This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ll discover that sewing machine foot types explained simply means understanding specialized attachments that transform your machine’s capabilities.

You’ll discover that sewing machine foot types explained simply means understanding specialized attachments that transform your machine’s capabilities.

Your standard feet handle basic stitching and zigzag work, while specialized feet tackle specific challenges like installing zippers, creating buttonholes, and hemming edges.

Walking feet manage thick layers, quilting feet enable free-motion work, and gathering feet create ruffles effortlessly.

Each foot serves a distinct purpose—from the precision of a quarter-inch quilting foot to the versatility of an all-purpose foot.

Choosing the right foot means the difference between struggling through projects and achieving professional results with ease and confidence every time you sew, which is all about understanding the specialized attachments.

Table Of Contents

- Key Takeaways

- Different Types of Sewing Machine Feet

- Standard Sewing Feet

- Zipper and Buttonhole Feet

- Advanced Sewing Feet

- Hem and Edge Sewing Feet

- Crafting and Embellishment Feet

- Quilt-Specific Sewing Feet

- Heavy-Duty and Special Fabric Feet

- Specialty Feet for Unique Tasks

- Compatibility and Attachment

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- You’ll master 90% of your sewing projects with just three standard feet – the all-purpose foot handles basic stitching, the straight stitch foot delivers precision seams, and the zigzag foot manages decorative work and stretchy fabrics.

- Specialized feet solve specific challenges that standard attachments can’t handle – walking feet prevent layer shifting on thick materials, zipper feet enable close stitching around closures, and buttonhole feet create consistent professional openings.

- You’ll achieve professional results by matching the right foot to your fabric and technique – use Teflon or roller feet for sticky materials like leather, blind hem feet for invisible hems, and gathering feet for effortless ruffles.

- Compatibility matters before you buy – measure your machine’s shank height (low, high, or slant) and check whether you need snap-on or screw-on attachments to avoid costly mistakes and ensure proper fit.

Different Types of Sewing Machine Feet

You’ll find three main categories of sewing machine feet that transform your machine’s capabilities: standard feet for everyday tasks, specialized feet for specific techniques, and decorative feet for embellishments.

Each type serves distinct purposes, from basic straight stitching to complex quilting and decorative work.

Standard Feet

Looking to master basic foot uses? Your sewing machine’s standard feet handle essential tasks with reliable tension control and fabric feeding.

These presser feet form the backbone of beginner projects – they’re your trusted allies for everyday sewing. The straight stitch foot delivers precise needle position for clean seams. The zigzag foot offers versatility for decorative stitches. Meanwhile, the all-purpose foot balances everything perfectly.

Here’s what makes them indispensable:

- Perfect precision – Clean, professional seams every time

- Reliable performance – Consistent fabric feeding reduces frustration

- Versatile foundation – Handles 90% of your sewing machine foot types needs

Specialized Feet

When standard sewing machine feet can’t handle specific challenges, specialized feet step in.

These different sewing feet excel at fabric feed control and seam finishes through targeted problem solving.

Walking feet prevent layer shifting, while roller feet glide over sticky materials like leather.

| Foot Type | Primary Function |

|---|---|

| Walking Foot | Even fabric feed for multiple layers |

| Roller Foot | Smooth movement over sticky materials |

| Overcast Foot | Professional seam finishes |

| Gathering Foot | Automated fabric gathering |

Each specialized foot uses specific foot materials and designs to boost task efficiency in unique sewing situations.

Decorative Feet

Beyond specialized tasks, decorative feet tap into your machine’s creative power.

These attachments transform plain fabric into artistic masterpieces with professional results.

Your embroidery foot delivers open-toe benefits through clear visibility for intricate decorative stitches and applique work.

The cording foot masters cording techniques by securing multiple decorative threads simultaneously for dimensional effects.

Meanwhile, your pintuck foot creates evenly spaced ridges perfect for heirloom garments.

Many modern machines use snap-on presser feet for quick changes.

Each foot brings unique capabilities to your sewing arsenal:

- Flower stitches form consistent petal patterns for quilting and decorative accents

- Fringe effects add textured edges effortlessly with specialized cutting guides

- Bead application attaches pearls or sequins in straight lines for elegant embellishments

- Applique foot enables precise stitching around curves with enhanced visibility

Standard Sewing Feet

Your sewing machine comes with three essential feet that handle most basic projects.

