This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

laminate fabric laminating machines are a handy tool for crafting enthusiasts and small business owners looking to protect and enhance their materials. Not all fabrics can be laminated, but many can. Laminated fabrics are great for projects that might get messy, like makeup bags or baby bibs. You can find machines with different working widths and speeds, and some use hot-melt technology for eco-friendly lamination.

laminate fabric laminating machines are a handy tool for crafting enthusiasts and small business owners looking to protect and enhance their materials. Not all fabrics can be laminated, but many can. Laminated fabrics are great for projects that might get messy, like makeup bags or baby bibs. You can find machines with different working widths and speeds, and some use hot-melt technology for eco-friendly lamination.

If you’re considering investing in a laminate fabric laminating machine, you’ll want to know about the different types, key components, and how to choose the right one for your needs.

Table Of Contents

- Key Takeaways

- Types of Laminate Fabric Laminating Machines

- Key Components of Laminate Fabric Laminating Machines

- 9 Best Laminate Fabric Laminating Machines

- 1. Scotch Thermal Laminator Extra Wide

- 2. Scotch Pro Thermal Laminator

- 3. Heavy Duty Laminator Machine

- 4. Commercial Laminator Machine 13 Inch

- 5. Cold Laminator Machine 9 Inch

- 6. Thermal Laminator Machine 11×17

- 7. Hot Cold Laminator Machine 17 Inch Roll

- 8. DEJUN 13 Inch Laminator Hot Cold

- 9. Laminator Kit All Pouch Sizes

- Laminating Processes and Technologies

- Selecting the Right Laminate Fabric Laminating Machine

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Laminate fabric laminating machines are a crafter’s secret weapon, turning messy makeup bags and baby bibs into wipe-clean wonders.

- With machines like the versatile Sunkist SA-6AC, you can tackle wide fabrics, thick materials, and speedy projects, all with eco-friendly hot-melt technology.

- From the LS Series’ tension control to the Cavimelt’s rotogravure system, these machines offer precise, customizable lamination for any project.

- Whether you’re a DIY enthusiast or small business owner, the right machine elevates your crafts, protects your fabrics, and gives them a professional finish.

Types of Laminate Fabric Laminating Machines

You’re about to enter the exciting world of laminate fabric laminating machines, where crafting dreams come to life. Whether you’re a DIY enthusiast or a professional fabricator, understanding the different types of these machines will help you choose the perfect one to elevate your projects.

LS Series Laminating Machines

The LS Series laminating machines offer five models to choose from, so you can find the perfect match for your needs.

These machines are space-saving and power-efficient.

They also come with a mobile trolley for flexibility.

The LS Series features a tension control system that adapts to different fabrics, ensuring your projects come out flat and fabulous every time.

Sunkist SA-6AC Laminating Machine

Looking to revolutionize your foam industry game? Meet the Sunkist SA-6AC, the Swiss Army knife of laminating machines. This versatile workhorse is ready to tackle your toughest fabric lamination challenges. Here’s why it’s a game-changer:

- Gobbles up materials up to 1500mm wide

- Handles thicknesses from 2-20mm like a champ

- Zips through jobs at speeds up to 1500M/Hr

- Plays nice with both water- and solvent-based adhesives

- Comes with a built-in electric heater for quick-dry action

Cavimelt Textile Lamination Machine

Now, let’s shift gears to the Cavimelt Textile Lamination Machine. This bad boy is like the Swiss Army knife of laminating machines! It’s got a rotogravure system that’ll make your head spin (in a good way). Check out this nifty table:

| Feature | Benefit | Application |

|---|---|---|

| Hot melt process | Eco-friendly | Fabrics, nonwovens |

| Pattern variety | Customization | Films, foams |

| Adhesive flexibility | Versatility | Membranes, knits |

With Cavimelt, you’re not just laminating; you’re crafting textile masterpieces!

Hot Melt Laminating Systems

Hot melt laminating systems take your fabric bonding game to the next level. Unlike their solvent-based cousins, these powerhouses use heat to melt adhesives, creating strong bonds without the wait. Here’s why you’ll love them:

- Lightning-fast production: Say goodbye to drying time!

