This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

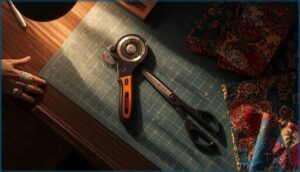

The first time you try to cut through eight layers of cotton with regular scissors, your hand will probably cramp up before you finish a single strip. That’s when most quilters discover rotary cutters exist for a reason.

The rotary cutter vs scissors for quilting debate isn’t about which tool is “better” in some absolute sense—it’s about understanding what each one does well so you can grab the right tool when you need it. Rotary cutters slice through multiple fabric layers like butter and give you laser-straight edges when you’re cutting strips or squaring up blocks.

Scissors shine when you need to navigate curves, snip threads, or cut intricate appliqué shapes that would be impossible with a rolling blade. Most experienced quilters keep both within arm’s reach because different tasks demand different approaches.

Table Of Contents

- Key Takeaways

- Rotary Cutters Vs Scissors: Key Differences

- Precision and Accuracy in Quilt Cutting

- Speed and Efficiency for Quilting Projects

- Safety Considerations for Quilters

- Ergonomics and Comfort During Use

- Cost and Long-Term Value

- Best Cutting Tool for Different Quilt Tasks

- Essential Accessories for Each Tool

- Top Rotary Cutters and Scissors for Quilting

- Choosing The Right Tool for Your Quilting Style

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Rotary cutters excel at slicing through multiple fabric layers with laser-straight edges for strips and binding, while scissors handle curves, appliqué shapes, and tight seam allowances better—most experienced quilters keep both tools within arm’s reach because different tasks demand different approaches.

- The real cost difference shows up over time through blade replacements and maintenance, with rotary cutter blades running $3-$8 each and needing replacement every 6-12 months of regular use, while quality scissors can last decades with occasional sharpening at $5-$20 per service.

- Rotary cutters cause less hand fatigue during marathon cutting sessions because the rolling blade action beats repetitive squeezing, but proper ergonomics matter for both tools—maintaining neutral wrist position, taking breaks every 20-30 minutes, and using smooth deliberate motions prevents repetitive strain injuries.

- Your cutting toolkit needs quality versions of both tools paired with essential accessories like self-healing cutting mats, acrylic rulers with clear grid lines, and proper storage solutions to protect blades and maintain cutting accuracy across different quilting projects.

Rotary Cutters Vs Scissors: Key Differences

You can’t pick the right tool until you understand how they actually work.

That’s why knowing the materials, construction, and long-term reliability of durable sewing tools makes all the difference in your results.

Rotary cutters and scissors look different and they move through fabric in totally different ways which means your hand does different things with each one.

Let’s break down the core differences so you know exactly what you’re working with.

Design and Mechanism

The core mechanism sets these tools apart. Rotary cutters feature a spinning circular blade on a fixed handle, rolling smoothly across fabric for continuous cuts. Scissors rely on two blades joined at a pivot that create a shearing action when you squeeze them together.

Understanding these design principles helps you pick the right tool for precision cutting.

| Feature | Rotary Cutter | Scissors |

|---|---|---|

| Blade Geometry | Circular, 18mm-60mm | Long, straight taper |

| Cutting Action | Rolling motion | Shearing squeeze |

| Tool Ergonomics | Handle with safety guard | Finger loops with pivot |

| Mechanism Comparison | Continuous edge | Deliberate snips |

Cutting Techniques Compared

Cutting Motion differs dramatically between these tools. Your rotary cutter glides in smooth continuous strokes, slicing through multiple layers with minimal fabric movement. Scissors demand deliberate snipping motions that require frequent repositioning. Fabric Prep stays consistent with rotary cutting since the mat holds everything steady, while scissors can shift your material. Proper Blade Care and Mat Selection keep rotary edges sharp and accurate.

| Technique | Rotary Approach | Scissors Method |

|---|---|---|

| Fabric Cutting Techniques | Long guided passes with ruler | Short controlled snips |

| Cutting Errors Prevention | Stabilize with mat and straight edge | Careful hand alignment |

Typical Use Cases in Quilting

Now that you know how each tool moves through fabric, here’s where each one shines in actual quilting work. Your rotary cutter demolishes yardage prep and strip piecing because it slices long straight edges across multiple layers in one pass. Scissors win at appliqué curves and trimming tight seam allowances where precision trumps speed every time.

| Task Type | Best Tool | Why It Works |

|---|---|---|

| Quilt Patterns strips | Rotary Cutter | Cuts uniform widths with ruler guidance |

| Appliqué shapes | Scissors | Maneuvers around delicate curves |

| Binding prep | Rotary Cutter | Processes long fabric cutting efficiently |

| Seam allowance trimming | Scissors | Reaches corners on Cutting Mat |

Precision and Accuracy in Quilt Cutting

When you’re piecing together a quilt you need perfect cuts or the whole thing falls apart.