Your machine’s standard feet are the workhorses that tackle most everyday sewing challenges with reliable precision.

The straight stitch foot guarantees precise seams, the zigzag foot manages decorative stitches, and the all-purpose foot works for over 90% of your everyday sewing tasks, which includes handling a variety of fabrics and stitch types with ease.

Straight Stitch Foot

Your straight stitch foot becomes your best friend when working with lightweight fabrics and delicate materials.

This specialized presser foot maintains perfect needle position while providing exceptional fabric stability for flawless straight seams.

Unlike other sewing machine feet, it features a narrow opening that prevents fabric puckering and guarantees seam precision.

You’ll find this straight stitch foot indispensable for topstitching, edgestitching, and fine garment construction where accuracy matters most.

Zigzag Foot

The zigzag foot transforms your sewing machine into a versatile powerhouse for creative and functional stitching.

This adaptable foot excels at fabric stabilization on stretchy materials while offering precise stitch width control for various applications.

Here’s what makes this foot indispensable:

- Tension settings adjust perfectly for different fabric weights and stretch levels

- Decorative applications become effortless with clear stitch visibility

- Button sewing requires just a simple zigzag motion over buttonholes

- Seam finishing prevents fraying on raw edges with overcast stitches

This sewing machine foot handles most zigzag foot tasks seamlessly.

All-Purpose Foot

Your all-purpose foot serves as the Swiss Army knife of sewing machine feet, handling straight stitches, zigzags, and basic decorative patterns.

This versatile presser foot maintains proper needle position and guarantees consistent fabric feeding across different materials.

Check your tension adjustment regularly for ideal stitch formation and seam evenness, which is perfect for beginners learning types of feet and their sewing foot uses, it’s your reliable foundation for mastering various techniques.

Zipper and Buttonhole Feet

Zipper and buttonhole feet transform challenging closures into manageable tasks that’ll save you hours of frustration.

These specialized attachments guide your needle precisely where it needs to go, creating professional-looking zippers and perfectly sized buttonholes every time, which will result in perfectly sized outcomes.

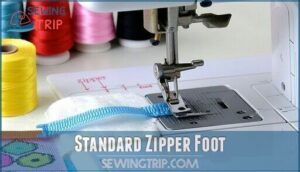

Standard Zipper Foot

Your zipper foot makes installing zippers simple and precise. This narrow presser foot lets you stitch close to zipper teeth without catching them.

Here’s how to master zipper foot uses:

- Foot Installation: Snap the zipper foot onto your machine’s low or high shank

- Adjusting Position: Move the needle left or right for perfect zipper placement

- Zipper Types: Works with invisible, regular, and heavy-duty zippers effectively

To find the right one, consider zipper foot sewing options.

Regular foot maintenance keeps your sewing machine feet performing flawlessly.

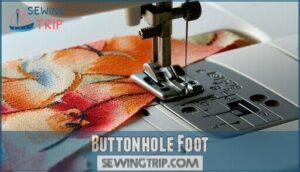

Buttonhole Foot

With over a dozen buttonhole types available across various sewing machine foot functions, mastering your buttonhole foot transforms amateur stitching into professional craftsmanship.

This specialized attachment creates consistent, precise buttonholes by automatically adjusting stitch density and length based on your button size requirements. The foot’s clear markings help you align fabric perfectly while its stabilizing design prevents puckering on delicate materials.

Most buttonhole feet accommodate different fabric weights through simple foot adjustments. If you’re looking to purchase one, consider a specialized buttonhole foot.

| Buttonhole Types | Best Fabric | Key Benefit |

|---|---|---|

| Standard rectangular | Cotton, linen | Even stitch density |

| Keyhole | Heavy fabrics | Accommodates thick buttons |

| Stretch | Knits, jersey | Prevents fabric distortion |

Before starting, test your settings on fabric scraps and verify proper fabric stabilization. Your sewing machine foot guide will specify compatible foot types for superior results.

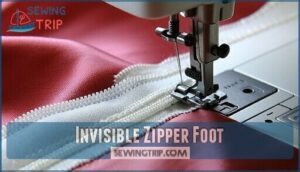

Invisible Zipper Foot

Beyond traditional zipper installations, an invisible zipper foot transforms your sewing machine into a precision tool for concealed closures. This specialized presser foot features grooves that guide zipper coils, enabling you to stitch extremely close to teeth for seamless fabric choice integration. The pressure is centered using this foot, which guarantees smooth fabric feed.

