This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Most industrial sewing operators discover their machine’s speed control the hard way—usually after a seam goes sideways at 5,000 stitches per minute. The difference between professional-grade work and costly material waste often comes down to mastering one overlooked skill: precise speed adjustment.

Industrial sewing machine speed control settings don’t just slow down or speed up your stitching; they determine fabric handling precision, seam consistency, and whether you’ll finish a production run on schedule or spend hours picking out crooked stitches.

Modern machines offer foot pedals, digital interfaces, servo motors, and programmable profiles, but without proper calibration and technique, even the most elaborate equipment won’t deliver the control you need. Understanding how each adjustment mechanism works—and when to use it—transforms your relationship with the machine beneath your hands.

Table Of Contents

- Key Takeaways

- Key Industrial Sewing Machine Speed Controls

- Step-by-Step: Adjusting Speed Control Settings

- Factors Impacting Sewing Speed and Precision

- Advanced Speed Control Technologies

- Top 9 Accessories for Speed Control and Precision

- 1. Simthread Black Prewound Embroidery Bobbins Thread

- 2. Adjustable Drafting Stool With Wheels

- 3. Prewound White Sewing Machine Threads

- 4. Blind Hem Sewing Presser Foot

- 5. Clear Carpet Chair Floor Protector

- 6. Sewing Machine Thread Bobbin Set

- 7. Janome Blind Hem Sewing Foot

- 8. Brother SA133 Blind Stitch Foot

- 9. Binder Sewing Machine Presser Foot

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Mastering foot pedal pressure, digital speed settings, and speed reducers transforms industrial sewing from guesswork into controlled precision—letting you match fabric weight to motor RPM and avoid costly material waste.

- Proper calibration of tension, needle size, and speed limiters directly impacts seam consistency, with digital systems maintaining ±2% speed deviation versus manual controls that demand frequent adjustment.

- Servo motors outperform clutch motors by delivering quieter operation, lower energy consumption, and razor-sharp speed control from 200 to 5,500 stitches per minute with sub-50-millisecond pedal response.

- Accessories like prewound bobbins, ergonomic stools, and specialized presser feet support consistent speed control by reducing tension fluctuations, minimizing repositioning fatigue, and improving stitch visibility during high-speed production runs.

Key Industrial Sewing Machine Speed Controls

Industrial sewing machines offer several ways to manage stitching speed and precision. Understanding these controls is the first step to getting the results you want.

Here’s what you need to know about the main speed control features.

Foot Pedal Pressure and Its Effects

When you master foot pedal pressure control on an industrial sewing machine, you’re balancing speed, stitch quality impact, and fatigue. Pedal Pressure Ergonomics matter—an ergonomic pedal reduces discomfort and aids precise pressure calibration methods.

For sturdy materials, increased foot pedal pressure boosts Fabric Feed Accuracy, while lighter pressure suits delicate fabrics. Adjusting the presser foot pressure can solve common sewing problems. Consistent technique means fewer skipped stitches and smoother seams.

Speed Control Sliders and Dials

Once you’ve got a feel for foot pedal pressure, speed control sliders and dials offer another layer of finesse. Slider ergonomics matter—front-mounted sliders within easy reach, as seen on Janome and Brother, simplify adjusting sewing machine speed.

Dial precision lets you fine-tune speed increments; user feedback consistently favors illuminated tracks and ridged surfaces for accuracy. Brand comparisons show clear advantages. Understanding the importance of machine speed control is essential for efficient sewing.

Programmable Digital Speed Settings

If sliders and dials are your steering wheel, programmable speed settings are the cruise control. With digital speed control systems, you can preset stitch density and speed variance for each pattern, fine-tune motor calibration, and use electronic pedals for variable control.

Servo motors enable precise motor speed adjustment, letting you weave consistency and efficiency into every stitch—no guesswork required.

Speed Reducers and Their Functions

For industrial applications, speed reducers are your secret weapon for sewing precision. By introducing a mechanical advantage—usually via gear or pulley systems—you achieve significant speed reduction and torque increase.

That means you can stitch through leather or upholstery without breaking a sweat. Paired with an adjustable-speed servo motor, a speed reducer transforms industrial sewing machines into finely tuned tools for controlled, accurate work.