The tool you choose makes a huge difference in how accurate those cuts actually turn out.

Let’s look at how rotary cutters and scissors stack up when precision really counts.

Straight Line Cutting Performance

When you’re slicing through fabric for quilting, a sharp rotary cutter gliding over a quality cutting mat delivers straighter lines than scissors, especially on long strips or multiple layers. The circular blade tracks along your ruler without the hand drift you get with scissor blades.

- Blade sharpness keeps your rotary cutter rolling cleanly without pulling fabric off course

- Edge tracking improves when you press your ruler firmly and maintain steady cutting speed

- Fabric tension stays even with rotary tools, whereas scissors compress fibers slightly

- Cutting mat quality with grid lines helps you align straight cuts accurately every time

Cutting Curves and Intricate Shapes

Tight curves and appliqué work call for a rotary cutter when you’re rolling along gentle arcs with a curved ruler, but scissors give you more control around tiny inner corners where blade tips let you pivot precisely.

For intricate shapes under one inch, scissors win every time, and blade sharpness matters—a fresh rotary blade glides smoothly on your cutting mat without snagging, while dull scissors fray delicate edges.

Maintaining Consistent Cut Widths

Width consistency depends on ruler alignment and blade sharpness—a fresh rotary cutter blade holds within 1/16 inch when you press evenly on your cutting mat, while scissors can drift beyond 1/8 inch as hand fatigue sets in.

Edge control improves when you keep fabric tension steady and align your ruler parallel to the grain, preventing those frustrating tapers that throw off your quilting piecing later.

Speed and Efficiency for Quilting Projects

When you’re working on a quilt project with dozens of pieces to cut, speed matters more than you might think.

A walking foot can help you align those layers precisely, especially if you’re dealing with bulky seams or fabric that tends to shift.

Rotary cutters and scissors don’t just differ in how they feel in your hand—they can totally change how long you spend at your cutting table. Here’s what you need to know about getting your fabric prep done faster and smarter.

Cutting Multiple Fabric Layers

Here’s where rotary cutters dominate: multi layer cutting. You can slice cleanly through six cotton fabric layers in one pass while scissors struggle past two or three without fraying edges.

Stack alignment stays tight when you’re using an acrylic ruler with your rotary cutter. That kind of cutting efficiency transforms fabric stacking from tedious chore into quick work, especially for quilting techniques demanding identical pieces.

Time-Saving Benefits

Think about how much faster cutting becomes when your rotary cutter slices through eight fabric layers in seconds versus snipping with scissors.

That efficient workflow means you can prep quilt backing and batting strips in minutes instead of hours. Reduced labor on cutting frees you up for actual sewing and quilting, boosting your productivity whether you’re working on lap quilts or king sized projects.

Project Size Considerations

Large quilts demand different cutting strategies than baby blankets. When you’re batch processing yards of fabric for a king sized quilt, a rotary cutter manages material optimization better than scissors by slicing multiple layers across a 24 by 36 inch mat.

Small wall hangings or appliqué work flip that logic. Cutting complexity matters too—scissors give you control on intricate shapes while rotary cutters excel at project scaling with straight strips.

Safety Considerations for Quilters

Sharp blades are tools you need to respect whether you’re working with scissors or a rotary cutter and knowing how each one can bite you is the first step to staying safe.

You don’t want to lose focus during a big quilting session and end up with an injury that could have been prevented with simple awareness. Here’s what you need to know about keeping your fingers intact and your workspace secure.

Blade Safety Features

Modern rotary cutters pack serious safety tech that scissors just don’t have. You’ll find spring-loaded blade guards on most OLFA models that automatically cover the edge when you lift pressure—vital for preventing those oops moments.

Blade locks freeze the wheel completely during storage. Some sophisticated cutters even include proximity sensors and transparent guards so you can see your cutting line while staying protected. Scissors offer simpler edge protection through basic sheaths.