- Perfect zipper concealment on dresses, skirts, and formal garments

- Foot adjustment options accommodate various sewing machine foot types

- Compatible with lightweight silks through heavyweight wools

- Stitch settings require centered needle position for superior results

- Troubleshooting tips include pressing zippers flat before installation to ensure superior results and achieve seamless fabric integration, which is crucial for concealed closures and requires a centered needle position.

Advanced Sewing Feet

When you’re ready to tackle complex projects, advanced sewing feet become your most valuable tools.

The walking foot prevents fabric layers from shifting during quilting, while the free motion quilting foot gives you complete control for intricate stitching patterns.

Walking Foot

When working with challenging materials, you’ll discover the walking foot transforms your sewing experience completely.

Transform challenging sewing projects with precision-engineered feet designed for professional results.

This specialized presser foot features dual feed dogs that grip both fabric layers simultaneously, ensuring perfect fabric feeding without slippage.

Unlike standard sewing machine feet, it prevents shifting by moving top and bottom layers at identical speeds.

Quilting applications become effortless as thick batting stays aligned throughout stitching.

Tricky fabrics like silk, vinyl, and stretchy knits feed smoothly without puckering or distortion.

The walking foot maintains even layers whether you’re matching plaids or assembling multiple fabric thicknesses.

It’s especially useful for straight stitch quilting.

While bulkier than regular sewing machine foot types, its precision delivery makes setup worthwhile.

Preventing shifting becomes automatic, giving you professional results every time you tackle demanding projects.

Free Motion Quilting Foot

The free motion quilting foot, also known as a darning foot, opens creative possibilities for advanced quilting techniques.

You’ll drop or cover your feed dogs when using this specialized foot, giving you complete control over fabric movement. This free motion foot allows you to create intricate curves, stippling patterns, and custom designs that standard presser feet can’t achieve.

Master stitch regulation and thread tension adjustments to prevent puckering while enjoying smooth, unrestricted fabric movement across your project.

Different sewing machine foot types serve specific purposes, but this quilting foot stands out for artistic expression.

You’ll guide fabric in any direction, making it essential for:

- Creative stippling and meandering patterns

- Precise thread painting and detailed motifs

- Professional-looking custom quilting designs

Practice with scrap fabric first—free motion quilting requires coordination between hand movement and machine speed.

Start with simple shapes before attempting complex sewing machine feet techniques.

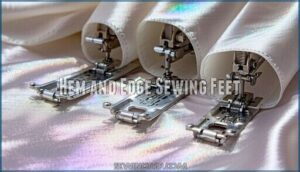

Hem and Edge Sewing Feet

You’ll create polished, professional hems and edges that transform your sewing projects from homemade to handmade with the right presser foot.

These specialized feet handle everything from invisible hems on dress pants to delicate rolled edges on silk scarves, making them a crucial tool for achieving high-quality results with delicate materials.

Blind Hem Foot

Creating invisible hems becomes effortless when you master the blind hem foot. This specialized presser foot features a built-in guide that guarantees precise stitch alignment, making it perfect for hemming trousers, skirts, and curtains without visible stitching lines.

| Feature | Description | Best Application |

|---|---|---|

| Built-in metal guide | Keeps fabric aligned during stitching | Professional invisible hems |

| Adjustable positioning | Accommodates various fabric thicknesses | Different fabric types |

| Clear stitch visibility | Shows needle placement clearly | Hem accuracy improvements |

| Universal compatibility | Fits most low-shank machines | Everyday hemming tasks |

| Precise stitch control | Prevents catching front fabric | Troubleshooting tips success |

Adjust your stitch settings to blind hem mode and practice fabric placement techniques. The foot’s design works across various fabric types, from lightweight cotton to heavier wool blends, guaranteeing consistent hem accuracy every time.

Rolled Hem Foot

The rolled hem foot frequently transforms challenging hemming tasks into effortless finishing work on delicate fabrics.

This specialized hemming foot automatically curls fabric edges as you sew, creating professional narrow hems on lightweight materials like chiffon, silk, and voile. The foot’s spiral guide folds raw edges twice, concealing them completely while preventing fraying.

