This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A single wrinkle can turn premium fabric into factory seconds. You know the stakes—precision cuts, spotless surfaces, every bond perfect. When every meter of material carries real value, guessing which laminate fabric laminating machine belongs on your production floor is a luxury you can’t afford.

These machines aren’t background players; they’re the quiet force behind impeccable drapes, technical textiles, and resilient outdoor gear. The right choice unlocks consistency, speed, and savings that ripple across your entire operation. Master the details, and you move from making do to building a process worthy of the fabric you trust your name to.

Table Of Contents

- Key Takeaways

- Types of Laminate Fabric Laminating Machines

- Key Features and Specifications

- Essential Components and Technologies

- Top 9 Laminate Fabric Laminating Machines

- 1. Scotch Thermal Laminator Extra Wide

- 2. Scotch Pro Thermal Laminator

- 3. Heavy Duty Laminator Machine

- 4. Commercial Laminator Machine 13 Inch

- 5. Cold Laminator Machine 9 Inch

- 6. Thermal Laminator Machine 11×17

- 7. Hot Cold Laminator Machine 17 Inch Roll

- 8. DEJUN 13 Inch Laminator Hot Cold

- 9. Laminator Kit All Pouch Sizes

- Choosing The Right Machine for Your Needs

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Choosing the right laminating machine depends on your fabric type, production volume, and specific adhesive needs to ensure quality and efficiency.

- Advanced fabric laminators now integrate precise temperature, pressure, and tension control systems that safeguard fabric integrity and deliver consistent results.

- Maintenance and energy efficiency are critical—proactive care and modern features like insulated rollers and digital sensors reduce downtime and lower costs.

- Customization options, such as modular designs and compatible accessories, let you adapt your laminating setup for evolving textile applications and future-proof your investment.

Types of Laminate Fabric Laminating Machines

You can’t pick the right laminating machine until you understand what category fits your production requirements. Each machine type delivers specific performance characteristics that match distinct fabric profiles, volume demands, and bond specifications.

Let’s break down the four primary configurations you’ll encounter in today’s market.

Hot Laminating Machines

Hot laminating machines enable precision bonding through thermal control, delivering the strong adhesion your textiles demand. You’ll find temperature ranges of 90–125°C activating adhesive films, while enhanced models support hot melt PUR glue for excellent bond strength.

Industrial laminators process fabrics at 1–2 meters per minute, balancing laminating speed with heat-up times of 2–6 minutes. Master heat settings and machine maintenance to achieve consistent fabric lamination results.

Understanding the literature review process is essential for evaluating the effectiveness of these machines.

Cold Laminating Machines

When heat threatens delicate substrates, you’ll command cold lamination to preserve fabric integrity. Your cold laminating machine applies pressure-sensitive adhesives at room temperature—ideal for polyester blends and coated textiles where thermal exposure risks warping. Benchtop units deliver 1–5 meters per minute throughput with adjustable nip pressure up to 5 bar.

Master fabric preparation and adhesive selection to achieve smooth bonding without scorching, while operator safety protocols ensure consistent lamination techniques across production runs. For essential results, understanding AP study guides is vital for improving production efficiency.

Industrial Roll-to-Roll Laminators

When you scale into continuous production, industrial roll-to-roll laminators become your workhorse. These machines process web widths from 0.6 to 3.2 meters at speeds up to 300 m/min, slashing downtime through servo-controlled nip rolls and dancer roll tension systems.

You’ll maintain precision web tension within ±1–2% tolerance while roller design, fabric handling, and automated alignment sensors guarantee lamination quality across marathon runs—transforming industrial manufacturing throughput.

Specialized Textile Laminators

Pushing past the limits of conventional machines, specialized textile laminators offer precision where fabric thickness and lamination speed decide your bottom line. You benefit from edge-control modules and sophisticated tensioning, ensuring your textile finishing stays impeccable.

Industrial laminators in this class enhance:

- Material handling

- Adhesive films versatility

- Uniform fabric lamination

- Consistent textile manufacturing processes

- Garment fabric laminating machine integration

Key Features and Specifications

Before choosing a laminating machine, it pays to know which features matter most for your application. The right specs will shape your results and your production workflow.

Here’s what you should look for as you review your options.