Proper Handling Practices

Safe handling starts with your stance—plant your feet shoulder width apart and keep wrists neutral while cutting. Grip the rotary cutter or scissors firmly but don’t death-grip the handle or your joints will protest after twenty minutes.

Always cut away from your body and use rulers to guide blades rather than fingers. Store tools with blade covers on and keep your workspace clear of fabric scraps that cause slips.

Child and Pet Safety

When you’re quilting with kids or pets around, safe storage isn’t optional. Lock rotary cutters and scissors in high cabinets or drawers and never leave blades exposed on work surfaces.

Child supervision matters most during cutting sessions—barrier gates help separate curious toddlers from sharp tools.

Pet proofing your sewing space with closed doors reduces hazard reduction headaches, and emergency planning means keeping first aid supplies within arm’s reach for quick response.

Ergonomics and Comfort During Use

You can’t cut fabric for hours without feeling it in your hands and wrists. That’s where the real battle between rotary cutters and scissors shows up because comfort makes or breaks those marathon quilting sessions.

Let’s look at how each tool stacks up when you’re working through multiple layers and long projects.

Hand Fatigue and Prolonged Cutting

Fatigue prevention starts with smart grip techniques and regular hand exercises. When you’re powering through a big quilting project, the right cutting posture makes all the difference between finishing strong and nursing sore wrists. Rotary cutters usually cause less strain than scissors during marathon sessions because that rolling blade action beats repetitive squeezing every time.

Rotary cutters beat scissors for marathon cutting sessions because that rolling blade action beats repetitive squeezing every time

- Maintain neutral wrist support to dodge repetitive strain injuries

- Take breaks every 20–30 minutes to keep your accuracy sharp

- Use smooth deliberate motions instead of sudden grip tightening

- Strengthen forearms and wrists to extend your cutting endurance

- Proper hydration aids muscle performance during long sewing sessions

Left Vs Right-Handed Options

Your hand dominance directly affects cutting comfort and control when you pick up rotary cutters or scissors for quilting.

Left handed ergonomics matter because most standard sewing tools favor righties, but ambidextrous tools level the playing field for everyone.

Brands like Gingher offer true left handed scissors with reversed blade orientations, while some rotary cutters feature reversible grips that work beautifully for both hands without compromising ergonomic design.

Tool Weight and Grip Comfort

Choosing a cutter that feels good in your palm transforms marathon cutting sessions into comfortable work instead of an endurance test. Weight and grip design matter more than you might think:

- Ergonomic Grips with contoured finger grooves align naturally with your hand to reduce grip pressure during long quilting sessions.

- Grip Materials like soft rubberized surfaces or textured plastic provide better traction when your hands get sweaty while sewing tools stay secure.

- Weight Distribution differs between rotary cutters (4-8 ounces) and scissors (6-12 ounces), with balanced designs requiring less effort for straight cutting.

- Fatigue Reduction comes from padded grip sections that absorb shock and cushion pressure points during extended fabric work. Look for lightweight options with foam or gel inserts if hand comfort ranks high on your priority list.

Cost and Long-Term Value

You need to think beyond the price when you’re choosing between a rotary cutter and scissors. The real cost shows up over months and years of use when you factor in blade replacements, sharpening services, and how long each tool actually lasts.

Let’s break down what you’ll spend upfront and what these tools will cost you down the road.

Initial Investment Comparison

You’re probably wondering what you’ll spend upfront for these essential fabric cutting tools. Basic rotary cutters start around seven to fifteen dollars, while quilting scissors run eight to twenty dollars. Don’t forget budget planning for accessories, though—rotary cutters need a self-healing cutting mat and acrylic ruler, adding another twenty to forty dollars to your tool pricing.

| Tool Type | Approximate Price Range |

|---|---|

| Basic Rotary Cutter | $7–$15 |

| Mid-Range Rotary Cutter | $15–$40 |

| Basic Quilting Scissors | $8–$20 |

| Premium Quilting Scissors | $60–$120 |

| Mat + Ruler Bundle | $20–$40 |

Blade and Scissor Maintenance Costs

Your maintenance budget matters more than you think. Blade sharpening for rotary cutters runs eight to eighteen dollars per blade, while scissor maintenance costs five to twenty dollars per pair. Replacement costs stack up fast—new rotary cutter blades are three to eight dollars, but specialty titanium versions hit fifteen.

Smart sewing tool comparison shows scissors win on cost analysis since you can sharpen them more affordably. Regular tool durability checks save money long-term.

Routine upkeep goes a long way, and prioritizing regular blade maintenance practices can prolong the life of your cutting tools.