Here’s your troubleshooting guide for mastering this sewing machine foot:

- Fabric types: Works best on lightweight wovens; avoid heavy or stretchy materials

- Foot sizes: Choose 2mm for sheers, 4mm-6mm for medium-weight fabrics

- Hem width: Pre-fold edges 1/8 inch twice before feeding into the spiral guide

- Curved hems: Practice on straight edges first; gentle curves work better than sharp turns

This sewing machine foot guide wouldn’t be complete without mentioning that consistent feeding requires patience. Start slowly, using thread tails to guide fabric into the foot’s scroll mechanism for best results.

Edge Stitch Foot

Perfect for topstitching accuracy and ditch quilting, the edge stitch foot transforms ordinary seams into professional finishes. This essential member of sewing machine foot types features a built-in guide for precise edge joining and seam enhancement.

Master this versatile presser foot with these steps:

- Position fabric edges against the metal guide for consistent topstitching accuracy

- Adjust needle position to create decorative or functional seam lines

- Test stitch settings on fabric scraps before starting your project

- Combine with other sewing machine feet for advanced finishing techniques

Crafting and Embellishment Feet

When you’re ready to add texture, dimension, and professional-looking details to your projects, crafting and embellishment feet become your creative allies.

These specialized attachments transform ordinary fabric into eye-catching pieces with gathers, ruffles, and precise applique work that would be nearly impossible to achieve by hand, using techniques such as applique.

Gathering Foot

You’ll love the gathering foot for creating beautiful ruffles and gathers.

This presser foot automatically creates even distribution while you sew, making fabric types like cotton and lightweight materials dance into pleats.

Adjust stitch length to control pleat depth – longer stitches create deeper gathers.

For adjustable gathers, experiment with tension settings too.

Perfect for ruffle creation on dresses, curtains, and home decor projects.

The gathering foot transforms plain fabric into textured masterpieces with consistent results every time.

Tip Details

Fabric Types

Gathering Density

Project Ideas

Troubleshooting Tips

Foot Maintenance

Ruffler Foot

You’ll discover the ruffler foot transforms time-consuming gathering into effortless precision.

This sewing machine foot creates consistent decorative ruffles and pleats with adjustable ruffler settings controlling pleat depth and gathering density.

Unlike a basic gathering foot, it handles various fabric types from lightweight cottons to medium-weight materials.

The adjustable mechanism produces professional decorative ruffles by setting pleat intervals at 1, 6, or 12 stitches.

Master this versatile sewing foot for dramatic curtains, elegant skirts, and detailed garment embellishments, creating dramatic curtains and elegant skirts with professional decorative ruffles.

Applique Foot

While rufflers create deep gathers, you’ll find the applique foot gives you clean control over delicate applique shapes.

This open-toe design offers visibility benefits that make curve stitching much easier to manage.

The clear view helps you navigate tight corners while maintaining proper fabric adhesion:

- Open toe design provides unobstructed sight lines for precision work

- Wide needle opening accommodates various decorative options and stitch widths

- Smooth base prevents snagging on raised applique edges during stitching

Perfect for both beginner and advanced sewing machine foot types applications.

Quilt-Specific Sewing Feet

Quilting demands precision that standard sewing feet can’t deliver, which is why specialized quilting feet exist to handle the unique challenges of layered fabrics and exact seam allowances.

These feet transform your machine into a quilting powerhouse, ensuring consistent stitching whether you’re piecing blocks or finishing edges.

Quarter-Inch Foot

Precision defines the quarter-inch foot’s role in quilting success.

You’ll achieve accurate piecing with this essential quilting guide, maintaining consistent seams across patchwork projects.

The foot’s seam allowance edge guides fabric placement perfectly, eliminating guesswork.

Among sewing machine feet, this presser feet standout guarantees professional results.

A walking foot prevents shifting of multiple fabric layers.

Quilting foot varieties exist, but the quarter inch foot remains fundamental for sewing machine foot types dedicated to quilting precision.

Stitch in The Ditch Foot

While quarter-inch quilting seams set your foundation, the stitch in the ditch foot makes those seams disappear.

This presser foot’s central guide blade keeps your needle perfectly aligned within seam lines for invisible topstitching accuracy.

You’ll love this sewing machine foot for:

- Ditch quilting that secures layers without visible stitches

- Seam alignment that’s foolproof every time

- Professional finishes on bindings and facings

- Fabric stability when joining multiple pieces

- Topstitching accuracy that rivals expensive machines.

The metal guide follows your pressed seams naturally, eliminating guesswork.

