This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Weight measures mass per unit area, thickness describes the physical dimension between surfaces, and transparency refers to how much light passes through the weave. A fabric can check one box without checking the others—cotton voile weighs little but stays opaque through a tight plain weave, while organza feels stiff and structured despite its see-through finish.

Understanding these distinctions changes how you choose materials for garments, home décor, and projects that demand specific performance.

Table Of Contents

Key Takeaways

- Weight, thickness, and transparency are independent fabric properties—a material can be lightweight yet opaque through tight weaving, or thin but non-sheer due to fiber density, meaning GSM alone doesn’t predict how see-through a fabric will be.

- Weave structure controls performance more than fiber alone: plain weaves boost tensile strength by 15% but reduce drape, while fabric density impacts porosity twice as much as weave pattern itself, directly determining transparency levels.

- Each sheer fabric serves distinct functions—chiffon transmits 80-90% light with fluid drape for evening wear, georgette offers textured grip with moderate transparency for structured garments, and voile provides semi-sheer balance ideal for layering applications.

- Working with delicate fabrics requires specific techniques: use microtex needles sized 60/8 to 80/12 with fine thread weights, stabilize materials during cutting to prevent distortion, and hand wash in cool water below 600 rpm to preserve fabric strength and prevent degradation.

Defining Lightweight, Thin, and Sheer Fabrics

When you’re shopping for fabrics or planning a sewing project, you’ll notice that "lightweight," "thin," and "sheer" get thrown around pretty freely—but they don’t mean the same thing. Each term describes a different quality of fabric, and understanding the differences helps you pick the right material for what you’re making.

Let’s break down what sets them apart.

Key Differences Explained

What actually separates these three categories? Lightweight fabrics generally weigh below 150 GSM, while thin fabrics emphasize fine yarns and low thread density rather than weight alone. Sheer fabrics prioritize transparency—how light passes through them.

Here’s the key: weight, thickness, and transparency are separate properties. A fabric can be lightweight yet opaque if its weave is tight. Another can feel thin but remain non-sheer due to matte fibers. Sheer fabrics like chiffon achieve translucence through low yarn density and fine fibers, creating breathable, fluid drape.

Weight, thickness, and transparency function independently—tight weaves create opaque lightweight fabrics while loose, fine fibers produce sheer drape

To assess this quality, one can perform a visual inspection by examining the fabric to a light source. Understanding these distinctions shapes how you select fabric for your projects and how the garment will actually perform.

Fabric Weight Vs. Thickness Vs. Transparency

These three properties operate independently, not as a hierarchy. Fabric weight—measured in grams per square meter (GSM)—tells you how heavy the material is. Lightweight fabrics generally fall below 150 GSM, but weight alone doesn’t reveal the full story. Thickness describes the physical dimension of the fabric, which can vary dramatically based on fiber type and weave structure. A loosely woven fabric might feel thick while remaining lightweight. Transparency is where it gets interesting: it’s determined by how densely the yarns are packed and how much light passes through.

Here’s what separates them:

- GSM measurement defines weight categories, but a tightly woven fabric at 100 GSM can block more light than a loose weave at the same weight

- Weave structure controls transparency regardless of weight—higher density yields lower open area and reduced see-through quality

- Material innovation in filament technology now allows ultra-sheer fabrics below 30 GSM to enter mass production, proving weight and transparency operate independently

Think of it this way: you can have a lightweight, opaque fabric for structured garments, or a lightweight, sheer fabric for flowing evening wear. The GSM number alone won’t tell you which one you’re getting. That’s why transparency testing uses spectrometers to measure actual light transmission in the 400–800 nanometer range. Understanding this distinction shapes which fabric you’ll choose for your specific use case. Fabric weight also impacts its durability, so consider intended fabric use when selecting materials.

How Fabric Structure Affects Each Category

Weave structure is what really drives the performance of lightweight, thin, and sheer fabrics. Plain weaves create tight yarn interlacements that boost tensile strength by up to 15% compared to twill weaves, but this density works against drape. Twill weaves, with fewer interlacements, give you better flexibility and flow.

Here’s the key: fabric density—how tightly yarns pack together—has twice the impact on porosity as weave pattern itself. Loosely woven structures increase open area by over 20%, directly affecting transparency.

Fiber morphology matters too. Finer fibers yield more sheer results, while thicker fibers create stiffer textile properties. Layering techniques can reduce transparency by up to 80% while preserving a lightweight feel. Understanding how these elements interact lets you engineer fabrics that meet specific performance demands.

