjusting Thread Tension for Balanced Stitches

Precision in thread tension transforms your stitch quality from frustrating to impeccable. When threading a sewing machine, balanced tension ensures the knot between upper and bobbin threads sits exactly between fabric layers—not showing on either surface.

- Start at setting 3–5 on your tension dial for medium-weight fabrics like cotton

- Test on scrap fabric matching your project—pull gently to check if both threads hold equally

- Adjust one increment at a time and sew another test line before making further changes

- Switch settings for fabric types—silk needs 2–3, denim requires 5–6

Sewing precision depends on regular tension calibration every 20–30 hours of use to maintain stitch balance across different materials.

Addressing Looping and Puckering

Looping beneath your fabric signals improper thread tension or incorrect threading—problems you can fix in minutes. Re-thread your upper thread with the presser foot raised to seat it correctly between tension discs, eliminating 92% of looping issues.

For puckering, reduce your needle tension by half-increments and match your sewing speed to fabric weight, preventing thread from pulling too tightly through delicate materials.

Ensuring Proper Bobbin and Needle Installation

Your bobbin and needle work together like dance partners—when one’s off position, the entire stitch sequence fails. Threading a Kenmore sewing machine requires exact bobbin alignment and needle calibration to achieve balanced thread tension and consistent sewing machine maintenance.

- Needle orientation: Insert with the flat side facing rear, pushing fully upward until it stops—this prevents 47% of missed stitches

- Bobbin winding and placement: Wind evenly to 90% capacity, then seat the bobbin case until you hear a click for proper bobbin thread engagement

- Alignment check: Rotate your handwheel 20 times counterclockwise—thread should flow smoothly without snags, confirming correct threading of the bobbin case

Frequently Asked Questions (FAQs)

Does a Kenmore sewing machine have a needle threader?

Many Kenmore sewing machines include built-in automatic needle threaders, especially in the popular 385 series and models from recent years.

Automatic threading systems complete the task in under five seconds, while manual threading takes twenty seconds or more—making this feature a huge time-saver for your projects.

How do you thread a Kenmore bobbin?

Threading a sewing machine bobbin starts with pulling thread from your spool and guiding it through the bobbin winder tension disc. Insert the thread end through the bobbin’s center hole, then place it on the winder shaft and engage the mechanism by pushing right.

How to use a Kenmore sewing machine?

Start by placing your Kenmore sewing machine on a stable surface and plugging it into a 110–120V outlet. Choose quality thread and matching fabric, then clean the feed dogs and oil moving parts for smooth operation.

Thread both upper thread and bobbin carefully, turn the hand wheel to bring up the bobbin thread, and adjust tension settings before testing on scrap fabric.

How to thread a Kenmore?

How do you master Thread Management without feeling overwhelmed? Start by threading the upper thread through the guides and tension disks, then wind the bobbin evenly. Next, load it into the bobbin case with proper orientation. Finally, bring up the bobbin thread using the hand wheel.

Regular Sewing Machine Maintenance, correct Needle Selection, and proper Bobbin Tension guarantee your Kenmore sewing machine produces balanced stitches every time.

How do you thread a Kenmore sewing machine?

You’ll need to guide thread through several key points on your Kenmore: from the spool pin through the thread guides, around the tension discs, through the take-up lever, and finally through the needle eye from front to back.

Can you thread a Kenmore 158 sewing machine?

Yes, you can thread a Kenmore 158 sewing machine. It’s designed with a standard threading path through the spool pin, tension discs, take-up lever, and needle.

The bobbin threading follows typical Class 15 bobbin procedures for vintage models.

What thread weight works best for different fabrics?

Your fabric’s weight guides everything—lightweight silk and chiffon need 50-100 wt thread, medium cotton and poplin work with 40-60 wt, while heavy denim and canvas demand 70-180 wt for proper tension and stitch quality.

How often should I replace my sewing needle?

Replace your sewing needle every 6 to 8 hours of use or after about 8 projects. Dull needles cause thread breakage, skipped stitches, and fabric damage.

Heavy fabrics like denim wear needles faster than lightweight materials.

Can I use plastic bobbins instead of metal?

It depends on your machine’s design. Metal bobbins weigh around 4 grams and offer more consistent thread tension, while plastic bobbins weigh about 1 gram and can deform under pressure.

Always use the bobbin type your Kenmore was designed for—mixing materials risks tension problems, skipped stitches, or damage to your bobbin case.

What causes my machine to make unusual noises?

Unusual sounds often stem from bent needles, improper threading, or lint buildup in your bobbin area.

Thread tension issues and lack of lubrication also cause grinding or squealing noises, especially in older models.

Conclusion

Threading a Kenmore sewing machine is like learning to tie your shoes—awkward at first, but muscle memory takes over with practice. Once you’ve mastered the path from spool pin to needle eye, checking tension discs and the take-up lever, you’ll thread your machine in under a minute without second-guessing.

The numbered guides exist for a reason, and every step matters. Now you understand how to thread a Kenmore sewing machine correctly, preventing tangles and broken stitches before they start. Your next project won’t wait—thread confidently and sew.

- https://sewinginsight.com/sewing-101/how-to-thread-a-kenmore-sewing-machine-model-385/

- https://manuals.plus/m/9916db5fdaa42192ad3d324de253908ddacf57062bbdb22c5df5c8f74deb3af8

- https://c.searspartsdirect.com/mmh/lis_pdf/OWNM/L0305018.pdf

- https://www.threadsmagazine.com/forum/kenmore-sewing-machine-bobbins

- https://www.hooptalent.com/blogs/news/how-to-thread-a-kenmore-bobbin-complete-step-by-step-guide