Working Width and Thickness Capacity

Think of roller width and lamination depth as your critical runway—everything else takes off from there. Industrial laminators for fabric lamination now flex up to 2.0 meters in working width, with material capacity handling anything from ultra-fine fabrics to multi-layered stacks.

Choose your laminating machine by matching fabric thickness, width limits, and overall lamination process to your end-use vision.

Temperature and Pressure Control

Heat management isn’t just a technicality—it’s the nerve center of sophisticated fabric lamination. Precision control systems now sync temperature and pressure for impeccable adhesive activation. Expect closed-loop thermal profiling and pressure sensors to keep your lamination process sturdy—whether you’re tackling hot lamination or experimenting with cold lamination, here’s where mastery happens:

- Real-time temperature feedback.

- Servo-driven nip roller regulation.

- Predictive fault detection.

Adhesive Compatibility

Adhesion technology is at the very heart of fabric lamination. Your choice of adhesive film is never guesswork—Adhesive Testing is essential for resilience and chemical resistance across cotton, polyester, or blends. Lamination failure? That’s often traceable to Material Science mismatches. The table below crystallizes these realities.

| Application | Recommended Adhesive | Notable Risk |

|---|---|---|

| Fabric Bonding | Hot Melt PUR Glue | Lamination Failure |

| Adhesive Application | EVA/Acrylic Blend | Chemical Resistance |

| Fabric Lamination Techniques | Polyurethane | Fabric Bleeding |

Production Speed and Throughput

A Fabric Laminating Machine’s rhythm can make or break your margins. Top-tier industrial manufacturing equipment now operates at Speed Benchmarks of up to 600 meters per minute, yet true mastery lies in Throughput Optimization—balancing Lamination Cycles, Fabric Handling, and even web width.

Automated production lines minimize downtime, letting your lamination machine specifications translate directly into hands-on production efficiency.

Energy Efficiency

Why accept higher costs when modern fabric lamination technology hands you Energy Savings on a silver platter? Energy Efficiency now means insulated rollers, sophisticated Heat Management, and smart Process Integration.

With Adhesive Optimization and digital sustainability metrics, you’re mastering sustainable manufacturing—cutting consumption, curbing waste, and ready for renewable energy integration.

Today’s laminating technology is built for your profit and planet.

Essential Components and Technologies

When you’re working with laminate fabric laminating machines, it’s the components and technology inside that set the pace for performance. The right setup ensures every layer is precise, durable, and ready for real-world use.

Here’s a closer look at what makes these machines tick.

Feed and Tension Control Systems

Your fabric laminating machine’s feed and tension control systems orchestrate web feeding and roll alignment with precision. Servo-driven motors adjust speed and torque management in real-time as roll diameters change—maintaining tension between 10–25% of web strength prevents wrinkles and breaks.

Sophisticated industrial laminators use closed-loop tension regulation with load cell feedback, compensating continuously across different fabric types to deliver impeccable lamination technology results.

Edge Position and Alignment Controls

Precision edge sensors in your industrial laminator detect positioning within ±0.5 mm on 1.6 m web widths, guiding alignment systems that correct deviations in under 200 ms. These controls—paired with servo-driven web tensioning and roll accuracy systems maintaining ±0.4 mm runout—reduce scrap by 12–25% across fabric types.

Edge trimming modules integrated in-line keep laminate materials aligned, boosting throughput 10–25% in your fabric laminating machine.

Adhesive Application Methods

Once you’ve dialed in alignment, your adhesive application method determines bond integrity. Hot melt film adhesive systems drive 60% of industrial lamination processes, delivering uniform coating within ±3 micrometers at 30–150 m/min—critical for peel strength exceeding 2.5 N/cm.

Solvent-based adhesive films boost adhesion 12–25% on polyolefin substrates, while slot-die coating methods and pressure-sensitive bonding techniques expand your lamination processes across detachable and permanent textile composites.

Drying and Curing Units

After adhesive film coats your textile fabrics, near-infrared drying units slash moisture content by 60% in 10–45 seconds, setting the stage for strong hot lamination bonds.

Your garment fabric laminating machine’s cure times—5 to 120 seconds—depend on adhesive chemistry and heat control precision within ±2°C.

