This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

That first crooked cut can haunt a quilter for hours—what started as a simple square block suddenly refuses to line up, leaving you with puckered seams and frustration. I’ve watched countless students struggle with this exact problem, and nine times out of ten, the culprit isn’t technique or talent. It’s ruler accuracy.

When you learn how to use quilting rulers accurately, everything changes. Your blocks fit together like puzzle pieces, your fabric stretches further, and those crisp points you’ve been chasing? They suddenly become achievable.

The difference between a quilt that looks handmade and one that looks professionally crafted often comes down to mastering a few key principles with your ruler and rotary cutter.

Table Of Contents

- Key Takeaways

- Why Accurate Quilting Ruler Use Matters

- Essential Types of Quilting Rulers

- Choosing The Right Quilting Ruler

- Preparing Fabric for Accurate Ruler Use

- Step-by-Step: Cutting Fabric With Quilting Rulers

- Preventing Ruler Slippage During Cutting

- Troubleshooting Common Quilting Ruler Issues

- Advanced Tips for Mastering Quilting Ruler Accuracy

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Ruler accuracy is the foundation of professional-looking quilts—cuts off by even 1/8 inch prevent blocks from fitting together and cause quilters to abandon projects entirely.

- Three essential ruler types cover most quilting needs: standard rectangular rulers (6″x24″) for strips, square rulers (6.5″, 9.5″, 12.5″) for block trimming, and specialty angle rulers for complex shapes like triangles and hexagons.

- Proper fabric preparation before cutting—prewashing, pressing with an up-and-down motion, applying spray starch, and aligning with the straight grain—makes the difference between wonky cuts and laser-straight precision.

- Preventing ruler slippage requires spreading fingers across the ruler like a spider for multiple contact points, keeping your pinky on the mat as an anchor, and using non-slip grips or adhesive dots for stability during rotary cutting.

Why Accurate Quilting Ruler Use Matters

If your cuts are off by even an eighth of an inch, your blocks won’t fit together right—and that’s frustrating. I’ve seen quilters abandon projects because their pieces didn’t line up, and it almost always comes back to ruler technique.

That’s why mastering your quarter-inch seam allowance is just as important as getting your cuts right—they work together to keep everything square.

Poor ruler technique is why quilters abandon projects when their misaligned blocks won’t fit together

Let’s look at three reasons why nailing your ruler accuracy changes everything.

Precision in Quilting Projects

Think of precision as your quilting superpower. When you master using quilting rulers for fabric alignment and measurement control, your blocks stay within 1⁄16 inch of target size—that’s quilting accuracy that makes seams meet perfectly!

Precision cutting with proper quilting techniques keeps triangle points sharp instead of blunted, transforming your patchwork from okay to absolutely stunning.

To learn more about essential tools for this process, explore this guide on versatile quilting rulers and accessories.

Reducing Fabric Waste

Accurate ruler work isn’t just about beautiful blocks—it’s your secret weapon for fabric scrap management and waste reduction strategies! When you nail precision cutting, you’re using every inch wisely. Here’s how efficient cutting techniques with quilting rulers save your precious fabric:

- Plan cuts before measuring to nest pieces tightly and save several inches per project

- Cut largest shapes first from strips to minimize offcuts that can’t be used

- Align your rotary cutter exactly with ruler edges to avoid losing that extra 1⁄8 inch

These sustainable quilting practices turn fabric measurement into smart resource use! For more tips, explore to improve your fabric efficiency.

Improving Cutting Efficiency

Beyond saving fabric, you’ll work faster when your ruler skills are dialed in! Batch cutting with quilting rulers lets you stack two to four layers and slice identical strips in one smooth rotary cutter pass—huge time saver.

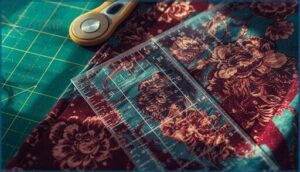

Pair your rotary cutting setup with a self-healing mat and sharp blade, and you’ll breeze through fabric cutting sessions while keeping every measurement spot-on.