Durability and Lifespan

Quality rotary cutters with stainless steel blades hold their edge six to twelve months with regular quilting, but blade longevity depends on maintenance schedules. Scissors can last decades if you sharpen them correctly. Grip durability matters too—reinforced polymer grips survive accidental drops while cheaper ones crack.

Consider these tool replacement factors:

- High carbon cutting heads retain sharpness 25 percent longer than standard steel

- Sealed housings reduce internal wear by 40 percent in rotary cutters

- Regular lubrication extends blade life roughly 20 percent

- Premium scissor pivots maintain alignment through 1000 cuts

- Humid conditions shorten lifespan without proper storage

Smart sewing tools and supplies choices pay off over years of projects.

Best Cutting Tool for Different Quilt Tasks

You don’t want to grab the wrong tool for the job because it’ll slow you down or give you wonky cuts. Different quilt tasks really do need different approaches and knowing when to use scissors versus a rotary cutter makes your whole project easier.

Let’s break down which tool wins for the most common cutting situations you’ll face.

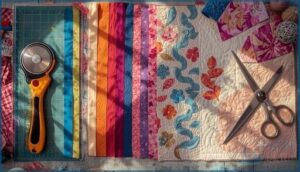

Cutting Straight Lines and Strips

When you’re slicing long straight lines or making uniform fabric strips for your quilting blocks, a rotary cutter paired with a ruler guide and cutting mat delivers unparalleled speed and accuracy.

Fabric alignment stays consistent when you press the ruler down firmly and the mat stability prevents shifting. Scissors can work but strip cutting becomes repetitive and edge finishing isn’t as clean.

Cutting Curves, Appliqué, and Details

Curves and appliqué demand different tools depending on how tight your radius is.

Rotary cutters glide along gentle curves when you rotate the blade smoothly but scissors win for tiny inner corners and micro details where you need to pause and adjust.

For appliqué techniques using fusible webbing, a sharp rotary blade slices clean edges across multiple layers while fine point scissors handle delicate contours and small burrs after stitching.

Recommended Tool by Project Type

Your project planning starts with matching the right quilting tools to your fabric selection and quilt patterns.

Consider these cutting strategies:

- Mass production quilts – rotary cutter slices 6 to 12 inch strips fast using rulers

- Heirloom designs – scissors handle intricate sewing techniques better

- Patchwork blocks – rotary cutter yields consistent strip cuts

- Appliqué work – scissors reduce fraying on delicate fabric cutting methods

Essential Accessories for Each Tool

You can’t just grab a rotary cutter or scissors and expect clean cuts without the right backup gear. Both tools need specific accessories to perform at their best and keep your workspace safe.

Here’s what you should have on hand depending on which tool you’re using.

Self-Healing Cutting Mats

You absolutely need a proper mat beneath your rotary cutter or those blades go dull fast and your table takes a beating. Most self-healing cutting mats use layered PVC that closes up after each slice, which is pretty cool when you think about it.

Look for clear grid alignment to guide your fabric cuts and check edge safety so corners don’t curl after storage. Mat maintenance is simple: just wipe with mild soap and store flat away from heat to keep that cutting surface smooth for years of quilting projects.

For more about the benefits and care of these tools, check out this resource on self-healing cutting mat properties.

Acrylic Rulers for Rotary Cutting

Your rotary cutter needs a clear acrylic ruler to keep those fabric alignment marks precise. Look for bold grid lines and angle guides at 30, 45, and 60 degrees to protect your blade from drifting off course.

Ruler materials like cast acrylic give you cutting accuracy across quilting projects while the transparent edges let you line up perfectly on your cutting mats every single time.

Sharpeners and Blade Replacements

Once you’ve mastered rotary cutter techniques with your OLFA and rulers, blade replacement becomes one of your quilting essentials. Most rotary cutters need fresh blades every few projects instead of blade sharpening since edge restoration rarely works. Scissors benefit from professional cutter maintenance or home honing.

Here’s what really matters for tool upkeep:

- Replace 45mm rotary cutter blades after extended use

- Choose manufacturer-matched replacements for perfect fit

- Dispose of dull blades in rigid containers

- Wipe fabric residue from edges after cutting

- Store sharp tools in protective sheaths

Top Rotary Cutters and Scissors for Quilting

You’ve narrowed down your choices between rotary cutters and scissors but now you need actual recommendations. I’m a huge fan of specific tools that make quilting easier whether you lean toward blades or shears.