- Eco-friendly operation: No solvents means less environmental impact.

- Versatile adhesive options: From thermoplastic to reactive PUR, you’ve got choices.

These systems are like the speedy superheroes of the laminating world, swooping in to save you time and energy.

Rotogravure Laminating Machines

Ready to take your laminating game to the next level? Let’s talk rotogravure machines! These bad boys use engraved rollers to apply adhesive in mind-blowing patterns. Check out this quick comparison:

| Feature | Benefit | Application | Wow Factor |

|---|---|---|---|

| Engraved rollers | Precise adhesive control | Fabric, films | ⭐⭐⭐⭐⭐ |

| Hot melt process | No drying time | Fast production | ⭐⭐⭐⭐ |

| Coating weights | Customizable (3-80 g/m²) | Versatile use | ⭐⭐⭐⭐ |

| Adhesive patterns | Endless creativity | Unique designs | ⭐⭐⭐⭐⭐ |

With rotogravure, you’re not just laminating – you’re crafting masterpieces!

Key Components of Laminate Fabric Laminating Machines

You’re about to discover the heart and soul of laminate fabric laminating machines. From feed devices to adhesive systems, these key components work together like a well-oiled machine to transform your fabric into durable, eye-catching creations.

Feed Device and Mobile Trolley

You’ve seen the different types of laminating machines, but let’s zoom in on a key component: the feed device and mobile trolley.

These unsung heroes are like the roadies of your laminating band.

They’re simple, fast, and oh-so-nimble.

With power-saving designs and space-saving setups, they’ll have you rockin’ and rollin’ through your projects in no time.

Plus, the mobile trolley is as flexible as a yoga instructor – no power needed!

Tension Control System

Ever wondered how your fabric laminator keeps things smooth? It’s all in the tension control system! This nifty component is like a fabric whisperer, ensuring your materials stay flat and happy during lamination. Here’s what you need to know:

- Adjusts tension based on fabric type

- Responds quickly to tension changes

- Comes in two flavors: detector-based and dancing-roller

- Really important for consistent, high-quality lamination

- Helps you become the master of fabric fusion

With this system, you’ll be cranking out perfect laminates faster than you can say "smooth operator"!

Edge Position Control System

Now that you’ve got your tension under control, let’s tackle edge alignment.

The edge position control system is your fabric’s GPS, keeping it on track during lamination.

You’ll find two main types: electronic sensors and oil-cylinder mechanisms.

These systems work hand-in-hand with tension control to make sure your fabric stays put.

Think of it as a dance partner, guiding your material smoothly through the process for precise, high-quality results.

Gravure Roller Specifications

Moving on from edge control, let’s talk about the unsung hero of your laminating machine: the gravure roller. This little powerhouse is like the artist’s brush, creating patterns that control adhesive application. With laser-processed surfaces, these rollers make sure your adhesive stays put without overflowing.

Here’s why you’ll fall in love with gravure rollers:

- They’re pattern wizards, turning your lamination into a work of art

- They’re adhesive whisperers, keeping things neat and tidy

- They’re versatile performers, working with various adhesive types

- They’re precision masters, giving you control over every detail

- They’re the secret sauce to achieving professional-quality results

Adhesive Application Systems

Alright, let’s tackle the sticky situation of adhesive application systems!

These bad boys are the unsung heroes of your laminating machine.

You’ll find a buffet of options, from solvent-based adhesives to PUR hot-melts.

Each type has its own personality, affecting quality, cost, and even safety.

The trick is finding the perfect match for your project – like finding the right dance partner for your fabric!

9 Best Laminate Fabric Laminating Machines

You’re about to discover the best laminate fabric laminating machines that’ll take your crafting game to new heights. Whether you’re a DIY enthusiast or a small business owner, these top 9 picks will help you create professional-looking projects with ease and efficiency.

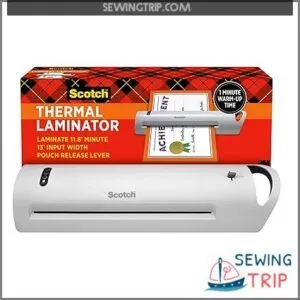

1. Scotch Thermal Laminator Extra Wide

Looking for a game-changer in your crafting arsenal? Meet the Scotch Thermal Laminator Extra Wide! This bad boy’s got a 13-inch input width, perfect for your bigger projects.