Essential Types of Quilting Rulers

Walking into a quilt shop for the first time, you’ll see dozens of rulers lining the walls—some long and skinny, others perfectly square, and a few that look like they belong in a geometry class. Here’s the thing: you don’t need them all, but knowing which ones actually matter will save you money and frustration.

Let’s break down the three essential ruler types every quilter should understand.

Standard Rectangular Rulers

Ever notice how a long acrylic ruler feels like your quilting backbone? Standard rectangular quilting rulers (think 6″x24″) are game-changers for cutting efficiency and fabric alignment. Here’s why you’ll love them:

- Clear acrylic material boosts visibility and accuracy tips.

- Perfect for slicing strips with a rotary cutter on a self-healing mat.

- Easy ruler maintenance keeps measurements crisp.

Square Rulers for Blocks

Your square ruler transforms chaotic patchwork into crisp, professional blocks. Popular sizes—6.5″, 9.5″, and 12.5″—handle most block trimming needs with built-in seam allowances.

Grid alignment becomes simple when you match the ruler’s bold 45-degree line to diagonal seams, ensuring cutting precision every time. Non-slip coatings keep fabric squaring steady during rotary work.

Choose your quilting tool selection based on your most common block dimensions—that’s smart quilting tips and tricks in action!

Standard sizes like 6″ or 12″ blocks work best with dedicated rulers, though fabric cutting tips for beginners can help you get precise results with any tool you choose.

Specialty and Angle Rulers

Triangle Rulers, hexagon rulers, and Dresden plate tools enable complex shapes without hand-drawing each piece. Built-in 45-degree, 60-degree, and 90-degree angle rulers cut diamonds and wedges fast—some multi-size triangle rulers handle several dimensions in one pass!

Shape rulers include quarter-inch seam allowances so your blocks finish perfectly. These fabric cutting techniques turn specialty quilting rulers into your secret weapon for intricate patterns.

Choosing The Right Quilting Ruler

Not all quilting rulers are created equal, and picking the right one can make or break your cutting accuracy. You’ll want to examine a few key features before you invest in your next ruler.

Let’s break down the three most important factors that’ll set you up for success.

Ruler Size and Thickness

Your quilting ruler selection starts with matching size and thickness to the job at hand. Standard ruler sizes like 6×24 inches span full-width fabric strips, while a 12.5-inch square block ruler variety lets you trim finished blocks with seam allowances in one move.

Acrylic ruler thickness around 3 millimeters keeps your rotary blade safely along the edge, and task-specific long ruler or smaller square options give you control without excess overhang.

Material Durability and Visibility

Clear acrylic ruler durability defines how long your measurements and cutting stay true. Most quality acrylic rulers resist bending under normal pressure, maintaining straight edges through thousands of rotary cutter passes without cracking.

UV impact from sunlight can yellow plastic and reduce marking clarity over time, so store rulers away from windows.

Scratch resistance matters—deep nicks change your cutting line, so use sharp blades to avoid gouging edges.

Non-Slip Features and Markings

Slippage turns perfect cuts into frustration—that’s why non-slip features matter. Integrated coatings on acrylic ruler backs grip fabric without repositioning hassle, while adhesive grip strips lock edges during pressure. Disc placement near corners prevents shifting on curved rulers and wide ruler foot areas.

High-contrast lines in neon shades let you see measurements on any fabric, and printed angle utility markings guide triangle cuts with zero guesswork.

Preparing Fabric for Accurate Ruler Use

Before you even pick up that ruler, your fabric needs some attention. Think of it like prepping ingredients before you cook—skip this step, and you’re setting yourself up for wonky cuts and frustration.

Let’s walk through the three essential prep steps that’ll make your ruler work like magic.

Squaring and Pressing Fabric

Before your rotary cutter ever touches fabric, proper preparation makes all the difference. Start with these essential steps for precise cuts on your self-healing mat:

- Prewash fabric and dry it completely so shrinkage happens before you measure with quilting rulers.

- Press with an up-and-down motion rather than sliding—this prevents distortion during fabric cutting.

- Apply spray starch to stiffen fibers, especially helpful for bias edges; the starch benefits include reduced stretch and cleaner rotary cutter lines.

Watch your steam effects carefully—too much moisture can relax cotton and throw off your measurements!

