This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your standard sewing needle just broke against thick denim for the third time this week, the thread’s bunching underneath your canvas project, and your machine sounds like it’s struggling to push through that leather belt you’re trying to repair. These frustrations aren’t signs you need a new machine—you’re just using the wrong needles.

Heavy-duty projects demand sewing needles for heavy fabric that pack the reinforced steel construction, chromium plating, and sharpened points needed to punch through dense materials without snapping or dulling. The difference between a broken needle mid-seam and smooth stitching through multiple layers comes down to matching the right needle size, point type, and coating to your specific fabric weight and thickness.

Table Of Contents

Key Takeaways

- Heavy-duty needles use reinforced steel construction, chromium plating, and sharp points to power through denim, canvas, and leather without breaking, while standard needles snap on thick materials due to weaker construction.

- Match needle size to fabric weight by using 90/14 to 110/18 for heavy materials, and select specialized point types—sharp points for denim, medium ball points for canvas, and wedge-shaped tips for leather.

- Replace heavy-duty needles every 8–12 hours of continuous stitching to maintain sharp cutting performance and prevent thread shredding, skipped stitches, or fabric damage from worn burrs.

- Proper machine setup requires adjusting tension settings incrementally, matching thread thickness to needle eye diameter, and using walking feet or Teflon presser feet to prevent fabric shifting on dense materials.

Best Sewing Needles for Heavy Fabric

You can’t sew heavy fabrics like denim, canvas, or leather with standard needles—they’ll snap, skip stitches, or leave you wrestling with your machine. Heavy-duty needles pack serious punch with reinforced steel construction, chromium plating, and sharp points designed to slice through thick materials without breaking a sweat.

If you’re tackling denim repairs regularly, a portable sewing machine for denim repair gives you the muscle you need without sacrificing workspace.

Standard needles snap on heavy fabrics—heavy-duty needles use reinforced steel and sharp points to power through denim, canvas, and leather

Here are five needle options that’ll handle your toughest projects, from upholstery work to leather repairs.

1. Singer Heavy Duty Sewing Machine Needles

Singer heavy duty machine needles pack serious punch for thick fabric work. You’ll find them in the 2045 system with flat shanks, reinforced steel construction, and chromium plating that resists wear when you’re pushing through multiple denim layers or canvas.

They come in sizes from 70/10 up to 110/18, so you can match the needle to your fabric weight. The shaped eye accommodates stronger threads without breakage, and that sturdy shaft won’t bend under high tension during long seams.

| Best For | Sewers working regularly with heavy fabrics like denim, canvas, upholstery materials, or leather who need reliable needles that won’t bend or break mid-project. |

|---|---|

| Brand | SINGER |

| Needle Count | 5 |

| Material | Steel |

| Machine Compatibility | Most quality machines |

| Weight | 0.2 ounces |

| Primary Use | Heavy fabrics |

| Additional Features |

|

- Color-coded sizing makes it quick to grab the right needle without squinting at tiny numbers

- Compatible with most major sewing machine brands, so you don’t need to worry about fit issues

- Convenient storage case keeps needles organized and protects them from damage

- Not suitable for delicate fabrics like silk or chiffon—you’ll need specialty needles for those

- Five-needle pack might run out quickly if you sew heavy materials frequently

- May snap if used on older machines with timing issues or improper tension settings

2. Heavy Duty Leather Sewing Machine Needles

Leather demands a specialized cutting edge, not just brute strength. You need needles with knife-like wedge points that slice clean holes through hide without tearing fibers or gumming up your machine.

Look for sizes between 90/14 and 110/18 with hardened chromium plating and reinforced shafts that won’t deflect when you’re layering full-grain or thick upholstery backing. The enlarged eye accommodates bonded polyester and waxed threads without friction buildup.

Replace them every 8–12 seams to maintain that sharp cutting performance through suede, leather, and dense materials.

| Best For | Sewers working with heavy materials like denim, canvas, and leather who need durable needles that can handle tough fabrics without breaking. |

|---|---|

| Brand | HLARTNET |

| Needle Count | 50 |

| Material | Iron alloy |

| Machine Compatibility | Universal household |

| Weight | 0.704 ounces |

| Primary Use | Thick fabrics |

| Additional Features |

|

- Large 50-piece set offers excellent value and ensures you always have backups on hand

- Size 100/16 is ideal for thick materials like jeans, leather, and upholstery

- Universal flat shank design fits most standard home sewing machines

- Only comes in one size (100/16), so you’ll need different needles for lighter fabrics

- May not have the specialized wedge point that’s best for leather specifically

- No warranty information provided, so quality consistency isn’t guaranteed

3. Sewing Machine Needles Set

Multi-size packs give you tactical flexibility without stocking separate boxes for every project. You get 50 needles spanning five sizes—65/9 for sheer overlays up to 110/18 for canvas and heavy denim—all crafted from high-strength steel with smooth chromium surfaces that resist corrosion.