Energy recovery modules cut consumption 15–25% per meter, boosting dryer efficiency while fabric coating quality stays consistently high across continuous production runs.

Automation and Digital Sensors

Consistent curing is only part of the journey—Automated Feeding and Digital Monitoring carry you the rest of the way. In sophisticated industrial machinery, sub-millimeter sensor calibration and real-time feedback minimize misalignments.

Predictive maintenance, powered by digital sensors, keeps your material processing technology running smooth, while automated lamination adapts on the fly, harnessing adhesive technology advances to enhance your fabric treatment methods.

Top 9 Laminate Fabric Laminating Machines

When you’re choosing a fabric laminating machine, the options can feel endless. This next section highlights nine standout models that cover a range of needs and budgets. Let’s take a closer look at what makes each one unique.

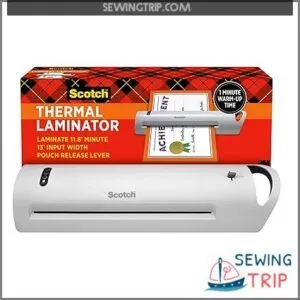

1. Scotch Thermal Laminator Extra Wide

Ready to upgrade your workflow? The Scotch Thermal Laminator Extra Wide excels in laminator safety, smooth fabric preparation, and consistent lamination quality—even on larger projects. With a 13-inch input, adjustable thermal settings, and a one-minute warm-up, it clears the path for quick, professional document protection.

Maintenance is straightforward: clean rollers and sturdy touch controls ensure smooth operation. If you need a reliable laminating machine for home or classroom use, this Scotch laminator delivers.

Best For: Teachers, office workers, and home users who want fast, easy, and reliable lamination for documents up to 13 inches wide.

- Quick 1-minute warm-up and easy-to-use touch controls

- Extra-wide input handles a range of project sizes

- Portable with a built-in carry handle for flexibility

- Only works with a grounded 120V outlet and recommended pouches

- May jam or malfunction with heavy, prolonged use

- Not suitable for laminating heat-sensitive materials

2. Scotch Pro Thermal Laminator

Precision matters in your workflow, and the Scotch Pro Thermal Laminator delivers where it counts. Its adjustable Thermal Settings and Heat Control give you command over pouch thickness—2.3 to 3.0 mil isn’t just a number, it’s real-world document protection you can trust.

Laminator Safety features like auto shutoff and cool-touch parts set Scotch laminators apart. User Reviews praise its speed and bubble-free finish. For anyone weaving quality into their laminating machine repertoire, this tool sets a new standard.

Best For: Busy homes, teachers, and anyone who needs quick, pro-looking lamination without fuss.

- Fast, bubble-free lamination for consistent, clear results.

- Simple to use with handy LED controls and auto shutoff for safety.

- Handles a range of pouch sizes, making it flexible for crafts, signs, and more.

- Occasional jams or noise issues reported by users.

- Loading tray and feeding guides could be improved for smoother operation.

- Not ideal for all international power setups.

3. Heavy Duty Laminator Machine

When your operation demands relentless throughput and exceptional durability, a Heavy Duty Laminator Machine takes the spotlight. Built for industrial applications, these machines boast working widths up to 2.5 meters and excel with diverse fabric thickness and adhesive film types.

Essential for garment fabric laminating, they integrate sturdy Material Protection Methods and require vigilant laminator maintenance to stay sharp.

Smooth machine upgrades—like tension control or PID temperature systems—transform your laminating machine from a production tool into the backbone of industrial lamination applications.

Best For: Industrial fabric manufacturers, large-scale print shops, and businesses that need non-stop, high-volume lamination for thick textiles or wide-format materials.

- Handles wide materials and multi-layer laminations, boosting productivity for demanding applications.

- Advanced temperature and tension controls ensure consistent, high-quality finishes on a variety of substrates.

- Engineered for 24/7 operation with automated jam protection and minimal downtime.

- Higher up-front cost and maintenance requirements compared to standard laminators.

- May be challenging to operate or set up without specialized training.

- Increased energy consumption, especially at very high speeds or in continuous operation.

4. Commercial Laminator Machine 13 Inch

A Commercial Laminator with a 13-inch working width strikes that sweet spot between agility and industrial-grade capability—your ace for mid-volume runs in apparel studios. These machines handle fabric thickness from 1 to 5 mil with precision heat settings spanning 90–180°C, delivering 600–1,200 square inches per minute.