Step-by-Step: Adjusting Speed Control Settings

Getting your sewing machine’s speed just right isn’t guesswork—it’s a series of simple steps. Each adjustment brings you closer to smoother, more accurate stitching.

Here’s how you can fine-tune your speed control settings.

Setting Maximum Speed Limits

Ever wonder why your machine sometimes feels too fast, risking both sewing efficiency and fabric protection? Setting speed limiters—whether via digital panels, manual dials, or servo motor controls—lets you cap the maximum RPM.

Calibrate these controls carefully. A well-set maximum speed also preserves your work and extends the life of your industrial sewing machine and its speed reducer.

Using The Foot Pedal for Precision

Foot control is your gateway to precision stitching. With careful pedal calibration and consistent foot pedal pressure, you command speed regulation and variable control for every seam.

For delicate work, practice gradual pedal movement and ergonomic positioning—your posture shapes your accuracy. Mastering the foot pedal transforms sewing machine speed into an extension of your skill, especially when handling complex patterns.

Calibrating Digital and Manual Controls

When adjusting sewing machine speed, digital calibration offers considerable consistency—machines maintain ±2% speed deviation over 500 hours, far outperforming manual calibration. Digital speed control systems simplify calibration steps, reduce human error, and drive automation trends.

Manual speed control demands precise resistance checks and scheduled maintenance.

Embracing calibration standards for both methods ensures your speed adjustments remain reliable, accurate, and compliant.

Practicing Speed Adjustments on Scrap Fabric

Want to master speed control without risking expensive materials? Practicing on scrap fabric builds muscle memory, sharpens stitch consistency, and helps you find speed limits suited to each project.

You’ll spot machine wear before it becomes a problem, improve emergency stop techniques, and experiment with servo motor settings.

These sessions transform your sewing techniques—making every adjustment deliberate and every seam precise.

Factors Impacting Sewing Speed and Precision

Getting the speed and precision just right on your industrial sewing machine isn’t only about the controls. A few key factors can make or break your results. Here’s what you’ll want to pay attention to next.

Fabric Density and Thread Type

Did you know that fabric density and thread type can make or break your seam strength? If you’re working with dense material, higher thread tension and slower speed settings are essential for precision. Thread compatibility isn’t just a technicality—it’s your insurance against skipped stitches and weak seams.

- Dense fabrics demand thicker threads and lower speed

- Real-time tension adjustment avoids defects

- Seam strength rises with matched thread density

Needle Size and Stitch Length

Ever noticed how the wrong needle size or stitch length can sabotage seam efficiency? Matching needle types to fabric thickness and thread compatibility is essential.

For heavy materials, opt for larger needles and longer stitch lengths—think 16/100 needles and 4.0 mm stitches. Fine fabrics thrive on smaller needles and denser stitches.

Smart machine settings keep your sewing machine speed and stitch density balanced.

Machine Type, Condition, and Maintenance

When your industrial sewing machine starts humming louder or the table shakes more than usual, that’s machine vibration and noise levels flagging overdue maintenance. Skipping regular lubrication needs or ignoring part replacement invites speed loss and stitch inconsistency.

Clean, dust-free environments matter—dust buildup shortens machine life. Consistent machine maintenance keeps your machine condition stable, safeguarding both speed control and precision.

Thread Tension and Needle Compatibility

Once your machine’s humming is under control, don’t overlook thread tension and needle compatibility—they’re the linchpins for stitch quality. Tension Troubleshooting starts with these five checks:

- Needle Selection matches fabric density.

- Thread Compatibility prevents breaks.

- Adjusting thread tension avoids ripples.

- Industry Standards guide pairings.

- Balanced tension secures unblemished seams.

Advanced Speed Control Technologies

When you want more control over your industrial sewing machine, sophisticated speed technologies can make a real difference. These systems bring precision, efficiency, and smoother operation to your workflow.

Here’s what you’ll find in the latest speed control options.

Digital Regulation and Sensor Systems

When you’re chasing precision, digital control and sensor integration change the game. Digital pedals translate foot pressure into programmable speeds, while real-time feedback keeps every stitch in check. Adaptive algorithms and smart manufacturing platforms let you tailor digital speed control for any job. It’s like having a sixth sense for fabric—always adjusting, always learning.

| Sensor Integration | Real-Time Feedback |

|---|---|

| Predictive control | Seam quality |

| Digital pedals | Live diagnostics |

| Smart manufacturing | Adaptive speeds |

Servo Motors Vs. Clutch Motors

With digital regulation setting the pace, the real choice comes down to servo motor versus clutch motor. If you want lower energy consumption, quieter noise levels, and razor-sharp precision control, servo motors win hands-down.

