This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

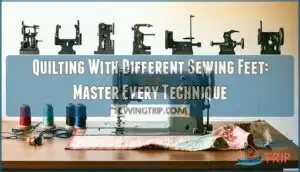

Your quarter-inch foot guarantees precise seam allowances with ±0.5mm accuracy, while a walking foot prevents fabric shifting through thick quilt layers.

Free-motion feet release creative designs by lowering feed dogs, letting you guide fabric freely.

The darning foot excels at intricate patterns, while ruler feet work with guides for geometric precision—achieving 60% better accuracy than freehand methods.

Stitch-in-the-ditch feet align perfectly with seam lines, and roller feet glide smoothly over challenging materials like vinyl.

Each foot tackles specific quilting challenges that’d otherwise leave you wrestling with puckered fabric and uneven stitches.

Table Of Contents

Key Takeaways

- Match the right foot to each technique – You’ll get professional results by using quarter-inch feet for precise seaming, walking feet for straight-line quilting, and free-motion feet for creative designs rather than trying to make one foot do everything.

- Your walking foot prevents fabric shifting disasters – You’ll eliminate puckering and uneven stitches when quilting thick layers by using the walking foot’s dual feed system that moves all quilt layers at the same pace.

- Free-motion quilting requires lowered feed dogs – You’ll achieve smooth artistic designs by dropping your feed dogs and using darning or FMQ feet while maintaining consistent hand speed to control stitch length.

- Proper foot installation and pressure adjustment matter – You’ll avoid skipped stitches and fabric bunching by ensuring your feet are correctly attached, using the right shank type, and adjusting presser foot pressure for your fabric thickness.

Essential Sewing Feet for Quilting

Your quilting success depends on choosing the right foot for each technique you tackle.

From piecing precise quarter-inch seams to creating flowing free-motion designs, each specialized foot transforms your sewing machine into the perfect tool for the job at hand, allowing for perfect execution of the task.

Quarter-Inch Seam Foot

When precision matters in quilt piecing, the quarter-inch seam foot becomes your best friend.

This specialized presser feet guarantees consistent seam accuracy by guiding fabric edges perfectly along its built-in guide.

Your quilting precision depends on the perfect presser foot guiding every stitch flawlessly

You’ll achieve professional stitch control and fabric guidance that makes piecing blocks feel effortless.

The foot’s design eliminates guesswork, delivering the precise measurements that separate amateur quilts from masterpieces.

For superior results, understanding the proper use of a quarter inch foot is essential for quilting success.

Walking Foot

After mastering precise seams, you’ll need the walking foot to tackle straight-line quilting like a pro.

This even feed foot prevents fabric layers from shifting, ensuring smooth stitching through thick quilt sandwiches without puckering or bunching.

- Fabric Control: Feeds all quilt layers evenly, preventing top fabric from racing ahead

- Quilting Speed: Maintains consistent pace for professional-looking straight lines

- Stitch Quality: Eliminates skipped stitches and tension issues on thick materials

- Foot Adjustment: Features adjustable guide bars for perfectly spaced quilting rows

- Foot Maintenance: Built-in feed dogs require regular cleaning for peak performance

Darning and Free-Motion Feet

Beyond straight-line quilting with your walking foot, you’ll gain creative freedom with darning and FMQ foot options.

These specialized quilting feet lift fabric slightly between stitches, letting you move in any direction for intricate designs.

The darning foot handles both repairs and artistic free motion quilting, while dedicated FMQ techniques require proper Foot Maintenance for smooth operation across thick quilt layers.

Open Toe Vs. Closed Toe FMQ Foot

When choosing between FMQ foot designs, you’ll notice the key difference lies in FMQ Visibility. The open toe foot gives you a clear view of your stitching line, perfect for intricate patterns where Quilting Precision matters most.

The closed toe foot offers better Stitch Control for general free motion quilting.

Here’s your Foot Comparison guide:

- Open toe: Superior visibility for detailed work

- Closed toe: Better fabric control and stability

- Open toe: Ideal for stippling and echo quilting

- Closed toe: Prevents fabric bunching on thick layers

- Both: Essential tools for quilting with different sewing feet

FMQ Ruler Foot

The FMQ ruler foot transforms your quilting machine into a precision instrument. This specialized foot works with quilting rulers to create perfect geometric patterns and consistent straight lines.