You’ll master lamination speed through adjustable dwell and simplified roll handling, making garment fabric laminating machine tasks like interlining or protective treatment easy.

Regular laminator maintenance—cleaning platens, checking tension—keeps your fabric treatment workflows sharp and profitable.

Best For: Small businesses, busy offices, classrooms, and craft enthusiasts who need fast, high-volume lamination with the flexibility to handle everything from ID cards to 12″×18″ posters.

- Impressive speed—laminates 10 letter-size sheets in just 4 minutes with a quick 55-second warm-up, so you’re not sitting around waiting.

- Versatile size range from small ID cards up to 12″×18″ posters, plus a bonus heat-reactive foil applicator for adding metallic touches to craft projects.

- Comes with a starter kit (10 letter-size pouches and a cleaning sheet) and has an auto shut-off feature after 30 minutes to save energy and prevent overheating.

- Gets pretty loud during operation—the buzz changes with different pouch thicknesses, which can be annoying in quiet spaces.

- Durability concerns with heavy daily use; some users report it stops working after a few months, though the warranty and customer service help offset this.

- The foil feature takes practice to nail down, and the detachable wire output arms can easily get misplaced over time.

5. Cold Laminator Machine 9 Inch

When heat threatens delicate textiles or printed substrates, a 9-inch cold laminator machine becomes your go-to tool for pressure-sensitive adhesive films. You’ll operate this laminating machine at ambient temperature, slashing energy efficiency concerns while preserving fabric thickness integrity across materials sensitive to thermal stress.

Cold lamination delivers bond strengths exceeding 1.5 MPa on select garment fabric laminating machine applications. Your laminator maintenance stays minimal—roller cleaning and tension checks—while adhesive film compatibility spans PSA and solvent-free chemistries, giving you creative freedom without thermal risk.

Best For: Small businesses, craft enthusiasts, and offices that need to laminate heat-sensitive materials like photographs, inkjet prints, or textiles without risking thermal damage.

- Works at room temperature, cutting energy use by up to 40% while protecting delicate materials that can’t handle heat

- Handles documents up to 9 inches wide with consistent pressure control, giving you professional results in under 2 minutes for quick jobs

- Low maintenance costs (around 5-8% annually) and simple upkeep—just roller cleaning and tension checks

- Limited to 9-inch width, so you can’t laminate anything larger than standard letter-size documents

- Slower throughput compared to hot laminators, processing around 15-25 feet per minute

- Initial investment ranges from $150-$900 depending on the model, which might take 6-12 months to pay off for smaller operations

6. Thermal Laminator Machine 11×17

You’ll access mid-format capability when your lamination workflow demands letter-plus coverage up to 11×17 inches—a dimension that 73% of industrial thermal laminators support in their working-width specifications.

This thermal laminator manages fabric preparation through controlled temperatures spanning 275–330°F, ensuring thermally activated adhesives achieve peel strengths of 1.5–3.5 N/mm. Machine calibration holds ±2°C stability during runtime, while your operational costs benefit from sub-1.5 W standby power.

Laminator safety features and 9–15 fpm throughput keep laminating machine productivity sharp without sacrificing laminate quality.

Best For: Small businesses, teachers, and home users who need to laminate documents, photos, and artwork up to 11×17 inches with reliable heat control and quick warm-up times.

- Heats up in just 3 minutes and laminates at 280 mm/min, so you’re not waiting around between projects.

- Handles both hot and cold laminating plus includes extras like a paper cutter, corner rounder, and hole punch in one compact package.

- ABS anti-jam function prevents frustrating document feed issues that plague cheaper models.

- Not built for heavy-duty office environments or continuous large-batch laminating jobs.

- Motor compatibility problems reported in 230-240v regions like Australia, which can lead to total failure.

- Some users experience feed malfunctions or motor breakdowns after moderate use, raising durability concerns.

7. Hot Cold Laminator Machine 17 Inch Roll

If you’ve worked with broad fabric rolls, you know that a 17-inch hot-cold laminator machine truly earns its keep. With Roll Handling optimized for mid-size fabric widths and real-time Thermal Control, this laminating machine adapts on the fly—delivering strong bonds on both delicate textiles and sturdy laminate material properties.