Maintenance costs drop, too, thanks to fewer moving parts. Market trends favor servo motors for motor speed adjustment and speed control in industrial sewing machines—efficiency pays off.

Closed-Loop PID Controllers

Precision isn’t just a buzzword—it’s the heart of closed-loop PID controllers. You get automatic error calculation, real-time actuator response, and force modulation that conforms to each stitch.

PID tuning and stability analysis keep your seam perfect, even when programmable speeds and motor speed adjustment push boundaries.

With motor calibration and digital systems, you’re not guessing—you’re mastering every variable.

Electronic Pedal and Acceleration Profiles

When your foot pedal pressure control delivers under 50 milliseconds response time, you’re commanding servo performance that transforms industrial sewing machine workflow.

Electronic speed control offers programmable settings with acceleration curve types that reduce operator fatigue by 28% while cutting stitch drop-outs to 0.5%.

Servo motor advantages shine through motor speed adjustment from 200 to 5,500 spm, ensuring pedal response times stay consistent across all fabric weights.

Top 9 Accessories for Speed Control and Precision

Getting the most out of your industrial sewing machine’s speed control isn’t just about adjusting settings—the right accessories can make precision work easier and more consistent. From ergonomic upgrades that reduce fatigue to specialized presser feet that handle tricky techniques, these tools support the control you’ve built through proper calibration.

Here are nine accessories that’ll help you maintain steady speed and improve accuracy across different sewing tasks.

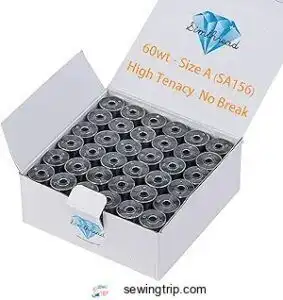

1. Simthread Black Prewound Embroidery Bobbins Thread

You’ll find that Simthread Black Prewound Embroidery Bobbins Thread directly facilitates consistent speed control in industrial sewing machine operations.

Manufactured from 90-weight polyester thread quality with machine-wound stitch uniformity, these bobbins eliminate tension fluctuations that force you to adjust your speed mid-run.

The prewound bobbin tension stays calibrated between 18–22 grams, maintaining reliable performance across varying speeds.

With colorfastness standards exceeding ISO 105-B02 and breakage rates under 1 per 30,000 stitches, they’re essential for industrial embroidery use where sewing machine speed control settings demand unwavering thread reliability.

Best For: Industrial and commercial embroiderers who want reliable, prewound bobbins to keep their machines running smoothly and efficiently.

- Saves time with prewound bobbins and reduces machine downtime.

- Delivers consistent tension and stitch quality across different fabrics.

- Strong, colorfast polyester thread stands up to frequent washing and long production runs.

- May not fit every embroidery machine model, so double-check compatibility.

- Some users report occasional thread breakage or quality issues.

- Not ideal for those who prefer winding their own bobbins.

2. Adjustable Drafting Stool With Wheels

Maintaining a stable posture during extended sewing sessions demands more than willpower—it requires ergonomic design that aids your body mechanically. Adjustable drafting stools with wheels improve sewing machine maintenance by letting you reposition quickly between adjustable-speed servo motor controls without standing, reducing fatigue that compromises precision.

Look for models with pneumatic seat height adjustment (18–31 inches), lumbar back support, and dual-wheel casters for smooth mobility. Some include adjustable arms to minimize shoulder strain. When your body stays aligned and comfortable, you’ll execute finer speed control adjustments and sustain accuracy throughout demanding industrial sewing operations.

Best For: Industrial sewers, tailors, and crafters who need a mobile, height-adjustable seat for long sessions at sewing machines or workstations requiring frequent repositioning.

- Pneumatic height adjustment (18–31 inches) and 360-degree swivel let you customize comfort and move smoothly between machines without standing, reducing fatigue during extended work.

- Dual-wheel casters and chrome footrests support dynamic positioning and leg comfort, helping you maintain precision during repetitive sewing tasks.