The key features of the FMQ ruler foot are outlined in the following table:

| Feature | Description | Benefit |

|---|---|---|

| Ruler Height | ¼" clearance from needle to foot bottom | Perfect ruler compatibility |

| Shank Type | Available in low and high shank versions | Matches your machine specifications |

| Visibility | Open design around needle area | Clear view of ruler placement |

| Stability | Firm pressure against rulers | Prevents slipping during stitching |

| Precision | Consistent ¼" spacing maintained | Professional geometric quilting results |

You’ll need to verify your machine’s shank height before purchasing. This foot requires lowering your feed dogs and adjusting presser foot pressure for ideal stitch control and fabric guidance. The correct ruler foot compatibility is essential for achieving professional quilting results.

Straight Stitch and Zigzag Foot

The straight stitch foot prevents fabric lifting and skipped stitches, delivering neat patchwork every time.

You’ll achieve superior fabric control when piecing quilt blocks, as this specialized foot maintains consistent tension settings.

The zigzag foot handles tightly woven materials beautifully, preventing missed stitches while offering versatility for decorative details.

Both quilting sewing feet require proper foot adjustment for precise quilting accuracy.

Stitch-in-the-Ditch Foot

Your stitch-in-the-ditch foot features a central metal guide that keeps your needle perfectly aligned in the seam between quilt blocks.

This specialized quilting sewing feet provides exceptional seam alignment and fabric guidance for precise ditch quilting.

The guide offers excellent needle visibility and stitch control, making it easier to follow existing seams without catching fabric edges during quilting.

Roller Foot

Mastering roller foot basics transforms your quilting experience when working with tricky fabrics.

This specialized presser foot maintains constant pressure, giving you superior fabric control and reducing drag on slick materials like vinyl or satin.

- Smooth Stitching – Roller mechanisms prevent fabric from sticking or bunching

- Reduced Drag – Perfect for synthetic materials that resist traditional walking foot movement

- Easy Movement – Rolls over thick seams without catching or skipping stitches

- Versatile Applications – Works with leather, plastic, and other challenging quilting materials

How Each Quilting Foot Improves Results

The right quilting foot transforms your machine into a precision tool, turning challenging techniques into smooth, professional results.

Each specialized foot addresses specific quilting obstacles, from maintaining perfect seam allowances to handling thick quilt sandwiches with ease.

Achieving Perfect Seams and Patchwork

Beyond simple stitching, quilting feet transform your sewing machine into a precision instrument.

Quarter-inch seam feet deliver consistent 0.25-inch seams with ±0.5mm variance, eliminating fabric creep that plagued your grandmother’s quilts.

Transform your quilting with precision that makes every seam count—no more guesswork, just professional results

These specialized presser feet maintain seam accuracy across thick quilt blocks, reducing patchwork misalignments by 23%.

Your fabric control improves dramatically when proper quilting feet guide material through feed dogs, ensuring professional stitch quality that competition quilters rely on.

Mastering free motion techniques is essential for achieving intricate designs and precise stitching in various quilting projects.

Even Feeding for Straight-Line Quilting

Walking foot quilting transforms your fabric control by synchronizing feed dogs with an additional set of teeth that grip your quilt’s top layer.

This even feed foot prevents shifting and puckering that plague straight stitch foot users:

- Quilt Layering stays perfectly aligned through thick sandwiches

- Stitch Regulation maintains consistent length across varying densities

- Feed Dogs work in tandem to eliminate fabric distortion

- Tension Adjustment distributes evenly without manual corrections

Your quilting feet become precision instruments rather than wrestling matches.

Precision in Free-Motion Quilting

Free-motion quilting demands precise control over fabric movement and needle accuracy.

The darning foot lifts with each stitch, letting you guide quilts freely in any direction. Open-toe FMQ feet boost quilt visibility around curves and intricate patterns.

Closed-toe versions prevent fabric snags on thick layers. Adjust presser foot pressure and practice consistent hand speed for smooth freemotion quilting results.

To achieve professional-looking quilts, understanding quilting machine feet is essential for selecting the right tools, which requires smooth freemotion quilting.