It’s like having a speed demon on your desk, zipping through 118 inches per minute. You’ll be up and running in no time with its 1-minute warm-up.

Plus, it’s got two heat settings and auto shut-off for safety.

Just remember, it’s a bit of a diva – it only works with Scotch Brand pouches. But hey, that’s the price of greatness, right?

Best For: Those who need to laminate larger-sized documents and projects.

- Fast laminating speed for efficient workflow.

- Wide input width allows for larger projects.

- Two heat settings for versatility.

- Limited to Scotch Brand pouches.

- Some users have reported issues with the back piece breaking.

- Some users have experienced jamming and sealing problems.

2. Scotch Pro Thermal Laminator

You’ll love the Scotch Pro Thermal Laminator for its sleek design and impressive performance. It’s a real game-changer, handling up to 9-inch wide documents with ease. Don’t sweat the warm-up time; in just 5-6 minutes, you’re good to go. Zipping through 15 inches per minute, it’ll have your projects done in a flash. With two temperature settings, you can tackle both 3 mil and 5 mil pouches like a pro. Just keep an eye out for potential jams when laminating multiple small items. It’s your ticket to bubble-free, professional-looking results!

Best For: The Scotch Pro Thermal Laminator is best for home, office, and school users who need to laminate documents and photos up to 9 inches wide.

- Fast warm-up time and laminating speed.

- Handles both 3 mil and 5 mil pouches.

- Compact and easy to use.

- Potential for jamming when laminating multiple small items.

- Pouches are not labeled.

- Laminator does take some time to heat up.

3. Heavy Duty Laminator Machine

This heavy-duty laminator machine is like having a personal bodyguard for your documents.

It’s got a 6-roller system (4 hot, 2 cold) for professional-level lamination every time.

The auto-sense thickness detection is a game-changer, adjusting settings on the fly.

No more paper jams thanks to its anti-jamming technology.

It warms up in just 50 seconds and can laminate a letter-size paper in 15.

It’s the Swiss Army knife of laminators, ready for any crafting challenge.

Best For: This heavy-duty laminator is perfect for busy offices, schools, and anyone who laminates frequently.

- 6-Roller System: Professional-level lamination for that polished look.

- Auto Sense Thickness Detection: No more guesswork, it adjusts for you.

- Anti-Jamming Technology: Peace of mind knowing your documents are safe.

- Price: It’s a bit pricier than other laminators, but you get what you pay for.

- Size: It takes up a bit more space on your desk, but it’s worth it.

- Limited Features: It doesn’t have all the bells and whistles of some other laminators, but it focuses on what matters.

4. Commercial Laminator Machine 13 Inch

Ready to take your laminating game to the next level? The Commercial Laminator Machine 13 Inch is your ticket to pro-level crafts. With a swift 55-second warm-up and blazing 40 inches per minute speed, you’ll be churning out projects in no time. It’s a beast, handling pouches from ID cards to 13" x 19" posters. Sure, it’s a bit noisy, but that’s just the sound of heavy-duty gears working their magic. Plus, with its foil applicator, you can add some sparkle to your creations. It’s not just a laminator; it’s your craft room’s new MVP!

Best For: The Commercial Laminator Machine 13 Inch is best for crafters, businesses, and educators who need a fast, versatile, and durable laminator for frequent use.

- Blazing speed: Laminates up to 40 inches per minute.

- Versatile: Handles pouches from ID cards to posters.

- Durable: Built for heavy-duty use with a 12-month warranty.

- Noisy: Designed for commercial use, so it’s louder than entry-level laminators.

- Higher price point: More expensive than basic laminators.

- No adjustable temperature: No option to adjust temperature settings.