When working with particularly challenging materials, check out this guide to choosing the right needle for thick fabric to ensure your heavier 110/18 needles perform at their best.

These sets fit Singer, Brother, Janome, and similar flat-shank machines, covering thin silk to thick upholstery in one compact case.

Swap out a 70/10 for a 100/16 mid-project when your fabric weight changes, keeping momentum without hunting through your supply drawer.

| Best For | Home sewers who work with different fabric weights and want a ready-to-go assortment without buying needles individually every time a project changes. |

|---|---|

| Brand | Generic |

| Needle Count | 50 |

| Material | High-strength steel |

| Machine Compatibility | Most household machines |

| Weight | 2.08 ounces |

| Primary Use | Various fabrics |

| Additional Features |

|

- You get five sizes in one pack, so you can switch from lightweight cotton to heavy denim without a supply run

- High-strength steel construction with smooth chromium coating helps needles glide through fabric and resist rust

- Works with most home machines like Singer, Brother, and Janome, plus you get bonus storage tubes and bobbins

- Not built for industrial machines, so if you’re running a commercial setup, these won’t cut it

- Some users report inconsistent quality—certain needles may dull faster or cause thread issues

- Durability can be hit-or-miss, meaning you might go through them quicker than expected on tougher projects

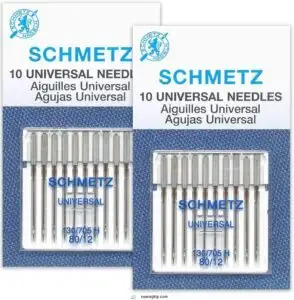

4. Schmetz Universal Sewing Machine Needles

Schmetz Universal needles in size 80/12 bring German engineering to everyday sewing, handling both woven and knit fabrics with their slightly rounded point that won’t snag delicate fibers.

You get 20 needles on two cards, each built from hardened steel with chromium plating that cuts friction and extends life through 8–12 hours of stitching.

They fit System 130/705 H machines—Brother, Singer, Janome—and accommodate standard-weight threads for quilting, alterations, and home decor projects without skipping stitches on cotton or polyester blends.

| Best For | Home sewers who work with a mix of woven and knit fabrics and want reliable, all-purpose needles that fit standard machines. |

|---|---|

| Brand | SCHMETZ |

| Needle Count | 20 |

| Material | Steel |

| Machine Compatibility | Most household machines |

| Weight | Not specified |

| Primary Use | Wovens and knits |

| Additional Features |

|

- Works smoothly on both wovens and knits without snagging, making them versatile for everyday projects

- German-made with chromium plating that reduces friction and lasts through 8–12 hours of continuous stitching

- Fits most household machines (Brother, Singer, Janome) using the standard 130/705 H system

- Size 80/12 won’t handle heavy materials like denim or leather—you’ll need specialty needles for those

- Limited to one size, so you can’t adjust for lighter or heavier fabrics without buying a different pack

- Not built for industrial use or high-volume commercial sewing

5. Singer Sewing Machine Needles

You need a 90/14 needle that won’t snap mid-seam, and Singer’s universal regular point needles deliver cold-forged steel construction that fights breakage when you’re layering denim patches or stitching canvas bags.

The larger eye feeds medium-weight threads smoothly, while color-coded heads help you grab the right size fast.

