This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Start with zigzag stitching—it stretches with the fabric and helps prevent fraying. For a sleek finish, try a turned edge where you fold the fabric under before stitching.

If you’ve got a serger, use it for clean, professional-looking seams that can handle chlorine and waves. Flat-felled seams add extra strength and a smooth inside finish, perfect for high-stress areas.

Don’t forget a stretch needle and polyester thread—they’ll keep your stitches intact. Ready to up your swimwear game? Let’s get started with the details.

Table Of Contents

Key Takeaways

- Use zigzag stitching or a serger to create flexible, durable seams that won’t fray over time.

- Topstitch seams with a wide zigzag or stretch stitch to secure the edges and maintain elasticity.

- Choose the right materials like stretch needles, polyester thread, and swimwear-specific elastic for strong and long-lasting construction.

- Line your swimwear with nylon blends and test for opacity when wet to ensure comfort and prevent transparency.

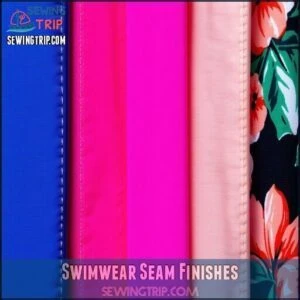

Swimwear Seam Finishes

You’ll find that proper seam finishes can transform your homemade swimwear from looking "crafty" to professionally polished, while also preventing uncomfortable rubbing against your skin during wear.

Whether you’re using zigzag stitching for stretch or flat-felled seams for durability, these finishing techniques will guarantee your swimsuit looks great and lasts through countless pool parties and beach days.

Zigzag Stitching

When working with stretchy swimwear fabric, zigzag stitching is your best friend for secure, flexible seam finishing.

You’ll want to adjust your stitch width (3-4mm works great) and stitch length (medium) to match your fabric’s stability.

Don’t forget to check your tension settings! A well-executed zigzag creates strong swimwear seams while maintaining stretch, and you can even use decorative zigzag for both function and style.

Turned Edge Finishing

While zigzag stitching prevents fraying, turned edge finishing takes your swimwear to pro-level territory.

This technique involves folding the raw edge under and topstitching it in place—perfect for reducing bulk around curves.

You’ll love how clean your swimwear seams look! For best results, trim seam allowances before folding, especially at corners.

The sewn and turned method works beautifully on stretchy fabrics, giving edges a polished, ready-to-wear appearance.

Hong Kong Seam Finishing

Anyone can achieve couture-quality swimwear with a Hong Kong finish, where bias tape elegantly binds each seam allowance.

This technique adds both polish and durability to your swimwear pieces.

- Perfect for medium-weight swimwear fabrics

- Creates clean edges that won’t fray in water

- Works beautifully on curved seams like leg openings

- Adds a pop of contrast with decorative bias tape

- Requires 1/2" seam allowance for proper application

Flat Felled Seam Finishing

While Hong Kong finishing adds a touch of elegance, flat felled seams bring unmatched durability to your swimwear projects.

You’ll love how these seams lie completely flat against the skin, eliminating bulk and preventing chafing.

For swimwear application, simply fold one seam allowance over the other, then stitch it down twice, creating both aesthetic appeal and structural integrity—perfect for high-stress areas where swimwear needs extra reinforcement.

Choosing Fabric Type

You’ll need four-way stretch fabrics with at least 50% recovery for proper swimwear seam finishing, typically a nylon or polyester blend with 10-20% spandex.

Your choice between lightweight and heavier fabrics will directly impact which seam techniques work best, much like choosing between a sporty one-piece or that daring bikini for your beach vacation.

Woven Fabric Considerations

While seam finishes create professional swimwear edges, selecting the right fabric is your next challenge.

Woven fabrics require special attention for swimwear projects because they lack the natural stretch of knits.

You’ll need to tackle fraying prevention by securing fabric edges with appropriate techniques.

Consider weave stability when selecting woven materials—tighter weaves offer better finish durability and less seam bulk when constructing your swimsuit.

Knit Fabric Properties

While woven fabrics have their place, knit fabrics reign supreme in the swimwear world.

You’ll want to focus on the Stretch Factor—four-way stretch is ideal, offering at least 50% give both horizontally and vertically.

Recovery Qualities matter too; your fabric should snap back after stretching.

Look for lightweight to medium Knit Weight with high nylon or polyester content (80-90%) plus 10-20% spandex for that perfect balance of support and movement.

Some swimwear may even use specialized function knits for performance enhancement.