Common Types of Lightweight Fabrics

Now that you understand the differences between lightweight, thin, and sheer fabrics, you might be wondering what options actually exist in the lightweight category.

The good news is that lightweight fabrics come in many forms, each with its own strengths and best uses. Let’s look at the most common types you’ll encounter.

Cotton, Linen, and Rayon

When you’re choosing between lightweight fabrics, cotton, linen, and rayon each bring distinct advantages. Cotton breathes well and absorbs moisture evenly, making it reliable for everyday wear. Linen exceeds both—it dries faster, tolerates 20% moisture without feeling damp, and runs cooler thanks to thermal regulation. Rayon offers the most fluid drape with its delicate filaments, though it’s less durable and weakens when wet.

For fabric density, lightweight cottons range 50–130 g/m², linens 100–180 g/m², and rayons 70–150 g/m², each affecting how the fabric feels and performs.

Polyester and Nylon

Polyester and nylon dominate synthetic fiber production, each offering distinct advantages in lightweight applications. Polyester’s polymer composition provides enhanced moisture management and quick-drying properties—critical for everyday wear—while its mechanical properties deliver high abrasion resistance.

Nylon, by contrast, excels in elasticity and tensile strength, making it ideal where flexibility matters. Both create sheer fabrics at weights below 30 g/m², though nylon’s softer fiber cross-section produces a silk-like luster compared to polyester’s crisp sheen.

For sustainability trends, recycled polyester now accounts for 15% of global output, offering eco-efficient options that nylon currently lacks at scale.

Viscose and Modal

Regenerated fibers like viscose and modal bridge natural comfort with lightweight performance. Viscose absorbs up to 400% of its weight in moisture, making it supremely breathable for warm climates. Modal goes further—its higher fiber density resists moisture swelling better while maintaining a silk-like feel and breathability that rivals cotton.

Both fabrics dominate Asia-Pacific markets, with viscose projected to grow 6% through 2033. They’re biodegradable and sustainable when sourced responsibly, though production methods matter.

These fibers excel in close-fitting garments where moisture management and comfort drive demand.

Sheer Fabric Types and Characteristics

Sheer fabrics are the most transparent of all lightweight materials, letting light pass right through them. Unlike regular lightweight fabrics that just feel airy, sheer fabrics are designed specifically to be see-through.

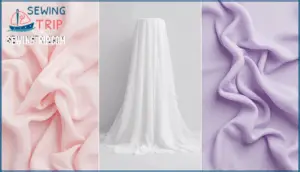

You’ll find several types of sheer fabrics, each with its own look and feel, so it helps to know what sets them apart.

Chiffon, Organza, and Georgette

These three fabrics define luxury sheer textiles, each with distinct properties. Chiffon, weighing just 20–50 g/m², transmits 60–70% of light through its open plain weave, making it the most transparent. Organza brings stiffness and structure, crafted from tightly woven silk or polyester fibers at 80–120 denier. Georgette stands apart with its signature crinkled finish from S- and Z-twisted yarns, offering excellent drape and durability.

Today, synthetic blends dominate—60% cheaper than silk versions and produced primarily in China and India.

Each has specific functional uses: chiffon for evening wear, organza for bridalwear, georgette for high-end dresses requiring breathability and movement.

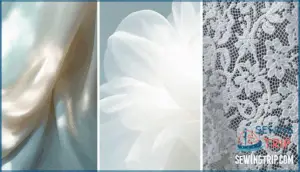

Voile, Tulle, and Lace

Voile offers a softer alternative to stiffer sheers, with its tight plain weave and high thread count creating semi-sheer transparency at 45–60% light transmittance. At just 70–100 g/m², cotton voile excels in summer apparel, delivering breathability with minimal shrinkage.

Tulle contrasts sharply—its hexagonal mesh structure weighs only 10–40 g/m², transmitting 75–90% light for structured, voluminous effects in bridal and dance wear.

Lace combines openwork artistry with complex patterning, dominating luxury markets at USD 38.44 billion globally.

Each provides distinct design applications: voile for layered dresses, tulle for petticoats, lace for high-end fashion and décor.

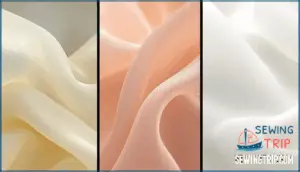

Transparency, Drape, and Texture Differences

How do you choose between fabrics that look nearly identical but perform completely differently? The answer lies in three distinct properties: optical transmittance, drape coefficient, and surface friction.