- Lumbar support and padded upholstery promote proper posture and reduce back strain, which keeps you focused and accurate through long sessions.

- The 250-pound weight capacity is lower than premium ergonomic models (which can support 550 pounds), limiting use for some individuals or heavy-duty industrial settings.

- Bonded leather upholstery may not breathe as well as mesh options, potentially causing discomfort during extended use in warm environments.

- Some users report the seat diameter feels larger than expected, and assembly or packaging issues can occasionally occur during shipping.

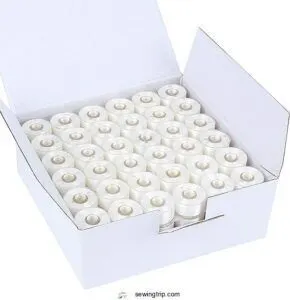

3. Prewound White Sewing Machine Threads

Switching bobbins mid-production eats into efficiency—that’s where prewound white sewing machine threads deliver measurable gains. Factory-wound precision ensures consistent thread tension across high-speed runs, reducing skipped stitches and uneven seams that plague manually wound bobbins.

With the global sewing thread market hitting USD 4.05 billion in 2025 and industrial efficiency gains reaching 20–25%, prewound bobbins aren’t optional anymore.

Verify bobbin compatibility with your machine’s core design, match thread material to fabric requirements, and adjust tension settings accordingly to optimize sewing machine speed without sacrificing stitch quality.

Best For: High-volume sewing operations and embroidery businesses that need to minimize downtime and maintain consistent stitch quality across long production runs.

- Factory-wound precision delivers consistent thread tension and eliminates the time spent manually winding bobbins, boosting productivity by 20-25% in industrial settings.

- Higher thread density per bobbin means fewer mid-project changes, allowing you to complete large garments or embroidery jobs without interruption.

- Reduced thread waste and machine wear from even distribution translates to lower material costs and less frequent maintenance on high-speed equipment.

- Thread weight and bobbin core design must match your specific machine specs—compatibility issues can cause jams or tension problems if you don’t verify before buying.

- Quality varies between suppliers, with some prewound bobbins showing burrs at seams or fibers that come loose, particularly problematic at high sewing speeds.

- Upfront cost per bobbin runs higher than bulk thread you wind yourself, making them less economical for hobbyists or low-volume projects.

4. Blind Hem Sewing Presser Foot

When precision hemming meets industrial speed demands, a blind hem presser foot becomes essential—it can boost workflow efficiency by 20% in production environments. Foot compatibility is vital across low-shank industrial sewing machine models from Brother, Singer, and Janome.

Adjust stitch settings to approximately 4.5 mm width and 3.5 mm length, then test on scrap fabric types before production runs. The adjustable guide aligns fabric folds precisely, ensuring hem invisibility while your speed control maintains consistent motor performance between 200–9900 RPM for best industry usage.

Best For: Home sewers and small production businesses who want professional-looking invisible hems on dress pants, skirts, and curtains without hand-stitching.

- Increases hemming speed and reduces manual folding time, with up to 20% efficiency gains in professional settings compared to traditional methods.

- Adjustable guide works across different fabric weights from lightweight wovens to medium knits, letting you switch between projects without constant repositioning.

- Affordable accessory (typically $10-25) that delivers professional results and reduces hem failure rates by 10-15% thanks to more secure stitching.

- Won’t fit all sewing machines despite compatibility claims—some users report the foot doesn’t match their machine or arrives bent.

- Struggles with very thin, smooth fabrics where catching just a few threads invisibly becomes difficult, and can’t handle very thick or multi-layered materials effectively.

- Requires specific low-shank system and practice with stitch settings (width, length, needle position) to get truly invisible results on the first try.

5. Clear Carpet Chair Floor Protector

Your workspace ergonomics directly influence how you control industrial sewing machine speed. An office chair mat protects carpets while enabling smooth chair mobility during extended production shifts.

Look for polycarbonate or enhanced polymer options offering mat durability up to 1000 lbs, with cleats gripping carpet fibers to prevent slippage. The HON ESS-8800C at 48″L x 36″W provides transparent carpet protection that won’t distract from your settings adjustments.

Consider eco-friendliness in polymer mats with recycled content, and select size options matching your movement range around servo motor controls operating between 200–9900 RPM.