5. Cold Laminator Machine 9 Inch

Looking for a compact solution? The 9-inch cold laminator might be your new best friend. It’s perfect for small projects and tight spaces. You’ll love how it handles photos, documents, and craft materials without the need for heat. No more waiting for warm-up time – just feed your items through and you’re good to go. Plus, it’s a breeze to use, even if you’re new to laminating. Remember, though, it’s limited to cold lamination, so keep that in mind for your projects. It’s like having a mini preservation station right at your fingertips!

Best For: The 9-inch cold laminator is best for those who need a compact laminator for small projects and don’t need the heat of a hot laminator.

- Perfect for small projects and tight spaces

- No warm-up time required

- Easy to use, even for beginners

- Only cold lamination

- May not be suitable for larger projects

- Limited features compared to hot laminators

6. Thermal Laminator Machine 11×17

Looking for a powerhouse laminator? Meet the Qfun SL999-US, your new crafting buddy. This grey beast handles 11×17 sheets like a champ, with both hot and cold modes at your fingertips. It’ll heat up in just 60 seconds and zip through 450mm/min, leaving no time for coffee breaks! Whether you’re working with 3mil or 5mil, it’s got you covered. Plus, it’s loaded with goodies like a paper cutter and corner rounder. With lifetime support and a 24-month replacement service, it’s like having a laminating superhero on speed dial!

Best For: This laminator is best for users who need to laminate a high volume of documents quickly and efficiently.

- Fast Heating and Lamination: This laminator heats up quickly and laminates at a fast speed, saving you time.

- Hot & Cold Modes: You can choose between hot and cold lamination options, which is great for different materials and needs.

- Included Accessories: The laminator comes with a paper cutter, corner rounder, hole puncher, and other useful accessories.

- Reliability Issues: Some users have reported issues with the machine malfunctioning after a short period of use.

- Limited Return Window: The Amazon return window is only one month, so you have a limited time to return the product if you’re not satisfied.

- Customer Service: While Qfun offers lifetime technical support, some users have reported difficulty contacting customer service.

7. Hot Cold Laminator Machine 17 Inch Roll

You’ll love the versatility of the Hot Cold Laminator Machine 17 Inch Roll! With its 450mm width, you can tackle a wide range of projects. The temperature control is a game-changer, letting you switch between hot and cold laminating with ease. Safety features? Check. It’ll shut off automatically if things get too hot. Plus, it’s whisper-quiet, so you won’t wake the neighbors during your late-night crafting sessions. Just remember, this power-hungry beast needs its own socket. Now go forth and laminate like a pro!

Best For: This laminator is perfect for crafters, educators, and small businesses needing a reliable and versatile machine for a variety of laminating tasks.

- Wide Laminating Capacity: Handles projects up to 17 inches wide.

- Precise Temperature Control: Switch between hot and cold laminating with ease.

- Quiet Operation: Won’t disturb others while you work.

- High Power Consumption: Requires its own dedicated power outlet.

- Heavy and Bulky: May be difficult to move or store.

- Limited Film Roll Included: Additional film rolls may need to be purchased separately.

8. DEJUN 13 Inch Laminator Hot Cold

Looking for a versatile laminator? The DEJUN 13 Inch Hot Cold Laminator might be your new best friend. With adjustable temperature and modes, you’ll breeze through various projects like a pro. It’s a real workhorse, tackling everything from photos to book covers with ease. Just remember, when feeding laminate rolls, start with the top layer first to avoid a frustrating tangle. While some users reported loose screws, most rave about its performance. So, if you’re ready to waterproof and preserve your creations, this little powerhouse could be your ticket to laminating bliss!

Best For: This laminator is perfect for anyone who wants to protect and preserve photos, documents, and creative projects.

- Versatile: Laminates both hot and cold, with adjustable temperature and modes.

- Durable: Designed for frequent use and can handle a range of materials.

- Easy to Use: User-friendly controls and a clear design.

- Loose Screws: Some users reported receiving units with loose screws, which could affect performance.

- Noise: The circuitry box can be noisy, which may be distracting for some users.

- Potential for Tangles: Care is needed when feeding laminate rolls to avoid tangles.