Here are some top picks that quilters rely on for clean cuts and solid performance.

1. Gingher Left Handed Scissors

If you’re a lefty who’s struggled with right-handed scissors, the Gingher G-8L changes everything. The blades are actually reversed for left-handed cutting so you can finally see your cut line without tilting the fabric at weird angles.

The bent handle lets you cut flat on the table without your hand getting in the way. These scissors feature a knife edge that slices through multiple layers with ease and a chrome-over-nickel blade finish that resists corrosion. The long blade is perfect for trimming seams and cutting out patterns.

| Best For | Left-handed sewers and crafters who need proper scissors that let them see their cut line clearly and work comfortably on flat surfaces. |

|---|---|

| Primary Material | Nylon/Metal |

| Weight | 8 ounces |

| Brand | Gingher |

| Target Use | Fabric Cutting |

| Durability Feature | Chrome-plated blade |

| Skill Level | All levels |

| Additional Features |

|

- Truly reversed blades designed for left-handed cutting, not just left-handed handles

- Knife edge cuts through multiple layers of fabric smoothly

- Bent handle design keeps your hand above the cutting surface for better control

- Some users report the blades aren’t as reversed as advertised

- Blades can dull if used on paper or other non-fabric materials

- May need professional sharpening over time to maintain peak performance

2. Fiskars Rotary Cutter Tool

The Fiskars 45mm rotary cutter is a solid workhorse for straight cuts and gentle curves. You get a titanium carbide blade that slices through multiple fabric layers cleanly, and the sliding button blade guard adds a layer of safety when you’re not actively cutting.

The symmetrical design works for both righties and lefties which is a nice touch. At just over 2 ounces it won’t tire your hand out during long cutting sessions. Replacement blades can get pricey but the initial investment is reasonable.

| Best For | Quilters and crafters who need precise cuts on fabric, foam, or vinyl and want a comfortable tool that works for both right- and left-handed users. |

|---|---|

| Primary Material | Plastic/Titanium |

| Weight | 2.08 ounces |

| Brand | Fiskars |

| Target Use | Fabric Cutting |

| Durability Feature | Titanium Carbide blade |

| Skill Level | Intermediate |

| Additional Features |

|

- Titanium carbide blade cuts cleanly through multiple fabric layers

- Symmetrical design makes it comfortable for both righties and lefties

- Lightweight at 2 ounces with a sliding safety guard for protection

- Blade sharpness doesn’t last as long as you’d hope

- Replacement blades can add up in cost over time

- Grip can feel a bit slippery during use

3. Olfa Self Healing Cutting Mat

You’ll protect your work surface and keep your rotary blade sharp longer with the Olfa RM-6×8 self-healing mat. This compact 8″ by 6″ mat features grid lines on one side for precise measurements and a plain reverse for general cutting.

The triple-layer construction seals itself after cuts so you don’t end up with grooves that deflect your blade. At 1.5mm thick it’s light enough to toss in your project bag for classes or retreats. Just store it flat and away from direct sunlight to prevent warping.

| Best For | Quilters and crafters who work on small projects like English Paper Piecing or need a portable mat for classes and travel. |

|---|---|

| Primary Material | Fabric |

| Weight | 2.08 ounces |

| Brand | Generic |

| Target Use | Cutting Mat |

| Durability Feature | Self-healing surface |

| Skill Level | All levels |

| Additional Features |

|

- Self-healing surface keeps cuts smooth and extends rotary blade life

- Double-sided design with grid lines for precision and a plain side for flexibility

- Compact and lightweight enough to pack in your project bag

- Not compatible with fixed blade utility knives

- May warp if stored improperly or left in direct sunlight

- Some users report the self-healing feature doesn’t work as well as advertised

4. Cottage Mills Acrylic Design Ruler

This 18-inch clear acrylic ruler from Cottage Mills gives you 1/16″ blue markings and a built-in grip knob for easy lifting. At around $11 it won’t break the bank and the laser-cut edges stay smooth enough for accurate rotary cuts every time.