Best For: Sewers and office workers who need reliable carpet protection and smooth chair movement during long production sessions at industrial sewing machines.

- Durable polycarbonate and enhanced polymer materials support up to 1000 lbs while maintaining transparency, so your workspace looks clean and professional without sacrificing strength.

- Built-in cleats or spikes grip carpet fibers to keep the mat stable during frequent position changes around servo motor controls and foot pedals.

- Smooth top surface reduces rolling resistance and ergonomic strain, making it easier to glide between different machine angles during extended sewing projects.

- The rigid polyurethane material can be stubborn to flatten after unrolling, often requiring weighted objects or heat treatment before it lies completely flat.

- Not suitable for hard floors, so you’ll need a different solution if your sewing space has tile, hardwood, or laminate flooring.

- Lower-end plastic versions may develop indentations from chair wheels or crack within 1-2 years under heavy daily use, requiring earlier replacement than premium options.

6. Sewing Machine Thread Bobbin Set

Proper bobbin thread types and pre-wound options save you time while directly impacting your sewing machine speed adjustments and stitch quality. You’ll find 40wt prewound bobbins offering consistent thread tension control, eliminating manual winding variability that can disrupt high-RPM servo motor performance.

Select Style M bobbins for upholstery or leather applications, ensuring needle compatibility with your industrial setup. Regular bobbin maintenance tips include cleaning lint buildup from bobbin cases and checking tension incrementally—usually 18–22 grams for standard work.

Consider bobbin material selection carefully, as smooth polyester threads may require increased tension to prevent backlash during speed transitions.

Best For: Sewers who want a ready-to-use bobbin collection that saves setup time and works across multiple machine brands, especially for DIY projects needing various thread colors.

- Comes with 50 prewound bobbins in assorted colors, eliminating the time spent manually winding thread and letting you jump straight into sewing projects.

- Compatible with Brother and other standard sewing machines, plus the reusable design means you can refill them once the prewound thread runs out.

- Includes a clear plastic storage box that keeps all your bobbins organized and easy to find when you need a specific color.

- Won’t fit every sewing machine model out there, so you’ll need to verify compatibility before buying to avoid frustration.

- The bobbins can crack or break if you accidentally drop them, which means you’ll need to handle them carefully during storage and use.

- Thread quality sits at just “OK” according to some users, so if you’re working on high-end projects you might want to invest in premium thread separately.

7. Janome Blind Hem Sewing Foot

Beyond bobbin selection, you’ll need specialized presser feet to maintain industrial sewing machine speed control during intricate work. The Janome Blind Hem Sewing Foot features a centered metal guide ensuring fabric guide precision, while three underside grooves prevent slippage at higher RPM settings.

Foot compatibility spans 5mm, 7mm, and 9mm stitch width machines, directly improving hemming speed on woven and knit materials.

User reviews confirm stitch invisibility when you pair proper speed reduction with this accessory—critical for leather and upholstery applications requiring torque adjustments on your sewing machine.

Best For: Sewers looking to create professional, nearly invisible hems on garments and home décor items like curtains, dress pants, and knit shirts without spending extra time on hand-stitching.

- Metal guide in the center keeps fabric folds aligned accurately, while three grooves on the underside prevent slipping during stitching for consistent results.

- Works across multiple Janome machine types with 5mm, 7mm, and 9mm stitch widths, making it a versatile accessory for various sewing projects.

- Priced around $10 and widely available through sewing stores and online retailers, offering an affordable way to achieve professional-quality hems.

- Some users report compatibility issues with certain Janome models even when the foot is listed as compatible, leading to frustration with fit.

- Requires practice and proper fabric folding technique to master blind hemming, which can be tricky for beginners.

- Mixed feedback on build quality suggests performance may vary depending on the specific foot version received.

8. Brother SA133 Blind Stitch Foot

The Brother SA133 Blind Stitch Foot enhances hemming precision with its adjustable seam guide and open-toed design, similar to the Janome foot. This feature ensures consistent stitch visibility control across left-to-right needle placements, which is crucial when adjusting sewing machine speed settings for industrial applications.

Its 7mm feed dog compatibility supports a wide range of fabrics, from lightweight cottons to upholstery weights. User feedback highlights that the channeled washer mechanism effectively maintains speed control during blind hem operations. However, proper thread matching remains essential for achieving invisible results, especially at higher sewing machine speed ranges.