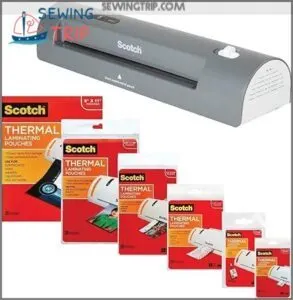

9. Laminator Kit All Pouch Sizes

Looking for a versatile laminator that won’t break the bank? The 3M Laminator Kit All Pouch Sizes might be your new best friend. This compact powerhouse handles items up to 9 inches wide and works with pouches up to 5 mil thick. You’ll get a variety of pouch sizes, so you’re ready for any project. It’s photo-safe too, perfect for preserving those precious memories. Just keep in mind, it might’ve a slight smell during operation. Oh, and don’t forget to stock up on extra pouches – you’ll be laminating everything in sight before you know it!

Best For: The 3M Laminator Kit All Pouch Sizes is best for home or office users looking for a versatile and affordable laminating solution.

- Versatile and works with a variety of pouch sizes

- Compact and easy to use

- Photo safe for preserving memories

- May have a slight unpleasant smell during operation

- Packaging doesn’t specify pouch heat settings

- Extra pouches will need to be purchased separately

Laminating Processes and Technologies

You’re about to discover the fascinating world of laminating processes and technologies that’ll transform your fabric projects. From Hot melt lamination to rotogravure techniques, we’ll explore the cutting-edge methods that’ll take your crafts to the next level.

Hot Melt Lamination Process

Ever wondered how hot melt lamination works? It’s a game-changer in the fabric world! This environmental-friendly process uses heat to bond materials without solvents or water. Here’s the scoop:

- Melts adhesive onto your substrate

- Applies pressure for a strong bond

- Cools quickly, reducing thermal stress

- Saves energy with no drying time

You’ll love how it transforms your foam and fabric projects in a snap, giving you more control over your creative process!

Rotogravure Lamination Technique

Ever wondered how those perfect patterns end up on your laminated fabric?

Enter the rotogravure technique!

It’s like a high-tech printing press for adhesives.

Picture a roller with tiny engraved cavities – that’s your pattern maker.

As it spins, it picks up adhesive and transfers it to your fabric in precise designs.

It’s the secret sauce behind those eye-catching laminates you love!

Adhesive Types and Applications

You have choices when it comes to adhesives for your laminating projects! Let’s explore the sticky world of adhesive types and applications:

- Hot melt adhesives: Quick-setting and versatile

- Water-based adhesives: Eco-friendly and great for porous materials

- Solvent-based adhesives: Strong bonds for challenging surfaces

- Pressure-sensitive adhesives: Perfect for temporary or repositionable applications

From apparel fabrics to industrial materials, choosing the right adhesive is key to mastering your craft. It’s like finding the perfect dance partner for your fabric – when you get it right, magic happens!

Drying and Curing Methods

For drying and curing, you’ve got options!

Heat is your best friend here.

Quick-drying methods use high temperatures to set adhesives in a flash.

For tougher materials, you might need longer curing times.

Some innovative composites require custom-made laminating machines with specific heat settings.

Don’t shy away from experimenting in a pilot plant to nail your laminating requirements.

It’s all about finding that sweet spot!

Solvent-free Lamination Technologies

Solvent-free lamination is your ticket to eco-friendly crafting! You’ll love these cutting-edge technologies that are kinder to Mother Earth and your workspace. Say goodbye to harsh chemicals and hello to sustainable solutions. Here’s why you’ll want to jump on this green bandwagon:

- Water-based adhesives that stick like glue without the fumes

- Powder laminating for a mess-free, precise application

- Biodegradable options that break down, not your conscience

- Industrial-strength results without the industrial-strength smell

Selecting the Right Laminate Fabric Laminating Machine

With so many options available, choosing the perfect laminate fabric laminating machine can feel overwhelming. We’ll walk you through the key considerations to help you select the ideal machine for your unique needs.

Working Width and Thickness Considerations

When picking a laminate fabric laminating machine, it’s important to think about the working width and thickness limits** so it can handle your projects.

Working width tells you the size of materials you can use.

Common widths range from 10 cm to 155 cm.

So, if you plan to work with larger fabric pieces, get a machine with a wider working width.

Thickness matters, too.