People love that it’s thick enough at 1/8″ to resist warping but still light to move around quickly. The blue grid shows up nicely against most fabrics though some quilters mention the markings can fade after heavy use.

| Best For | Quilters, sewers, and crafters who need a reliable everyday ruler for cutting fabric, trimming edges, and measuring seam allowances. |

|---|---|

| Primary Material | Acrylic |

| Weight | 2.46 ounces |

| Brand | Cottage Mills |

| Target Use | Measuring/Layout |

| Durability Feature | Laser cut acrylic |

| Skill Level | All levels |

| Additional Features |

|

- Laser-cut edges and 1/8″ thickness give you straight, accurate cuts without the ruler shifting around

- Blue grid and markings show up clearly against most fabrics, making measurements quick and easy to read

- Grip knob makes it simple to pick up and reposition without fumbling or losing your place

- Markings can fade over time with heavy use, which might require replacing it sooner than you’d like

- The acrylic can warp if exposed to high heat, so keep it away from irons and hot cutting tools

- Only comes in one size (2″ x 18″), so you’ll need additional rulers for larger projects or different measurements

Choosing The Right Tool for Your Quilting Style

Your quilting journey is unique and there’s no one-size-fits-all answer in terms of picking between a rotary cutter and scissors. The right tool depends on where you’re in your sewing adventure, what kinds of fabric you work with, and how you like to set up your workspace.

Let’s break down the key factors that’ll help you figure out which cutting tool fits your style best.

Experience Level and Learning Curve

If you’re just starting out, scissors feel natural right away—you already know how to hold them.

Rotary cutters need a few practice sessions to build skill, but most beginners nail straight cuts after three to five tries on scrap fabric. Your learning pace speeds up when you follow beginner tips like using a ruler and non-slip mat for user adaptation and consistent results.

Fabric Types and Cutting Needs

Cotton woven fabric is your quilting workhorse—it presses flat and works great with both rotary cutters and scissors.

Silk and linen fray fast, so grab sharp blades and a self-healing cutting mat for clean edges.

Heavy denim needs a strong rotary cutter to slice through multiple layers.

Your fabric selection drives your sewing tools choice and cutting techniques.

Personal Preferences and Workflow

Your cutting station setup matters more than which blade you grab. Some quilters keep a rotary cutter at the ready for quick strip slicing, while others organize scissors front and center for detail work.

Workflow optimization means pairing tool organization with personal ergonomics—adjust your mat height, rotate tools to avoid strain, and build quilter habits that keep your crafting and DIY rhythm smooth.

Frequently Asked Questions (FAQs)

Is a rotary cutter better than fabric scissors?

You’ll get faster cuts and better fabric handling with a rotary cutter on long straight lines, but scissors win for curves and detail work—blade sharpness and cutting accuracy depend on your project.

What is the best cutter for quilting?

For most quilting projects, a 45mm rotary cutter paired with a self-healing cutting mat and acrylic ruler wins every time because it slices through multiple fabric layers fast while maintaining straight line precision.

What do quilters use to cut fabric?

You’ll need two main fabric cutting tools for your quilting projects.

Rotary cutters with cutting mats handle straight lines and multiple layers fast. Sharp scissors tackle curves and detail work with precision.

Can rotary cutters work on thick batting layers?

Like a paper tiger that seems fierce at first glance, thick batting presents a manageable challenge for your rotary cutter blade when you use the right techniques and sharp fabric layers underneath on a quality mat.

How often should rotary blades be replaced?

Replace your rotary cutter blade after 6 to 12 hours of cutting time.

Blade wear factors like fabric density and multiple layers matter—dull blades fray edges and need extra pressure, signaling it’s time for fresh sharpness.

Do scissors damage fabric edges over time?

Your fabric scissors can dull over time when cutting paper or rough materials, leaving coarser edges on fabric.

Keep blades sharp through regular maintenance and reserve one pair exclusively for fabric cutting.

Which tool is better for bias binding?

A rotary cutter wins for bias binding because it slices uniform fabric strip widths in one smooth pass.

Scissors work for detail trimming, but rotary blades paired with rulers deliver the quilting edge accuracy your binding deserves.

Are ergonomic rotary cutters worth the extra cost?

Think of it as insurance for hands. Ergonomic rotary cutters from brands like OLFA reduce wrist strain during marathon cutting sessions, making the extra cost worthwhile if you quilt regularly or tackle large projects frequently.

Conclusion

Your quilting toolkit doesn’t need a winner in the rotary cutter vs scissors for quilting matchup. It needs both.

Rotary cutters devour straight cuts and thick fabric stacks while scissors handle the fiddly curves and thread snips that make quilts come alive.

Stock your workspace with quality versions of each tool and you’ll stop second-guessing which one to grab. The best quilters don’t pick sides—they just reach for whatever gets the job done fastest.