Aligning Fabric Grain

Once your fabric is pressed, the next step in fabric preparation is spotting the grain. Look at the selvage edge—straight grain runs parallel to it with minimal stretch, while cross grain crosses at right angles with slightly more give. Bias grain sits at 45 degrees and stretches the most.

Here’s a quick reference for grain alignment with quilting rulers:

| Grain Type | Stretch Level | Best Uses |

|---|---|---|

| Straight Grain | Minimal | Long borders, sashing, stable seams |

| Cross Grain | Moderate | Shorter pieces, forgiving joins |

| Bias Grain | Maximum | Binding, curved edges, diagonal units |

| Visual Check | Selvage reference | Align ruler edges before cuts |

| Stretch Test | Gentle pull | Confirms grain direction accuracy |

Try this simple stretch test: gently tug fabric in different directions. Straight grain use means finding that firm, stable direction. Cross grain cuts allow a bit of ease, perfect for smaller patchwork. Bias grain handling requires a light touch—it’s stretchy and distorts easily if you’re not careful!

When fabric hangs with a twist from the selvages, slide the layers until it hangs smoothly. This corrects off-grain issues before you place your quilting rulers. For directional prints that run slightly skewed, you can choose visual alignment over thread direction so your finished blocks look straight.

Single-layer fabric cutting works better for badly off-grain yardage because you can see the actual thread direction. Some quilters even dampen and block stubborn fabric, stretching it into alignment and letting it dry flat—a breakthrough for fabric management when dealing with challenging yardage!

Your quilting fundamentals improve dramatically when you master grain alignment. Line your ruler’s long edge with straight grain for stable strips that won’t bow or arch. Place the 45-degree line on your ruler against the selvage for true bias binding that stretches evenly around quilt edges.

Boom—your fabric cutting just leveled up!

Using a Cutting Mat Effectively

Your cutting mat is the foundation for accurate fabric cutting. A self-healing mat closes up after rotary cutter slices, maintaining smooth surfaces for years. Grid alignment lets you square fabric without constantly repositioning quilting rulers—just match fabric edges to the printed lines. Mat rotation distributes wear evenly, preventing grooves.

Regular surface cleaning with water removes fuzz for consistent cutting efficiency!

Step-by-Step: Cutting Fabric With Quilting Rulers

Now that your fabric is prepped and ready, it’s time to get into the actual cutting—this is where the magic happens!

I’m going to walk you through the three essential elements that make every cut clean, straight, and safe. Master these basics, and you’ll build the confidence and muscle memory that turn good quilters into great ones.

Ruler Placement and Alignment

Before you press that rotary cutter to fabric, nail your ruler placement—it’s the difference between blocks that fit together like a dream and pieces that won’t cooperate.

Here’s how to align quilting rulers for accurate fabric cutting and measurement:

- Edge Alignment: Place your ruler’s long edge exactly on the fabric edge with zero gaps—both top and bottom registration lines should touch for strips that don’t fan out.

- Grain Alignment: Line up ruler markings with the fabric fold, not the selvage, since folds reflect true grain after handling.

- Grid Line Use: Position the exact measurement line you need—say, 2½ inches—on the fabric edge while the ruler’s outer edge becomes your cutting reference.

Check that ruler angles and measurements stay consistent along the entire length!

Hand Positioning for Stability

Once your ruler’s in place, your hand becomes the anchor that keeps everything steady. Spread your fingers like a spider across the ruler—at least four contact points distribute pressure and stop wobble during long cuts. Keep your thumb and pinky off the ruler edge and onto the mat for extra stability, and position your palm over the first third where the blade starts.

Walk your hand up in short moves rather than stretching—overreaching is when rulers slip most. Apply firm pressure through your heel, keeping your wrist relaxed and in line with your forearm to avoid fatigue. For 24-inch rulers, stop mid-cut to reposition instead of trying one long pass!

| Hand Zone | Why It Works |

|---|---|

| Spider spread fingers | Four-plus contact points prevent ruler tipping and shifting |

| Thumb parallel to edge | Keeps half-inch safety buffer from rotary cutter blade |

| Palm over ruler center | Even pressure stops bowing and maintains flat contact |

Using a Rotary Cutter Safely

Three seconds of focus can prevent months of healing. Always close your rotary cutter‘s blade guard after every single pass—those modern sliding shields exist for accident prevention, not decoration!