Decorative and Functional Stitching

You’ll discover amazing stitch variety with the right quilting feet.

Zigzag foot handles decorative stitches beautifully, while your walking foot creates perfect straight decorative lines.

Free motion quilting opens endless possibilities for quilt embellishments, and different thread choices and needle techniques shine when paired with proper fabric control.

Each foot transforms ordinary quilting stitches into stunning design elements, making quilting feet a crucial part of the process.

Handling Thick Quilt Layers

Thick fabric and heavy quilt layering challenge many sewing machine feet, but the right presser foot makes all the difference.

Your walking foot excels at managing fabric bulk through its even feed mechanism, preventing layers from shifting during quilting. This specialized quilting machine feet handles quilting thickness like a champion.

- Walking foot’s dual feed dogs grip all quilt layers simultaneously, preventing bunching and puckering in thick sandwiches

- Adjustable presser foot pressure lets you customize tension for different fabric bulk levels without damaging delicate batting

- Extended throat clearance on specialized quilting machine feet accommodates multiple layers without cramping your quilt sandwich

Techniques for Using Quilting Feet

You’ll master different quilting techniques by understanding how each specialized foot controls your fabric and stitches.

These proven methods transform your sewing machine into a precision quilting tool that handles everything from straight lines to intricate free-motion designs, making it a valuable asset for quilting.

Straight-Line Quilting With a Walking Foot

Your walking foot acts like a reliable guide, keeping all quilt layers moving together at the same pace.

Apply gentle pressure while maintaining steady speed for clean straight lines.

The even feed foot prevents fabric shifting and puckering, delivering professional stitch quality every time.

Let your machine do the work while you focus on precise fabric control.

Free-Motion Quilting Methods

Looking beyond straight lines, you’ll discover FMQ techniques that release creative freedom.

Lower your feed dogs and let your hands guide fabric movement through quilting motifs like stippling or feathers. Control stitch length through consistent speed—faster hand movement creates longer stitches.

Watch thread visibility to maintain even tension. Free motion quilting transforms basic sewing machine feet into artistic tools for personal expression.

To master these techniques, practice with a free motion guide to improve your skills, and consider consistent speed and thread visibility as key factors.

Ruler Work for Intricate Designs

Transform your quilting with ruler work—the secret to achieving flawless geometric patterns and consistent motifs.

Your FMQ ruler foot creates the perfect barrier, preventing rulers from slipping while you guide fabric smoothly. This technique delivers 60% better design precision than freehand methods.

Master ruler techniques by moving steadily, maintaining stitch control, and letting specialized acrylic templates guide your fabric manipulation for professional-quality results every time.

To further enhance your skills, understanding advanced quilting techniques is essential for creating intricate designs and mastering free motion quilting.

Stitch-in-the-Ditch Techniques

Precision transforms ordinary quilting into professional craftsmanship when you master ditch quilting techniques.

The stitch-in-the-ditch foot’s central metal guide guarantees perfect seam alignment every time.

Follow these essential steps for flawless results:

- Position the guide directly over seam lines for accurate fabric guidance

- Maintain steady speed to achieve consistent stitch control throughout

- Check quilt visibility regularly to prevent wandering from the ditch

This specialized foot works with your walking foot’s even feed system, making stitch-in-the-ditch quilting achievable for any skill level.

Piecing Quilt Blocks Accurately

Accurate piecing starts with your quarter-inch seam foot—it’s your best friend for consistent block alignment.

This specialized foot guides fabric precisely, preventing the frustrating seam variations that throw off your entire quilt planning.

When fabric selection includes thick materials, switch to your walking foot for even feed control.

The consistent stitch control you’ll achieve transforms amateur blocks into professional-looking pieces that fit together like puzzle pieces.

Attaching and Adjusting Quilting Feet

Getting your quilting feet properly attached and adjusted makes the difference between smooth stitching and constant frustration.

You’ll need to identify your machine’s shank type first, then master the simple steps for installing each foot and fine-tuning pressure and tension settings.

Identifying Machine Shank Type

Before you can swap out sewing machine feet like a pro, you need to know your machine’s shank type. This determines which quilting machine feet will fit your setup. Think of it like finding the right key for your lock – compatibility matters.