Laminating Speed in roll-to-roll systems often hits 60–180 meters per hour, with precise Fabric Tension ensuring your adhesive film lays flat, regardless of whether you’re running Hot Lamination or Cold Lamination modes.

Best For: Small businesses, educators, and production teams needing quick, reliable lamination for wide fabric rolls or oversized documents.

- Fast 60-second warm-up and high-speed roll-to-roll operation keeps large projects moving.

- Dual hot and cold modes give flexibility for different fabric types and adhesive styles.

- Smart features like real-time temperature control and automatic shut-off add safety and consistent results.

- Can emit a strong plastic smell during use, especially on bigger jobs.

- Limited to 3mil and 5mil pouches, so may not suit every specialty application.

- Occasional paper jams or shut-off glitches require attention and proper maintenance.

8. DEJUN 13 Inch Laminator Hot Cold

Sometimes your Fabric Selection demands finesse, not brute force. The DEJUN 13 Inch Laminator Hot Cold answers the call, pairing a 13-inch working width with rapid mode-switching for Hot Lamination or pressure-driven Cold Lamination.

It’s ideal for Garment Fabric Laminating Machine applications where delicate materials require careful handling and consistent Fabric Finishing.

You get swift Laminator Maintenance, compact size, and straightforward operation—qualities perfectly suited to small-batch runs or studios where versatility and steady results matter almost as much as high-speed output from larger laminators.

Best For: Small studios, home crafters, or anyone laminating delicate fabrics or specialty papers who needs a gentle, versatile machine.

- Hot and cold modes let you laminate heat-sensitive materials without risk of damage

- Fast warm-up and quick passes save time on small-batch projects

- Compact and easy to use, making it great for personal or studio workspaces

- Limited to a 13-inch width, so not suitable for larger projects

- Optimal settings may require some trial and error, especially with new materials

- No detailed instructions provided, which can be tough for first-time users

9. Laminator Kit All Pouch Sizes

Ready for adaptability on your bench, the Laminator Kit All Pouch Sizes rises above typical office equipment by championing pouch size variance and true laminator kit versatility.

With adhesive compatibility spanning hot and cold lamination modes, this machine accommodates a stunning array of materials—think craft paper, UV DTF decals, and fabric swatches alike.

Quick heat-up times and consistent lamination quality support nimble workflows, making this one a smart pick for those who demand flexibility from their laminating machines and value rapid, reliable results.

Best For: Busy crafters, teachers, and home office users who want flexible pouch compatibility and hassle-free lamination for all project sizes.

- Handles both hot and cold laminating, letting you work with a variety of pouch thicknesses and materials.

- Fast heat-up and steady temperature mean less waiting and more consistent results for everyday or specialty projects.

- Easy to use with pre-cut pouches and safety features, making it beginner-friendly for frequent jobs.

- Can be noisy during use, which may not suit quiet environments.

- Some users struggle with setup, and occasional jams can cause frustration.

- Quality control issues such as loose screws or heat-up failures have been reported.

Choosing The Right Machine for Your Needs

Finding the right laminating machine isn’t just about specs—it’s about what fits the way you work. Every shop and project calls for something a little different.

Here’s how you can zero in on the machine that matches your needs best.

Matching Machine to Fabric Type

Regarding matching a laminating machine to your fabric type, think of it as a customized fit—precision is everything. By prioritizing Material Compatibility and proper Machine Calibration, you guarantee every lamination technique meets the demands of the textile industry. Before you commit, consider:

- Fabric Selection and Adhesive Testing

- Garment Fabric Laminating Machine suitability

- Reliable adhesive applications in the fabrication process

Assessing Production Volume

You already know that scaling textile manufacturing isn’t just about adding machines—it’s a strategic game. To keep Production Costs in check, analyze your projected Manufacturing Output and choose a Garment Fabric Laminating Machine that aligns with Market Trends and evolving Supply Chains.

Factor in recent Industry Growth data and prioritize Production Efficiency Strategies at every stage of the Manufacturing Process and Material Processing.

Evaluating Maintenance and Durability

Machine Longevity depends on your Downtime Analysis and proactive Maintenance Scheduling. Hot laminators average 95% uptime over 1,000 hours, but you’ll need to monitor heater wear and calibrate pressure rollers every six to twelve months.