Cut away from your body with firm, controlled strokes, keeping your ruler grip steady and fingers well back from the edge. Sharp blades need less pressure and won’t skip threads, making rotary cutting safety almost simple when you follow these quilting safety guidelines.

Preventing Ruler Slippage During Cutting

Nothing ruins a good cut faster than a ruler sliding at the last second. You’ve lined everything up perfectly, started your rotary cutter, and then—whoosh—the ruler shifts and throws off your measurement.

Let’s lock down three practical techniques that’ll keep your ruler exactly where you put it, so every cut is as accurate as the first.

Applying Even Pressure

Your hand is the anchor keeping everything in place while you cut. Use gentle fingertip pressure instead of forcing down with your palm—steady downward force works better than white-knuckling it.

Position your forearm so pressure direction travels straight down, keeping quilting rulers flat against fabric.

Proper ergonomic setup, with your cutting surface at elbow height, helps you control rotary cutter movement without strain.

Utilizing Non-Slip Grips or Adhesives

When grip enhancement makes all the difference, adhesive types transform slippery quilting rulers into stable cutting partners. Non-slip coatings like clear grip dots or textured strips stick to your ruler’s back, boosting traction against fabric on your self-healing mat.

These ruler stabilization additions prevent sideways movement during rotary cutter passes, keeping cuts laser-straight without extra hand strain—a total breakthrough for quilting tools accuracy!

Stabilizing The Ruler With Hand Techniques

Your cutting posture changes everything when you want rock-solid ruler grip. Spread your fingers across the quilting ruler with slight pressure from your fingertips—that’s where real hand alignment starts.

Keep your pinky just off the edge as an anchor while your rotary cutter glides beside your hand on the self-healing mat. This blade control technique beats white-knuckling every time!

Troubleshooting Common Quilting Ruler Issues

Even with the best techniques, you’ll run into a few frustrating hiccups—crooked cuts, rulers that won’t stay put, or measurements that seem to shift mid-project.

The good news? Most of these problems have simple fixes once you know what to look for. Let’s tackle the most common ruler headaches and get you back to smooth, accurate cutting.

Fixing Crooked or Uneven Cuts

Ever notice how a crooked strip can throw off your entire block? When you spot uneven cuts—strips wider at one end or blocks that won’t nest—it’s time for some edge trimming magic. Here’s your fabric realignment game plan using quilting rulers and your rotary cutter:

- Realign one straight woven edge with your ruler width markings before recutting

- Open strips fully, smooth flat, then trim curves using a long ruler for strip adjustment

- Square oversized blocks with a square ruler for uniform cutting corrections

- Remove wavy borders, recut straight strips to exact measurements, then reattach

- Trim corner triangles by aligning both ruler edges with quilt sides for true right angles

Addressing Slipping and Shifting

Your ruler acting like it’s skating on ice? First, lock in stable body posture—stand square to your cut so pressure stays straight. Next, check work surface stability and place your self-healing mat on a non-slip table. Sharp blade importance can’t be overstated; dull rotary cutters push rulers sideways. Finally, add adhesive grips to your quilting rulers for extra traction. These quilting tips transform slippery fabric cuts instantly!

Ensuring Consistent Measurements

Once slippage stops, measurement drift sneaks in. Align the same edge of your quilting rulers every time—creeping differences add up to more than ⅛ inch across blocks! Match ruler lines to the fabric’s cut edge, not the selvage, for uniform strips.

For ruler calibration, confirm that 1 inch, 2 inch, and 5 inch markings sit flush along the fabric edge. Boom—cutting precision locked in!

Advanced Tips for Mastering Quilting Ruler Accuracy

You’ve mastered the basics, and now it’s time to take your ruler skills to the next level. These sophisticated techniques will help you discover hidden features on your rulers, tackle more complex cuts with confidence, and keep your tools in top shape for years to come.

Let’s explore three game-changing strategies that’ll transform the way you work with quilting rulers.