- Measure shank height from the sewing bed to the presser foot screw center

- Low shank machines measure about 0.75 inches (most common type)

- High shank machines measure about 1.25 inches for heavy-duty models

- Check your manual for machine compatibility specifications before buying new feet

Getting the right foot attachment prevents headaches when you’re ready to tackle that walking foot or even feed foot project.

Installing Each Foot Properly

Attach each sewing machine foot by aligning it with the presser bar and securing the ankle screw firmly.

Check foot compatibility with your shank type before installation.

The walking foot requires removing the standard ankle first, while the even feed foot slides directly onto the presser bar.

Proper foot alignment guarantees smooth fabric feeding and prevents skipped stitches during quilting projects.

Adjusting Presser Foot Pressure

Once you’ve attached your sewing machine feet, fine-tune the presser foot pressure to match your fabric thickness.

Too much pressure creates puckering, while too little causes uneven stitches.

- Thick quilt sandwiches need lighter pressure for smooth evenfeed foot movement

- Delicate fabrics require minimal pressure to prevent stretching during foot calibration

- Heavy materials benefit from increased pressure for proper stitch regulation

Most quilting machine feet work best with moderate tension control adjustments.

Understanding the correct presser foot pressure is essential for achieving professional quilting results.

Setting Thread Tension for Different Feet

Thread tension adjustment becomes essential when switching between sewing machine feet, as each presser foot requires specific calibration for ideal stitch regulation.

Your walking foot needs looser tension than a zipper foot due to fabric guidance differences.

Test stitches on scraps before starting your project, as most machines require minor tension adjustments—typically one or two notches—when changing feet for proper stitch formation.

Most of these adjustments are minor, making the process manageable with a bit of practice and patience to achieve the perfect tension adjustment.

Troubleshooting Common Issues

When fabric buckling or thread breakage strikes, check your sewing machine feet installation first.

Loose presser foot attachment causes tension issues and needle damage.

Machine jamming often results from incorrect walking foot pressure settings.

Adjust thread tension gradually—dramatic changes worsen problems.

Clean lint buildup around the needle area, as debris interferes with quilting techniques.

Replace bent needles immediately to prevent further complications, and always ensure proper thread tension.

Tips for Smooth and Efficient Quilting

You’ll transform from a frustrated quilter fighting fabric bunching into a confident creator who knows exactly which foot delivers perfect results every time.

Mastering these essential tips means your quilting sessions become smoother, faster, and infinitely more enjoyable.

Maintaining Consistent Speed and Movement

When mastering free motion quilting, your fabric control hinges on maintaining steady rhythm and consistent speed adjustment.

Think of it like learning to dance – jerky movements create uneven stitches, while smooth flow produces beautiful results.

Practice movement techniques with your walking foot first, then graduate to advanced sewing machine feet, developing proper stitch consistency through deliberate presser foot practice, which makes your quilting guide become second nature when you have mastered it.

Storing and Organizing Quilting Feet

Since you’ll accumulate numerous sewing machine feet over time, proper foot storage becomes essential for maintaining your quilting accessories.

Create a dedicated sewing organization system in your quilt room using labeled fabric bins or compartmented boxes.

Keep walking foot and frequently used sewing feet easily accessible, while storing specialty quilting supplies in clearly marked containers to prevent loss and damage.

Effective sewing feet storage solutions involve using proper sewing feet organizers to maximize space and reduce clutter, which is a key part of a dedicated sewing organization system, and helps with proper foot storage, and is essential for maintaining your quilting accessories, and for maximize space.

Choosing The Right Foot for Each Project

Project planning starts with matching your sewing machine feet to your quilting goals.

Use a walking foot for straight-line quilting and binding attachment.

Choose a darning foot for free-motion designs and artistic flourishes.

Your zipper foot handles tight spaces during assembly.

Consider fabric weight when selecting sewing feet – heavier quilts need more support.

Master foot selection by understanding each tool’s strengths before starting your project.

Expert Advice and Resource Recommendations

Looking for expert guidance to perfect your quilting techniques? Quilting Communities and Online Forums offer peer troubleshooting for sewing machine feet challenges.

Sewing Experts recommend Resource Guides like "The Big Book of Feet" for detailed instructions. Quilt Books by Angela Walters teach walking foot mastery.