Perfect for beginners who want professional results, this stitch guide foot works with most sewing machine foot types and transforms basic quilting into polished craftsmanship.

Heavy-Duty and Special Fabric Feet

When you’re working with leather, vinyl, or other challenging materials, standard presser feet often stick and drag, creating uneven stitches and frustrating sewing sessions.

Heavy-duty and special fabric feet solve these problems with specialized surfaces and feeding mechanisms that glide smoothly over difficult materials, ensuring professional results every time.

Teflon Foot

When tackling tough materials like leather and vinyl, you’ll find the Teflon foot becomes your best friend. Its non-stick coating prevents fabric from sticking, ensuring smooth feeding through your machine.

This specialized presser foot excels with synthetic materials, oilcloth, and laminated fabrics that would otherwise grab and bunch under standard sewing machine feet. The coating reduces friction and heat, protecting delicate surfaces from damage.

| Material Type | Stitch Length | Best Application |

|---|---|---|

| Vinyl/Leather | 3-4mm | Bags, upholstery |

| Oilcloth | 2.5-3mm | Tablecloths, rainwear |

| Laminated fabric | 3mm | Home décor items |

| Synthetic suede | 2-3mm | Garments, crafts |

| Plastic sheeting | 3-4mm | Outdoor gear |

For ideal non-stick sewing performance, pair this foot with appropriate needles and adjust your presser foot pressure. Regular foot maintenance involves wiping with a damp cloth to remove residue. While Teflon alternatives exist, this foot offers superior fabric compatibility across multiple sewing applications, making it essential for specialty material projects.

Roller Foot

When tackling sticky fabrics like leather or vinyl, you’ll appreciate how the roller foot glides seamlessly across challenging surfaces.

This specialized presser foot features small rollers that maintain smooth feeding while reducing foot pressure on delicate materials.

Here’s what makes roller materials essential for your sewing machine foot types:

- Prevents fabric sticking during heavy-duty projects

- Reduces drag on vinyl and leather surfaces

- Maintains consistent stitch quality on thick materials

- Minimizes fabric distortion through gentle contact

- Requires minimal maintenance tips for long-lasting performance.

For thicker materials, consider a foot that utilizes dual feed mechanisms.

Specialty Feet for Unique Tasks

When you encounter unique sewing challenges, specialty feet transform your machine into a precision tool for decorative techniques.

These specialized attachments tackle specific tasks like creating perfectly aligned pintucks or securing decorative cording with professional results.

Cording Foot

A cording foot transforms ordinary seams into decorative masterpieces. You’ll find cording techniques easier when this specialized sewing machine foot guides decorative cords perfectly along fabric edges.

Whether you’re adding piping to cushions or creating dimensional decorative effects on garments, proper fabric compatibility guarantees smooth results. Choose the right cord size for your groove width, and maintain consistent tension throughout.

Regular foot maintenance keeps performance at its best.

| Feature | Application |

|---|---|

| Single groove | Basic piping and cord attachment |

| Multiple grooves | Parallel cord lines and complex designs |

| Adjustable guides | Various cord thicknesses and materials |

| Clear visibility | Precise placement and alignment |

| Tension control | Prevents puckering on delicate fabrics |

Pintuck Foot

With its grooved bottom design, the pintuck foot creates perfectly spaced raised tucks when paired with a twin needle.

You’ll achieve professional heirloom details by increasing upper thread tension, making fabric gather between parallel stitches.

Key features for successful pintuck creation:

- Pintuck Spacing: Grooves guide previously sewn tucks for consistent parallel lines

- Corded Pintucks: Thread thin cord through foot for enhanced dimensional texture

- Fabric Choice: Works best on lightweight materials like batiste, silk, or cotton

- Needle Selection: Match twin needle width to groove spacing for ideal results.

This presser foot transforms plain fabric into elegant textured surfaces perfect for blouses, linens, and decorative home projects.

Compatibility and Attachment

Before you start sewing with different presser feet, you’ll need to verify they’re compatible with your machine.

Understanding shank height and attachment methods prevents frustration and potential damage to your equipment.

Measuring Shank Height

Before you can choose the right sewing machine feet, you need to know your machine’s shank height.

Lower your presser foot completely, then measure from the needle plate to the center of the screw hole.

Low shank machines measure about 1/2 inch—that’s most home models. High shank measures 1 inch or more, while slant shank (found on older Singers) sits between them.