Fabric Weight and Opacity

Diving into fabric weight and opacity can make or break your swimwear project.

The thickness of your fabric directly affects how your seam finishing techniques will work. When testing opacity, stretch the fabric to see how transparent it becomes when worn.

- Nothing’s worse than finishing a suit only to discover it’s see-through when wet

- The satisfaction of finding that perfect medium-weight fabric is truly unmatched

- Your confidence will soar knowing your swimwear lining choices prevent any embarrassing situations

- The pride of selecting the perfect color that won’t become transparent is worth the extra effort

Lining and Elastic Options

You’ll need the right lining and elastic to keep your swimwear from becoming a see-through disaster when wet or stretched.

The perfect combination of nylon linings with proper opacity and swimwear-specific elastic (preferably rubber or cotton blend) will guarantee your handmade suit stays comfortable, maintains its shape.

The suit must pass the "bend-over test" with flying colors, which is a crucial aspect of ensuring that your swimwear remains comfortable and functional in all scenarios.

Lining Materials and Opacity

Now that you’ve selected your fabric, let’s talk about what goes underneath! Your swimwear lining choices directly impact comfort and confidence.

| Lining Type | Weight | Opacity | Best For |

|---|---|---|---|

| Nylon/Spandex | Lightweight | Moderate | Quick-drying, Stretch Direction flexibility |

| Power Mesh | Medium | Low | Extra support, Color Matching challenges |

| Poly Lining | Medium | High | Breathability, economical Cost Analysis |

| Self-fabric | Varies | Highest | Maximum opacity, doubles material cost |

Remember, your lining should match your swimwear’s stretch properties while providing adequate coverage when wet!

Elastic Types for Swimwear

When picking the right elastic for swimwear, durability and recovery are key.

Rubber elastic handles chlorine, salt, and UV like a champ, staying strong and flexible. Cotton elastic offers a comfy, durable option for snug swimsuits.

Skip polyester elastic—it won’t last underwater. Always choose swimwear elastic designed for stretch and lasting shape, so your suit never sags.

Many retailers offer various elastic options for swimwear.

Applying Elastic to Swimwear

When applying swimwear elastic, precision is key. Start by stretching the elastic evenly along the edge to match fabric tension—this prevents twisting later.

Use a zigzag stitch for secure seams, or try casing methods for clean finishes. Overlapping seams guarantee durability, allowing elastic to bounce back after wear.

Matching elastic types to fabric guarantees a polished, professional look. For best results, consider adjusting for stretch to prevent puckering, ensuring a professional finish.

Sewing Techniques for Swimwear

When sewing swimwear, you’ll need tools and techniques that let the fabric stretch without breaking seams.

Whether you’re using a serger or a zigzag stitch on a home machine, the right needle, thread, and seam allowance make all the difference.

Using a Serger or Sewing Machine

Achieving professional results comes down to understanding your tools.

Professional swimwear starts with the right tools and techniques—master them for durable, stylish, and perfectly polished results.

A serger excels with serged edges and an overlock stitch for durability, while a domestic sewing machine handles versatile seam finishing like zigzag or stretch stitches.

Experiment with stitch types and adjust thread tension for smooth seams.

Combine these techniques for strong, reinforced swimwear construction that lasts. You’ve got this!

Needle and Thread Selection

Choosing the perfect combo of needle types and thread material for swimwear makes a splash in your sewing success.

Use:

- Ballpoint, jersey, or stretch needles for slick fabrics.

- Polyester thread to resist chlorine.

- Wooly nylon thread for stretchy seams.

- Stretch thread for flexibility.

- Color-matching serger thread for polished finishes.

Test on scraps—it saves you from stitch disasters!

Many retailers offer a variety of swimwear needle options for you to find the best combination.

Seam Allowance and Stretching

Start with a 3/8-inch seam allowance width—it’s a sweet spot for swimwear.

Prevent stretching by not tugging fabric while sewing, and use a walking foot for smooth feeding.

Elastic integration at stress points adds strength, while reinforcement stitching boosts durability.

Always test stitches on scraps first, avoiding fabric distortion.

Considering that swimwear requires four-way stretch is key for a comfortable fit.

Seam finishing techniques guarantee perfect fits and flawless finishes.

Professional Finishing Tips

You can take your swimwear from “homemade” to professional by mastering a few finishing tricks.

From binding raw edges to using anti-fraying techniques, these tips guarantee a polished, durable look every time.