They fit Brother, Janome, and Bernina machines using the 130/705 H system, though you’ll want to swap them after 6–8 hours of heavy use to keep stitch quality sharp.

| Best For | Sewers working with medium-weight woven fabrics who need reliable needles that fit most domestic machines without breaking mid-project. |

|---|---|

| Brand | SINGER |

| Needle Count | 5 |

| Material | Cold-forged steel |

| Machine Compatibility | Domestic machines |

| Weight | Not specified |

| Primary Use | Medium-weight fabrics |

| Additional Features |

|

- Cold-forged steel construction prevents needle breakage during layered or dense stitching

- Larger needle eyes accommodate medium-weight threads and reduce skipped stitches

- Color-coded heads make it easy to identify the right size quickly during projects

- Some users reported needles breaking or feeling brittle despite the steel construction

- Limited to size 90/14, so you’ll need different needles for lightweight or heavy-duty fabrics

- Occasional quality control issues like empty packages reaching customers

How to Choose Needles for Thick Fabrics

Choosing the right needle for thick fabrics isn’t rocket science, but it requires matching three critical factors to your project. You need to factor in fabric weight, material type, and your machine’s capabilities to avoid frustration and broken needles.

Let’s break down exactly how to select needles that’ll power through denim, canvas, and leather without skipping a stitch.

Matching Needle Size to Fabric Weight

You need to pair needle size with fabric weight to avoid skipped stitches and broken threads. Heavy fabrics demand larger needles—90/14 to 110/18—to handle material density and thread diameter without deflecting.

When fabric thickness increases or sewing tension feels off, bump up one size within the same family. This needle calibration keeps your heavy-duty sewing needles punching cleanly through dense weaves. For more guidance, refer to the detailed.

Selecting Needle Types for Denim, Canvas, and Leather

Fabric density drives your needle choice, and each heavy material demands a different point geometry. You’ll need specialized tips to push through thick layers without snagging or breaking threads.

- Denim needles use a sharp point and reinforced blade to pierce dense weaves while maintaining stitch alignment

- Canvas needles feature medium ball points that push yarns apart rather than cut through the weave

- Leather needles pack a wedge-shaped tip that slices clean stitch holes in hide without tearing

- Universal heavy-duty options cover multiple materials when you match the correct size to your project

Needle coating and material compatibility affect thread tension and sewing speed, so calibrate your machine after switching between denim needles, canvas needles, and leather needles.

It’s also important to understand needle sizes and measurements when selecting the best option for heavy fabrics.

Considering Thread Thickness and Machine Compatibility

Thread thickness, needle size, and fabric weight form a performance triangle that determines your sewing machine’s ability to handle heavy materials. You must match thread diameter to the needle groove and eye opening, then verify that your machine’s tension disks and bobbin case accept the paired combination.

Thread tension and machine calibration work together to prevent skipped stitches on high fabric density projects.

Key Features of Heavy-Duty Sewing Needles

Heavy-duty needles aren’t just thicker versions of regular needles—they’re engineered with specific features that let them power through dense materials without breaking or bending. Understanding what makes these needles different helps you pick the right one for your project and avoid frustration mid-seam.

Let’s look at the three core features that separate heavy-duty needles from their lightweight cousins.

Reinforced Steel and Chromium Plating

You won’t believe the beating heavy-duty sewing needles take when punching through denim or leather—that’s where steel reinforcement and chromium coating save the day.

The plating process deposits a hard chromium layer that boosts surface hardness, shields against corrosion, and fights metal fatigue during repeated stitching cycles.

This combo delivers serious needle durability for heavy fabric sewing.

Sharp Points and Enlarged Eye Design

Two critical features separate heavyduty sewing needles from standard ones: precision point geometry and an enlarged eye design that transforms how you tackle thick fabric.

Point tips measure 0.75 to 1.0 millimeters, ground to a 60-70 degree angle that delivers serious piercing force through denim, canvas, and leather without deflection or skipped stitches.

- Eye diameter expands to accommodate thicker thread or doubled strands on leather needles and sewing machine needles

- Polished bore alignment minimizes friction, ensuring smooth thread flow through dense fibers

- Elongated eye shape prevents thread snag when penetrating bulky seams

- Hardened eye area resists wear after repeated passes through heavy materials

- Sharp conical tips slice cleanly, reducing fabric fraying at needle entry points

Together, these features cut rethreading time and maintain consistent stitch formation across multiple layers.