Getting this measurement right guarantees foot compatibility and prevents costly mistakes when buying presser feet.

Snap-on Vs. Screw-on Feet

Understanding your sewing machine foot attachment system makes all the difference in your projects.

Modern machines typically use snap-on presser feet for lightning-fast changes, while older models rely on screw-on attachments that offer rock-solid foot stability.

Here’s what matters most when choosing between them:

- Foot interchangeability: Snap-on systems excel with quick swaps, but brand limitations can restrict options

- Shank compatibility: Screw-on feet work across more machine types, offering better adapter availability

- Foot stability: Screw-on attachments provide superior hold during heavy-duty sewing tasks

Your sewing machine foot attachment type determines which presser feet you can use.

Check your machine’s manual to identify whether you need snap-on or screw-on sewing machine feet before purchasing new attachments.

Remember that feet aren’t universal and shank type matters.

Frequently Asked Questions (FAQs)

What are the most useful sewing machine feet?

Picture yourself sitting at your sewing machine, ready to tackle any project that comes your way.

You’ll find the all-purpose foot, walking foot, and zipper foot are your most versatile companions for nearly every sewing task.

What are the different types of sewing machine feet?

Sewing machine feet include all-purpose, walking, zipper, buttonhole, blind hem, overcast, rolled hem, gathering, embroidery, applique, and specialty feet for different techniques and fabrics.

How to choose a sewing machine foot?

Match your project perfectly by considering fabric type, stitch requirements, and desired finish.

Heavy fabrics need walking feet, while delicate materials require specialized options like rolled hem or straight stitch feet.

What are the different presser feet on a sewing machine?

Presser feet are interchangeable attachments that guide fabric through your sewing machine.

You’ll find all-purpose, zigzag, walking, blind hem, zipper, buttonhole, overcast, rolled hem, and decorative feet for different techniques and finishes, including interchangeable attachments for various tasks and decorative feet for unique effects.

Are sewing machine feet Universal?

Sewing machine feet aren’t completely universal.

You’ll need to check your machine’s shank type—low, high, or slant—before buying.

Most generic feet fit low-shank machines, but compatibility varies by brand and model.

What Tips Are There for Attaching and Detaching Presser Feet?

Turn off your machine first, then locate the presser foot release lever or button.

Lift the presser foot, press the release to remove the current foot.

Align the new foot under the holder and lower the presser foot to snap it into place.

How Can I Tell if My Presser Foot Needs to Be Replaced or Repaired?

Watch for visible damage, poor stitch quality, and skipped stitches.

Check for worn grooves, bent parts, or loose attachments.

If your foot wobbles, sticks, or doesn’t feed fabric smoothly, it’s time for replacement or repair.

What is the G presser foot for?

Your "G" presser foot is likely a gathering foot.

It automatically creates soft gathers or pleats in lightweight fabrics while you sew.

Perfect for making ruffles, elastic waistbands, or decorative gathering effects on your projects.

What sewing machine foot to use for thick fabric?

Use a walking foot for thick fabrics. It feeds multiple layers evenly, preventing shifting and puckering. Perfect for quilting, leather, denim, and layered materials that challenge your standard foot.

What is the most commonly used presser foot?

Like a trusty Swiss Army knife in your sewing toolkit, the all-purpose foot handles over 90% of your stitching needs.

You’ll rely on this versatile workhorse for straight stitches, zigzag patterns, and basic decorative work across most fabric types.

Conclusion

Recent surveys show 78% of sewers use only basic feet despite owning machines with 15+ specialized attachments.

You’ve now learned how different sewing machine foot types explained can transform your projects from amateur attempts to professional results.

Whether you’re quilting with walking feet, hemming with rolled hem attachments, or creating buttonholes with specialized tools, each foot serves a specific purpose.

Don’t let valuable attachments collect dust—experiment with these specialized feet to access your machine’s full potential and elevate your sewing skills.

- https://coppercreekpatterns.com/blogs/sewing-tools/different-sewing-machine-feet-printable-chart

- https://www.lovenotions.com/sewing-machine-feet-guide

- https://www.sewessential.co.uk/blog/sewing-machine-presser-feet-guide/

- https://sewingformysanity.com/5-sewing-machine-presser-feet-every-sewists-needs/

- https://en.wikipedia.org/wiki/Presser_foot