Best For: Home sewers and quilters who want invisible hems on garments and need consistent seam spacing across different fabric weights.

- Adjustable seam guide with channeled washer lets you customize seam widths and maintain precise fabric alignment during blind hemming.

- Compatible with a wide range of Brother 7mm feed dog machines and works with any left-to-right needle position for maximum flexibility.

- Open-toed design provides clear visibility of your stitching area, making it easier to achieve professional-looking invisible hems.

- Instruction manual is unclear and many users report needing trial and error to get tension, length, and width settings right.

- Build quality feels somewhat cheap according to customer feedback, with mixed opinions on the adjustment bar’s durability.

- Less effective on very thin or smooth fabrics where stitches may remain visible even with proper thread matching.

9. Binder Sewing Machine Presser Foot

The binder foot transforms edge finishing techniques by folding and feeding bias tape in one fluid motion, which directly impacts your industrial sewing machine’s speed control settings. Its hollow conical trough accommodates binding widths up to 25mm while maintaining accuracy at higher sewing speeds.

When adjusting the foot’s positioning screw, you’ll notice improved stitch placement that reduces errors by 30-50% in industrial applications. This binding foot design works across most low-shank systems, though proper adjustment considerations for fabric thickness guarantee consistent performance when fine-tuning your sewing speed settings.

Best For: Sewers and quilters who regularly work with bias tape and binding applications and want to speed up edge finishing while maintaining precise, professional results.

- Saves significant time by folding and feeding bias tape automatically in one step, reducing binding application time by 30-50% compared to manual methods.

- Works with multiple binding widths from 10mm to 25mm (⅜ inch to 1 inch) and fits most low-shank snap-on machines from popular brands like Singer, Brother, Janome, and others.

- Improves accuracy and reduces errors with its adjustable screw positioning system, creating cleaner, more consistent stitching on both straight edges and curves.

- Not suitable for thick quilts or heavy-duty projects due to its design limitations with thicker fabrics.

- Doesn’t include instructions, which can make it challenging for beginners to learn proper setup and adjustment techniques.

- Fit and compatibility issues reported by some users, even with machines listed as compatible, requiring trial and adjustment to work properly.

Frequently Asked Questions (FAQs)

How do ambient temperature changes affect speed control?

Temperature fluctuations directly impact servo motor accuracy and control electronics. For example, a shop floor exceeding 40°C doubles electronic speed control failure rates.

Heat causes thermal drift in PID compensation systems, reducing precision while increasing needle heat and demanding better motor cooling strategies.

Can speed settings impact thread tension automatically?

Yes—sophisticated machines with servo motors and tension sensors automatically adjust thread tension as sewing machine speed changes. Programmable tension curves and real-time corrections reduce defects by 25%, minimizing manual adjusting of thread tension during operation.

What causes speed fluctuations during continuous operation?

Motor instability, mechanical load shifts, thread tension irregularities, environmental factors like voltage drops, and control anomalies from worn sensors all trigger speed fluctuations in industrial sewing machines during continuous operation, requiring systematic motor calibration.

How often should speed controllers be recalibrated?

You should recalibrate your speed controllers every 12 months under normal conditions, though high-vibration environments or continuous production at over 3,000 rpm may demand recalibration every 6–9 months to maintain precision.

Conclusion

The next time you approach your machine, you’ll no longer wrestle with runaway stitches or frustrating hesitations—you’ll command every seam with deliberate intent.

Mastering industrial sewing machine speed control settings isn’t about flawlessness on day one; it’s about building muscle memory through consistent calibration and practice. Your pedal becomes an extension of your expertise, your digital interface a trusted ally.

When speed aids precision rather than undermining it, production quality rises and material waste disappears.

- https://www.sewingmachinespare.com/SEWING-MACHINE-MOTORS/POWER-SAVE-SERVO-MOTOR-550W

- https://www.youtube.com/watch?v=ejfRzFYmk58

- https://www.linkedin.com/pulse/10-best-industrial-sewing-machines-2024-pijus-maity-vokdc

- https://repositorium.uminho.pt/bitstreams/886cd9e3-3554-460b-ad37-ae8467aa6b38/download

- https://pubmed.ncbi.nlm.nih.gov/15676925/