Chiffon dominates with 80–90% light transmission and a drape coefficient of 0.75–0.9, creating fluid movement ideal for evening gowns. Georgette offers moderate transparency (40–60%) with controlled drape around 0.55–0.7, thanks to its textured, high-twist weave structure. Voile strikes a balance—semi-sheer at 50–70% transmittance with firmer body (0.5–0.65 drape coefficient) perfect for layered designs.

Surface friction varies too: chiffon feels slippery, georgette grainy, voile smooth. These texture differences directly influence how fabric acts on your body, light, and intended functional usage in everything from bridal wear to home décor.

Best Uses for Lightweight, Thin, and Sheer Fabrics

Now that you understand the differences between lightweight, thin, and sheer fabrics, it’s time to see where they actually excel in real-world applications.

Each type fulfills specific purposes depending on what you’re making and what you need from the fabric. Here’s how you can put each one to work.

Fashion Apparel (Dresses, Blouses, Lingerie)

Fashion apparel drives massive demand for these fabrics. Lightweight and sheer materials account for 35% of dress and blouse consumption globally, with chiffon, georgette, and voile leading flowy designs. Lingerie relies heavily on sheer fabrics—lace and mesh appear in 70% of units.

The material composition matters: cotton-rayon blends dominate non-sheer lightweight pieces for breathability, while nylon and polyester comprise 65% of fast-fashion sheers. Durability varies greatly—polyester sheers withstand 200 washing cycles before strength loss, but silk sheers degrade after roughly 80 cycles.

Sewing techniques matter too: micro-needles (60/8 to 70/10) preserve weave integrity when working with delicate materials.

Home Décor (Curtains, Tablecloths)

Home décor applications showcase how lightweight and sheer fabrics transform spaces. Curtains and tablecloths depend on light diffusion and privacy levels to balance brightness and functionality. Voile and organza transmit 60–80% of natural light, reducing energy costs while maintaining visual comfort.

Layered treatments—combining sheer panels with heavier drapes—give you flexible control over daylight and sightlines. Polyester sheers withstand 300+ wash cycles, while natural fibers require gentler care to extend fabric lifespan.

Consumer demand for sustainable home décor fabrics has surged 40% recently, making organic cotton and recycled polyester popular choices for curtains and table linens.

Seasonal and Special Occasion Applications

Beyond home décor, seasonal shifts and special events demand fabrics that balance aesthetics with performance. Summer apparel thrives on lightweight cottons and voile—materials under 150 gsm that keep you cool while drying fast. Winter layering benefits from sheer organza over wool, adding visual depth without excess weight.

Bridal wear and eveningwear dominate with chiffon and organza, where 75% of gowns leverage their fluid drape and transparency.

Event décor relies on voile and tulle overlays to diffuse light and reduce heat buildup, while sportswear uses mesh panels and ripstop nylon under 100 gsm for strength-to-weight optimization.

Tips for Working With Sheer and Lightweight Fabrics

Working with sheer and lightweight fabrics requires a different approach than standard textiles. These delicate materials demand careful treatment at every stage, from cutting to storage.

Here’s what you need to know to get professional results.

Cutting and Sewing Techniques

When working with lightweight and sheer fabrics, your cutting and sewing techniques make all the difference. Start by stabilizing your fabric with tissue paper or lightweight interfacing—this prevents stretching and distortion during cutting. Use a rotary cutter on a mat for precision, or try the "tissue paper sandwich" method to reduce bias distortion, especially with chiffon and georgette.

For seam construction, baste with long stitches first to improve accuracy on slippery materials. Use narrow zigzag stitches to stabilize thin weaves, and consider French seams to enclose raw edges and reduce fraying. These sewing techniques work together to keep your damage prevention strategy intact and help maintain clean, durable seam finishes.

Choosing Needles and Thread

Your needle and thread choices directly impact stitch quality and fabric preservation. For lightweight and sheer materials like organza and chiffon, use microtex or sharp needles sized 60/8 to 80/12—their narrow shafts reduce snagging. Pair these with fine thread weights between 80wt and 100wt to create smooth, nearly invisible seams.

Mismatched needle-thread combinations increase skipped stitches by up to 40%, so tension balance matters. A 70/10 microtex needle with 80wt polyester thread offers best results. Avoid heavier needles above 100/16, which puncture delicate weaves and cause distortion.