Some machines handle up to 20 mm thick materials, which is great for foam-based stuff.

Make sure you check these specs so your machine can handle the thickness of your laminated creations.

Speed and Production Capacity

When choosing a laminate fabric laminating machine, speed and production capacity are key factors. You don’t wanna be stuck with a slowpoke that holds up your entire operation.

Make sure the machine’s working speed and output capacity match your project needs. Also, think about the floor space it’ll take up and the power it needs to run efficiently.

For example, the Sunkist SA-6AC has a working speed of 0-1500M/Hr and a compact floor space requirement of L 6160mm x W 2020mm x H 2125mm, making it a speedy and space-efficient choice.

Adhesive Compatibility

When picking a laminate fabric laminating machine, it’s important to think about adhesive compatibility to get the best results. Here’s what you need to keep in mind:

- Choose a machine that works with your preferred adhesive type, whether it’s water-based, solvent-based, or hot-melt.

- Think about the benefits of hot-melt adhesives, like quick fabrication and consistent application.

- Look for machines that work with reactive and thermoplastic adhesives for more flexibility.

- Prevent adhesive overflow with features like gravure rollers, making sure you have a well-controlled coating process.

Energy Efficiency and Environmental Impact

Energy efficiency and eco-friendly choices are a big deal when selecting a laminate fabric laminating machine. The last thing you want is a machine that guzzles energy and hikes up your bills. Not to mention, going green is the way to go to lower your carbon footprint.

So, what should you look for?

First off, keep an eye out for machines that use hot melt technology. This process is more energy-efficient than traditional methods since it doesn’t need drying or sintering. Plus, it’s solvent and water-free, so it’s easier on the environment.

Also, consider the power requirements. Some machines might need 208 or 230 electric, single or three-phase power. Make sure you’ve got the right setup to avoid any nasty surprises.

Customization Options and Accessories

Customization options and accessories are the cherry on top when you’re picking out the right laminate fabric laminating machine. You can tailor your machine to your specific needs and add a personal touch.

Color Customization

You can choose the color of your machine, adding a unique aesthetic and a touch of brand identity to your workspace. It’s like picking out a new outfit for your trusty workhorse.

Accessories

Think of accessories as the cherry on top, enhancing functionality and making your machine even more versatile. Here are some options:

- Roll Stock Feed Attachment: Easily feed rolled stock laminate materials like a pro.

- Hot Knife Adhesive Cutter: Cut through adhesives like butter with this nifty tool.

- Infeed & Outfeed Conveyors: Extend your machine’s reach and handle full-size panels with ease.

- Conveyor Sections: Customize the length with or without legs to fit your space like a glove.

Frequently Asked Questions (FAQs)

Whats the difference between hot melt and flame lamination?

Hot melt lamination uses a separate adhesive substance, while flame lamination uses the material itself as an adhesive. Hot melt is faster, stronger, and more versatile.

How do I know if I need a single or three-phase electric machine?

If you need a lot of power, a three-phase electric machine is best. They’re also more compact, less costly, and longer-lasting than single-phase motors. Single-phase motors are simpler and work with two wires.

Whats the benefit of a laser-processed gravure roller?

Laser-processed gravure rollers offer a host of benefits. They provide maximum precision, efficient and cost-effective production, and no additional steps like manual polishing are needed. They also create a hygienic working environment as they don’t produce dust or chips.

Whats the working speed of the Cavimelt machine?

The Cavimelt machine has a working speed of 2-200 m/min. The operating speed is up to 40 m/min.

How do I choose the right working width for my machine?

First, decide the largest width of material you’ll be laminating. Then, pick a machine that fits that width. For example, if you’re laminating letter-sized documents, a 12" or 25" film should work.

Conclusion

Whether you’re a crafting enthusiast or a small business owner, choosing the right laminate fabric laminating machine is key to taking your projects to the next level.

With the right machine, you can protect and enhance your fabrics, giving them a professional finish.

From hot-melt technology to eco-friendly options, there’s a machine to suit every need.

Now that you’re equipped with knowledge about the different types, key components, and top picks, you’re ready to make an informed decision and revolutionize your crafts with the perfect laminate fabric laminating machine.