Leveraging Angle and Grid Markings

Mastering those printed lines transforms your Quilting Rulers from simple straightedges into precision instruments! Grid Alignment lets you see exactly where your rotary cutter will land, while Angle Cutting becomes second nature once you understand how those diagonal markings relate to your fabric edge on the Self-Healing Mat.

Here’s how to leverage every marking for Diagonal Trimming success:

- Match seam lines to 45-degree marks when squaring half-square triangles—the line becomes your trimming roadmap

- Use contrasting grid lines to keep Precision Markings visible on both light and dark fabrics

- Align vertical grids with fabric grain for perfect Ruler Calibration before every cut

- Follow diagonal grid spacing when planning straight-line quilting with your Ruler Foot

These reference points work together like a GPS for your fabric!

Combining Rulers for Complex Shapes

Once you’ve nailed those angle markings, you’re ready for the real fun—pairing straight rulers with curved or arc rulers to build stunning feathers, fans, and clamshells!

Start with your straight edge to establish “spine” lines, then overlay a circle ruler or arc template at those reference points.

When you combine rulers, maintain that same 0.25-inch offset from your rotary cutter edge so multi-segment curves flow seamlessly together.

Maintaining and Storing Rulers Properly

After you’ve mastered combining rulers for those show-stopping curved designs, let’s talk ruler maintenance—because clean, well-stored rulers keep your measurements accurate year after year!

Here’s my three-step system for ruler organization:

- Clean with mild dish soap and lukewarm water (never ammonia or alcohol—they’ll cloud your acrylic!)

- Store vertically in slotted racks or hang by holes to prevent warping

- Keep frequently-used rulers within arm’s reach of your cutting mat

Boom—your quilting tool essentials stay sharp and ready!

Frequently Asked Questions (FAQs)

What are common mistakes when using a ruler?

Many quilters make ruler misalignment and measurement mistakes by misreading markings, using dull rotary cutters, or applying uneven pressure—all leading to cutting errors, fabric distortion, and wasted material on their self-healing mat.

How to read a quilting ruler for beginners?

Reading a quilting ruler is like decoding a treasure map—locate whole inch numbers first, then count shorter tick marks for eighths or quarters.

Grid lines and angle markings guide your precision every step of the way.

How to improve accuracy when using a ruler?

Pressing fabric flat before cutting eliminates bumps that throw off edge alignment.

Place your pinky on the mat like a stabilizer, distribute pressure evenly across the ruler, and always cut with a sharp blade for measurement precision.

Can I use quilting rulers on stretchy fabrics?

Yes, you can use quilting rulers on stretchy fabrics, but stabilize them first with spray starch, interfacing, or a backing layer to prevent distortion and keep your cuts accurate and clean.

How often should I replace my rotary blade?

Replace your rotary blade every two to three weeks with daily cutting, monthly for moderate use, or when you notice skipped threads, jagged edges, or the need for extra pressure.

Blade sharpness directly affects your quilting rulers’ accuracy.

Whats the best lighting for accurate ruler placement?

You’d think better light wouldn’t matter much, but it’s everything.

Bright task lighting with 5000K–6500K color temperature, glare control, and illuminated rulers transform quilting ruler work into precision sewing room essentials.

Can quilting rulers be used for paper piecing?

Standard quilting rulers work great for trimming fabric around paper templates and squaring finished blocks.

For even faster, more precise seam allowances in paper piecing, grab an Add a Quarter ruler with its built-in lip.

Conclusion

Think of your ruler as the compass that guides every piece of your quilt home. When you learn how to use quilting rulers accurately, you’re not just cutting fabric—you’re building confidence with every slice.

Those perfectly matched seams and sharp points aren’t reserved for professionals anymore. They’re yours now. Press firmly, cut deliberately, and watch your quilts transform from patchwork experiments into heirlooms worth passing down.

- https://sarahgoerquilts.com/2017/07/14/my-favorite-tips-and-tools-for-accurate-fabric-cutting/

- https://snugglesquilts.com/rulers-cutting-safety-and-other-tips/

- https://www.quiltingboard.com/main-f1/making-rules-non-slip-t247474.html

- https://quilterscandy.com/quilting-ruler-hack

- https://www.google.com/search?q=quilting+ruler+market+growth