Pinking Shears and Anti-Fraying

Pinking shears are perfect for simple seam finishing, especially on tightly woven fabrics.

Their zigzag cuts minimize fraying, adding cost-effectiveness and durability.

While pinking isn’t foolproof, it’s a solid anti-fraying application for edge finishing.

For more advanced solutions, consider specialized sealant options.

Test your fabric’s compatibility first, and remember, seam sealants like Fray Check are handy alternatives when pinking alone can’t cut it—pun intended!

Binding and Enclosing Edges

For a polished swimwear finishing look, binding techniques like using bias tape can work wonders.

It’s perfect for decorative edges and achieving clean finishes.

Enclosed elastic adds function to edge finishing while keeping seams smooth.

Consider a serged edge finish for washable fabrics.

With patience and a steady hand, these methods guarantee professional results.

Who doesn’t want their swimsuit seams looking runway-ready?

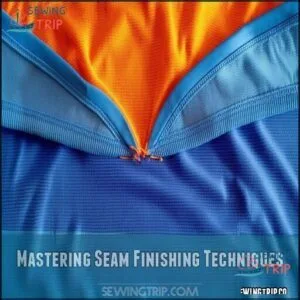

Mastering Seam Finishing Techniques

Mastering seam finishing for swimwear takes some finesse.

Use these techniques to elevate your sewing game:

- Seam Reinforcement: Strengthen high-stress areas with zigzag or triple-stitch seams.

- Edge Stabilization: Apply fabric stay tape to prevent stretching.

- Bulk Reduction: Trim seam allowances minimally for flexibility.

- Comfort Focus: Use soft wooly nylon thread for smooth edges.

- Aesthetic Appeal: Finish seams with clean, professional topstitching.

Frequently Asked Questions (FAQs)

What are the 4 seam finishing techniques?

Think of seams as the unsung heroes of swimwear.

Four techniques: zigzag stitching for stretch, serging for durability, turned edges for sleekness, and enclosed elastic casings for polished edges.

Each guarantees strength, comfort, and style.

Do you topstitch swimwear seams?

Yes, always topstitch swimwear seams.

It secures the fabric, flattens bulky edges, and adds a polished finish.

Use a wide zigzag or stretch stitch while carefully stretching the fabric to maintain elasticity.

What do you line swimsuits with?

It’s funny how the right lining transforms a swimsuit.

Use lightweight nylon-Lycra blends for a "barely-there" feel, or heavier options for support.

Test for opacity when wet or stretched—trust me, it’s worth it.

Can you sew swimwear on a regular sewing machine?

You can absolutely sew swimwear on a regular sewing machine.

Use stretch or ballpoint needles, polyester thread, and a zigzag or stretch stitch.

Avoid pulling the fabric, and test on scraps first for best results.

How to waterproof seams for swimwear?

To waterproof swimwear seams, use a stretchable, waterproof seam sealant or liquid polyurethane applied over sewn seams.

This prevents water entry and adds durability while keeping the fabric’s flexibility intact.

Let it dry completely to ensure the waterproof sealant is effective.

What is the best seam repair method?

Did you know improperly finished seams can weaken swimwear by 40%?

To repair, trim frayed edges, secure with a zigzag stitch, and reinforce the seam using stretch thread.

It’s durable, flexible, and swimsuit-ready!

How to reduce seam bulk in swimwear?

Trim seam allowances to 1/4 inch, use flatlock seams for flexibility, and choose lightweight swimwear elastic for less bulk.

Press seams gently, and avoid over-folding. A serger or zigzag stitch helps keep everything tidy.

How to test seam stretch durability?

Stretch your seam by hand, mimicking swimwear movement.

If stitches pop or fabric puckers, adjust your stitch type or length.

Try a zigzag or triple stretch stitch; testing on scraps saves headaches later!

Can decorative seams work on swimwear?

You might think decorative seams are just for show, but they can shine in swimwear.

Use zigzag or flatlock stitches to add flair without compromising stretch.

Choose durable, chlorine-resistant threads to balance function and style.

Conclusion

Think of sewing swimwear like building a sandcastle—every detail matters for structure and durability.

Seam finishing techniques for swimwear, like zigzag stitching, serging, and flat-felled seams, add strength and style to your creations.

Use stretch needles, polyester thread, and the right elastic for flawless flexibility.

Don’t skip lining for comfort and opacity.

Experiment, practice, and soon you’ll master techniques that survive the surf and sun, and with smart finishes, your work won’t fray, because swimwear may stretch.