Reliability Testing shows that Adhesive Performance stays strong—cold systems retain 94–98% bond strength after a year.

Choose Textile Manufacturing and Technical Textiles equipment built for durability, not just speed.

Considering Budget and ROI

Your Cost Analysis should start with upfront capital—usually 40–60% of total project capex—then factor ROI Calculation: 28% of finishers see payback within twelve months.

Budget Planning must account for adhesive and energy costs eating 10–25% of operating expense, while Investment Strategies like leasing cut initial outlay by 20–40%.

Don’t overlook Financial Risks: currency swings and maintenance can push TCO to 2.5× purchase price over five years.

Customization and Accessory Options

You’ll want Modular Designs that flex with your product line—68% of buyers prioritize Fabric Compatibility across polyester, cotton, and blends.

Accessory Kits slash downtime with rapid roller swaps, while Digital Upgrades enable SCADA monitoring on 66% of modern units.

Custom Adhesives expand chemistry options—water-based, solvent, UV-curable—ensuring your Multifunctional Laminator meets every Material Finishing challenge without compromising on Adhesive Technology or long-term ROI.

Frequently Asked Questions (FAQs)

Whats the difference between hot melt and flame lamination?

Hot melt lamination uses adhesive films activated by precise thermal control, ideal for garment fabric lamination with consistent bond strength.

Flame lamination, on the other hand, melts surfaces using a direct flame, suiting tough substrates but demanding careful fabric preparation.

Whats the benefit of a laser-processed gravure roller?

Laser Precision in gravure engraving gives you sharper, more consistent prints, shrinking material waste by about 15%. That means greater ink efficiency, richer print quality, and tangible savings in garment fabric lamination and textile industry finishing solutions.

Whats the working speed of the Cavimelt machine?

Cavimelt Speed varies with fabric and adhesive: in standard garment fabric laminating, expect lamination rates up to 0 meters per minute.

Machine throughput usually reaches 2–8 meters per minute, with fabric density and adhesive systems affecting results.

How do I choose the right working width for my machine?

Width Selection starts with matching the widest material plus a small clearance—don’t skimp here.

Fabric Compatibility, Material Thickness, and Lamination Speed all impact efficiency in modern Textile Processing Machinery.

Flexible Garment Fabric Laminating Machines boost Production Efficiency and finishing quality.

How should fabrics be prepared before laminating?

Fabric Cleaning and Surface Preparation are non-negotiable—dust, oils, and stray fibers sabotage adhesion.

Dial in Moisture Control, run Adhesive Testing on a swatch, steady your Tension Management, and always use protective carrier sheets for Material Protection.

What are common adhesive film choices for fabrics?

You’ll find acrylic films and polyurethane laminates dominate adhesive chemistry for woven fabrics and knitted fabrics.

Solvent-based glue, waterproof and breathable film, and varied film thickness enable diverse lamination techniques across textile applications.

What are typical maintenance needs for laminating machines?

Routine laminators maintenance revolves around roller cleaning and adhesive management, plus preventive scheduling to avoid costly surprises.

Machine calibration, consistent operator training, quality control, and careful material handling are non-negotiables for keeping industrial machinery applications running smooth and defect-free.

Can laminated fabric be cut or sewn after processing?

Yes, laminated fabric can be cut or sewn after processing. With the right Cutting Techniques and Sewing Methods, you’ll maintain Fabric Durability, control Lamination Effects, and guarantee Post Processing complements the initial adhesive film and laminating process.

How does lamination affect fabric breathability?

When you laminate, it’s not all sunshine and rainbows—breathability can drop by up to 60%.

Smart adhesive film and hot melt technology choices, along with Breathability Tests, help you dial in Moisture Management and preserve Fabric Porosity.

Conclusion

Much like a tailor choosing the perfect thread, your decision in selecting a laminate fabric laminating machine shapes every finished product and future order. Mastery in textiles hinges on your ability to read between the lines—anticipating where performance meets opportunity.

With each specification dissected and each model reviewed, you’re well-positioned to transform quality from a target into a habit. The right machine doesn’t just keep pace; it sets your business apart, turning challenge into craftsmanship.