Care, Maintenance, and Storage

Proper washing techniques directly affect how long your delicate materials last. Hand wash chiffon, lace, and organza in lukewarm water around 30–35°C, or use a mesh bag with gentle cycles below 600 rpm. Skip bleach and enzyme detergents—they reduce fabric strength by up to 25%.

Air dry away from direct sunlight, as UV exposure fades dyes by 40% in under 20 hours.

Store in breathable containers with relative humidity below 60%, using acid-free tissue between layers to prevent yellowing and maintain fabric properties.

Frequently Asked Questions (FAQs)

How Do I Identify Lightweight Fabric?

You can identify lightweight fabric by checking its weight per square yard, usually under 4 ounces. Examine the fiber content and weave type—loosely woven materials feel airy.

Assess the feel and drape by lifting it up. Use a transparency test to see how much light passes through.

What is the Difference Between Lightweight and Sheer Fabrics?

Lightweight fabrics emphasize reduced weight for comfort, while sheer fabric types prioritize transparency through their open weave structure.

Fabric properties like opacity separate these categories—lightweight fabrics aren’t always see-through, but sheer fabrics always are, affecting their intended purpose and layering options.

What is the Best Way to Sew Lightweight Fabrics?

Start with a fine needle—size 60/8 or 70/10 works well for lightweight fabrics. Use shorter stitch settings and a stabilizer underneath to prevent puckering.

Press seams gently with low heat to avoid damage.

What Are the Most Popular Lightweight Fabrics?

Cotton, linen, and rayon dominate Summer clothing for breathability. Performance fabrics like polyester and nylon offer durability at lower cost. Sustainable options include organic cotton and viscose.

Regional preferences vary—chiffon fabric and voile fabric remain popular for lightweight fabrics globally.

Are There Any Special Care Instructions for Lightweight Fabrics?

Yes, you’ll want to treat these delicate materials with care. Washing techniques matter—hand wash or use a gentle cycle with cold water. Drying methods should avoid high heat; air-dry flat when possible. Ironing guidelines recommend low temperatures with a pressing cloth. Storage solutions include folding loosely or hanging to prevent creasing. For stain removal, treat spots immediately with mild detergent.

Proper fabric care and maintenance extend the life of your lightweight fabrics, making sewing techniques and fabric care simpler over time.

What are the different types of lightweight fabric?

You’ll find plenty of options in fiber content and weave structures. Cotton, linen, voile fabric, and chiffon fabric offer breathability factors perfect for seasonal suitability, while gauze fabric and sheer fabric types provide varied transparency.

What is a thin sheer fabric called?

Thin sheer fabric goes by several names depending on its weave and fiber content. Chiffon, organza, and georgette are popular choices with transparent qualities. Voile and tulle also fall into this category, each offering different texture and drape characteristics.

What do you call very thin fabric?

You’ll find terms like voile, gauze, and batiste describing these delicate materials. Fabric terminology evolves from historical context—voile comes from French, meaning "veil."

Types of sheer fabrics include organza and chiffon, where weave types and fiber content determine transparency levels.

What fabric is thin but warm?

Merino wool stands out for warmth without bulk. This natural fiber traps heat efficiently while staying thin and breathable.

Thermal knits made from cotton blends or microfiber insulation also deliver excellent warmth, offering smart fleece alternatives that regulate temperature effectively.

How do I identify lightweight fabric?

Like grasping a piece of cloud, lightweight fabric reveals itself through fabric weight (under 4 oz per square yard), fiber content, and weave density.

Visual inspection and hand feel confirm its airy characteristics—these fabric identification techniques help you spot truly lightweight fabrics instantly.

Conclusion

The next time you run your fingers across fabric, you won’t just feel texture—you’ll decode weight, thickness, and transparency like a textile engineer reading blueprints.

Each property tells a different story about how the material will perform under stress, drape across surfaces, or filter morning light through a window.

Mastering lightweight vs thin vs sheer fabric types means you’ll stop guessing and start building projects with the exact characteristics you need, whether that’s a structured organza overlay or breathable cotton voile for summer wear.

- https://icefabrics.com/blogs/news/what-is-gsm-in-fabric

- https://journals.sagepub.com/doi/full/10.1177/15280837251321854

- https://sanvt.com/blogs/journal/fabric-weight-a-guide-to-gsm

- https://media.neliti.com/media/publications/264811-prediction-of-seam-performance-of-light-4d525fcf.pdf

- https://www.archivemarketresearch.com/reports/sheer-curtain-fabric-259762