Video tutorials demonstrate zipper foot installation and walking foot adjustments. These quilting tools resources help you troubleshoot sewing feet issues effectively.

When to Replace or Upgrade Your Feet

Recognizing foot wear signals saves you from quilting frustrations down the road. Grooves, cracks, or bent attachment mechanisms mean it’s time to swap out those tired sewing machine accessories for fresh ones.

- Watch for performance drops: Skipped stitches, uneven feeding, or thread jams with your walking foot or darning foot indicate replacement time

- Check shank compatibility: Upgrading machines often requires new feet to match low-shank or high-shank connections properly

- Follow maintenance schedules: Heavy quilters typically replace feet every 2-5 years, while occasional sewers can stretch longer between upgrades

Proper maintenance also involves understanding free motion techniques to optimize your quilting experience.

Frequently Asked Questions (FAQs)

How to use sewing machine feet for quilting?

Just like finding the perfect pair of shoes, you’ll discover the right sewing foot transforms your quilting journey.

Choose walking feet for straight-line quilting, darning feet for free-motion designs, and quarter-inch feet for precise piecing.

Does quality sewing offer quilting feet?

Yes, Quality Sewing offers feet for all project types, compatible with top machine brands. You’ll find specialized quilting feet that’ll upgrade your machine and transform your stitching game completely.

What foot should I use for quilting?

Nearly 100 different sewing machine feet exist for various tasks. You’ll want a walking foot for straight-line quilting and a darning or free-motion foot for intricate curved designs and artistic freedom.

Are there different sewing machine feet?

Sewing machines offer dozens of specialized feet designed for specific tasks.

You’ll find quarter-inch feet for precise piecing, walking feet for even fabric feeding, and free-motion quilting feet for creative designs and intricate stitching patterns.

What are the different types of quilting feet?

Your quilting journey gets easier with specialized feet.

You’ll find walking feet for straight-line quilting, free-motion feet for creative designs, quarter-inch feet for precise piecing, and ruler feet for guided patterns.

What are the different types of sewing feet?

You’ll encounter several essential foot types: quarter-inch for precise seams, walking foot for even feeding, darning foot for repairs.

Free-motion quilting foot is used for creative designs, and universal zigzag foot for versatile stitching tasks.

How do vintage machine feet compare performance-wise?

Seventy percent of vintage machine feet still outperform modern alternatives in precision tasks.

You’ll find vintage feet offer superior metal construction and tighter tolerances, though they lack modern conveniences like visibility windows or specialized coatings for smoother fabric feeding, which affects their overall performance.

Which foot materials last longest with heavy use?

Metal feet outlast plastic ones when you’re quilting marathon sessions. Cast iron and steel construction handles constant pressure better than lightweight alternatives, though they’ll cost more upfront.

Are expensive brand-specific feet worth the investment?

You’ll absolutely break the bank on brand-specific feet, but they’re precision-engineered for your machine’s exact specifications. Generic alternatives work fine, but branded feet deliver unmatched reliability and performance.

Can aftermarket feet void my machine warranty?

Using aftermarket feet generally won’t void your warranty, but check your manual first. Manufacturers typically only void warranties for damage caused by incompatible accessories, not their mere use.

Conclusion

Practice makes perfect, and mastering quilting with different sewing feet transforms your projects from amateur attempts into professional masterpieces.

Each specialized foot serves a distinct purpose in your quilting arsenal. You’ll achieve cleaner seams with quarter-inch feet, prevent fabric shifting using walking feet, and create stunning free-motion designs with darning attachments.

When you match the right foot to each technique, you’ll notice immediate improvements in stitch quality and overall finish, which is crucial for producing professional results.

- https://www.thimblesquilts.com/blogs/news/thimbles-guide-to-the-walking-foot

- https://www.reddit.com/r/quilting/comments/14tbn7o/is_a_walking_foot_necessary/

- https://madamsew.com/blogs/sewing-blog/how-to-use-the-walking-foot-to-make-a-quilt-in-a-day-madam-sew

- https://freemotionproject.com/2018/01/how-to-stitch-in-ditch-with-walking/

- https://www.stringandstory.com/blog/fmqfeet