Durability and Resistance to Wear

Behind sharp points and wide eyes, you’ll find the true backbone of heavy-duty sewing needles: engineered wear resistance that keeps your stitches clean through thousands of passes. Chromium plating and hardened steel construction deliver material hardness that resists dulling, while ceramic or PVD needle coatings slash friction on dense canvas and denim, protecting edge integrity against abrasion.

| Feature | Benefit |

|---|---|

| Hardened carbide tips | Maintain sharpness through thick seams, cutting dense threads with minimal edge wear |

| Reinforced needle cores | Resist fatigue testing cycles, preventing cracking under heavy fabric loads |

| Corrosion-resistant alloys | Stop rust-related micro-pitting in humid environments, extending sewing machine needles lifespan |

| Surface coating thickness | Balance friction reduction with binding prevention for ideal heavy fabric sewing |

Replace leather needles every 8–12 hours of heavy use to prevent progressive wear from compromising your stitch quality and needle size accuracy.

Tips for Sewing Thick and Heavy Fabrics

You’ve got the right needle, but sewing heavy fabrics takes more than just dropping it into your machine. Machine settings, thread selection, and proper maintenance all work together to keep your stitches clean and your needles from snapping mid-project.

Let’s break down the essential techniques that’ll save you frustration and wasted materials.

Adjusting Machine Tension and Pressure

Your machine won’t conquer heavy fabrics without proper tension settings and pressure control. You need to balance thread tension through small, incremental tweaks—tighten upper tension when stitches loop, loosen when bobbin thread peeks through.

Adjust presser foot pressure so your fabric feed stays smooth without crushing layers. Test on scrap material first, then fine-tune stitch quality for perfect results.

Using The Right Thread and Attachments

Once tension and pressure work together, thread selection and fabric feed attachments seal the deal. You’ll boost stitch quality with the right combo:

- Polyester core spun threads deliver strength without stretch on heavy materials

- Waxed thread grips leather and thick denim through multiple layers

- Walking feet prevent shifting when fabric weight stacks up

- Teflon presser feet reduce friction on coated textiles

- Thread thickness matching needle size ensures smooth tension control

Thread compatibility and proper attachments transform challenging projects into clean, professional seams.

Needle Maintenance and Replacement Practices

Your attachments and thread won’t carry you far if needles dull or crack mid-project. Wipe needles with a lint-free cloth after each session, inspect for bent tips before you start, and replace universal sewing machine needles every 8 hours of continuous work. Store heavy-duty sewing needles in labeled racks sorted by needle type and needle size to prevent mix-ups and corrosion.

| Needle Inspection | Needle Storage | Thread Management |

|---|---|---|

| Check for micro cracks and dull points before every session | Keep unused needles in dry containers with protective caps | Match thread weight to needle size for smooth tension |

| Replace immediately after breaks or bends during stitching | Label racks by type and size to avoid cross-contamination | Verify eye remains unobstructed to prevent fraying |

| Record results in a maintenance log to track lifespan | Rotate stock so older needles get used first | Clean bobbin area to prevent lint transfer to needle point |

Frequently Asked Questions (FAQs)

Can I use heavy-duty needles for thin fabrics?

You can, but it’s not ideal. Heavy-duty needles may cause fabric damage and poor stitch quality due to needle mismatch.

Fine needles suit lightweight materials better—always test needle size against fabric weight first.

How do I prevent needle bending on thick layers?

You’ll prevent bending by matching needle size to fabric density, slowing your sewing speed, adjusting tension control, and choosing heavy duty sewing needles with reinforced steel construction and proper needle lubrication for thick fabric layers.

What causes thread shredding with heavy-duty needles?

Worn needles develop burrs that abrade thread fibers, while mismatched needle size creates excessive friction at the eye.

Thread breakage accelerates when upper tension runs too tight or cheap thread meets heavy-duty sewing demands.

Are titanium needles better than chrome-plated ones?

Like race car tires versus all-season ones, titanium needles outlast chrome-plated needles by 40% to 60% on heavy fabric.

You’ll change titanium coating sewing machine needles less often, though chrome-plated options deliver reliable fabric penetration at lower cost.

When should I switch from universal to specialty needles?

Switch when you notice thread breakage, skipped stitches, or fabric fraying.

Heavy fabrics like 12-16 oz denim, leather, canvas, and layered materials demand specialty needles for proper stitch quality and material compatibility.

Conclusion

You’ll never stare down a broken needle mid-project again once you match the right sewing needles for heavy fabric to your toughest materials. Chromium-plated steel tips, reinforced shanks, and enlarged eyes aren’t just fancy features—they’re the difference between smooth stitching and constant frustration.

Grab the correct size for your denim weight, swap needles every eight hours of sewing, and watch your machine handle canvas, leather, and upholstery like they’re cotton sheets.